-

Posts

1,593 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Trox

-

I got detail pictures of that lock from the man that designed it

- 22 replies

-

- swiss leather tools

- swiss army leather

-

(and 2 more)

Tagged with:

-

Great work Hans! I've been looking for both a pot meter pedal for a frequency drive and a large thick aluminum plate for a long time now. Obviously I got to find the plate for a clicker hammer (head) locally (Norway) but that pot meter pedal, can I ask where you bought that. And does it make you motor sound bad, scream on some rpm's? Thanks Tor

- 182 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with:

-

Okay I see, thanks!

-

Hi, sorry for the late reply's. Thank you for the link, that was certainly cheap. That shape of roller is much better than the long one that followed my machine, much easier to adjust. Mine doesn't equals the shape of the stone roller anymore. I may customize it, cutting away half but the bearing needs to be replaced as well. I will order the one you have but is the hole tapered as on Italian machines (like on mine Alpha SM, FAV etc.) looks like you got a gap there, material thickness different maybe? Thanks Tor

-

Thanks, I already have the foot that Tom E shared a link about. But it has been worn a bit by previous owner, it came with my machine that I bought used many years ago. I guess I can make a new roller for it on my lathe. The roller profile do not longer match the profile of the feed wheel... difficult to adjust for splitting use. The minimalistic guide for turns and stiffer leather makes most skiving tasks in soft leather difficult. I really miss a decent guide. Thanks Tor

-

Thank You, I already have that roller foot that came with my Italian machine. Do Randall have this guide as well? The Italians are notorious difficult to deal with. Even if I'm much closer to Italy, I prefer dealing with USA. Now before Trump's tax are in play. Thanks Tor

-

Hi Uwe, I like the stand you have built for your Adler. I'm looking to build a couple of tables like that for some leather machines. Are the legs available online? Thanks Tor

-

How can i activate foot lifter for 45k25

Trox replied to depodarcom's topic in Leather Sewing Machines

These types of stands had knee lifters, but since you don't have one a pedal attached to a tube around the tramp shaft would do the job. -

Hi, is it your machine in the video? You are wild Harry? I'm looking for a wide guide like the one on you skiver. That roller foot also looks good, I got one that came with my machine but it's pretty worn out. Where did you get this. Thanks Tor

-

I know this is an old post, I had to make a new such piece myself when I bought my 267-373 years ago. Made it from a piece of hard plastic, the old way with saw and file. Then I ordered one from my local DA dealer, price was under 10 US$. Lesson learned, check availability first. By the way, even when your machine may not be supported anymore. This part is the same on the newer machines , 267, 268 and 269. Maybe on more models too.

-

Yes these machines aren't made for anything larger than max 20 thread, maybe 15 on top and 20 in the bobbin. I guess you even have trouble getting anything thicker than 20 in to the needle bar thread guide. Using anything thicker is just the same as asking for trouble. I don't think your machine even have a hook safety clutch, birds nests could get real serious.

-

A BUSM #4

-

Some black dye are containing iron, that is an early method of making black leather dye. Or some tanning chemicals may be magnetic. As mentioned before a piece of steel could be inside the leather. Some steel rubbed off inside the holster, like the black on the stropping board after polishing. Or its just the surface stats sticking to it.

-

Nice job! I was going to ask you about the weldability of the Pfaff cast iron, but you didn't weld that; it was a Singer part you welded. Related to you questions about the stitch length, I assume you know there must be an "N" in your subclass number if it's a 6 mm max stitch length machine. N=6 mm maximum stitch length. There are plenty of pictures of your subclass plate but their resolution are to bad, I can't read it. If you do not already have the 345 H3 service manual I can share that with you. I has no pictures and they use some special "gouge" parts for adjustment, these are listed in the last pages of the part list. When you adjust this machine you got to do control all adjustments in chronological order. About the special Pfaff adjustment gouge parts we do not have access to: To measure the needle bar lift I use a caliper and the needle bar lock just a hose clamp etc. Let me know if you need the service manual, I've shared it here before.

