-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

Servicing a Singer Clutch Motor

Gregg From Keystone Sewing replied to ndnchf's topic in Leather Sewing Machines

Nice. My dad started when he was sixteen working at Ace Sewing Machine Co. on N 3rd street, working for Danny Burg. His job started out by rebuilding these types of motors, a lot of 58 and 59 class, pressing new bearings, sending the motors out to be rewound. All that stuff, now history. Today, and for a long while now, these motors are like clock radios; there is no real practical reason to fix them. Time labor and parts will put you in the range of a new motor, and you'll still be stuck with an old motor. -

Stitch length changing

Gregg From Keystone Sewing replied to keithski122's topic in Leather Sewing Machines

CLICK HERE for the LU-563 book, it's on our website for download. On owners manual page 11, check out part # 14, and adjust the wing nut so that it up as high as it can go, or climb, for heavy materials. Also, check the tension like people said, so that it is a balanced stitch. Also, see attached image for Juki LU-1500 Series. I think this fits in perfectly into the content of this thread, and helps explain a lot. As far as getting into feed mechanisms on sewing machines can get you. -

Damaged sewing machine

Gregg From Keystone Sewing replied to George1520's topic in Leather Sewing Machines

It's not that easy, unfortunately, once you've signed for it. Not as far as UPS goes anyway. Obviously, there is such a thing as 'hidden damage' from shipping, but are going to have to prove that it was packed exceptionally well, and unless you can demonstrate that, UPS is not going to do a heck of a lot here, based on past experiences. Heck, it can even be packed in the original, international shipping container, and still not be covered. It's a darn shame it can go three quarters around the world without any damage, but can't make it across state lines. Nothing grinds my gears like a poorly packed machine, yet I see it all the time, and do my best to prevent it from happening from machines both coming and going. -

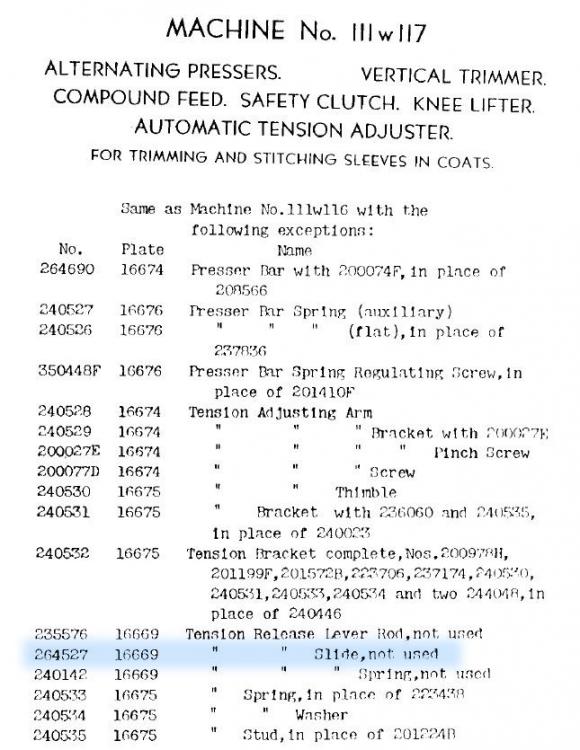

Singer thread tension slide - part #264527

Gregg From Keystone Sewing replied to dikman's topic in Leather Sewing Machines

Glad to help! It's always fun to share, and I've learned a quite a bit here too, as usual. Sharing here is ALWAYS a two way street. -

Singer thread tension slide - part #264527

Gregg From Keystone Sewing replied to dikman's topic in Leather Sewing Machines

OK, here we go. Let me preface that this post comes with some emotional turmoil; Seeing the Abco SOS tag make me feel like "If you can't find anything to do, don't do it here!" "Get back to work!" Thanks for that, Dad. Abco was formerly who we are now. Abco was chosen so we would be listed at least near the top of the list, close to first listed sewing machine dealer in the Philadelphia telephone book. Today, of course people don't think like that any longer. For some younger folks, this is why you see so many names like AAA, A-1, or the like. My mom got tired of spelling Abco for people all day. This was between 1977 through 1980 before we moved into the building we are in now. Small window into my mind, thanks for giving me at outlet to share! Anyways, let get on with it if your still reading up to this point. I think the machine in question is missing some parts, and this is how the tension release works, very different than just about any other machine I can think of, but very few have an edge chopper. BTW, the chopper arc is missing on these two, I've got one more with it not pictured. Between all three, we may have one complete machine. Check the pics, think this is going to provide the best visual explanation I can give. There are no internal sewing parts that are going to release the tension, as setup from the factory. -

Singer thread tension slide - part #264527

Gregg From Keystone Sewing replied to dikman's topic in Leather Sewing Machines

OK, now my interest perked up. Few things. Number one, are you sure this part is going to work in conjunction with this machine? Second, make sure (SURE) if you do go with this part, use a good quality item; a good quality tension release slide will break like glass; poor quality will bend like a paper clip. I've got more than one of these 111W117s here, and now I have to see for myself what is going on. I'll report back. -

