-

Posts

5,809 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

I have used a needle bar of a 111w needle feed machine (see my post from Aug 27). The 111 series had 2 different needle bars. One for triple feed machines (small diameter) one for needle feed machines (larger diameter). Reg. the 51w - the early one (the one you and I have) needs the large diameter NB and the later 51w (the one eddo has) needs the small diameter NB. Let me check if I can figure a bushing you could use. EDIT: Singer 111w foot bar bushing should fit the NB but I´m not sure if it is long enough so check with the dealer for measures. https://www.ebay.com/itm/302295485545 EDIT II: measure your NB again - mine is ~ 8.74mm

-

Durkopp 231 or 237 information

Constabulary replied to youdesiremenow's topic in Leather Sewing Machines

please post pictures of your machine from front back and underside. The 231-02 seems to be roller foot + wheel feed according to a list I have. I do not know the machine but I assume something similar to the Singer 110w which has 3 preset stitch length and you can change the stitch length by "shifting gears" - but I only can guess. -

Another "making something out of (almost) nothing" project. I bought this pneumatic press for a bargain on Ebay a few years (!!!) ago already and always wanted to set it up for clicking out this and that. But as so often other things crossed may way and it started collecting a lot of dust. Back then It was just the press w/o any accessories except a spare piston (massive thing) and some paperwork. Meanwhile I got a quite cool machine stand (donated by a friend whos Adler 69 I set up for him) and panted it olive drab and I cut down the better end of a f*cked up sewing machine table plate, sanded and clear coated it and reinforced it with some steel profiles. Also had to add a 3/4" slat on the rear side. Plate turned out quite nice I think. I don´t know how this will end or if with will work sufficiently at all but it´s a nice project I think. I'm curious myself Some pictures...

-

What makes a good or bad hot foil machine?

Constabulary replied to TestTube's topic in Leather Machinery

We do not know what models you talk about please pots some pictures or links.... some may have an automatic foil feed and it also depends on how big the heating element is / what size or kind of stamp it can hold.... -

Pedersen 309 operator Manual needed

Constabulary replied to DeanM's topic in Leather Sewing Machines

The Rapid E 317 manual I linked to in the 2nd post does not help? -

2nd what Wiz said. A missing or worn off gib on the stitch length adjuster could be a problem too or a wrong adjusted thread take up lever regulator... I have attached a manual and parts list please compare and check for the gib # 82230 also check al adjustments mentioned in the manual. If all that does not help please post pictures and a Video. 29k71-71-73 Service Manual and Parts List.pdf

-

The problem is you barely (if at all) find new made in USA or made in UK sewing machinery anymore. And the considerably low prices for CHICOM machinery allows many people to run a new industrial sewing machine (f.i. when new to hobby or open a small business) which they could not afford when new made in the the USA, Canada, UK or Germany. Thats the same with wood working machinery, 3D printers, and so forth. The medal always has 2 sides. I for my self do not like CHICOM sewing machinery and don´t even want to pay the "low" prices (putting machine prices and output in relation) so my way is restoring vintage Singer machinery - and that is very rewarding. And I relay like to figure out when parts of different brands are interchangeable to keep the old cast iron running. Like Singer, Dürkopp, and some CLAES have several parts in common on certain machines - not mentioned the whole lot of Singer based Japanese brands - even Pfaff and Adler using a few Singer standard parts - f.i. of the flat bed straight stitchers like the 31K /96K class... long story). My oldest Singer was from 1905 and that thing was great. Not sure when my 51w was made (maybe approx same age) but that is unbelievable fine machinery for that age. Maybe new machinery is more comfortable but in the end you often do not see on what machine a piece is sewn. Though I'm in "Pfaff and Adler land" I prefer Singer because of the parts situation and technical documentation. But yes - I bought some great quality CHICOM parts for my Singers too cause OEM accessories are hard to find so CHICOM parts are the only or the most economic way sometimes. As I said before the medal always has 2 sides. To answer the question I would buy the JUKI too cause - IF the machines are comparable. But you have not mentioned any model numbers. Just the brand names do not tell us a lot. Like do I better buy a Ford or a Dodge... Know what I mean? Give us more details...

-

The 332 needle seems to be too long. Ex factory the Singer 17 (left arm version of the Class 18) is using Singer 16 needles (other nomenclatures for this needle are 287 or 1738) but you can also try 134R / 135x5 / DPx5 needles. They have the same lengths as the class 16 needles but have a larger shank diameter and are more common / easier to find. Since the 332 fits your needle holder the 134R should be no problem.