-

It's an option on all motors if you want the needle to stop down or up when you heel the pedal, it must be down. But you won't get this to stop where's supposed to with a speed reducer. It's bases on a 360° rotation with a belt direct to the machines pulley. Expensive position motor controllers can account for belt slippage, but no system will calculate for an extra belt and two pulleys. There aren't any motors that can do that. I've seen some have put the synchronizer head on the speed reducer instead of the machine handwheel. But still it will not be accurate. Luckily these motors will work without the syncro head. Expensive motor systems like Efka won't run without a synchronizer. But on Chinese cheap motors the syncro head is just a 15$ extra. Most of these systems aren't accurate anyway. It's important that these systems are accurate, it has to stop at exactly the same place/degree of the revolution every time. It's when the needle has past it's lowest position and picked the bobbin thread. If it stops earlier and you raise the foot to turn your work a stitch will be skipped. To late and the needle is out of the work. I know the earliest Chinese designes wasn't any good, but they should have been able to figure this out by now. German motor brands have use this system since the 1970 ties. The problem is that accurate servo systems are expensive to make. Accurate speed controls too. There are enough power in these motors, people put speed reducers on them to get better speed control. With the price of the reducer and motor combined your not far from what a proper motor system costs.

-

Pfaff 345 / Bringing it back from the dead

Trox replied to karmazine's topic in Leather Sewing Machines

Thanks but he don't need that part fixed, it's just a extra feature for handicapped people who can't lift more than 200 grams. Nothing wrong with handicapped people, but it's not worth using time fixing; this the machine will work just fine without it. Most machines doesn't have this feature, anyway. I won't use anymore time on this. -

