-

Posts

1,591 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Trox

-

Yes that that's nice with Fibings and ink based edge paint. But with Giardini you must apply a thick floating layer so it would not work out.

-

Arturo, Yes the tool Giardini don't have any bearings or it's faulty designed. It will not turn freely unless it's held horizontal in certain positions. Solution was buying two others from eBay with bearings inside. They both works very well in all position. The gold color one has bearings in the top and in the bottom a trust bearing, I will recommend it. The other one with the bamboo shaft has a bearing in the top and a stop ring on the shaft. Therefore, the shaft won't jam. It's has a very good cylindrical aplicator roller that works very well. Also the bamboo handle makes it pleasant to use. I recommend it. Look at this on eBay https://www.ebay.com/itm/373136243866 eBay swarming with these tools, you got to carefully read the descriptions before you buy. Tor

-

Yea that's what those Chinese guys make money on these days since the Regard tool became popular some years ago. Buts please don't call it a Creasing machine because that's something completely different. It's an electric creasing iron and it's a over 100 year old system. The electrical supply would need enough watt output and a PID to constantly maintain the temperature. And of course a suitable handle you don't burn yourself on.

-

It's a terrible nightmare that happen to him! My thoughts and best wishes to Terry!!

-

French Edge Skiver - is this going to be a problem?

Trox replied to Alaisiagae's topic in Leather Tools

It should be an advantage to have used such tool before giving advice of how to sharpen it This is a inexpensive Tandy model tool that have several issues. It doesn't matter if it "slants upwards from right to left" It has a wrong edge, double instead of a single one on the bottom side. The toes are to thick and it's not polished. I use better tools but I once started out with a similar one. Here it's how it should look like, straight on top and the edge on the bottom side. Looking like yours (with a double edge) it will tend to steer downwards instead of Skiving. It doesn't matter if it's straight cut off between the toes or in an angle. Reduce the thickness of the toes and polish off the blueing black color. That will give it less drag and make it acceptable to use. Use a small stone/file that fit between the toes to make it flat on the top. Take a sand paper around the stone with finer grits until polishing grit's. Polish the hole tool on a buffing wheel or a strop. A strip of leather that fit between, with polishing paste placed on the desk etc. will polish the top side. Make it look like in my pics and it will skive very well. Tor -

