-

Posts

1,591 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Trox

-

Hi, this is my opinion, the value of the die is determined based on demand. Most clicker dies are custom jobs based on a particular patterns, the universal dies are most in demand. Like dies for belts, different size squars and holster dies are easy to sell. Spesial dies and shoemaking dies etc. not so much. I have a big box full of shoe making dies and I do not even want the trouble to sell them. Of course the quality of steel and construction adds value, but only if somebody needs it. I think there is a Facebook group about trading dies, it's a closed group but it is out there and you might apply for membership. There are other groups for selling leather tools like " leather tools for sale" and "leathertools for sale trade or collect" One is open and the other wants membership. Anyway, I find these groups easy to sell and buy everything connected to leather work. It's no auction, cost free and with paypal pretty safe. Especially the first group were the moderator has done a good job to exclude bad users/scammers. Many people out there looking for second hand clicker dies my self including, take some pictures of the die on top of a meter ruler and post them in the Facebook group. Good luck Tor

-

Hi Allan, I do not think there will be competition over such knife. It would be nice to get my plough all original, but mine is unmarked and have replaced parts already. The gradings/scale on ruler is also pretty worn out, perhaps I will get in good working condition and pass it on to others. I bought a good portion of tool to a good price and got a portion of Norwegian saddler history with it. You cannot find much information about that now a days. I know we had a unique way of making horse harness here in Norway and you can tell a lot about a craft man studying his tools. I have also been promised copies of working drawing on all from chairs to saddles from the same old company. I look forward to that and I will do my best secure that history for further generations. You are right about the German tool makers, they often made such clean skin tools, stamped them with their customers brands for further sales. I have not heard the same about the French, I think they mostly used their own brands marks. However, in the older days there where tool makers in every back yards making tools for other suppliers. I belive my plough is made by the same tool makers as yours, a possible German maker with the phoenix bird brand. I have not bought any tools on Ebay for a long time, and yes I too know how it is to live far away with large shipping expences; I buy a lot from the USA. We talk later. Tor

-

Hi Allan, I see you have found a plough with the same phoenix bird stamp as on my round knifes. I always suspect them to be of German orgin, I also hav another knife (a cornette or French pattern knife) with the same handle material and made exactly the same way. That has only the inscription "Gesmiedet" which is German for forged. There was also a unmarked plough in the same tool lot as the round knifes, that look exactly like yours (pic). Apart from some changed out parts: The steel guide between the ruler and the material guide, who protects the ruler from screw markings among other tings. I put that piece in my self along with the home made locking thumb screw (I will make another one like yours later) Then the knife is of another German brand (Langenhans, I believe). When you look on the details on it, it looks exactly like yours. I always thought it to be German. It was also very common to buy German tools here before, still is when it's awailable. Other stuff in the lot was of German orgin too. I never seen a bigger collection of plougs than yours Allan, do you collect other leather tools as well. There was also a newer Blanchard 20 cm plough in the same tool lot, in very good condition. Together with half a dusin more or less used up Blanchard plough gauge knifes (no Vergez only old stock Blanchard). A good plough will survive at least ten knifes and the Blanchard has always been there to deliver spare knifes. Since most of the other European plougs are copies of theirs (part from the UK ones) Blanchard knifes could be used in most of them. I'm sure thats the reason for your missing knife. I'm not sure but I can imagine that many European tool makers that copied Blanchards tools where careful to do so after the big "copycat" trial between the house of Blanchard and Mayer Flamery. It ended in favor of the house of Blanchard. Perhaps that's the reason there was some brands that only made a few tools like that, I'm only guessing here Nox, If I have not told you before, thank you very much for your post and pictures. It been of big help and is very interesting reading, for sure.

-

Ok, two lines and ground yes. Then it's just clicking away. Good luck, Tor

-

HI, Like mentioned by others in an earlier post there are different color machines of the 1245, first one gray color, then yellow and current model is white. The current white 1245 is different from the older ones. The exterior is very different but I do not think they are very different inside. However, the new one might also be produced in China. Perhaps not all the new white ones are produced there, but today's machines most likely is. I do not know for sure where they are produced, China will be my guess. When it comes to spec on the new machine, these are avaiable on Pfaff industrial http://www.pfaff-industrial.com/en/applications/naehen/lederwaren I do not think is much different in thread/needle size, bobbin size or foot lift between old and current version. Nevertheless, I cannot be sure before I go in and compare the machine leaflets. Im sorry but do not have these data in my head, I belive you also will find documentation on the old type in Pfaff´s web site. When it comes to quality the old gray machines was better made that the later yellow same looking model. However, what it gains in quality it looses on age/usage. Anyway, if you find a old Grey machine in good condition you have a machine for life. Tor

