-

Posts

4,405 -

Joined

-

Last visited

About bruce johnson

- Birthday 06/15/1960

Contact Methods

-

Website URL

http://www.brucejohnsonleather.com

Profile Information

-

Gender

Male

-

Location

Oakdale, CA

-

Interests

leather tools and history

LW Info

-

Leatherwork Specialty

Leather Tools

-

Interested in learning about

everything

-

How did you find leatherworker.net?

Ive been here from about day one

Recent Profile Visitors

59,105 profile views

bruce johnson's Achievements

Leatherworker.net Regular (4/4)

-

Recommended Source for Hermann Oak Tooling.

bruce johnson replied to Latigo Smith's topic in All About Leather

Have you looked at Panhandle Leather? That's another source and good feedback. Personally I have been dealing with Matt at Maverick for at least 25 years (before it was Maverick). They knew what I liked and I never had an issue with any side being misrepresented that I bought from them. If I said "I need clean" it was clean. If it was going to be fully stamped I told them and got a probably B. If I said I need the crappiest side of 8/9 you have to test splitter blades and tools - it was crappy or had some test pieces cut out of prime areas. There is something to be said for that kind of a relationship. Since I transitioned to leather tools, my wife started doing leather work. Her source? Maverick. Good people, fast shipping, and no surprises for her either. -

As a follow-up, at one time when I was doing a lot of semi-production work I figured up the cost per hit of my one-pound Jueschke maul. It is on some posting on this form someplace. On a rope can cover between beveling, border, and basket stamp or floral patterns, I had at least a thousand hits. At that time I had done about 150 rope cans. On that $90 maul, it had cost me 0.06 cents per hit. Good tools generally pay you back in either dollars or ease and pleasure of use.

-

With no disrespect, anything will be a step up from a rubber mallet. The soft face of the rubber mallet absorbs a lot of the force so it doesn't transfer to the leather. Once you upgrade there are a ton of choices. There is the mallet style, not as popular as the maul but available. Materials may be urethane, versions of nylon, or rawhide. There are fans of each. If you look at mauls, there are a lot more options. If you've never used a maul they look a little intimidating. You are hitting a small object with a round object. The learning curve goes pretty fast though for most people and once they use a maul they don't go back to a mallet. You can buy mauls in all kinds of quality and price levels. I have had mauls through here from $15 Amazons up to $225 custom-made's. Head material could be a whole topic by itself – urethane, nylon, Delran, other exotic plastics, rawhide all have fans. Some materials are more slippery than others, some are more durable, and some just have a certain "feel" that a person prefers. Straight versus tapered – again fans of each. With the straight mauls you need to hold your elbow higher than you do with the tapered maul. The tapered mauls for many people are easier to use for longer runs, especially if you've had shoulder injuries or just have large projects. With the tapered maul I can have my elbow at my side instead of up level with my shoulder. That makes a huge difference. Handle material is another factor. Wood and plastic handles tend to transfer more vibration than leather. That can also be a fatigue issue. There are some rubberized sort of handles or foam covered that are okay. I prefer the stack leather handles - less vibration and better grip for me. Finally handle shape – everyone has a favorite. I like a handle shape that is fairly narrow behind the head so I can almost ring my thumb and index finger to grip it. Then widening out past that so the maul doesn't slide up my hand as I use it. Some like a big fat bulb at the end, some like a gentle taper. It's all personal preference and definitely one size does not fit all. Everybody has a favorite, some for me just fall right into my hand like an old glove and others feel like I'm holding the fat end of a bat. You get into weight of the mauls and that is another factor. My belief is that everyone tooling leather needs a 1 pound maul. That will do most stamps with little effort. You may find with larger basket and geometric stamps you want something heavier. Then the 1.5 or 2 pound mauls fall into place. You may find for small faced sharper stamps like seeders and bar grounders that a lighter maul is easier, and I like a 12 ounce maul. I sell mauls from Wayne Jueschke. I do that because I believe in them, I've been a user for probably close to 20 years. The first maul I bought from Wayne is still in great shape after thousands of hits. Like pretty much all leather tools I was a user for a long time before I became a seller. I like the handle shape, I like the material, I like the balance of the Jueschke mauls. Other makers to consider for better quality mauls would be Barry King, Clay Miller, and Ed LeBarre. I know that Barry and Clay make mallets as well as mauls. I'm not sure if Ed makes a mallet. Hope this helps, – Bruce

