-

Posts

1,591 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Trox

-

Perhaps "SV" stood for "Stolen Version" since they later became regular subclasses Can't see anything SPECIAL with them.

-

Pfaff cl. 27 and 28 drop feed cylinder bed with barrel shuttle. Looks to be something a bit lighter than the Adler cl. 5 (Singer 45K). I do not know what needle system they use, might have been similar to the Adler cl 5 (328) Or perhaps something in the same range of the Singer cl 17. They look a bit like the last, but has described to have a barrel shuttle. The Singer have a shuttle, but not a barrel shuttle. It if those needles fit your Adler cl. 5, they cannot be similar to the 794 system the 441 use. They are way to long for a class 5 machine.

-

Hi Simon, yes the "Rossler" have the horse symbol too. But I seen it on French tools too, If I'm not mistaken. I'm not sure anymore, when you forget to write such information down its forgotten after time. The second one is German I think, it's a couple of German tool companies with that name. It do not look that old to me, looks like something made in the 1960 and later. Perhaps not that good looking, but looks like a very good tool to me.

-

Thank you very much Nox, Yes the knifes are still a mystery. I still have a feeling they might be German made, just a guess based on the handle material and ferulle. Thank you so much for the links/catalogs. It's a very interesting site about round knifes, I do have several of those knifes (around 25, but not all are different) Gomph tools are very collectible, I just lost two nice round knifes during shipping from USA. I favor a good HF Osb. or a W. Rose over a Gomph. First time I've seen his catalog, very interesting indeed. When I have a French tool expert here, I have a few other French brands I want you to take a look at (I might have more, but these will do for now). If you do not mind ? There where two nice circle/washer cutters in that same tool lot as the 2 mystery knifes. One has a beautiful stag handle and a horse brand (did not have the time to clean it up yet), I belive it's a "PORTRAIT". It's in very nice condition, blade is not even Re sharpened. (pic 1 & 2). Next is a double washer cutter 30 cm of brand "Prisma", it might be German and not very old. (pic 2 & 3). Next is a "serpette" I bought from France some years ago. It's marked "S:N:C:F and a laying B" (pic 4 & 5) It's a typical Blanchard pattern knife and has very good steel for leather( gets very sharp). One last tool a small 20 mm. English strap end punch from "Dumay a Paris" (pic 6 & 5) Also bought in France. I know this was a lot to ask about at once, not every day we have an French tool expert on the forum. By the way, it's first time I've seen anything from "Ullathorne & Cie". I do have an old large round knife from them, I'm afraid it's in to bad shape to be saved (or need to much work). There was also an Ullathorne in the UK, do you know if it's the same one or family? I love old French"sellerie" tools, I use and collect them. If you have any info about these tools Pls let me know. Thank you very much for your help and insight Madame, email sent

-

You're welcome Steve

-

I got all different strap cutter tools, but nothing beats a good modern Blanchard plough (with a old type knife attached). Knife set up with the bevel on the inside only, it works as a rudder and compress the leather against the guide.

-

Takk(thanks) Simon, not a bad suggestion, it's more like it. "Phoenix raising from the flames" that's Greek mythologi isn't it. A quick Google places the phoenix in Egyptian, Persian, Greek, Oriental Judaism and Christianity. Phoenix surrounded by flames (but not hurt by them), several cities in USA and Europe uses this symbol in their municipal emblem to denote the one time destruction and consequent rebuilding of the city. It's a very commonly used symbol, but now I have more to search for. It's a German coats of arm, along with several other countries, the search is on . Thanks Tor

- 3 replies

-

- knife maker stamp

- maker stamp

-

(and 1 more)

Tagged with:

-

There always some old iron around you might be lucky if the add can be seen by enough people, "bump" it to keep it alive frequently. It's like someone asked me to sell the original saddlers attachment pack for my old Adler 5-27 (who's basically the same machine as a 45 K cyl.bed with jumpfoot) without buying the machine. I could not sell one without the other. That said, you can't get anything without trying; and there's a lot more Singer machines out there than Adlers. Good luck Tor

- 29 replies

-

- singer 45 throat plate

- singer 45 needle plate

- (and 2 more)

