-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Often the main problem is a seized needle bar. I would loosen the the 2 clamping screws on the NB clamp and apply heat (maybe with gas blowtorch) on the bushings and oil them and try to free the NB with a piece of wood and gentle hammer strikes. Heat and oil will most likely loosen the top shaft too if it is seized. this was my ".45" project - pretty much the same machine :

-

First industrial sewing machine

Constabulary replied to Kawakneurder's topic in Leather Sewing Machines

I´d go with #3. Though I like the Durkopps very much cause they share a lot of parts with Singer 111 machines so presser feet sets are available fairly cheap. -

Consew 255B Oiling Wick Routing

Constabulary replied to leonardzelig's topic in Leather Sewing Machines

Maybe the parts list of the Consew 255 or similar machines like Singer 211 / 212 give you an idea. If not helpful just oil the machine manually. I have a Singer 212 and so do I. -

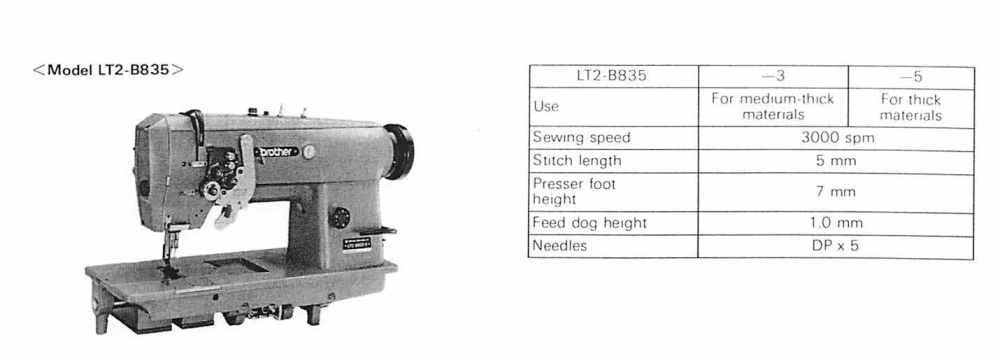

Brother LT2-B836-5 Double Needle Machine

Constabulary replied to Jholden0's topic in Leather Sewing Machines

manual can be found here. https://manualzz.com/download/29222852 Parts list: https://www.manualslib.com/manual/483282/Brother-Lt2-B835.html looks like a machine with switchable needle bars. I do not know if it is possible to adjust the needle bar space. Other than that I´m sure the machine is using the the standard gauge sets as used for Singer 212 needle feed machines as well as for their Seiko, JUKI, Consew... equivalents. EDIT: looks like there are special gauge sets for this machine available. Apperas needle holder are different: https://www.ebay.com/itm/1SET-AUTO-THREAD-TRIMMER-GAUGE-SET-FIT-FOR-BROTHER-LT2-B835-LT2-B845-/163232435756 -

Please post pictures of your machine. There were 2 Types of 51w machines and early and and a later model. Maybe this helps a little bit:

-

29k15 shuttle gear remanufacturing

Constabulary replied to 29k15engine's topic in Leather Sewing Machines

The World was waiting for someone like you -

175 yrs of sewing machines and they are still inventing new needles... I had to look up MR needles. See attachment. It may solve some issues but a properly set up machine and the right needle size is still mandatory. The_special_application_needle_MR.pdf

-

Sewing with the thread sock on?

Constabulary replied to JHLeatherwood's topic in Leather Sewing Machines

it may depend on the thread sock and how tight it is on the cone but I leave it on (the fine white ones) - no issues and no need for adjusting tension so far. -

Posting pictures will help to figure your problem. Needle clamp screw should be parts number 201030 and should be available from a sewing machine dealers. But better check the parts list of your machine. Check the needle hook timing when the hook is not catching the thread. Most likely needle bar is a tiny bit too high.

-

When sewing patches on existing shoes then yes, the patcher will be the only machine. I though you probably want to produce the shoes from scratch.

-

45k & 132K6 Guide Plate screw size

Constabulary replied to LomaeArts's topic in Leather Sewing Machines

Forgot - this is the screw for attaching the plates: https://www.college-sewing.co.uk/1381-needle-plate-screw-singer-132k.html -

Post bed vs cylinder arm sewing machine.

