-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

New (to me) machine for skate tongues

Constabulary replied to Hockeymender's topic in Leather Sewing Machines

The more I look at it - the more I like it. Machine just has 2 issues: 1.) its not made by Singer 2.) too bad they did not make it with a short arm version of it Both are my personal issues -

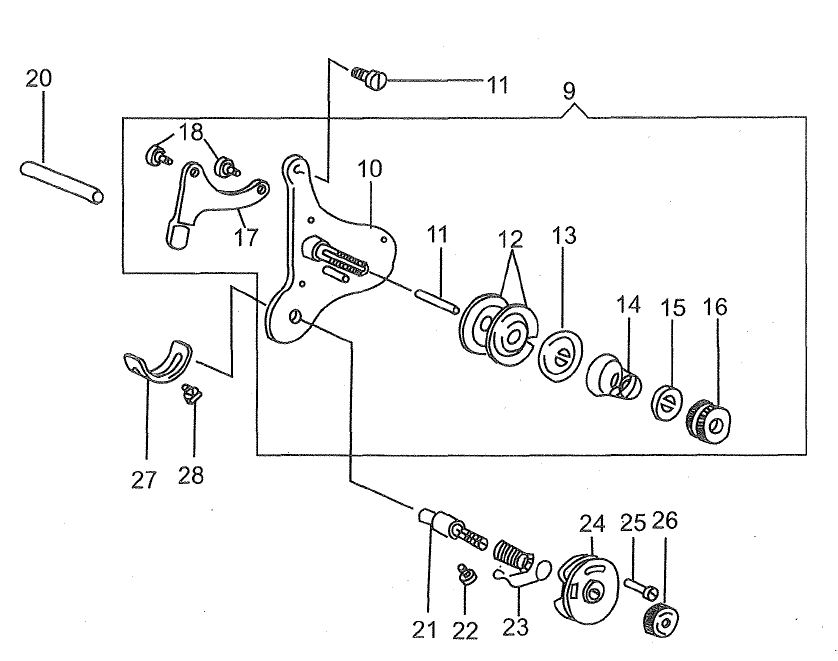

curved piece #27 is where the spring rests on. It is mounted with 1 screw (Singer manual picture screw "P") - loosen the screw and you can adjust the spring travel

-

The 25 screw is just for fixing the position of the disc #24 - I have the screw centered in the oval slot (so it is shown in the manual) - never had an issue with this position. Other tension units - f.i. Pfaff 145 and the like - do not have this screw. The disc at Pfaff tension units is held in position by just a pin so its not adjustable. So on Singer type tension units you "could" adjust the position of where the thread pops over the hook tip when threading the machine but being honest I never thought of changing this position or playing with it. If I had to change the travel of the regulating spring I´d do it on the curved piece #27 (on either Pfaff and Singer). But maybe there is an explanation for the slot in the disc 24 - yet I have not figured its purpose but that does no mean anything.

-

-

Why Does My Consew 226 Need so Much Upper Tension?

Constabulary replied to Pintodeluxe's topic in Leather Sewing Machines

#15 is a part that not all tension units have - sometimes #15 has a toothed surface and so is the thumb screw so you have a "ratchet" effect but I don´t have this on my Singer 111 so it´s not really a part that has a an effect on the tension. Its just for holding the thumb screw in place. - OR - You have the part #15 when your tension spring DOES NOT have a small tab across the narrow end of the spring - see picture below - I think you know what I mean.- 11 replies

-

- consew 226

- upper tension

-

(and 1 more)

Tagged with:

-

Sorry to say that but people could do more business when giving more information to the people at the 1st time. This "give me a call thing" is outdated. Sure some do like the old school business but times have changed. Nowadays customers have many options and they often choose the service where they get the most information just the moment they need them - especially when prices are quite comparable. Proper larger scale pictures should be natural today - and not just one.

-

Why Does My Consew 226 Need so Much Upper Tension?

Constabulary replied to Pintodeluxe's topic in Leather Sewing Machines

I´d try a heavier tension spring #14 in the tension unit. Or you probably have a minimal permanent top tension release. If so probably have to shorten the pin #11 a little bit (maybe 1/2mm) or adjust the center bar of the release disc #13 a tiny bit (tap the center small bar a tiny bit from the inside). Just a guess w/o sitting in front of your machine. See picture- 11 replies

-

- consew 226

- upper tension

-

(and 1 more)

Tagged with:

-

- 11 replies

-

- sewing machine

- 441

-

(and 1 more)

Tagged with:

-

if you don´t mind please send me a PM or I probably forget it...

-

Phili222 - I probably have the parts you are looking for but I would like to send you a PM with pictures and measures. I´m a cell phone hater and my fingers are not touch screen compatible. Not sure if you have the bobbin winder and drawer for your machine - I have them too and I guess they are the same as for your machine Seems you opted out sending you a PM so If you are interested please send ME a PM.

-

$600 a good deal on Pfaff 1245 with servo?

Constabulary replied to SheltathaLore's topic in Leather Sewing Machines

ha - okay - civic is a quite useless car for transporting something bigger than a beer crate - check out a Mazda 6 station wagon - you get 2 sewing machines in it You still could disassemble the stand - not a too big deal - then even the civic can haul 2 machines -

$600 a good deal on Pfaff 1245 with servo?

Constabulary replied to SheltathaLore's topic in Leather Sewing Machines

sounds good BUT seems the stitch length adjuster knob is NOT the original one!!! Not sure if it is working as it should - test the machinate before you buy it!!! I´d also test the built in bobbin winder. And check the condition of the timing belt (afaik the 1245 has a timing belt). You don´t need a truck for this machine. -

6mm ZZ is a good score already. There might be machines with wider ZZ (some Singer 20 models I guess) but most used industrial machines have 6mm ZZ or less.