-

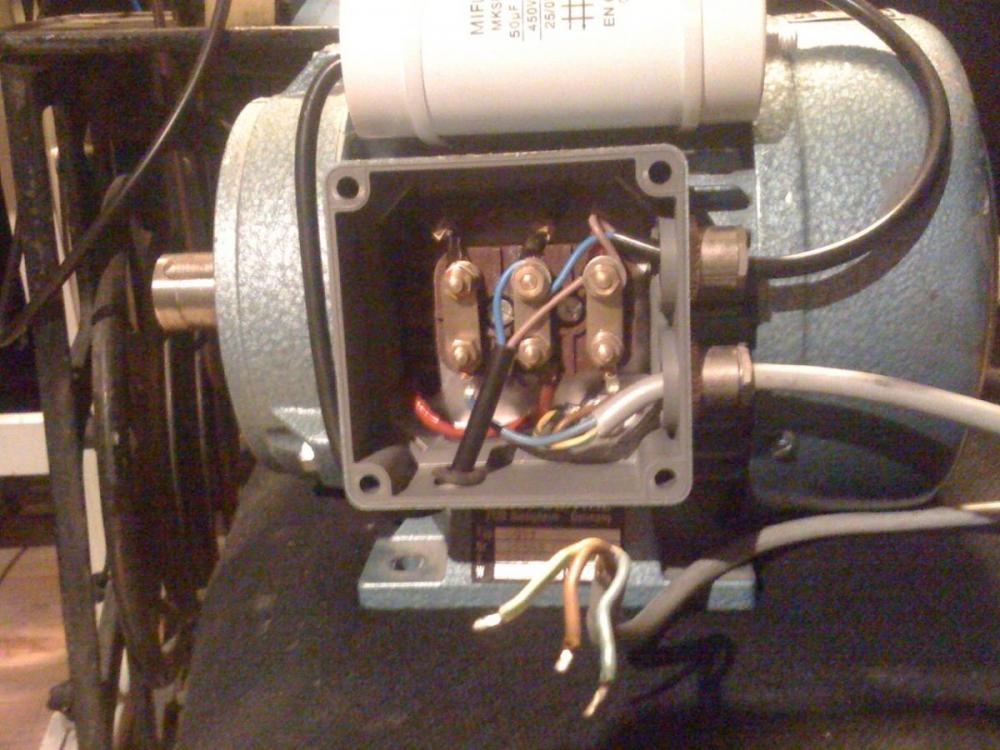

Every AC motor are originally 3 Ph, if it runs on single Ph it's rewired like in my picture above. (Or a little bit differnt) If the motor has a capacitor or two like mine (the white plastic cylinders) it's rewired for single Ph current. I'm talking about AC motors, DC motors (servo motors) are different, they are not used on machines like this (very expensive when they get this big). When a AC motor is rewired for single Ph it looses a bit torque, but it's always normal to use a bit bigger motor than neccessary when they build machines like these. Therfore, changing the motor will (narmally) not be necessary, just rewire the existing motor like in my example. By using two big capacitors, enough startup torque is stored in them to get the motor running (startup) like normal. When a motor is a bit to small for the aplication, it will struggle to make the startup. Fuses will blow and so on. Get hold of a couple of big capacitors on Ebay and get an electrician to rewiring the motor with them. Mine are on 50 micro farad each and will work fine on motors from 750 to 2000 Watt. A electrician can calculate what power your clicker needs too, but my setup looses minimal power on a 1,2 Kw motor. It's not a big expensive job. Frequency converter/drives are only neccessary when you need to regulate the speed (or other aprameter) on the motor. They are quite expensive too, no need for such on a clicking machine. Tor

-

Hi, These are knifes for the French plough gauge Blanchard and will also fit most other French and German ploughs of Blanchard pattern. Knifes are sold separately and together with rest of the tools because they do not last as long as the rest of the tool. A new knife like that is 47 Euro @ Vergez Blanchard, but the old steel stamped "Blanchard a Paris" is much better. Here you see some different types of plough gauges, your knifes will fit the two tools from bottom right. The English type of ploughs, Dixon and other (left two from bottom). Uses a other style of knife. Your middle knife have not seen much use, lots of blade left on it. When they get to short they will not ride far enough up against the roller of the tool and have to be changed out. All yours are still usable after some cleaning up but the middle is the best. (If you clean them up do not sharpen them unless you going to use them your sel. Because the bevel should be on the left side of the blade and users like different/personal style of sharpening). I could use a spare knife or two for one of mine tools, if you decide to sell any of them. Thanks Tor

-

I think that is an old picture of the Don Carlos knife. I have noticed they have changed design during the years, to the worse I'm afraid. It's no idea buying a cheap new round knife today. No doubt it's a real knife, I'm afraid this is what you get buying a cheap factory made knife today. Why not buying a good used US made knife or and old French Blanchard (if you find a good one). Old CS. Osborne Newark stamped rosewood and brass, you might find one from 50 to 100 usd. in fairly good shape. These are good knifes and there are still many around keeping the price down. Has to be Newark stamped or early Harrison stamped with cocobolo and brass. There is no such thing as an cheap good head or round knife, there are only lucky finds Good luck, Tor

-

Ok, a modern type of machine (FAV also made those regular Fortuna types with arm). As I said the before, the picture/angle do not reveal much. But what's the brand?

-

Global was the first Chinese clone by brand in Europe. It's a good Chinese brand who have been used by big European sewing machine manufacturers for part making and so on. Sold by Imca BV in Netherlands, their sewing machines are as good as any other big Chinese brands or maby better. I do not know anybody that owns their skiving machine, but I reckon it is of the same quality as the sewing machines. 1000 euro has to be a new price ? I do not know where you are based, If it's Europe you can check Sieck.de for similar machines. I think their own brand "Sieck" is manufactured by Hightex (Cowboy). Similar one motor bottom feed runs at 950 Euro, with constant speed bell knife and servo on feed roller (much easier machine to learn and use) twice that much. A bottom feed machine like the Global SK 111 will work fine for your task, but will need some training to master. Good luck, Tor

-

Hi, yes and I wish there was one where I'm based too (Oslo, Norway). But I'm used to buy most of my parts/tools abroad. The shipping for a foot like that is not expensive. Just ask Dan Naegle in CR to send you a list/leaflet of every presser fot/ assesories he has for these machines. He is a very nice man to deal with. And other thing you can do is to search the Ebay for a foot like that. There are Chinese presser to be found on there sometimes and most of the times they give you free shipping all over the world. The Chinese still have some kind of trade advantage/ very cheap shipping posebilities. Most of the time I buy something from them (small things) they give me free shipping. Takes a bit longer, a couple of weeks. But your not far away from them. My guess is that the foot Darren has can't be more expensive than 50 USD, probably 30. Perhaps that's why it's difficult to get the price Send him and PM or an email. Here is some of my pressers. This roller presser is best suited for splitting operations, double skiving. That little adjustable one is very useful for firm leather short skives. Tor

-

Fortuna V50S Skiver grabbing and scalping leather...advice?

Trox replied to wrightsofman's topic in Leather Machinery

It's always important to have a sharp bell knife, after grinding remove any inside burr with the deburring tool. Grind outside edge and use the de burring tool inside simultaneously and stop at the same time, the there will be no burr at any side of the edge. I use the metal roller wheel for thick leather and wegtan. The stone wheel for upholstery type of leather, delicate thin leather. Move the bell knife as far to the left as possible so the edge will be at the top center of the feed wheel, the roller should be adjusted to follow the radius of the bell knife. I use paper strips to adjust it, this way I can have the exact same distance to the bell knife on both sides of the roller. Then the angel of the skive is set with the presser foot alone. My machine is an Italian Alpha SM, with a constant speed bell knife and an extra little servo motor for the feed roller. On this machine you can feed the material with the feed roller motor. When you have a machine with one motor that control both the roller and bell knife speed is important to use the method that Electrathon describes. The feed roller spring pressure is set differently for different types of leather, more pressure for firmer leather (and wegtan) than for upholstery types. Ones you have setup your machine to the so called zero position (described above) you should only need to adjust the presser foot hight for different thicknesses. If you use one millimeter clearance between the knives and feed roller or two, just measure up some paper strips at the wanted thickness. Place them between the knife and the feed roller and adjust the feed roller until you have the same drag on the paper strips all over the radius of the feed wheel (hold the paper with one hand and adjust the feed wheel with the other) I find this method very usefull, it may save you a lot of leather tests this way. Good luck, Tor -

Campbell Randall sell presser and roller presser for these types of skiving machines, he has many different types. They fit mostly every machine and are bought for the feed roller witdh. Some fit 50 mm roller and other 30 mm roller width...and so on, they are not very expensive. Tor

-

Unless you have the missing parts is useless. Nice cabinet thought. You are missing key components and its looking old, it can be very difficult to find parts for it. Unless it's a Fortuna, then you can have it rebuilt by the Fortuna company. But I'm afraid you can buy a Chinese skiving machine for less than this key parts will cost you. If you have all the parts (in working order) then it's not rocket science to get it working again. What brand is it ? The picture is not the best quality. Try to find the name and model number on it. Tor

-

It's cast iron of course, crap! If not is very bad heat threatment. Should not be that coarse grits on proper heat treated tool steel.

-

By the way, not a very good way to attach a speed reducer; you cannot tension the machines V belt this way. Tor

-

I use such frequency controllers (drives) all the time, sine I do not have 3 phase current in my workshop. Here (Norway) its 220v on single and 380v on 3 phase but the principals are the same. I use the drives on solutions when I need to control the speed on the motor (in addition to convert the current). On my clicking machine I rewired the motor to have it running on single Ph. I used two big 70 micro Farad capacitors not to loose any staring up torque, it is as strong now as it was before running on 3 Ph. You can loose a little torque when you use these drives and on some frequencies they tend to make bad sounds. That's no problem when you can adjust the speed, just change the speed/Hertz and the sound dissappear. On a clicking machine you have to run on maximum speed/Hertz all the time, you just have to hope it will not sound bad on that frequency. Here is an other AC motor (1,2 Kw 3 Ph) I had wired for the single Ph current. This is a air compressor motor but of similar size as the clicking machine, wired exactly the same way. Sorry for the bad picture quality, I can take new pictures if you are interested. Tor

-

Nice find

-

I wonder if our tool expert Bruce Johnson have seen this maker stamp before Bump

- 3 replies

-

- knife maker stamp

- maker stamp

-

(and 1 more)

Tagged with:

-

You better move this add to the marketplace forum, this is a discussion forum only, thanks

- 7 replies

-

- jewels

- accessories

-

(and 7 more)

Tagged with:

-

Impressing work Tom, you have a future as a tool maker. Looks like your machine uses a very different angle on the blade and a more stable blade support. Are you able to skive upholstery type of leather on your machine or only firm leather.

-

I looked true is FB site and saw four machines in his workshop. a Pearson harness stitcher (or simmilar), a Adler 205-64, a Tipperman Boss and a old Singer 29K. No picts of the Pfaff, I look forwards to see that machine. Tor

-

You can see how the Pfaff cl. 27 and 28 looks like in Sieck.de web site. Go too category "arm machines" (English language), to compare to the one you are talking about.

-

I would check out Imca BV in Harleem (Nederland) Globalsew.com. (my links do not work, you got to type them in your self) They sell Global who was one of the earliest clones in Europe, they have made machines/parts for Duerkopp Adler. They also sell Hohsing motors (who are one of the best pro sewing motors on the marked today. They have a very good little needle position motor for a reasonable price "G 60", this motor works very well). They also sell used machines. Sieck.de is already mention above. But do not forget Frank Brunnet GmbH "www.frank-brunnet.com"Germany, he sell several types of clones. I have a Danish friend who bought a clone from him he is very satisfied with, same class you are looking for. He has Global and perhaps Hightex too, and his a nice man to deal with who knows his trade well; good support. Do consider customer service/support as the most important factor when buying a Chinese clone machine. The price comes second, good luck. Tor

-

What subclass are you Adler 5. If been sewing 16 mm thick leather with my old 5-27, it has a spring loaded jump foot and bottom feed. It preform pretty good on leather (it's built for leather work). You do not need that much foot pressure with this jumpfoot, it follows the material backwards and takes the pressure off the feed dog. (less marks underneath the leather compared to a regular bottom feed system). I also have a complete original saddlers attachment pack for it, with presser feets and needle plates etc.. It's a very good machine, I keep it as a backup machine it's still in new condition. I also like the old 328 needle system, it produce much less heat compared the longer 794. The needle on my 441 can be hot enough to melt thread sometimes, it need to use lubricant to cool it down on long runs.