Constabulary replied to Devid82's topic in Leather Sewing Machines

agree - visit a dealer and test different machines. Sewing through that plastic material may be quite challenging for certain machines. That may require a needle feed or triple feed machine. Maybe you end up with two more machines - a post bed + cylinder arm machine. -

45k & 132K6 Guide Plate screw size

Constabulary replied to LomaeArts's topic in Leather Sewing Machines

They are pretty much all the same. Singer, Seiko, Juki... were using this type of screws on basically all industrial sewing machines. They differ in length sometimes. I even use them for attaching presser feet to the needle bar on my 45D91 https://www.college-sewing.co.uk/50190-long-thumb-screw.html -

I`m not a shoe guy. Do you sew on the patches during the manufacturing process or later when the shoe is finished (f.i. as a customers option)? If during the manufacturing process then a flat bed machine or post bed machine would probably be the better choice. Patchers are not the ideal machines for the manufacturing process. They are meant as repair machines. Of course patchers can do a thousand jobs that other machines can´t do but usually they are not involved in a manufacturing process of shoes. Check out some videos where people ares sewing shoe uppers. That may give you can idea what kind of sewing machines they are using.

-

needle systems Needle size causing a problem?

Constabulary replied to Marykins's topic in Leather Sewing Machines

when the machine is set up for 135x17 / 16 then shorter needles will not work - never ever - only when you lower the needle bar but better buy the right needle system. -

29k15 shuttle gear remanufacturing

Constabulary replied to 29k15engine's topic in Leather Sewing Machines

agree! Really Impressive and it really looks cool. Any chance that you have a pattern for this jacket? -

Its a tapered pin it only goes out one - you have to figure which way. If it was me I would leave it where it is. I would neither remove the top shaft nor the cams on the top shaft. Just wash out the gunk with brushes and kerosene or paint thinner or similar.

-

Free Wheeling Servo Motors For Sewing Machines

Constabulary replied to stelmackr's topic in Leather Sewing Machines

Not possible afaik. Let me guess the speed reducer makes it harder to turn the hand wheel by hand. If so I think the reduction is too big. I have the same issue on my Singer 45D91. The big reduction makes it hard to turn the hand wheel. I don´t have the problem on other machines with smaller reduction. -

What does Abbey say? Would not surprise when certain things go down and prices go up because of BREXIT. Maybe raw materials became harder to get for them. I checked with College Sewing and they do not deliver to EU countries since Brexit took place. Quite a loss for them I guess.

-

You answered most of your thought by your self. Adler 30-7 is not Chinese made and in your price range - even better it is local. Adler parts are expensive but bobbins and shuttle hooks are the same as for the large hook Singer 29K (like 29K72) so they are available fairly cheap. Most important - test the maximum stitch length, ex factory it should be approx 5mm but used machines often have a shorter stitch length because of wear but thats not unusual. Download a user manual and test the machine I´d say.

-

Adler 98 zig zag machine

-

Please post pictures of your threaded machine so maybe we can see if something is wrong. There are 2 types of 52w. THis manual is for the earlier type. Maybe it helps Singer 51w100 and 52w100 - instructions for using and adjusting.pdf

-

https://www.marktplaats.nl/a/antiek-en-kunst/antiek-naaimachines/m1703886539-leer-naaimachine-gebruikt-voor-patchwork.html?previousPage=lr Pretty much like a Pfaff 23 - same class as Singer 17, Adler 48 oder Seiko TF-6. I´m not sure but it could have a CB hook. The needle plate is definitely Pfaff type (as used on Pfaff 25 or 28). By far not as heavy ad a Singer 45k - pretty much 2 classes lower than the 45K Pfaff 23: https://www.google.com/search?q=pfaff+23&client=firefox-b-d&tbm=isch&source=iu&ictx=1&fir=2YTZG27KdMIblM%2CEtY9M0A0uYrXWM%2C_&vet=1&usg=AI4_-kTxARoNIs5P8-lreC_DuDBYGuljQw&sa=X&ved=2ahUKEwjh28WImKPxAhXJgP0HHRObCUoQ9QF6BAgIEAE&biw=1280&bih=852#imgrc=2YTZG27KdMIblM

-

Electrolysis is the way I would go.

-

Looking for attaching swing up guide

Constabulary replied to chrisash's topic in Leather Sewing Machines

Both topics have been covered several times. Maybe a google forum search will get you some pictures or more information. Really, we talked about it several times already.