All Activity

- Past hour

-

Have you tried a roller foot?

- Today

-

How about painters tape or something like it on the presser foot? Might be a middle ground between Teflon and glue.

-

Unfortunately no additional knife pics. There was a hard leather knife sheath with welt made first and then the elk and deer skin applied after. You will notice the leather just to the right of the red lace goes over the lip of the underlying sheath.

-

What would your ultimate needle positioner/synchroniser do.

fibersport replied to beefy's topic in Leather Sewing Machines

I can understand the desire to make something, good luck with it. Keep us informed, might be something others would like to have. - Yesterday

-

Inadequate knife sharpness, or too much moisture. Ugly "drag line"

Mablung replied to LakeOtter's topic in How Do I Do That?

Having had a similar issue on the most recent carving I did, I'd say that looks like excessive moisture. I find the "wait until it dries to the point that it looks close to its natural, dry color" tip the most helpful, as far as assessing moisture goes. My swivel knife is not quite as sharp as yours but more than adequate, and once I let the leather dry sufficiently, I didn't have that wrinkling problem anymore. -

I have been painting the suede side of my very soft, thin leather with washable school glue as a barrier to prevent sticking under the presser foot of my straight sewer machine. After sewing I then wash the leather under water to remove the glue and dry. Is there another method or product that would be easier to apply and remove? If I don’t use the barrier of glue I have trouble with the feed and stitch length. I have tried sewing with a teflon foot, on tissue paper etc. As I sew small pieces and very close to the edge of the leather some methods are quite cumbersome.

-

JackLeather joined the community

-

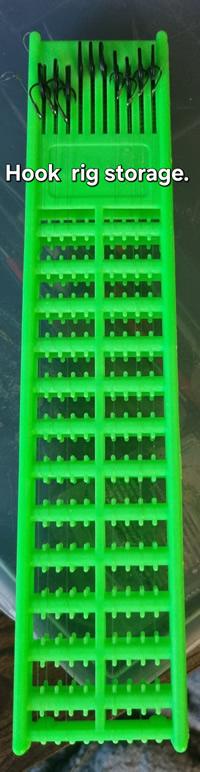

I bought some of these spring loaded hook length holders for fishing. They're great except for the hooks being vulnerable. So I made a case. I hadn't done any wet moulding for a long time and it gave me the flavour so I dug out my centerpin reel which doesn't have a case. So I found some old chipboard. Watch this space.....

-

What would your ultimate needle positioner/synchroniser do.

toxo replied to beefy's topic in Leather Sewing Machines

Did dust ever cause the optical sensors to work correctly ? No! It usually has a cover over it and looks the same as any other. -

I had that same thought. But if they made 10 different bobbin setups, I'm thinking the spring must be l pretty fine tuned to the intended thread size.

-

You may want to grind it to accommodate your desired thread. Here is a photo of my pfaff 545 when I got it. (note the ill-fitting bobbin case)

-

What would your ultimate needle positioner/synchroniser do.

dikman replied to beefy's topic in Leather Sewing Machines

I can understand that! I often do/make things because "it seemed like a good idea at the time" or it was just a challenge to do it. I suspect it will end up being more complex than you think but best of luck. -

Arwen joined the community

-

JoJo81 joined the community

-

Anyone like to have both of the YAPA calf skins. Discounted price today is $225.00 plus shipping

-

What would your ultimate needle positioner/synchroniser do.

beefy replied to beefy's topic in Leather Sewing Machines

Thanks for explaining that AIZilla. Had a little laugh with what you said, "Simple to do, but apparently takes a lot of words to explain..." That's just like the programming of my needle positioner. Seems such a simple task yet the coding takes a lot of time and focus, and keeps getting longer. -

southwestskydive joined the community

-

What would your ultimate needle positioner/synchroniser do.

