-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

2x Plough Gauge - 1x 4" Blanchard + 1x 6" other Brand

Constabulary replied to Constabulary's topic in Old/Sold

I´m open for offers - I´m not in a hurry selling em but need some bucks for a project -

2x Plough Gauge - 1x 4" Blanchard + 1x 6" other Brand

Constabulary replied to Constabulary's topic in Old/Sold

-

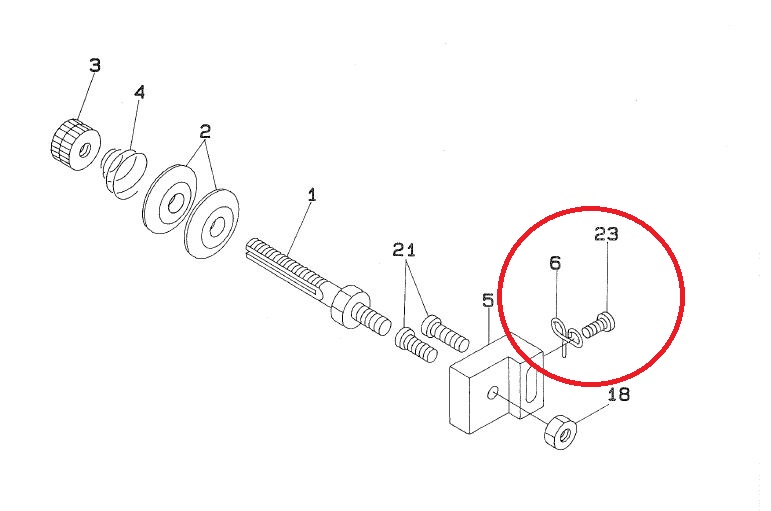

I´m selling these 2 vintage plough gauges. Both blades require sharpening. On either plough gauge 1 screw has a bad screw head but I´m sure you can cut a slot and solder or weld in a round or oval piece of sheet metal or even a small metal ball with hole... or the like - not a too big issue I think. maybe some of the leatehr tool dealer have spare screws... You know em - check with em. The Blanchard has measures in Inch & Centimeter and the other one only in Centimeter. See below pictures for details. 10cm / 4" Plough Gauge (Blanchard, Paris made): 200€ / $240 + 9.50€ / $12 for registered & insured worldwide Airmail shipping 15xm / 6" Plough Gauge (to me unknown maker stamp looks like a horse): 200€ / $240 + 9.50€ / $12 for registered & insured worldwide Airmail shipping If you want both I take care of the shipping costs. Shipping is trackable through USPS website Some pictures: 10cm / 4" Blanchard Plough Gauge:

-

2x Plough Gauge - both Blanchrd, Paris - Or Not?

Constabulary replied to Constabulary's topic in Leather Tools

They are for sale by the way - will list em in the market place section. -

I came acros 2 plough gauges - one obviously is Blanchard Paris but I´m not sure about the other one - It also has a horse (?) stamped on but no makers name. Or is the Blanchard stamp a dog? Some pictures

-

3 vintage ADLER & DURKOPP Straight Stich Sewing Machines

Constabulary replied to Constabulary's topic in Old/Sold

These are not typical leather sewing machines, rather upholstery or garment leather machines. If I were in your situation I´d rather choose a walking foot / triple feed sewing machine for 8oz veg tan DHL Shipping for 1 machine to the US is 125€ (Euro not US Dollar) Combined UPS shipping for 2 machines to the US is 200€ (Euro not US Dollar) UPS Shipping for 1 machine to EU countries is 29€ (Euro not US Dollar) Combined UPS shipping for 2 machines to EU countries is 55€ (Euro not US Dollar) Shipping is insured and trackable. Prices include proper packing materials like ~1.5" thick styrofoam plates and heavy carton boxes for safe shipping. -

I have a dismantling instruction for the 145. I once got with a bunch of Pfaff manuals, it written with typewriter and in English language. I can send you a PDF if you send me your email by PM. I also can send you an old 145 parts list so you have the right parts numbers mentioned in the instruction. Files are too big to attach.