-

If i get this tagging right @Johanna will know. You know those ads featuring the most interesting man in the world? In my humble opinion Billy 2-Shews has a claim to that title. Before the days of phone plans I had a couple $100+ phone calls with him, and several chat strings. You never knew when you'd hear from him and it was worth it everytime. Interesting factoid - Leatherworker.net started because of Billy 2-Shews and a pizza baking mama from Ohio.

-

Info on machine. Looks older and huge.

bruce johnson replied to bigsig11010's topic in Leather Sewing Machines

As Wiz said - American Straight Needle. Old, heavy, and no new parts available. The guy who taught me a lot about tools repaired and restored a lot of the old needle and awl machines in this area. His advice to me was to never buy a needle and awl until he was gone. He'd worked on his last one. He said when if I did buy one, get a Landis 3 and second choice a 16, Champion deep throat next, and run away from the Americans. Sam had a shop in Canada for a while. He had a pretty good story about a guy who moved up to that area. He tried to sew some saddle skirts on an "ol' wore out loose straight needle sloppier than the back end of a gummer Holstein cow". The skirts got chewed up and that guy vowed to hand sew the rest of his life, and according to accounts - did that in fact. You may have read about him doing this. -

Jason, First off, just a tip. linking your pictures to outside sources like Imgur is a bit sketchy for some people to click on. Attaching them here on this site where they show up in the post will get more interest. I have had enough Palosanto edgers through here to say those are really suspect. I don't recall any being that rough on the bottom side. that looks unfinished, really unfinished. It looks like they did the first step, they stuck a handle on, and sent it on. Does the groove actually stop before the end of the edger? if so, it's like a flat chisel. Depending on what the top profile is, it could sure be scooping and not cutting a round over.

-

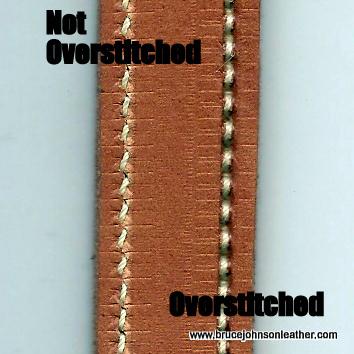

Yes, but only in the sense of the older hook and awl machines. They have an awl that prepunches the hole followed by an needle that carries the thread. They can pull a tighter stitch by nature and a cleaner looking bottom stitch. I know that is not your question but it is my answer. As far as the closed needle machines I don't think that one particular machine will shine above the others once you get to decent machines. The variables of thread size overall, one size smaller thread in bobbin vs same thread top and bottom, needle size, type of needle (straight vs slanted), stitch length, leather thickness and consistency, chrome tan will pull in tighter than veg tan, bottom feed dog, tension top and bottom, and probably more all affect the appearance of the bottom stitch more than the model and mechanics of the machine. We have three closed eye machines - Ferdco 1245, Ferdco 2000, Cobra 26, and have had others. I can make one look better than the others if the others aren't set up optimally. I can make them all look the same too with the changes above. What does improve the bottom stitch on all of the closed eye needle machines? Overstitching. Roll the bottom side stitch line with the appropriate size overstitcher. It sets the stitches, rounds the stitches between holes, and gets as close as you can get to the top side appearance. It is the 2 minute time difference that makes a big appearance difference. This example I did on the fly several years ago. I purposely put an old needle back in the machine to get some "blowout", probably 207 thread, 9 or 10 SPI, same size thread top and bottom. hard leather, heavy presser foot pressure. I think it looked pretty rugged right out of the machine. The right side looked the same as the left in the picture but was then rolled with an overstitcher. All it needs after that is the presser feet marks rubbed out to be pretty nice appearing stitching.