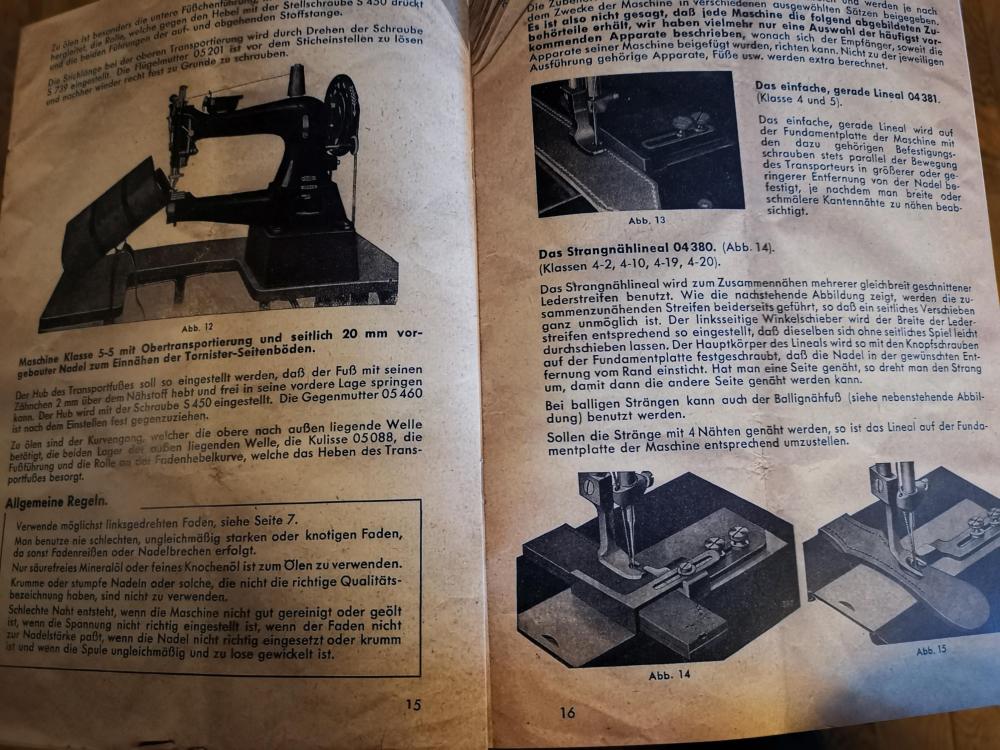

Hi Sallis, I do have the same manual as Constabulary has..German. Don't think there are any English ones out there. The German one have good illustrations. Your machine is a bottom feed with roller foot and was made for leatherwork when new. The needle system is Schmetz 328 LR but you can of course use other 328 needle points..LL, D and spear point (round) Sizes listed in manual goes from Nm 100 to 300, but it's only a couple subclasses that take the biggest needle. Practically it will sew with needles from Nm 160 to 250, perhaps 280. Needle to thread chart: Nm160 is for thread tkt 20 Nm 180 for tkt 15 thread Nm 200 for tkt 10 thread Nm 230 for tkt 8 thread Nm 250 and 280 for tkt 6 thread If you can find that thick thread or linen 18/6 thread. Linen threads: Needle Nm180 for 25/3 and 4 cord or 18/3 cord Nm 200 for 18/3 and 4 cord Nm 230 for 18/4 and 5 cord Nm 250 for 18/6 cord Nm 280 for 18/6 cord Nm 300 for 18/7 cord That's the linen thread table I doubt it will take the thickest threads above tkt 8 and 18/5. The adjusted needle, normal needle your machine will perform best with is a 200 tkt 8 thread (the needle your machine is adjusted to work with). The 160 and smaller will be to long and thin, easily bend away from the hook and cause skipped stitches. The thicker 250 to 300 will easily get birds nests in your bobbin. The thicker needle could also get to close to the hook tip, hitting it and damage your shuttle. Always try turning by hand first when using big needles, check that it will not hit the shuttle tip. Normal problems with these are worn groves in bobbin and tension spring, causing insufficient bobbin tension. Worn broken bobbin tension adjustment screws etc. The original cl. 5 small open shuttle is now obsolete so you can't find part for it. You have to buy a new small closed shuttle, DA part # 0005 002904. Price is between 400 to 100 Euro, original to aftermarket. The new closed shuttle will fit and is not to be confused with the similar Singer 45 K shuttle, that are often sold to fit the class 5 by after marked dealers. It's a difference between them on the hook tip. If your shuttle is good and tension thinner threads not much else can be broken on these machines. Pic #3 shows the original (now obsolete) small open Adler shuttle that came with the machine. Original part #05 195 (not sold anymore, replaced with DA # 0005 002904) Of course the hole machine is now obsolete and parts not available anymore. But some parts from the newer generation 105-64 that still are supported will fit your machine. You motor looks to be a Kobold slow speed clutch motor. I will be easy to sew slow on thinner materials but when you try on thick stuff it may struggle to keep at a slow pace. You could install a speed reducer gear pulleys or change it to a servo motor, or both. These are quality machines but will of course mark up the backside of your leather by the feed dog. Try release the foot pressure and help the feed by hand (in the right moment only) Use water , a bone folder or a saddlers hammer to smooth out markings at once they are made. Good luck with it! Tor

-

Look for a complete shuttle for Pearson model 2

Trox replied to Philaupatte's topic in Leather Sewing Machines

What is wrong with your shuttle, the broken screw? that screw can be easily replaced and you can buy a new spring too. -

gordond's Machinery NewZealand

Trox commented on gordond's gallery album in Our Leatherwork Galleries

-

Pricing of Adler 5-27 with electrical motor?