-

Excellent machine - I once owned one. But there are differences some have 4.5mm or 5mm zig zag and only very few have 6mm zigzag. Mine only had 4.5mm (measured). I now have a Singer 307G2 and I do not regret. 307G2 also is an excellent machine but you barely find parts (feet, hooks, bobbins and smaller bits are available). Timing belts are no longer available - however I personally prefer the 307G2. Advantage of the 138 is that it has no timing belt but a problem with the 138 is that the Zig zag dial often is gummed up but with a heat gun and oil you can solve this. Other than that the 138 really is an excellent machine.

-

Leather needle/foot for normal sewing machine?

Constabulary replied to purplecinnamon's topic in Leather Sewing Machines

What means "normal sewing machine" - what machine do you have? Wall Mart plastic bomber, Industrial sewing machine...? Brand and model number would help very much... -

Singer 45k1 Restoration Decals

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

don´t know if it was meant for trimming leather - but could be (depends on thickness I think) since it is an SV machine. The cloth trimmer (originally for trimming soft shoulder pads) was 132K12 - this one is 132KSV11 - who knows... but I I have no use for a trimmer... -

Singer 45k1 Restoration Decals

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

NO WAY - ha ha - Jimi just bothers me a bit with this because I paint most of my restored machines silver and put on black decals. THIS one will stay as is and because the original paint job + decals are very nice I will try to turn it into a 132K6? Why? Because the parts for putting it back into its original configuration are no longer available and I have no use for a machine with a trimming device. BUT it has a lot similarities with the 132K6 and lost of K6 parts are still available.... sooo thats a future project.... This was my original post reg. this 132K. Your 45K looks very nice with this crackle coating But I think I would have painted the flat bed with glossy black Reg. 132K decals - yes shading looks gray. Most likely you would not see a black shading on a black machine. -

Consew 206RB-5, "kickstand" placement issue?

Constabulary replied to justpaul's topic in Leather Sewing Machines

okay could not really tell from the picture... -

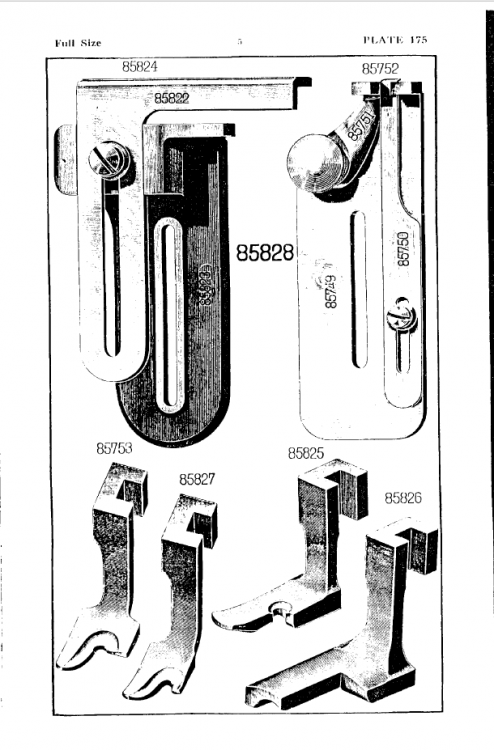

Can Singer 45k25 use for binding work

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

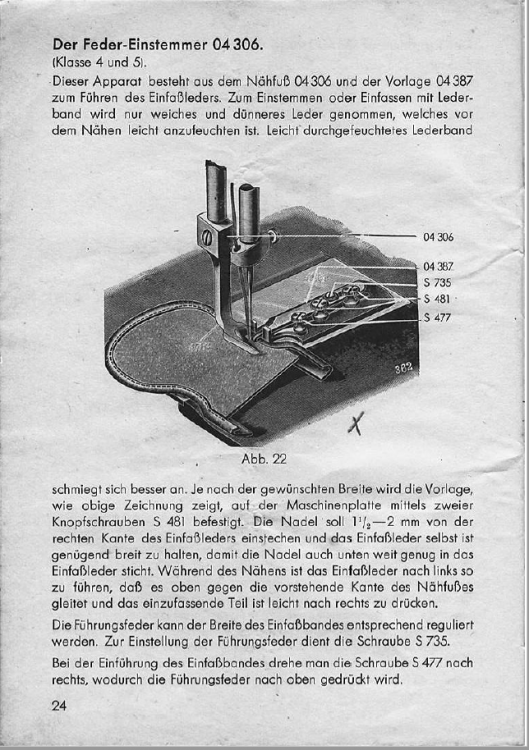

I have not tried it but there is some sort of special binding attachment for these machines. This is an extract from an Adler 5 manual which is pretty much the same machine as the 45K. It shows the attachment in use. So if the 45K25 comes with he attachment plate right of the needle plate you could use this attachment. Singer shows a similar attachment in their 45K25 parts list -

Consew 206RB-5, "kickstand" placement issue?

Constabulary replied to justpaul's topic in Leather Sewing Machines

or just shorten the peg a bit... -

Singer 45k1 Restoration Decals

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

These are the decal from my 132K - its actually a 1948 made machine. Its a bit different but maybe it helps -

Machine is located in Germany. I don´t think they will ship overseas.

-

Singer 45k1 Restoration Decals

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

I was not thinking.... I have a 132K on my shelf waiting for "modification" and it has a nice clear original decal - I will take pictures later and take some measures.... -

Singer 45k1 Restoration Decals

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

WOW - well done Tony the font looks awesome!!!