-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

the website no longer exists. Sorry!

-

Singer Needle Bar - I Could Use Some Help

Constabulary replied to Constabulary's topic in Leather Sewing Machines

In my has I only had to adjust the needle bar height but it is fiddly because the NB is governed by a V shaped cam but I got it back to live and it worked very well. But when your needle bar is technically okay you do not need a new one just for using 135x17 needles. My old NB worked with 135x17 w/o problems. I only replaced it cause it bent when I tipped over the machine. sure. I have used needle sizes up to NM 140 but again if you current NB is functional you don´t have to replace it just for using different needle sizes. A 34K11 is a much much heavier machine than the 34K2 or 34K5. it weights approx twice as much as a 34K5 and the 34K11 (system 328 or 214x1) is using a needle system that the 34K2 or 34K5 cannot handle. The 328 needle is much longer it does not work in the other 34K machines. How thick is your "thick leather" - in total, not single layers? -

New Servos on old machines?

Constabulary replied to Cumberland Highpower's topic in Leather Sewing Machines

Maybe the motor has a poor electronic brake. Honestly if someone puts a disclaimer like this in a description I would not buy it. They may not be available in the US but I love my two JACK 563 servos very much. Oldest works flawless since 2014 on a Singer 111w156 with speed reducer and the other on a Singer 45D91 with heavy flywheel and speed reducer. -

fredk - this is in your playground ;-)

Constabulary replied to Constabulary's topic in Leather Sewing Machines

yeah - now it´s gone - no surprise at that price - sorry! EDIT: aaaaah, well... You have to be logged in into facebook as it seems - I still can see it when I´m logged in. -

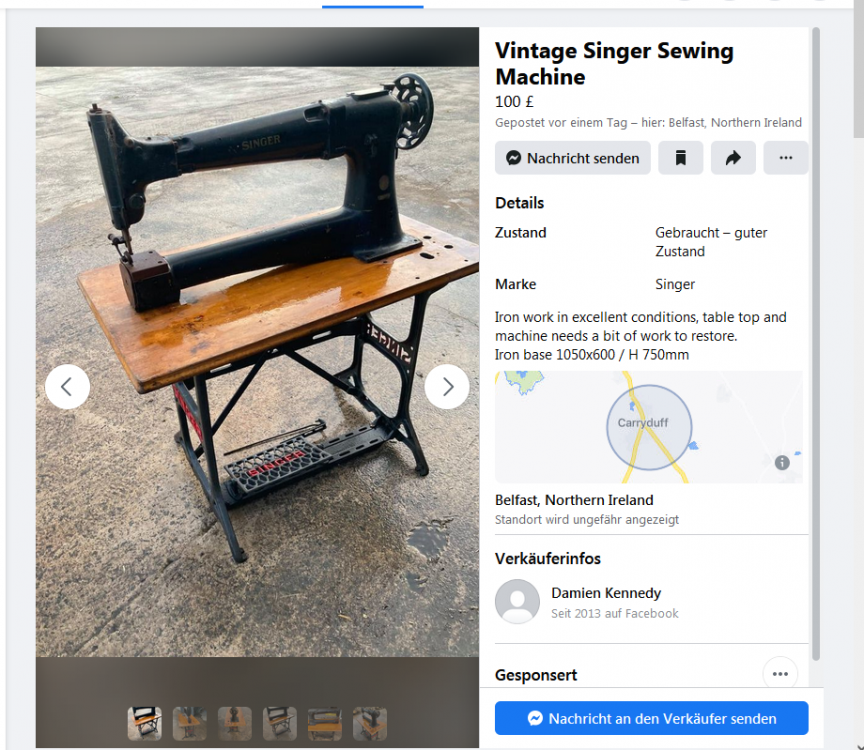

fredk - this is in your playground ;-)

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Or maybe not looks like it is still available. The roller foot alone sometimes goes for that money, not speaking of the very nice stand and well, the long arm machine. -

Bargain Singer 133K17 /as it seems) with loooooooooooonh arm and drop feed + roller foot in NI. https://www.facebook.com/marketplace/item/590592535716845/

-

Maybe this manual is better: https://www.manualslib.com/manual/1105531/Consew-227r-2.html Same machine - different brand. What Uwe said - if it has a servo motor then you usually can change the rotation direction w/o problem - hope you have a manual for the motor. If it has a clutch motor you most likely have to change some wiring to change the rotation direction.