-

Singer 45k1 Restoration Decals

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

Sewing machine finish often has to do with personal preferences - I have restored a few already and most of the time I have used Keeler decals. My preference is silver with black decals but your black crackle finish really is excellent!!! What sort of paint have you used? How about this one: http://www.keelersales.com/singer-model-31-basic-decals-for-restorations/ It is - in my opinion - a bit too bold but this set has the best value for money ratio - I have used it on My Singer 133K3 Or check Pinterest if you see something you like: https://www.pinterest.de/gmcculty/restoration-decals-for-singer-sewing-machines/ -

Cowboy 3200 issue with tension adjuster HELP

Constabulary replied to CarlosURSUS's topic in Leather Sewing Machines

Is there a loop at the thread tension? Thread has to go through the loop before is slides between the tension discs... Just a guess. You know what I mean? EDIT: Not sure if its the same on the 3200 as on the 441 clones: Or try to play with the tension on the pre tension Unit. -

Consew and Mitsubishi Twin-Needle machines

Constabulary replied to Ogoki's topic in Leather Sewing Machines

You are right - picture was not very clear! However - I´m not sure about the availability of the walking foot / triple feed gauge sets. I talked about needle feed gauge sets. But I´m sure some of the known sewing machine dealer like Toledos Sewing Machines or Keysew can help you with gauge sets - just check with them. -

Consew and Mitsubishi Twin-Needle machines

Constabulary replied to Ogoki's topic in Leather Sewing Machines

Most likely they are needle feed machines (not walking foot). A picture for the back side could tell. Or a picture form the left side - it you see 3 bars (needle bar and 2 presser foot bar) they are waling foot if you see 2 bars (needle bar and 1 presser foot bar) they are needle feed. Keep in mind that they have fixed distance needles. When you want to alter the needle distance you need a complete gauge set which contains needle holder, needle plate and feed dog. Fortunately both machines are based on the Singer 112 and 212 model so you can use Singer gauge sets. BUT there are 2 different styles of needle holder available - one screw in type and and one push in tye. After market gauge sets are avail. on Ebay for approx. $20 and up. You also have to reposition the 2 hook saddles when you want to change the needle distance. The closer I look... I´m sure they are needle feed machines. -

3 vintage ADLER & DURKOPP Straight Stich Sewing Machines

Constabulary replied to Constabulary's topic in Old/Sold

sorry seems atm I cannot find shipping options to AU for packages above 20Kg. -

dikman What machine should I go for

Constabulary replied to Ballu's topic in Leather Sewing Machines

Well - the optical condition and missing parts at the Brother makes me change my mind... Still not much information for making a decision but from the pictures I see I would most likely go with the 267 and add a servo motor (looks like it has a clutch motor) - $500 is a very good price for a 267. If the Brother is not complete its most likely not complete for a reason - I´d consider it as a restoration project - at least from what the picture tells. Wasn´t the 267 the last w/o a oil pump in the x67 series? Not sure... As Wiz said - test sew the machines when ever possible! Also - check the condition of the timing belts - when they are brittle, cracked, have missing teeth or seem to be very worn better do not buy the machine - replacing timing belts is not the funniest work you can do on a sewing machine. It can be a real pain ITA. -

When you have a high volume output a custom made binder can make sense. When you brake down the costs to the piece it no longer "looks" too expensive. But when you bind 10 bags it does not make much sense except your work is exceptional and you ask very high prices for your work. I´m using some cheap standard / off the shelf binder attachments which I have modified a bit and they work very well. But I`m not binding with leather straps, I´m using 1 - 1.5mm webbing tape. I´m using a Pfaff 345 with synchronized binder. I have attached a Pfaff 145 flat bed binder bracket and it works fine. See this thread: I posted this in another thread already, maybe this binder works for you but check with the seller because of the mouth width and tape thickness you can use: http://www.ebay.com/itm/CONSEW-225-226-Singer-111G-111W-211G-211U-211W-RAW-TAPE-BINDER-WIDE-MOUTH-CHOOSE-/391723527924?var=&hash=item5b348aaef4:m:mYIrxdPFJ4Ux6fcJPCE3_9Q

- 6 replies

-

- cylinder arm sewing machine

- binder

-

(and 1 more)

