-

Posts

1,591 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Trox

-

Okay, when the foot presses the material down the feed dog will catch the material even when it doesn't prolong over the plate. But if it's above needle plate level it will for sure interfer. It goes just back and forth, not in a square like a normal bottom feed. First it feeds the right way and then when the stitch is made, it's feed it back again. For leather work it's the needle feed that's important, alternating pressers are there to climb different levels but the lower feed isn't that important. It just make marks in the leather anyway, but it's serves a purpose as a lower needle guide. It makes sure the needle doesn't bend away from the shuttle, causing skipped stitches. But just lower it a millimeter or two below the needle plate. Let me know how that worked out for you. Tor

-

Your feed dog interferes with your material feed, you got to lower it. I haven't read the hole topic but I see this is a H2 machine with binding feed. You just have to lower the feed dog so it doesn't prolongs above the needle plate. 1 mm. belove the plate level is good. Then you can't use those thick threads in this machine, I wonder how you where able to thread it true the needle bar's lower thread guide. A 110 needle is a Tex 40 to 69 thread size. A Nm 120 needle is a Tex 69 thread size. A 145 H2 is one of the smallest sub classes, it doesn't like those thick threads. Just thread it with a new needle (110 or 120) with correct thread size and drop the feed dog, adjust it so it doesn't interfer with the feeding. That's why you get the feed back on the stitch regulator lever. I have a 345 H3 myself with the same feed, I remember that's what happened to me before I realized it had a binding feed, the first time I used it. Just adjust the feed dog, lower it so it doesn't interfer with the feeding. It's there to propel a synchronized binder. Tor

-

The TEX 207 is a European (TKT) 10/3 and the minimum needle size for that is a Nm180 needle. No wonder you get a mess out of that. Your maximum needle size is 160 that's a Tex 90 to 95, European sizes 15/3 who is the parameters Dürkopp Adler is using in their manuals. If you use a thick thread on top you can use one size thinner in the bobbin, not several sizes thinner. From a 69 to a 207 there are several sizes, it won't work. The thread has to pass freely true the needle eye. Read the topic " Neat Trix for Needle Sizing" pinned on the top of this forum. When I sew leather I always try to use the smallest needle possible for the thread size, for better stitch apperence. But the thread must fit the long groove in the needle and pass freely true it's eye. Good luck! Tor

-

Hi, I do have a DA 267-373, great little machine. I use for upholstery and light leather w. The largest needle I have for it is a 160. But a rarely use other than 120 and 140 in it. I would say 160 is maximum. I never tried any bigger, that wouldn't work well. (I have bigger machines for those thicker threads). Like Kgg says above, you have to check the number on its plate to see what sub class it is (the number after 268). I see there are only two machines out of 30 sub classes that uses a 180 needle and non of them are using the longer 135 -34 needle. They're using the shorter 134 needle and that tells me these two sub classes are for stitching shoe soles. Post a pic of the number plate and check the manual. DA would always be a little conservative with the needle sizes, so you can probably go up to a 160. That's a metric 15/3 thread, I believe that's a TEX 138. Always check that the needle doesn't hit the shuttle when you try a bigger needle. The machine is adjusted to be used within these stated sizes, so there is always a risks for errors pushing it. Aka birds nest, broken needles, clutch release etc. Tor

-

What about needle position? Then you can go stitch by stitch

-

100 rpm is the slowest maximum speed. You can go slower on the pedal, I would not recommend using a speed reducer. Use a needle position instead, needle position will not work with a reduser. And the motor setup will be way to strong with an reducer, you can break the hook (there are no safety clutch) The extra belt and tension with a reducer makes it sometimes harder to control. Because you need more power to start turning the machine. I think it will be perfect as it is now. I have a reducer on mine, that's just to much for such machine. That's the setup for s 441 type of machine.

-

Nice work! You would not need s reducer on this setup, just a small pulley on the motor.

-

Interesting old thread about gouging a stitch line in straps that has to endure heavy strain. I do have have special pressers on my sewing machines that's sets the stitch deep. On my 441 I have foot that has a profile that makes a channel for the stitches. On my Busm/Pearson N⁰6 I have pricking feet's that does the same job, Only wish I had more sizes of them thought. If someone has any for sale please let me know. Thanks Tor

-

College is a great company, but I don't think they are a Dürkopp Adler dealer. They have some parts but not all the parts as DA are obligated to have.