-

Singer 29u171 needle and foot synchronisation

Constabulary replied to eddo's topic in Leather Sewing Machines

I assume you have the manual for this machine and have followed the timing instructions, right? If yes and it did not help then most likely you have installed the cam / pulley it in the wrong position. I´d remove it, rotate it by 180° and reinstall it. But I cannot judge what you did so I only can guess.- 13 replies

-

- singer 29k 171

- singer 29 rebuild

-

(and 2 more)

Tagged with:

-

Most likely 332 is the wrong needle system. Or adjust the needle bar if you want to use 332 needles. See attached manual for Seiko TE / TF 6 - hope it helps. Seiko TE TF-6, -6B Instruction Manual.pdf

-

Thread and Wind bobin on a Pearson & Bennion A1 Thank you.

Constabulary replied to JohnShep's topic in How Do I Do That?

it´s not as big as you think or as it looks in the picture A Singer 111w is heavier - weight wise. But it is a phenomenal cool machine with driven top feed + bottom feed. I owned one a while ago. I unfortunately cannot keep em all. -

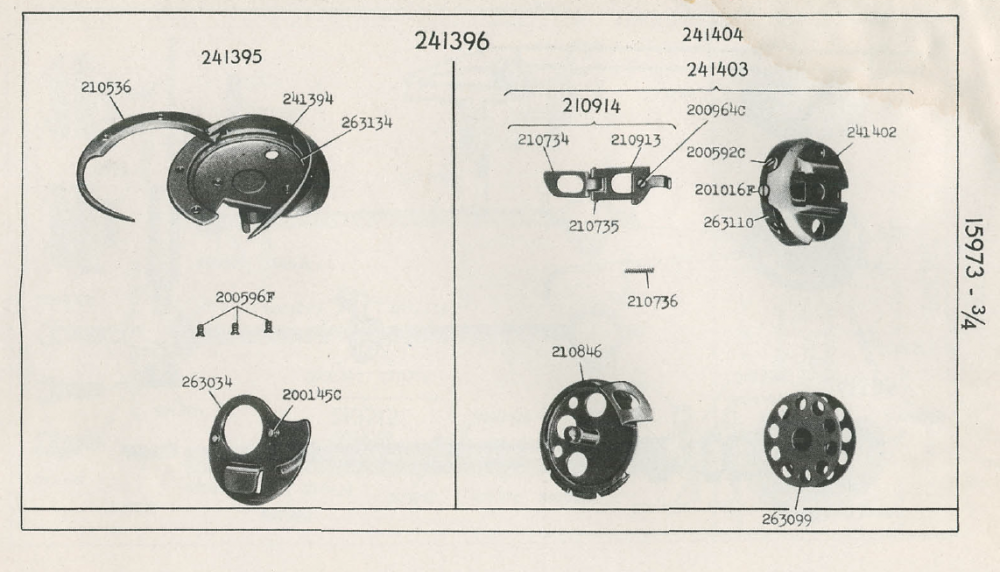

Yeah, in your case you cannot lower the NB any further.Your hook tip definitely looks badly worn / ground down so the hook tip no longer catch the loop in the correct position. I honestly think you have to replace it. The original hook tip is longer and steeper and has a sharp pointed tip. This is a 143w hook (see below) If it was my machine I definitely would look for a reasonable priced HIROSE HSH-51-1 hook. EDIT: I just measured the distance hook tip to hook body. But my hook is old and maybe the tip is a bit worn already and maybe there were tolerances between the parts lots made at different times or by different manufacturers. But maybe it helps to judge your hook. This is a OEM Singer hook 241394 as shown in the picture I posted.

-

I cannot see the hook tip of your hook. But maybe the timing is just 1 timing belt tooth off (don´t know). You know what I mean? Or maybe the hook tip is too far away from the needle? What needle system are you using? Maybe its just the needle bar that is set too high (happens with the time that the NB rises a little bit) Holy Smokes! Don´t know where that offer came from but $290 IMO is a rip off. Even for a rare part and even when it is OEM Singer. Here are two hooks from the UK - maybe worth checking with them: https://www.dowlings-sew.co.uk/proddetail.php?prod=Hirose_HSH-51-1 https://www.college-sewing.co.uk/hsh511-hook-and-base-hirose or look for HIROSE HSH-51-1 hook.

-

I have a 108w20 - basically the cylinder arm version of the 151w. The feet of the 111w and 108w fit w/o problem but depends on what foot you need for your needle plate. There are many different feet for the 111w series. Do you need a complete hook or just hook parts? Bobbin case and other hook parts except the hook body (263141) seem to be the same as for the 107w / 143w (I have both). The hook is basically the same as for the 107w / 143w I think but it has a different mount. The 143w hook has 2 prongs and yours (I guess) has a hole where the shaft goes in and it is pinned, right? This is from a 143w parts list - please compare with the 151w parts list. Hope this helps a little bit.