beefy replied to beefy's topic in Leather Sewing Machines

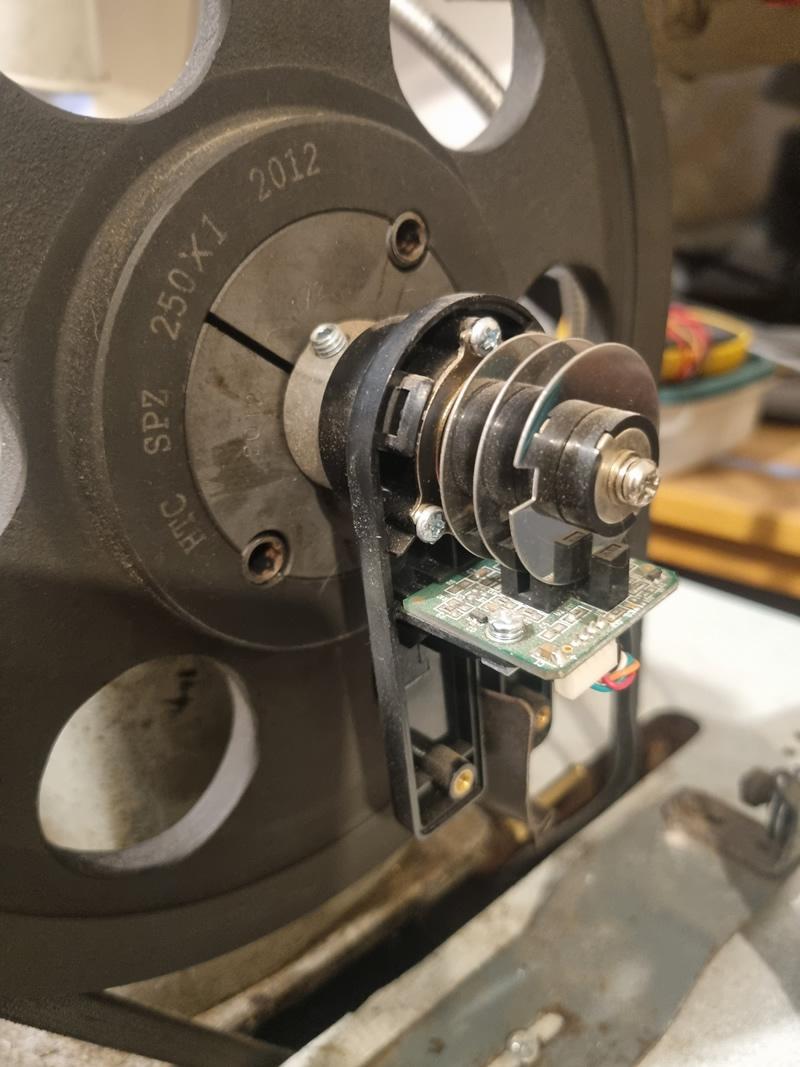

Hi Toxo, Thanks for posting that picture. I might actually use the design method of that one to make my own but with magnetic hall sensors instead. Only problem I can foresee is a hall sensor on on disk may pick up the magnet field from a magnet on a neighboring disk. No I've never seen your old type, as I am very new to this industrial sewing machine stuff. I've only seen the ones all over Ebay, Aliexpress, etc. My guess is the sensors on your old one are infra red receiver/transmitter types. What I like about that physical design is it's easy to build (I've got a lathe). Downside is it's a bit more bulky as more position disks are added. Did dust ever cause the optical sensors to work correctly ? Yep, seems many Chinese sellers think the need for instructions is just plain silly. The instructions that came with mine are just completely wrong, and probably based on some other controller. And when you hassle them enough to give you some instructions it's still terrible and not complete. That's what has made me give up on them and play with this idea instead. -

In N.I. they put a pork sausage in a long bun and call that a 'hot dog' ! The nearest proper hot dog can be bought at the Bistro food counter in Ikea when its open. At least that one tastes a bit like a wiener. You put on your own sauces et cetera

-

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

NeilMott replied to NeilMott's topic in Leather Machinery

Just tried to call and they're closed until Monday. Yeah, it's frustrating because it shouldn't happen on a new machine. It seems like they rushed this out the door. There's no way this worked properly when they tested it and then doesn't now. To me, it seems like air is getting into the mechanism because after I pump it a few times, it'll go down smoothly. I'm definitely not going to play mechanic on it. -

Would you by chance have a link to a place that sells Schneider's Veg-Tan? Thanks in advance. Jim

-

spring flowers and good food

AlZilla replied to chuck123wapati's topic in All About Us and Off Topic

In New England you can even start a Holy war by bringing the wrong kind of hot dog bun. This is a proper Hot Dog bun. Although a righteous Chicago Dog requires an entirely different bun. -

I have been trying to figure out how the weaver Master Tool Creaser and Embosser is able to release pressure and lift up to move belt and then put pressure back to where it was and how the gears fit into all this. I would love to see some pictures of how this is done. Thanks

-

What would your ultimate needle positioner/synchroniser do.

toxo replied to beefy's topic in Leather Sewing Machines

@beefyI haven't understood half of this thread so I just want to throw in my two penn'orth. Firstly the Chinese usually copy everything so I doubt that your servo won't do what all the other servos do. I still haven't got to the bottom of tuning my N/P because my machine came with a speed reducer. My China contact has asked for a video which I've sent and am awaiting a reply but Chinese holidays can be quite long. The N/P on my new machine has a N/P that I'm not familiar with so Im wondering if yours is the same. Here's a pic of what I'm gonna call "the old N/P". This is completely different from "the new one". The old one was a breeze to adjust (no speed reducer but a very big handwheel instead) As you can see, the old one can be adjusted simply by turning the relevant disc which breaks the circuit by way of a cutout. I'm thinking that you might not have seen this type. Forgive me if I'm teaching granny how to suck eggs. -

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

AlZilla replied to NeilMott's topic in Leather Machinery

I know nothing about that machine but I know a little about mechanical things. From your video, it just looks like a rough spot or a piece of metallic debris need to be cleaned up. I would definitely get LMC or whoever you bought it from to bless you taking it apart beforehand. It shouldn't be like that on a new machine but it doesn't seem like a fatal flaw. I'll be interested to find out what it ends up being. -

What would your ultimate needle positioner/synchroniser do.

AlZilla replied to beefy's topic in Leather Sewing Machines

Yes. The thicker threads we use for leather create a lot of unsightly bulk when you start forward, back up and come forward again. And the hole created by the needle isn't really big enough to have 3 stitches run thru. I use V138 and up. I start, needle up, where the 3rd hole would be and drop the needle 3 times, backwards. That gives me 2 complete stitches, with my needle all the way down and at the beginning of my intended stitch line. Now I can stitch the "right way" (forward) and I get 2 locked stitches when I hit the 3rd hole again. With domestic sizes of thread and needles on fabric it's not so obvious. On my machines without reverse, I do the same thing by turning the material around. Simple to do, but apparently takes a lot of words to explain... 😃 -

Cobra NP4 Leather Skiving Machine - bad presser foot mechanism?

NeilMott replied to NeilMott's topic in Leather Machinery

My friend who's been advising me on fixes also has a Techsew SK4. He said that his feet didn't need any polishing. He has another machine from LMC and also thought they'd be very helpful. At least I kept the box in case I need to send it back. -

lunabambi joined the community

-

Bunker85Hu joined the community

-

That is a beautiful sheath. How does such soft leather hold its shape? And do you use a hard leather welt? I'm sure a knife like that is razor sharp. In any case, that is a setup fit for a chief - well done!