-

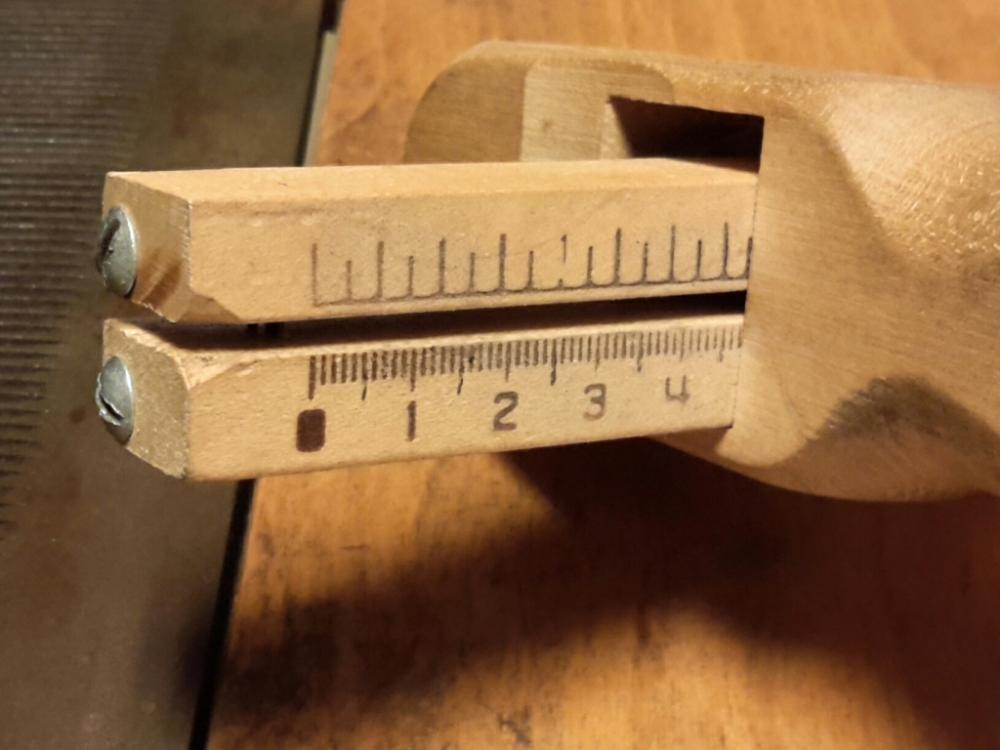

That was a nice modification Red Cent. It's also smart to take of some of the edges on the wooden bar (see pic), This way it will not leave marks on the remaining leather and are easier to feed in too. (it's a Stohlmans trick). I got a brand new one (top) I can sell if is hard to get the original, I'll keep one because they are good on very thin leather. Tor

-

Those modern draw gauge blades are not very good (unless you re sharpen them with the bevel on one side only, like a rudder that press the leather against the guide). Terry Knipscield makes a very good draw gauge blade, you find it in his web site. (It to wide for the HF. Osb Latta pattern draw gauge, but It will fit most other). A good blade makes the job easy and it's well worth the extra money. By the way I do have a couple original strap cutters laying around, I could sell you one cheap. I use plough gauges (and Draw gauges on narrow reins). But I'm based in Oslo , Norway so the shipping will perhaps kill the deal. I do not stop me from buying in the USA

-

The 45K came in a variety of different subclasses and even more different presser footˋs. Without knowing your/what subclass you are looking for a presser foot/ plates for is difficult. The only new stuff sold for the 45K Adler 5/4 and clones are the narrow harness foot manufactured in China (sold by Cowboysew, try Cowboy Bob, Toledo Industrial Sewing machines) You can see this harness foot in the site of Cowboysew.com . I think it would be very difficult to find the parts you looking for, you might be lucky. I had some of these parts before, unfortunately I sold them several years ago. I would advice you to specify what parts you are looking for with a picture and part number. This way it would be easier, somebody might have these old part but do not know what they are for. Good luck Tor

- 29 replies

-

- singer 45 throat plate

- singer 45 needle plate

- (and 2 more)

-

Hello Steve and Angie http://sew24.blogspot.no/p/downloads.html try that link first (I'm unable to paste in links on this site editor, since the big site update) If not try to search on Google for the blog "the world of duerkopp Adler parts" and select downloads. There you will find most obsolete Duerkopp and Adler classes. And there are several manuals on the class 20 (leaflet,part and user manual. Perhaps also a service/adjustment manual), have some patience because the downloads will start slowly. It seems like the links do not work, but they do. Thought, they might be in German. Tor