-

ID this Singer / Seiko Double Needle Cylinder Machine

Constabulary replied to Constabulary's topic in Leather Sewing Machines

That is a single needle CW-8 clone - see my 1st post But the 387 has a Singer "211 upper" but the one I shown has a "111 upper". I´m aware of all the Consew and Seiko models but haven´t yet figured the name name of THIS PARTICULAR machine shown in the 1st post. I´m sure it is a Seiko built machine with Singer label (not unusual) but... which? Considering this model Singer 153-B8B (which is similar to the Seiko CW-8, Consew 227 and the like) then logically the above machine should be a 154-B8B. But zero information out there as it seems. https://for-sale.yowcow.com/listing/135450024/ EDIT: For the records the pic of the 153-B8B -

Odd stitch on the piping of an old LV Saumur bag

Constabulary replied to unionattic's topic in Leather Sewing Machines

it´s a 1 thread chain stitch as it seems -

I´m a bit stuck.... I have access to a Singer double needle cylinder arm machine with walking foot and reverse (converted to single needle as it seems) - but I cannot figure the model. Should be easy, right - cause its Singer... It`s not ... So to my knowledge it is a Seiko built machine (hand wheel + reverse lever + #tag helps to ID)- so the CW-8 (similar to Consew 227R) could be an option but the CW-8 did not come as a double needle as far as I figured. Maybe a 154w / 154K model - the 154w103 is a walking foot - but has no reverse and different stitch length adjuster. When putting the 111 / 111G subclass in relation it COULD be a 154w156 - but it did not exist AFAIK. I also cannot find anything among the 154B or 154U... Maybe someone else knows more - I can´t figure it. I´m not worried to run this machine cause it seems a hybrid between 154w103 and Seiko CW-8 (kind of) but I just wonder what "the name" of this machine is . Some pictures (only pics I have):

-

Stitches become shorter the thicker the material thats because of the pendulum effect. Maybe this thread is interesting fro you: https://leatherworker.net/forum/topic/87658-official-stitch-lenght-for-singer-29k-is/ I can sew close to 12mm with my 29K71

-

This is a Dürkopp 18 but its the same. Picture is from a machine I restored in 2017 (see link below picture). Thats the closes I haven - machine is sold. https://leatherworker.net/forum/topic/76826-dürkopp-18-patcher-restoration-long-journey/page/2/

-

INCOTERMS are international meaning they are used in all countries worldwide when it comes to freight shipping / forwarding and the like (usually not in the plain postal business) but when a seller chooses DDP you as a recipient / private customer will never take note of it.

-

CS does not pay me for mentioning them either - maybe I should ask them . Before BREXIT CS was my preferred supplier sadly they cannot (???) deliver to the EU atm. But to be honest so far I have all I need and rarely need anything new for my projects. I know armastore but actually haven´t yet bought from them. Ooouh - seems I have to dive through their 1€ presser foot range - hell thats cheap... tempting...

-

I had a fiscars rotary cutter - I did not like it blade always released / jumped back when I applied pressure even when locked. I´m now using a KAI rotary cutter - works much better https://www.ebay.de/itm/192411303843 bought mine from CS https://www.college-sewing.co.uk/n5045-45mm-kai-round-knife-wheel-cutter.html

-

DDP (Delivered Duty Paid) is an INCOTERM and basically means that everything is up to the seller - like door to door delivery with all risk at the seller and the costs of export is also up to the seller meaning they are paid at delivery.

-

TRYING to set up a small pneumatic clicker....

Constabulary replied to Constabulary's topic in Leather Machinery

Paperwork says 8KN at 5 Bar (72.5 PSI) but I´m sure the thing will not blow off at 6 Bar or so - but we will see. Still quite some work... I´m just cleaning it and replace the gasket. Thats quite a piston and its in really like new condition (and I still have a spare piston) -