Pfaff 345 / Bringing it back from the dead

Trox replied to karmazine's topic in Leather Sewing Machines

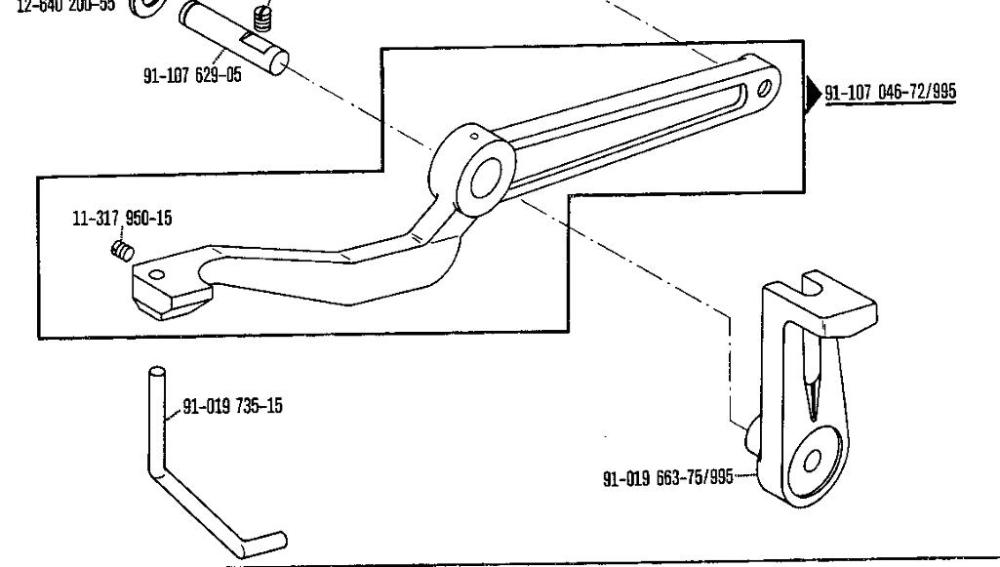

I try to explain this again. You do not need to change this lever (pic 1) Just run a chain from the lever true the hole in the base, see arrow pic 1. Drill a corresponding hole in the table and run a chain to the pedal. Pic 2: I don't know where you found this underlined part, it looks like it fits so it's probably the same. If you find it that's great, if not it's simple to make. If it's to long or to short, modify it. I would just make it, that would be much faster than even write a post about it. Pic 3: You see this isn't the same presser foot lifting lever/arm as on our machines, so you can't use the angle iron part from this one without changing the arm/lever to. The design is changed, I would think the one in my part list is a later design; because it allows a height adjustment. Just use the arm in pic 1 you already have.. You don't need the geared linkage who's probably there to making it easier to lift with a knee lever lift. It's not necessary! Not even if you have a knee lifter, it's not a heavy lift. There is nothing wrong with your presser foot lifting lever/arm!? You don't need messing with that geared assisted linkage, there are plenty of Pfaff machines that didn't come with that extra feature. -

Pfaff 345 / Bringing it back from the dead

Trox replied to karmazine's topic in Leather Sewing Machines

I agree, I've been saying the same thing. If the country his searching in was all other than Poland. I would say; save your phone fare. It could be he finds something there. Otherwise buy that H2, that's would be the cheapest option. depended of how far it has to be shipped of course. Older Pfaff parts are expensive and he could use much from such a machine. -

Pfaff 345 / Bringing it back from the dead

Trox replied to karmazine's topic in Leather Sewing Machines

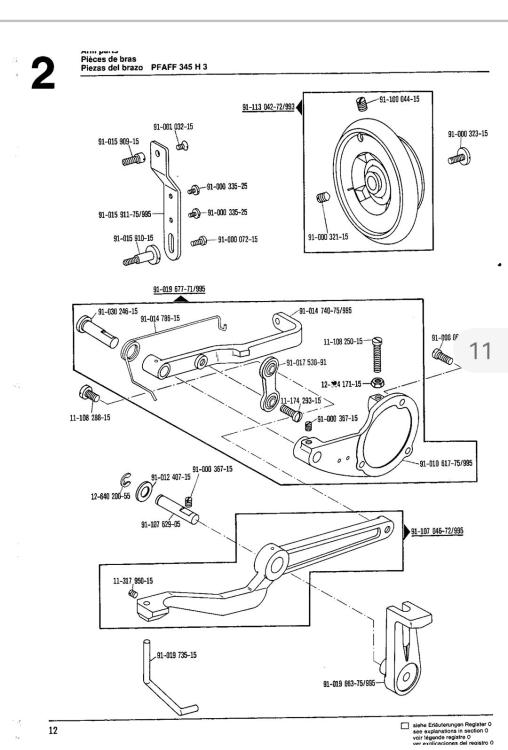

Here are the binder parts. The binder plate attachment to the right in pic 2, I've made myself. The syncro plate in pic 3 is Pfaff. Pfaff quoted me these parts some 10 years back and they wanted 1100 USD for the needle plate, feed dog and syncro plate. That's was about 10 years ago, imagine what they will cost today ( if they're available) Anyway, A friend gifted me the feed dog, the small binder and the back foot. Binders, front foot are Kwokhing. These parts where available then, I've haven't had the need for anymore Pfaff parts, so I don't know what's available today. Older Pfaff parts are very expensive, that's why I brought up the donor machine option. It could be that many of the parts you need are the same on other Pfaff model's. Old 335, 145 and 545 have the same upper arm, I believe some of the postbed models also have. -