-

As Constabulary says, this is a part Dürkopp Adler are obligated to have in stock.

-

As I said contact Dürkopp Adler, My Norwegian Dürkopp Adler agent will get you this screw. This is a part they have!!

-

You need to change the screw! Contact your nearest Dürkopp Adler dealer. They have this screw in stock. The 69 is still produced today, or it was the last time I checked. Anyway the machine is still supported and they have all the spare parts. It doesn't cost much. The little I can see of your needle bar looks correct to me. Good luck!

-

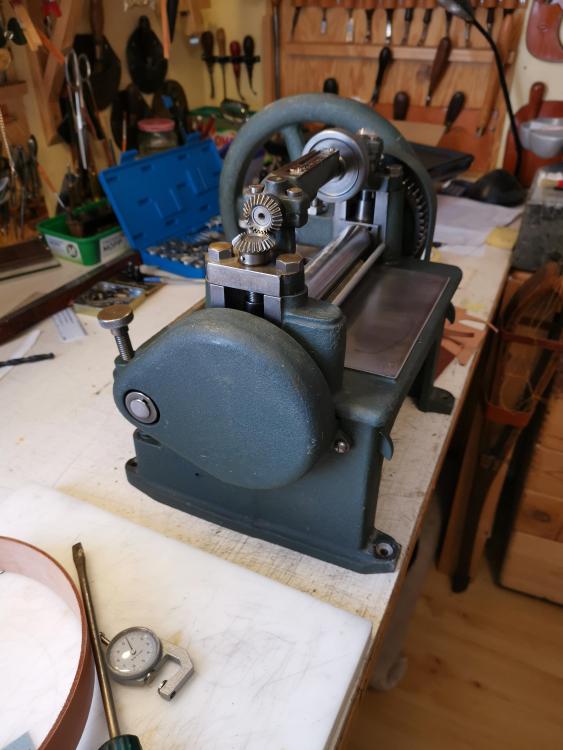

I recently went to Denmark and bought two Wilh Pedersen 8" splitting machines. These are very presise splitting machines that split down to 0.5 mm. thickness. I haven't restored these myself but I've restored plenty of other machines. Wilh Pedersen Maskinfabrik Høng Denmark started up in 1910. In 1912 he started producing shoe machinery that was sold in the Scandinavian countries. Later also clicking machines, milling machines and lathes that was sold world wide. Now his closed down years ago, I don't know the date. Anyway, I know he produced at least 3 different spitting machines in addition to shoe 3 in 1 and 5 in 1 machines. In addition to the type you have, the one I have he also produced a smaller 6" shoe sole crank splitter. The one you have might have been made in different widths. How many inches are your blade? I can't see the motor side of your splitter but there should be a gear motor attached to one side of your machine. Depended of condition you should clean it up, use a wire brush and some evaporust on parts you dismantle. Get the blade sharpener up and polished. But make sure you get it back in right position. If it turns I suggest you leave the inside parts as is, it can be challenging to get it all back in place and adjust it right. What's wrong with it's motor? Please post a pic of the motor side. Thanks Tor

- 2 replies

-

- manual

- machine help

-

(and 1 more)

Tagged with:

-

It's a Great machine! Advantages are: constant speed bell knife, dedicated servo motor for perfect control of the feeding and suction device with dedicated fan motor. I do have many different feet's, foot roller for skiving and serated steel roller for feeding heavy leather. I've had this for about 10 years now, I know that standard feet's, feed roller and bell knifes fit this. I do have a part list on paper, but it will do you no good now. What parts do you need? Where are you located, I'm in Oslo Norway. Tor

-

Wow, it's strange to see an other one like this. First time I've seen one exactly like mine. Alpha SM doesn't exist anymore. Dependent of what part you need, feet's, roller's and bell knifes are standard parts that fit most machines. This a great machine, mine has three motors. One for a constant feed roller, one little 12v servo for the feed roller (inbuilt in the head) and one for the vacuum suction device. I have it hooked up to a frequency controller, no 3 phase in my shop. What pars do you need?