-

Hello Nox, very nice tool collection you have there. I tried to reach Walter too (true a PM) but no answer yet, perhaps he in a holyday trip somewhere. I do collect and use French leather tools too. Here the other day I scored a large lot of old tools from an closed down Norwegian Saddlery (Henriksen Jensen, Skien Norway. Etbl. early 1800 to 1992) There was mostly French Blanchard and Portrait, such as Ploughs, compasses and circle cutters. There was two round knifes of a maker I never seen before, thought looks to be of French pattern. But perhaps made in Swiss or Germany, I'm only guessing here because I can't remember seeing this maker Stam before. The knife tangs goes right true the handle and are latched in the end (just like ordinary old Norwegian knifes are made) One is 5,5 and the other 6 inch wide. (See pic) I filled the shafts with epoxi and are ready to clean them up. Have anybody seen this maker before, please let me know. By the way, I would love to have a copy of that Gomph catalog, I do not have the pages you are missing anymore (I received them from Walter, but they was stored in a broke down computer and are lot) Thanks Tor

-

Some kind of bag stitcher maby, since it's portable. Like for potato sacks or such

-

Thanks for posting, very interesting!

-

Versa grover get the thumbs up from me

-

Hi all leather tool freaks, I was lucky to buy a lot of old Saddlery tools from a closed down Norwegian saddlery, Henriksen & Jensen Skien Norway (Etbl. Early 1800 and closed down 1992). I bought them from the son of one of the partners. He showed a lot of dokumentation, diplomas (several best Saddlery in show, working drawings on everything from furniture to saddles/harness) . I did not have the heart to try talking him in to sell the dokumentations, it was hard a enough selling his father's tools. However he promised me to give me copies of the historical documents. This is the first time I have ever found any history on old Norwegian saddleries. I'm very excited with it, because I was afraid everything was lost. I bought a wooden tool box full of mostly old French leather tools, among other: two ploughs (modern type Blanchard 20 cm and older 10 cm), lovely stag handled circle cutters, Blanchard scratch compass and all kinds of tools a saddler needs. There was two nice round knifes in the box I never have seen the like of before. A 5,5 and a 6 inch that looks to be of French pattern but perhaps made in Swiss or Germany. That's just a guess based on ferulle and handle materials, they could very well be made in France or Spain (or anywhere else in Scandinavia or western European main land). What is unusual (but very wisely done), the blade tang goes right true the handle and are latched in the end (or what's the right English term for it is, please see pic). Just the same way we make ordenary hunting and decorative knifes (knife of silver worn with old national costume) here in Norway. I have filled the handles and ferrules with epoxi and are ready to clean them up, blades looks very good and have pretty hard steel. Have anybody here seen these maker stamps before, looks to be "cocks on grass bottom" with some letters above, perhaps " H F" . Later I will post documentation and pictures in the Historical forum and perhaps here. Thank you, Tor

- 3 replies

-

- knife maker stamp

- maker stamp

-

(and 1 more)

Tagged with:

-

Ferdco Super Bull / Cobra Class 4 Issue

Trox replied to tagger609's topic in Leather Sewing Machines

It's easier, cheaper to make a copy or clone just like the real thing; than make it different. Therefore, you can trust they are all the same. Of course there have been some modifications/improvements and different material qualities. I'm sure we can help him get his machine sewing as it should. Nevertheless, that the dealer job in the first place. Just return it and demand they fix it and pay for the transport. Is it not a brand new machine and you paid for a fully operational sewing machine. If you want a DIY project you can buy it direct from China yourself to a fraction of the price. I'm sure any of our dealers would have replaced/repaired it and not told you to seek advice here on their mistakes. If the dealer will not help you, then tell us where we should not buy sewing machines. Let them earn their pay check like our dealers have too. Tor -

Dürkopp Adler 869 180122 M Type Cylinder-Arm Machine

Trox replied to Anna1980's topic in Leather Sewing Machines

Hi Floyd, I can answer regarding the reduction pulley. I can ensure you both that is not neccessary or even possible in such motor systems. The Efka DC 1550 delivers up to 8 NM of torque, more than enough for any known lock stitch machine model out there without the use of a speed reducer/reduction pulley. (Such pulley can't be used with modern Efka and DA drives because it will mess up the control box calculations, therfore they made their motors strong enough in the first place; strong enough to not need one) I use my Efka DC1550/DA321 on my 16 inch 441 clone and do not have to use all of its power (The torque is adjustable in the control box, I can turn on more if needed and I never had to to that yet). The 896 will handle heavy material and thread from Nm 80/3 up to 10/3 (Tex 270) and this are factory specs. meaning it probrably will take more. Perfect machine for leather bags and medium leather work. Heavier options are the DA 969H from Sieck, prices from Euro 6500 and up. Tor -