Hope this one helps: Singer 236w Manual Operators Guide.PDF

-

Durkopp 231 or 237 information

Constabulary replied to youdesiremenow's topic in Leather Sewing Machines

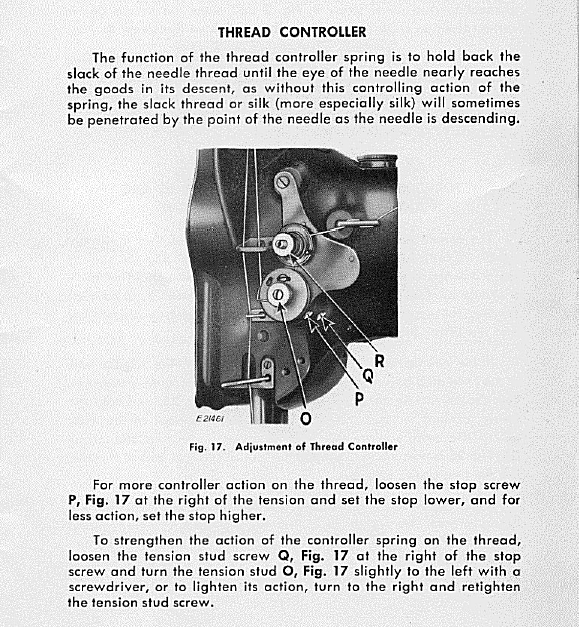

as I said I do not know the machine but I´m almost certain when you loosening the thumb nut on the pats picture you can shift the gears or the shaft with the gears. Can you post a full view bottom side picture please? BTW the thread regulator spring needs adjustment. The tension unit is the same as on the Singer 110w / 111w and other. -

A lot of new models of the Dürkopp Adler machinery is made in the Czech Republic by MINERVA and they still have a huge facility in Bielefeld. https://www.duerkopp-adler.com/en/index.html https://www.minerva-boskovice.com/ I do - I loved his #9 which is kind of a modern type of the classic BUSMC / Pearson #6HM. I think it is (or was) available from Weaver for a while.

-

that's a thread oiler / lubricator with a felt pad. 10759A ARM THREAD GUIDE D LOWER SEIKO JW28BL 10760 THREAD GUIDE FELT SEIKO LSW I have a double needle machine too and I´m using left twist in both hooks - no issues yet. I´m using #30 Gütermann TERA Polyester thread (not bonded) https://industry.guetermann.com/en/products/product-finder/tera-30-wa BTW - the guy in the Video hast the right angle thread guide on the tension unit installed incorrectly and therefore he is threading not the way it should be threaded. However - if it works it works. Regarding bonded or not - you have to ask your self if a bonding is REALLY required on your product - or not. I never use boded thread.

-

check ebay if you can´t find a US supplier: https://www.ebay.com/sch/i.html?_from=R40&_nkw=seiko+tf

-

I have used a needle bar of a 111w needle feed machine (see my post from Aug 27). The 111 series had 2 different needle bars. One for triple feed machines (small diameter) one for needle feed machines (larger diameter). Reg. the 51w - the early one (the one you and I have) needs the large diameter NB and the later 51w (the one eddo has) needs the small diameter NB. Let me check if I can figure a bushing you could use. EDIT: Singer 111w foot bar bushing should fit the NB but I´m not sure if it is long enough so check with the dealer for measures. https://www.ebay.com/itm/302295485545 EDIT II: measure your NB again - mine is ~ 8.74mm

-

Durkopp 231 or 237 information

Constabulary replied to youdesiremenow's topic in Leather Sewing Machines

please post pictures of your machine from front back and underside. The 231-02 seems to be roller foot + wheel feed according to a list I have. I do not know the machine but I assume something similar to the Singer 110w which has 3 preset stitch length and you can change the stitch length by "shifting gears" - but I only can guess. -

Another "making something out of (almost) nothing" project. I bought this pneumatic press for a bargain on Ebay a few years (!!!) ago already and always wanted to set it up for clicking out this and that. But as so often other things crossed may way and it started collecting a lot of dust. Back then It was just the press w/o any accessories except a spare piston (massive thing) and some paperwork. Meanwhile I got a quite cool machine stand (donated by a friend whos Adler 69 I set up for him) and panted it olive drab and I cut down the better end of a f*cked up sewing machine table plate, sanded and clear coated it and reinforced it with some steel profiles. Also had to add a 3/4" slat on the rear side. Plate turned out quite nice I think. I don´t know how this will end or if with will work sufficiently at all but it´s a nice project I think. I'm curious myself Some pictures...