-

Nice machine! It's an advantage to bolt a aluminum plate underneath the hammer head. Especially on these mechanical machines because they hit the dies rather than presses like hydraulic machines. This protects both the head and dies. You can also use double sided dies this way. I do have a German Sandt mechanical clicker myself. I would like to see how they retrofitted these with double triggers, if just the power on switch that wouldn't be any good for these. They need to run some revolution after starting to get some moment on the flywheel, thanks.

-

And of course you can do leather with it. It's a upholstery class machine but you can do leather belt and bags etc. If you're going to sew vegtan you need smooth pressers and lower the feed dog to the level of the needle plate (at its top position)

-

Take pic of than number plate please. I don't believe it's a 167 but a 67 -373 T The description of the 67-373T is: For seat cushions, seat upholstery, medium-weight fabrics; lower, needle and top feed, 25 mm stroke. Needle system Schmetz 134-35

-

Nice work! I have a 345 H3 myself, with a binding feed. Feed dog goes back and forth only, it's for propelling a synchronized binder. If your machine has the same type of lower feed, just adjust the feed dog so it doesn't prolong above the needle plate. (About 1 mm. under the level of the needle plate). If it's above the needle plate, it will just interfer with the material feed anyway ( If your machine has a binding feed, that if). These machines have no hook safety clutch, that means big trouble if you get a birds nest in the hook. They don't like coarse threads that much, with a speed reducer/bigger handwheel it's easy to knock it out of timing. If it jams, the hook will turn out of position on the hook shaft. The needle bar might also move out of position, so take care! My hook has moved on its shaft so many times, the hook's set screw's has made grooves in the hook shaft. I had to remove the shaft to repair that. That made me more aware. I can't emphasize this enough; no clutch= big trouble if it jams. My machine have a strong servo motor and a speed reduser. It's there to control the speed, but that's more power than these are design to be used with. I make sure not using too heavy threads in it. As I'm blessed with two heavier class machines, I don't need to be doing that. I look forwards to see you finishing this project, and to see the new handwheel. A bigger handwheel is always a better solution than a speed reduser. Because the extra belt and pulleys makes much more friction. And you can't use a needle position motor with a reduser, it will not work well. Good luck with your project! Tor

-

Same as the Adler class 43 who came with stitch up the arm and regular straight stitch. First time I see a Pfaff version of this machine, great find!

-

I bought from Beilers, they have all styles. Thick, thin and wedged steel. Best source for wood is Abbey's England.

-

New Dürkopp Adler 969 And 967 H Type Machines For X Heavy Work

Trox replied to Trox's topic in Leather Sewing Machines

If I was to buy one I would be sure I had the needed support. I buy only stuff that I don't need support on from Sieck. I look forwards to your review, good luck with it!- 79 replies

-

- 967 h type

- 969 h type

-

(and 1 more)

Tagged with:

-

New Dürkopp Adler 969 And 967 H Type Machines For X Heavy Work

Trox replied to Trox's topic in Leather Sewing Machines

Dealers have to defend their price. But why would he need that, your dealer provides service, support and set up on site. That's worth the difference, perhaps more. Sieck's machines are just sewn of by their mechanic, not set up for individual needs as yours. But I doubt it's used, maybe stored but not used. I have no reasons to believe that.- 79 replies

-

- 967 h type

- 969 h type

-

(and 1 more)

Tagged with:

-

New Dürkopp Adler 969 And 967 H Type Machines For X Heavy Work

Trox replied to Trox's topic in Leather Sewing Machines

Look at the price I posted here 6 years ago (top of the thread) The price has gone down since that time when it was new on the marked. Knock off's has dominated the marked and "Original machines" producers had to lower their prices. When it comes to tables/stands most dealers have their own.- 79 replies

-

- 967 h type

- 969 h type

-

(and 1 more)

Tagged with:

-

New Dürkopp Adler 969 And 967 H Type Machines For X Heavy Work

Trox replied to Trox's topic in Leather Sewing Machines

http://www.sieck.de/en/machines/sewing/arm-type-machines/?produkt=5656 When it says brand new, why wouldn't it be? That what Sieck does, they just sell machines cheap without investing much talk in to it. I've dealt with them several times, you get what is announced. But do not expect any support or answer to question's- 79 replies

-

- 967 h type

- 969 h type

-

(and 1 more)

Tagged with: