-

Posts

2,274 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Ferg

-

Art, Are these machines, like "dirtclod's" , configured so you can use feed dogs with them? ferg

-

I have a 206RB-5. You aren't going to sew i/2" with these machines. Three eighths is max. ferg

-

Ray, You might want to check Harbor Freight for their press with the hydraulic jack. It would give you more surface and pressure. May also help with the impairments you have. ferg

-

Probably could if you only wanted Concho size pieces. There isn't enough surface for a good clicker. Weaver has a hand operated clicker, very expensive I think, may work fine. ferg

-

You need a drill press and a good material clamp so you can hold onto the Ram. I made the hole just deep enough so the stamps and snap hardware would be about 1/3 the length of the tool handle. Remember, you also need a threaded hole and a thumb screw to hold the tool in place. I used mine for snaps. It is easy to clamp the snap button too tight. Takes a little practice, beats that mallet. ferg

-

I am going to show my stupidity here but I do not know what you use this blade for. Can I assume that it is used to cut straps more accurately than a draw knife? Fill me in please. LOL ferg

-

I hope you can get your stamps made but from what I know you aren't going to get them made for a couple dollars per stamp. think about that for a minute, you couldn't even buy the metal for that???? Your best bet would be a Chinese company, there are certainly some around. Good luck ferg

-

Wait until your leather has dried enough for carving, then apply the tape. If you follow the correct way of casing your leather, sponging a little on top will show you how bad an idea this is. You need to immerse the leather in tepid water until you see no bubbles rising from it. If you place the wetted piece between glass or plexiglass and leave it for more than 24 hours you can expect to see some mildew form. After wetting the leather, I wrap it in an old T-shirt or something of that nature so you don't transfer any texture. Leave it over night, remove from wrap, allow to dry correctly, carve. If you do your carving in the correct steps everything works great. If your piece is too large to finish in one session wrap it in Saran Wrap or place between two layers of glass to retain moisture. When you rewet leather to finish your tooling you will likely lose some of your depth of previously finished work. I may spritz a little water or use the sponge if the leather is getting too dry to work but only after it was initially cased. When using the glass burnisher you are making the fibers of the leather move closer, it stretches very little unless you are pressing too hard. Move the burnisher in one direction if possible. ferg

-

Horse Hide Thickness

Ferg replied to J Hayes's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I cannot stretch the horse hide strip with my hands. If you were tugging on a horse or something of that sort it might be another story. I did not wet the leather, it may stretch some if it got wet. ferg -

I assume you did not buy from Steve. Even so, call them, phone number on banner above. They will get you straightened out. ferg

-

Horse Hide Thickness

Ferg replied to J Hayes's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Have never tried to make lace or braiding from it, the leather is very dense, not particularly hard but dense. ferg -

Doug, Call Bob Kovar at Toledo Industrial. 1-866-362-7397. He has at least one of everything ever made for a sewing machine. BTW: Lowe's has a board attached to a post next to the Metric screws. It has "fittings" on it for your correct sizing etc. ferg

-

I seldom tell folks to go to You Tube but there are hundreds of tutorials there. Some are even pretty good but most are showing how to do a particular type of sewing. Will give you some ideas. ferg

-

Doug, Lowe's has a fairly good supply of metric screws/bolts. If you have a good Ace Hardware close to you they are more likely to have what you need. I think I remember that screw is a "4" and what we would call a fine thread. What the stores have will possibly be longer than you need, I just cut them to the length I need. A "Fastenall" store may them also. ferg

-

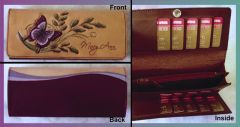

Colored Floral On Clutch Purse

Ferg replied to js5972's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Too wet for stamping. ferg -

Colored Floral On Clutch Purse

Ferg replied to js5972's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I think you done a decent job on your dyeing. When you make another without a border, don't let the design get into the stitch line. Your carving on the flower side looks pretty good, I believe your leather may have been too wet when you done the basket weave. Also: don't let the BW stamp impinge on the stitch line. ferg -

I used strips cut 3/4" , fastened them with 1/2" screws to my "Back" board. I held each tool on the board after placing the first/last screw, pulled the strap over the tool so it was held firm but not too tight to remove easily, marked strap for a screw, punched a hole in the leather and placed the screw. Works great. One thing I learned right away, don't place most used tools too high to reach when siting at the bench. Least used doesn't matter much. Also, longer tools like leather shears need to have more space between the rows of tools. I didn't tool any design on my straps but that does look nice. Length for straps just happened to be what I had available to cut them from. Don't get the most used too far left or right side of center of your stamping/work area as well. ferg

-

My youngest daughter is a Graphic Artist for a publishing company. She has an eye for beauty of design. You have that gift also. Your design choices are as near to perfection as anyone I know. Combined with your excellent abilities as an Artisan. I am blown away by your abilities. Keep them coming. ferg

-

A quick search provides this info: Adler 105 -64105-64 N/F W/F Cylinder Heavy duty fabrics and leather Saddles and harness work It seems most heavy duty machines such as this do not handle light weight leather well at all. Wiz or some other individuals can fill in more info. ferg

-

Ladies purse with 16 card slots.

Ferg commented on Anet du Toit's gallery image in Our Leatherwork Galleries

-

Problem with the metal brake..... The bar that presses the edge of the leather down needs to go all the way down plus adjustable for thickness of the leather you are folding. Hold-down is located about an inch from the folding edge of the leather. That dimension would be determined by the thickness of the presser bar. Metal brakes of the type HF has aren't adjustable as accurately as would be need for leather. ferg

-

Chris, I am one that hates PayPal. I think it is a total rip-off. I sold an item awhile back, sent an invoice to the customer, they paid from that invoice. The transaction cost over $20.00. Bought an item, it was requested I pay via PayPal, I reluctantly have an account. They charged me $7.95. I absolutely refuse to use them unless there is no other way. ferg

-

Try this company: http://www.universalsewing.com/tek9.asp?pg=parts_pfaff Actual page: http://www.universalsewing.com/images2/parts_lists/all/aokko5oe.pdf You do know that machine is an upholstery machine? ferg

-

I do not intend my remarks to be demeaning in any way so please do not take it that way. The knives on old splitters are very often in poor condition. That is: they have been ground so many times they are too narrow and edge nicks make them almost impossible to use without changing the blade. Also have been ground to the wrong shape/angle. I would give you $200 for the splitter if you don't get any better offers. You may PM me. ferg