Tagged with:

-

dikman What machine should I go for

Constabulary replied to Ballu's topic in Leather Sewing Machines

If the Brother has a large capacity hook just as the Durkopp 267 I would choose the Brother. Why? Because it is a Singer 211 based model and parts and accessories (like different presser feet) are available almost everywhere and they fare fairly cheap. You can also use a lot of Singer 111 (predecessor of the 211) parts and accessories. If the machines are set up to factory standards the sewing capacity should be approx. the same compared with the 267. But if you don´t mind please post detailed pictures of either machines because machines can be set up with different "bells & whistles" and to compare them some more information than just the model name would be helpful. Condition, accessories and motor also matters. What are the prices the seller is asking for? -

TECH SEW 2750 PRO BINDING ATTACHMENT

Constabulary replied to Appaloosa's topic in Leather Sewing Machines

These "plain" binder attachments are most likely for thin fabric tape or bias tape. If you want to bind edges with lets say 1.5mm thick leather "tape" the above would probably fail doing the job. When I was hunting for binding attachments I figured almost no seller mentions the tape thickness you can use with a certain binder since most "expect" that you use bias tape as it is the most common. When you buy a biding attachment the thickness and width of the tape and the width of the mouth opening on the binder matters. This attachment looks quite promising but check with the seller if is works for your purpose (tape width / mouth width) http://www.ebay.com/itm/CONSEW-225-226-Singer-111G-111W-211G-211U-211W-RAW-TAPE-BINDER-WIDE-MOUTH-CHOOSE-/391723527924?var=&hash=item5b348aaef4:m:mYIrxdPFJ4Ux6fcJPCE3_9Q -

well, its a 100 years old patcher - almost no parts are available anymore - maybe some used parts but you never know if they are really better. Just very few parts from "modern" 29K71 fit for can be made to fit. It does not help much If you buy it from a seller who just knows that it can sew. The stitch length matters - worn patchers sometimes just produce 2.5mm stitches when set to the max stitch length which is 5mm in best case (when new of well restored). So be careful - better test the patcher before you buy it. Buy a pack of 29x3 / 29x4 needles (135x17 / 135x16 also fit) and download a manual and test it. If you buy it for decorative purposes or the historical background matters - why not. if you really want to use it I´d look for a patcher you still can get parts for. Old patchers are always a gamble!!! EDIT: I once restored a similar one - maybe this will give you an idea for restoration:

-

Which feet should I have for a Pfaff 335?

Constabulary replied to GeorgiaK's topic in Leather Sewing Machines

maybe some piping feet - keep in mind the size to order is the thickness of the piping + the thickness of the material the piping is covered with. -

Which feet should I have for a Pfaff 335?

Constabulary replied to GeorgiaK's topic in Leather Sewing Machines

At least a Right Toe Foot and Left Toe Foot and everything else depends on the work, I´d say. A good source in the EU for Pfaff presser feet is College Sewing in the UK. https://www.college-sewing.co.uk/pfaff-industrial-sewing-machine-spare-parts/ Pfaff 145, 345, 545, 1245, and similar also fit your machine. -

no way - it never can sew 24mm leather - check the needle system - if it could sew 24mm it should be at least 794 or longer like 1000 or 331 or similar. I would guess the advertiser just mistyped.

-

You bought that from a dealer and he is even delivering it? WOW - thats a hell of a deal! I´m sure he is not making much money here! Congratulations!!!

-

was on the wrong track with the timing belt - 206 has a drive shaft and not a timing belt but I´m sure you figured already

-

Machine looks very good. That's rather old dried and discolored oil than rust I´d say - try whipping it off with kerosene or the like. Download the manual and oil it accordingly. Open the faceplate and remove the needle plate and check for lint / dirt and gunk. Open the top plate and check the condition of the timing belt. Thats what I would start with.

-

not sure but seems the little tongue on your bobbin case it not in the gap of the needle plate - know what I mean?

-

Singer Needle Bar - I Could Use Some Help

Constabulary replied to Constabulary's topic in Leather Sewing Machines

I think Singer 45K or GA5 presser feet will work on it.