-

Thinner leather - grain side only. Skirting leather - heavier on grain side/lighter on flesh side. The fibers on the grain side are denser and slower to wick through. The flesh side is looser and wicks in faster. Butt and top of the back is denser, lower belly and neck is looser on grain side so that is a factor also. Just because a piece of leather sucks in the oil does not automatically mean it is dry. Likewise oil that sits and does not absorb right away does not mean the leather is well oiled already. Apply light coats and wait. I applied my oil to nearly every project with a fine napped paint roller and paint tray. Dip the roller in the oil, roll off the excess on the ramp, and apply. I did 3 to 4 belts side-by-side, spur straps arranged in a single layer, and most other small projects. If I needed to overlap for wider projects I just butted up the next roll to the last one, I didn't overlap and over oil that section. It will wick over to the dryer areas faster that it will wick away from an over applied area. After a few times you develop a feel for how often to wait and decide to reapply and how much oil to leave on the roller for thinner or thicker leather.

-

Las Vegas leather show video.

bruce johnson replied to chuck123wapati's topic in Leatherwork Conversation

Chuck, Yeah, we take quite a bit! We usually take the longest to set up and at the end, the last ones out the door. I take a "show mix" - new and refurbished. It varies what sells from show to show and year to year at the same shows. About a 4 hour setup and 2-1/2 hour breakdown this last show and still the last to leave again. We have gotten a lot better. The logistics have grown from assorted plastic totes in a pickup camper shell to rolling totes and a 5x8 cargo trailer. With enough totes and hauling a machine home for someone it was like Jenga to pack sometimes. I use Milwaukee Packouts now. I upsized to a 6x12 tandem axle trailer before the Pendleton show a few months ago and we are up to 8 packouts, one rolling tote, and a tool chest base that is the checkout and show supplies stand. Prescott, AZ in 5 weeks and then Sheridan, WY in May. I do love my retirement! -

I have never seen an 8 inch Landis for what that's worth. The only 8 inch I know of is Weaver's version.

-

Las Vegas leather show video.

bruce johnson replied to chuck123wapati's topic in Leatherwork Conversation

Thanks for posting the link Chuck! We left this morning and just got home from the show. At the 20:00 or so mark it shows my booth. I was busy with a young customer. Personable, enthused, and polite. He had finished a carving class that morning. He had been told in the past he needed his stamping to be more intentional. I helped him pick out a new maul and a couple hand tools to step up his game. It seems like at about every show I found a good young person and we barter. I give them the tools and they make me something of their choice. I can’t wait to see what this young man comes up with! -

We got one at the Sheridan show last May. My wife has used it some. I played with it and thought it has some real possibilities.

-

Mike, Thanks for catching that! Yes, 3/64 inch edger and I went back corrected that. Merry Christmas to you and yours!

-

The whole topic of edgers came up in an email yesterday. I made the reply that edgers could be an hour long topic in a class (easily). I did a thumbnail reply in another thread about types of edgers. Besides type, the other common question with edgers is "What size?" Here is my take. There are no standards for the number sizing for edgers between makers. One makers #2 may be different than another maker's #2. Even among a single maker the measured size/number may vary between styles of edgers. Historically the Gomph, HF Osborne, and vintage CS Osborne edgers were all 1/16 inch of cut per size number. For example the #1 was 1/16" of cut, the #3 was 3/16 inch of cut. Somewhere along the line, the sizes changed and a #3 now from a maker might be 3 mm, 1/16 inch, or some other measurement. The key is to know the maker edger style and then the actual cut measurement. What size of cut edger do you need? Everybody has a preference but here is mine. For most work like flat goods, belts, etc. I want my edger to have a cut width around 1/3 the thickness of the leather for edging top and bottom. For a 12 ounce piece (3/16 inch) I grab a 1/16 inch edger. For an 8 ounce piece (8/64") then I go with something like 3/64 inch of cut. These widths do two things - 1) they don't get into my stitch line on edges and 2) they round off the square edges and leave about half the edge of the piece square. By the time you rub that edge it will compress and shape some and that 1/2 thickness remaining square rounds over more. I like that look and feel for most work. If you want a heavier rounded edge for some applications (saddle horn or skirts) then choose an edger around half the thickness of the leather.