Dürkopp Adler 869 180122 M Type Cylinder-Arm Machine

Trox replied to Anna1980's topic in Leather Sewing Machines

I forgot to welcome you to the forum Anna, tried to edit my last post but for some reason I was unable to do that. Tor -

Dürkopp Adler 869 180122 M Type Cylinder-Arm Machine

Trox replied to Anna1980's topic in Leather Sewing Machines

First of all, excellent choice of machine. If I could afford such machine I grab it in a hartbeat When it comes to choice of motor. I do have the Efka DC1550/ DA321 control box. However, I use it on my 441 machine. That is a very strong motor, very happy with iThe DC 1550 first came as early as 1994. I'm not sure but some of these internal drives and direct drives are Efka too (the first ones where Efkas). The direct drive system is an update/advantage over the traditional V belt drive system, it requires less active components. Therefore, it's less that can go wrong; no belt slippage and less cables/components. Machine do not need the synchronizer head, where on the older motors (DC 1600 and prior to that) the needle positions was adjusted. On the DC 1550 and later motors it's only there to calculate belt slippage. With direct drive you will not have any belt slippage and it's not neccessary. Is there any price difference between the two motor options? personally I would choose a direct drive option, unless the motor used are of less power/quality. That's a much better system than the traditional V belt drive. Ask for motor/control box specs on direct drive option too. The subclass of your choice have all the extras I would ever need on such machine, it still should be possible to add more if neccessary (possibility on control box to add extras like it is on the DA 321 box). I belive there are huge price difference with different European dealers, not all of them will offer the same customer service prior sale. A economical option for those who do not need that much customer service is Sieck.de. However, good customer service is gold. Efka is well known for their service. I think the price offer you received was a bit high. The classic is more expensive than the Eco. However, Sieck sells the 869 Eco-Efka DC1550/Da 321 for only 3600 Euro. I will advice you to ask several dealers for offers, perhaps Duerkopp Adler offers "brand support" just like Efka does. That means, does not matter where you bought your motor as long as it is an Efka they will support you. Check out Frank Brunnet GmbH too. It seems like there are huge differences in price even inside Germany. Good luck, Tor -

Madmax, that only proves our machines have incorrect feed adjustment or faults in the castings (or both). Without leather point needles I do not have any problems with back stitching in the same holes. My old Adler machines never had these problems using LR needles, always backstitched in the same holes without thread fraying. However, they where not trippel feed machines. With trippel feed there are more that can go wrong. It's seems like it's just in the comercial videos these clones back stitch fine with LR needles ? Is there any of you that have a 441 clone that backstitch fine with LR needles, without thread fraying (when using heavy threads)?? There might be other factors than influence the outcome, like thread type and needle sizing. Perhaps bonded nylon is more resistant to fraying than polyester. Perhaps using a larger needle to the thread size will give more space for the thread. Thanks Tor

-

Ferdco Super Bull / Cobra Class 4 Issue

Trox replied to tagger609's topic in Leather Sewing Machines

The first thing you do with stitch errors are to change to a new needle, bad needles cause 90 % of all stitch errors. No matter how old that needle is and do not look for burrs on it, just change it for a new one. Then look for burrs on your hook tip, check the inside foot and hole in the needle plate for the same. Use your finger and a magnifiers, look for anything that might cause that fraying. When it comes to the adjustment, it's not your job to adjust the machine. Have it delivered back for repairs or let them come and adjust it in your place. You have a warranty, if you start doing repairs yourself that might not be valid anymore. You will learn how to adjust the machine soon enough, a brand new machine should be sewing fine when you receive it. Tor -

The best 441 clone set up for I tried so far is the slotted plate with a Ferdco lower needle guide. It seems like the machine back stitch in same holes much easier when there is no feed dog that " works against" the top feed. Even with a LR needle there is minimal thread fraying. I also use a Efka needle pos. motor assuring the needle stops where it should be. Thank you both for addressing this "non existing" problem that looks like every 441 clone owner have experienced.

-

Yes I have split all kinds of firm leather on such fixed knife splitters, for soft leather you need a bandknife machine like my old 400 kg Fortuna Tor