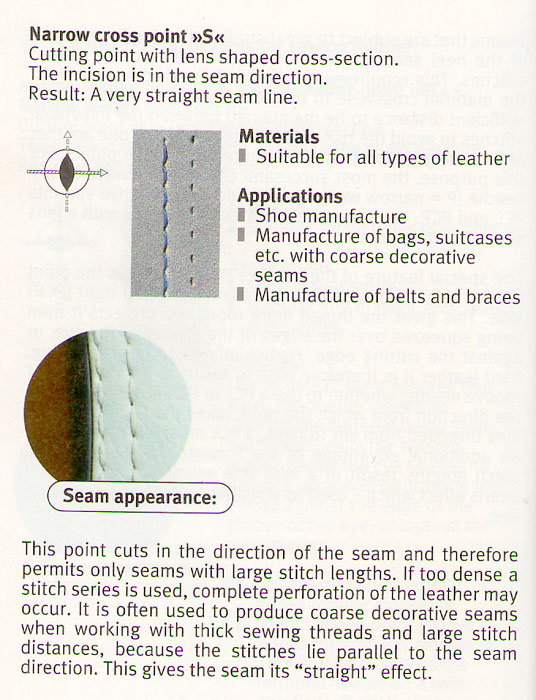

The only constant with needles is that it's next to impossible to designate every system designation, system cross references, needle point, size, finish (coating) and shank variety within a system. And boy have people tried over the years. I wanted to share with everyone what an "S" point designation was from Schmetz, as I had no idea myself, and had to look it up in the book. And I only have read books about needles and deal with them nearly on a daily basis. On a related note, my understanding is that Schmetz is being bought out by Groz-Beckert, and have no idea how that is going to play out. Not the first time Groz-Beckert made a move like that, but not with a name as prominent as Schmetz, for sure.

-

As far as machines go, this one here looks complete,ready to sew. Just flip the handwheel 180 degrees, put the slide plate covers over the hooks, and I think your ready to go? gottaknow obviously speaks from (a lot) of experience, and if you are not going to use this or any machine for angular stitching, then it's true this machine may not be for you. But if you are in need of machine with needle feed, drop feed only, with split needle bar, this is as good as any out there, new or refurbished. And if the mechanism is weak in terms of wearing premature, then you have to deal with it, otherwise you are not going to be able to do angular stitching at all on any machine!

-

Pfaff 438 Instruction Book

Gregg From Keystone Sewing replied to Hockeymender's topic in Leather Sewing Machines

Didn't know this was a thing trying to find this book, I'll check our physical books here. -

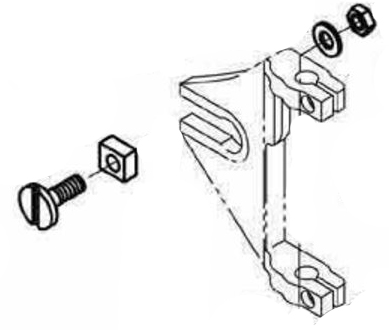

Sounds like you have to fix it with a hammer to move it. Preferably a leather mallet would do it. Don't over tighten the screw, it can break the casting and create a true mess.

-

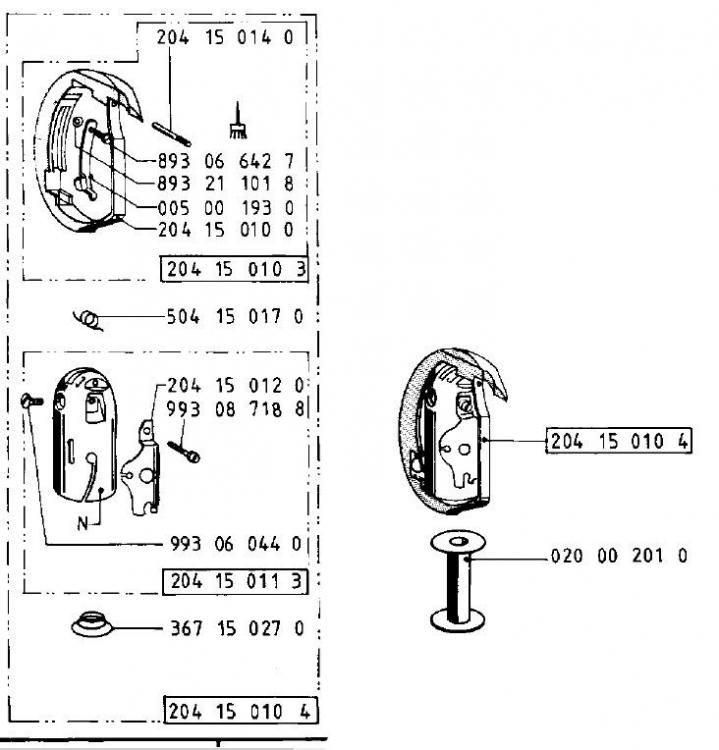

Juki/Ferdco "Bobbin Case Spring"

Gregg From Keystone Sewing replied to JerseyFirefighter's topic in Leather Sewing Machines