Trox replied to Mocivnik's topic in Leather Sewing Machines

Hi, I've owned and sold a few of these Adler class 5. This is the 5-27 with a following jump foot and bottom feed. I consider it the best of the 5 class for sewing leather. But still you are buying a obsolete model with only bottom feed, the only part available for this today is the shuttle. (Read post about what you need sewing leather etc.) Okay, being in good condition you probably won't need anything else for years to come. As the price on Asian made heavy triple feeds economical solution's continues to drop, so does the values of these. Without any pictures is hard to put a value on such machine, and you get a servo motor for a little over 100€ today. I've seen them sold from 50 to 1000 € depending of who sold them, condition and equipment. Post a picture and check the shuttle wear (if it still can tension thinner threads). If it's been little used the original black paint will not have wear signs from materials etc. Repainted, stay away until closely checked by sewing technical. Shuttle new is 150 to 400€. (Knock off to original) Try sewing with it! Don't offer anything before you checked if you can sew with a 160 needle and corresponding thread thickness. It will sew and tension that thread fine if the shuttle is in good condition. You don't buy a car or a sewing machine from a stranger without testing it first. Price is also depended of what's available in you local marked. Good luck! Tor -

Nice, but it's a user manual not a service/adjustment manual.

-

I missed a little bit on the angle of the guide, therefore I just made it adjustable

-

I just took a piece of aluminum and made my own bracket and ordered a long guide. Anyway, I really hate the hand lifter on the 411; why couldn't they place it on the top like on the Adler machines.

-

http://www.kwokhing.com/da/ you just have to browse true their web site. All these guides attach the same but you need and adaptor/bracket unique to your machine. If you are going to use it on a 441 clone check with Uwe´s solution. Otherwise you can make your own bracket out a piece of aluminum like I did. perhaps they now sell a 441 bracket, ask them. Good luck!

-

Ordered one

-

Pfaff 335, Adler 69 type Cylinder arm caps.

Trox replied to RockyAussie's topic in 3D Printers and Lasers

Nice! I heard you can smooth the surface of the ABS plastic with aceton, does it work -

Hi, I have had several requests for service manuals for old Pfaff 345 and 335 machines. So here is what I have avaiable for these machines. For the Pfaff 345 here is a download link to the partlist, subclass list and service manual, link is valid for 30 days. https://rushfiles.one/client/publiclink.aspx?id=n5JAdmYzGl For the new 335 casting machine you are supported by Pfaff industrial https://www.pfaff-industrial.com/en/support/downloads/technical/documentsearch For the old 335 you can use this general service manual for several similar contruction Pfaff classes. https://rushfiles.one/client/publiclink.aspx?id=VSZEdZXfUv The old service manuals are without pictures and many terms can be difficult to understand. However, the new 335 service manual is good illustrated and can be used as a reference in addition to the old. Just change the parameters to the correct ones from the old manuals. I hope this will help. Thanks Tor

-

Send me an PM with your email and I can send you the manuals Tor

-

hot foil machine ironbridge hot foil stamping machine

Trox replied to IronbridgeKOREA's topic in Member Gallery

Hello Ironbridge, if you get this message I'm interested Ed in buying some alphabet letter types from you. Can't read the Korean language, Thought. Do you ship to Norway or USA, Thanks Tor- 15 replies

-

- hot foil stamping machine

- stamping machine

-

(and 1 more)

Tagged with:

-

- 2 comments

-

- hot foil machine

- hot stamping machine

- (and 3 more)

-

-

Round knife looks like a Gomph, Blanchard alo used the same ferule but mostly on their plough knifes..Most likely a Gomph.. But if you wire brush/clean the tools you would see the maker stamps on them and be able to identify them.

-

And I love those plates too, using them for my creasing machine table I'm building soon.

- 181 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with:

-

Well, can't see there are any difficulties getting part or feets for this machine. I you still have trouble let me know and I shoot you a couple of links.

-

Sorry, I now see its an old add, just curious about the brand of it, thanks