Pfaff 345 / Bringing it back from the dead

Trox replied to karmazine's topic in Leather Sewing Machines

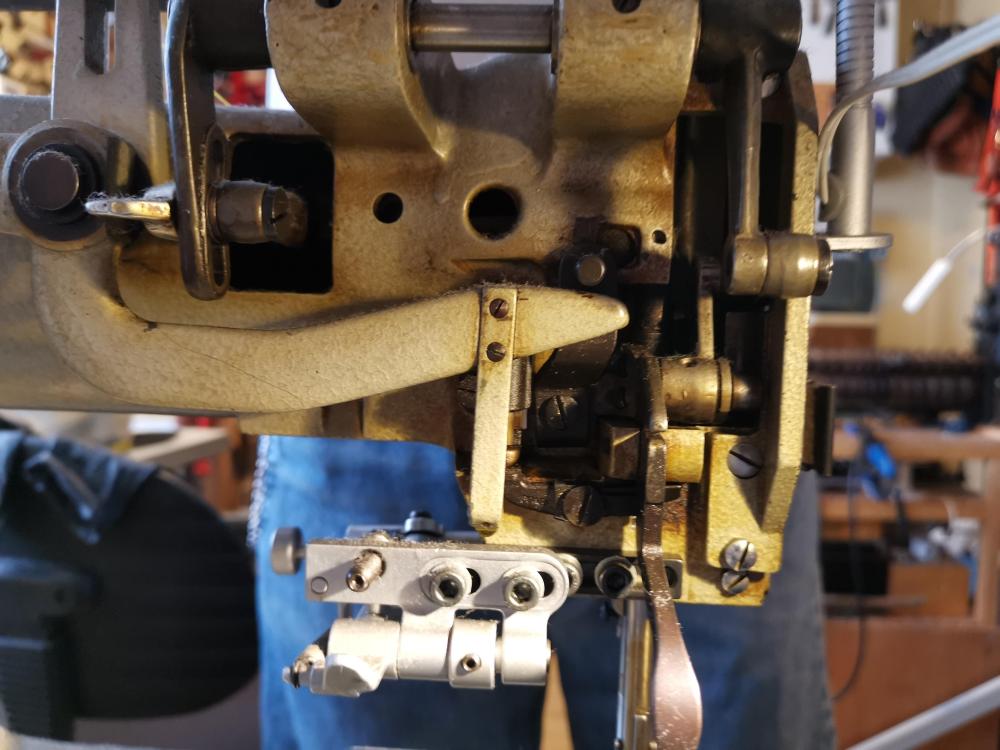

Here are som pics from back if machine. Quality is what expected when there's limit space behind it, Im not moving it out from the wall to get better pictures. This is the needle plate this came with, the binder parts are extras. -

Pfaff 345 / Bringing it back from the dead

Trox replied to karmazine's topic in Leather Sewing Machines

You are not the only one that writes to me for advise, I do the best I can on my time off. I this is the only 345 H3 partlist I got. That's the only one I've seen. I see that the part # 91-010 378-45 isn't in the document. That's because the pdf is newer or older that the machine, they've changed the foot lift arm and use the parts in the pic below instead. If the document are older or newer than our machines, I don't know. I doubt your able to find any of these parts new anyway. That means you have to search for the # 91-010 378-45 instead. If your going to use the other parts in the partlist below, you also have to change the arm. Alternately drill and tap for the new part. You just got to get what you find. All the geared levers in the pic 1 isn't necessary, don't use time on them; just run a chain directly from the end of the arm you have to a pedal. If you find them it's a bonus. The other parts you need are in the part list. In the world of industrial sewing machines, machines get changed all the time. Part lists gets updated by the producer only when it's supported. This machine is now obsolete, they don't support it any more and they're not obligated stock part for it anymore. Today Pfaff doesn't have anything for these of machines, the only ones that has something for them are companies like College I.s.m. https://www.college-sewing.co.uk/parts-books/pfaff-parts-books.html (They have pdf, aftermarket parts like hooks, feet's and common wear part) When it comes to what feed dog it is in your machine, that's depending of those last numbers in your subclass number. It's the same feed dog in mine. You best hope is to find a donor machine, non of the parts your looking for are made anymore. It shouldn't be to difficult to make these parts, the hand lifter and the angle iron can easily be made from a piece of flat iron, just som cutting drilling and filing. I believe your goal are to get it sewing, not get it in showroom condition. If your lucky to find some parts, be prepared to modify them to fit. That's how we all have to do it. Maybe you find something in Poland, if anywhere in the world that would be the best place to look yes. Good luck Tor -

Pfaff 345 / Bringing it back from the dead

Trox replied to karmazine's topic in Leather Sewing Machines

5ao8mf6d.pdf -

Pfaff 345 / Bringing it back from the dead

Trox replied to karmazine's topic in Leather Sewing Machines

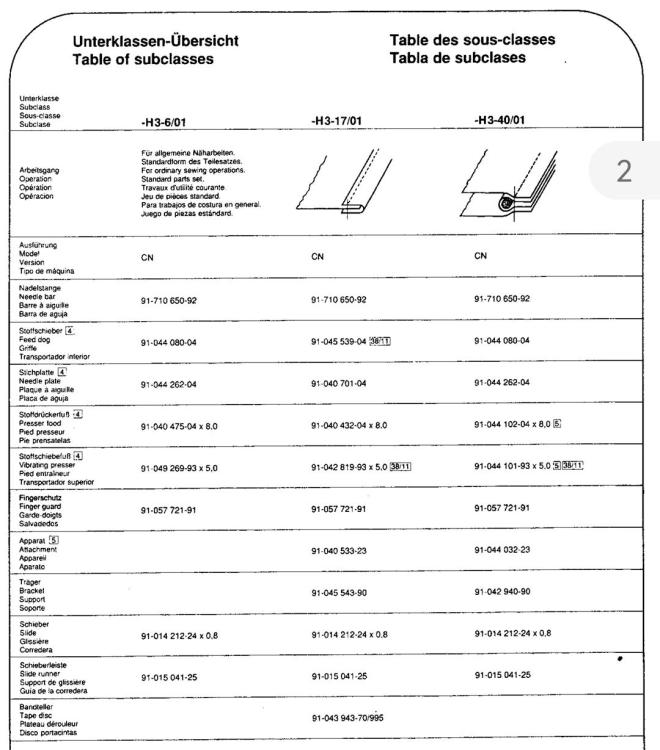

I have big trouble sharing/uploading stuff here today, I'm on my phone. Guess I'm out of practice, I spend most of my time online on Facebook. However the subclass is H3-17/01 it's set up for regular binding. This is a list of gouge parts and the numbers refers to what feet's, needle plate and equipment it's set up with. It's not easy to get a overview over Pfaff's old codes and sewing equipment numbers. I don't think there are anybody working in Pfaff today that know these anymore. Pfaff sent me these manuals and lists years ago. I've done my best to share it with you people in this forum. Do you have the 345-H3 part list? All the parts are listed in that part list. The presser bar lifting lever/arm in your pic isn't the right one for the 345-H3. It's a intricate system of lever's that makes a geared presser bar lift. But you don not necessarily need all of that. They are there to make it easier to lift. There are also a hole in the base head that can accommodate a chain for a regular un assisted lift. You better show us a pic of the backside, it's easier to see it for ourselves. You better hope you will find a donor machine, if these parts should still be available; they will cost you more than a new Chinese machine. -

Pfaff 345 / Bringing it back from the dead

Trox replied to karmazine's topic in Leather Sewing Machines

Here is the subclass listkgi582aa.pdf -

Okay du er Norsk ja where are you located? You know the needle system and you can recognize other differences if you study the manual. Skinnlåven sells bonded nylon in USA sizes yes (not cheap though) Amatec selling Gütterman thread, C.Hemsen Oslo have Serafil polyester and are number one in leather prices. (They also have that nice French Fil au Chinois, for hand stitching) The cheapest threads are sold by T. Plassen, Aman Serafil, Coats and Gütterman. Let me know how that works out. Tor