-

Convert seiko / consew binding machine to standard

Constabulary replied to Dashed's topic in Leather Sewing Machines

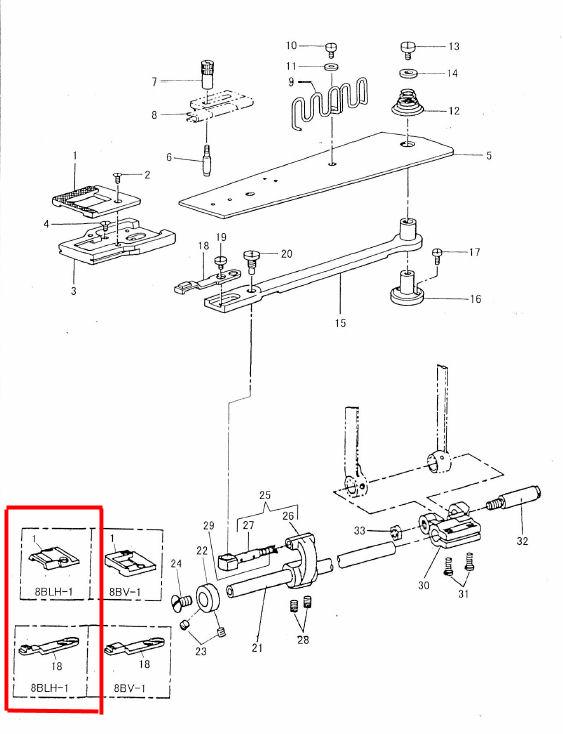

I just checked the parts list. My bad - you are right! Different feed systems. But seems there is a needle plate and feed dog for the 8BLH-1 for "plain sewing" -

wiping with denatured alcohol / ethanol a few times?

- 10 replies

-

- ruined leather

- oily

-

(and 2 more)

Tagged with:

-

Convert seiko / consew binding machine to standard

Constabulary replied to Dashed's topic in Leather Sewing Machines

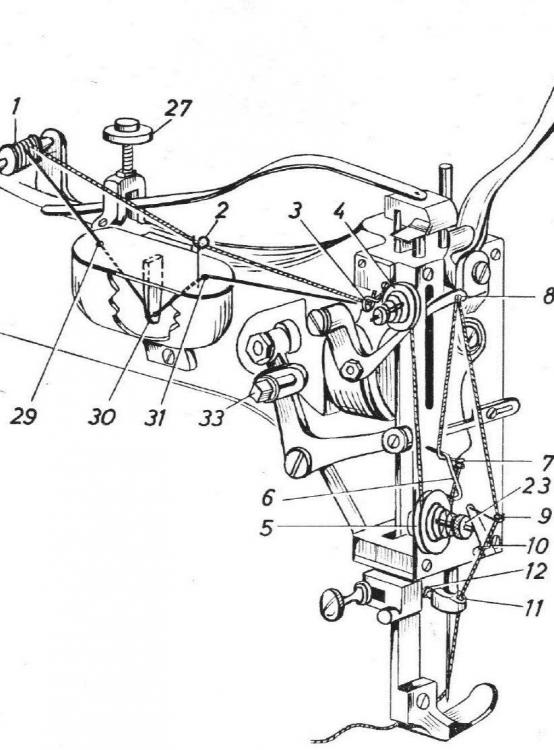

Haven`t done the converting on a Seiko LSC but on an Adler 69 and Pfaff 335 for a friend. Adler 69 and Pfaff 335 are the same class machines and kinda similar reg. the mechanism in the arm. Basically you need a feed dog, throat plate and the arm cover plate of a LSC-8b-1 (or -2) and the screws. Maybe the LSC has some special parts that I cannot see but these are the basic parts for a conversion. I recall on the Adler 69 I also have replaced the frame or bracket the throat plate is mounted to. Later it should look like this (picture comes from https://brutalforcegear.blogspot.com/) Should not be a too big issue but finding the parts may be a little challenge. BTW - you can download the parts list from the SEIKO website. It should show all the parts you need. http://www.seiko-sewing.co.jp/en/partslist -

This is the thread I had in mind (BCL touching casting) - not sure if this happens in your machine https://leatherworker.net/forum/topic/74521-singer-111w155-presser-foot-adjustment/ Open the face plate and check what is going on mechanically. You can also limit the foot lift this this guide thingy here that slides up and down in the "fork" thingy - see picture. Maybe you have to lower it. Maybe the above helps already but we cannot judge your machine from the distance or w/o seeing pictures or a video.

-

Leathershop Fundraiser, asking for help

Constabulary replied to Campleathergoods's topic in Leatherwork Conversation

@LatigoAmigo Like it or not - but thats what Kickstarter is for - raising funds for starting a business / implementing a project. https://www.kickstarter.com- 28 replies

-

- leathercraft

- diy

-

(and 3 more)

Tagged with:

-

You seem to have the early version of the 51w - a Singer 211 needle feed bar or 111w151 needle feed needle bar (or similar) would have been easier I´d say. That way you can use the OEM lower bushing and only have to add a bushing on the top. Keep in mind the needle bar has to fit the needle bar clamp. Your clamp seems to have a larger diameter than the 111 triple feed needle bar you have used. But not sure though, hard to tell from the picture.

-