Sounds about right; I was skiing in Vermont Friday! All the best. -

Juki/Ferdco "Bobbin Case Spring"

Gregg From Keystone Sewing replied to JerseyFirefighter's topic in Leather Sewing Machines

I deal with parts issues as they come, deal with them and move on. I think I remember sending this off to someone recently for this very issue; this is a parts book from an Adler 366 that shows the anti backlash spring installed. This is a common hook used in a lot of machines, and the spring in question can be used here, or not. -

Pfaff 438 Instruction Book

Gregg From Keystone Sewing replied to Hockeymender's topic in Leather Sewing Machines

Books are too large to upload here, I'll link them to my website for download; Pfaff 438 Parts CLICK HERE Pfaff 438 Service Manuals that cover this machine, book one CLICK HERE book two CLICK HERE -

Glad things are looking on the up and up on this thread. On the rock arms in the back we want a 10 degree angle.

-

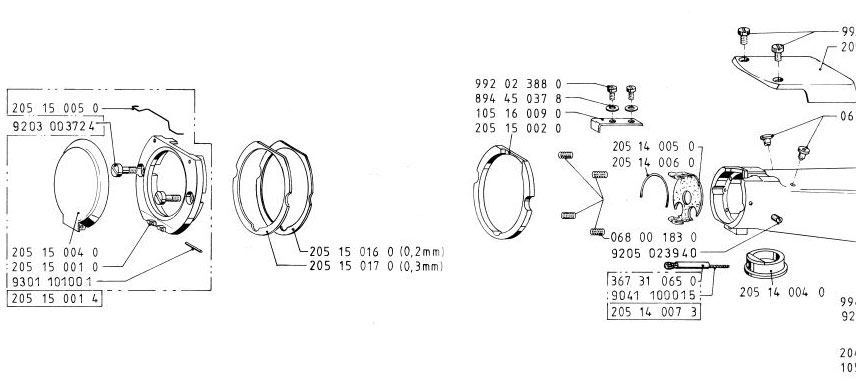

If they were formerly using the shorter, incorrect needle system, you are going to have to raise the needle bar to the correct height to accommodate the correct needle. As for spacers, Adler 205 uses shims here to bring the hook closer or farther away, depending on needle thickness, sold in .2mm and .3mm shims.

-

-

1)That's the way, no other way to do it. Usually we can repair by going one size bigger on the taper pin, or go one size taper pin bigger. At some point, though, the taper pin's thickness becomes equal to or greater than the shaft on either size of the pin, then it's time to replace the arms and shaft and start over again. Not cheap, and not easy to realign, but it's not often that we need to repair like this. 2) The small set screw on bottom and or dimple is only really good for installing the pin; the amount of pressure going through this is such that a set screw is going to do very little here; the taper pin is doing almost if not 100 percent of the work. 3)Absolutely correct. Pin hole should like clean as a shotgun barrel, especially where the arm and shaft meet inside the shaft. Otherwise the pin will not be in the hole for long. 4)Again, absolutely correct. BUT, that's if the hole is ovaled out, exactly as stated. Then, we need to go in, with the correct reamer, again, making a large size pin, and fixing that way. The important thing to understand is that when parts are properly fitted and the pins break, that does not at all indicate that the parts are worn; it may just only mean that the pin is broken, in three places, and needs to be replaced.

-

The DNU-1541 bottom load can pick up the bobbin thread in the middle of the run without removing the goods being sewn from the machine. However, the upper thread is the most important to hold at the beginning of the run, taking the slack out of the thread, on BOTH LU-1508 and DNU-1541 Series, or anything like these for that matter. Not twice as much, but normally low $400 through high $600, if I can generalize here.

-

top tension disc alt threading

Gregg From Keystone Sewing replied to mixmkr's topic in Leather Sewing Machines

This 'fix' is to prevent the thread from losing tension; what can happen is the thread can pop out of the top of the tension disks, and ride on top of them instead of sandwiched in between them. But if you are asking, yes, this will and more tension, overall, threading it through the pin. -

Singer 307G2 Problem

Gregg From Keystone Sewing replied to maxharley's topic in Leather Sewing Machines

That was the 1st thing we thought to look for; if these were the same, part number would be the same. -

top tension disc alt threading

Gregg From Keystone Sewing replied to mixmkr's topic in Leather Sewing Machines

This is the best I could come up with on short notice, check out the threading; once more through the thread regulator, three hole post before the tension assembly. Next, go under the pin, and then follow through like before. The thread will never come out again, but one more item, over time, will suffer from a thread cut over extended time, and some will eventually begin to cut the thread. You can then either replace the pin or the tension complete, at that point. Again, it should take years unless you are using fiberglass thread or Mitchells round emory cord through it. -

Singer 307G2 Problem

Gregg From Keystone Sewing replied to maxharley's topic in Leather Sewing Machines

Funny how this site pops up when I'm trying to find stuff as well...I'm currently on the hunt for this belt now as well, since we took one in on repair, also a Singer 307G2, cloth timing belt part # 506726. Some of our generic suppliers have this part part listed, but no one seems to have it...so far! No timing belt, no machine.