-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Class 29-18 patch sewing machine

Constabulary replied to Nalyappa's topic in Leather Sewing Machines

I think he means the new made Cobra 29-18 not Singer 29k-18 -

Still having same problem please help

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

I keep my bottom tension mainly fairly low and usually I only adjust top tension when needed and when I need a tighter stitch I add more bottom tension and then more top tension. But I almost never touch the bottom tension. Are you using a knee lifter or foot lifter pedal and you - for what ever reason - rest your foot on the pedal or touch the knee lifter with your knee while sewing? That could cause the top tension release and thread knots appear on the bottom side. But I rather guess the needle size is too small. Maybe you got your needle thread combination form a chart you found online. The needle / thread charts you find here and there on the www may differ a bit and they are rules of thumb or are based on experience but they can differ. There is no rule that suits for all sewing situations the charts are usually recommendations and not hewn in stone. -

ha ha - haven´t heard or read the term Chicom for a long time and I never draw a line to sewing machines. Like it, will keep it in mind!

-

Class 29-18 patch sewing machine

Constabulary replied to Nalyappa's topic in Leather Sewing Machines

like these - or look for Videos "sewing patches onto xxx" or similar: Min 2:25 onward -

SInger 29k13 singer part 81899 its a long shot

Constabulary replied to AnthonyClare's topic in Leather Sewing Machines

I may have something for you - I´ll send you a PM later today -

you have that knock in all stitch lengths?

-

check AMAN Serafil threads (Polyester) - or even better check the AMAN website - tons of information there other than on far east Cheap Charley thread of unknown source and specs. https://www.amann.com/products/

-

It´s not because it is a different different machine. Any machine can have problems like yours. Maybe check the set screws on your hook drive gears and the screws the hook saddle is attached with. Even better check all the set screws. It´s hard to make a diagnose when not sitting in front of your machine or seeing pictures or maybe a video. Don made a good point - the needle hook distance is often overseen. Generally - If you can´t solve your problems better check with a sewing machine dealer - maybe a different than before.

-

agree - same with sewing machines - domestic sewing machines are still sewing machine even when they do not suit our own requirements.

-

Seiko stw 8 / consew 225 what to adjust?

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

What are you sewing now - 2 layers of fabric? I´d say in this case the thread is too thick for the material and looks like the needle size is too small too (combination of both I´d say.) Thread size has to suit the material thickness, the thinner the material the thinner the thread cause the thread has to build the knot between the layers. But again I think your needle is too small for the thread cause the hole the needle punches is too small to pull in the thread knot. Thats why the thread knot appears on the bottom side. -

Lots of opinions here on servo motors. Questions like this pop up almost weekly. Maybe a google forum search helps you: https://www.google.com/search?client=firefox-b-d&q=servo+motor+site%3Aleatherworker.net%2Fforum

-

Kobe 1341 not bringing up knots.

Constabulary replied to pattysoup's topic in Leather Sewing Machines

Agree with KGG - try larger needles sizes! -

Check the thread path make sure needle is insert correctly and is threaded from left to right. Make sure you pulled the thread over the little hook in the tension unit disc. Make sure check spring is properly adjusted. I hope you have a manual for your machine. If not there is a mechanics handbook for the 211 - download it, print it can´t be wrong to have it near your machine: https://www.manualslib.de/download/89333/Singer-211G-165.html

-

Seiko stw 8 / consew 225 what to adjust?

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

removing the bobbin case: -

in the end the decision is yours - we just shared our thoughts.

-

Singer class 7-33 leather sewing, which needle ???

Constabulary replied to Jadu's topic in Leather Sewing Machines

that's most likely why the former owner has used a longer needle You can either try to lower the presser foot or use a longer needle to prevent this.- 12 replies

-

- singer class7

- 7-33

-

(and 1 more)

Tagged with:

-

Seiko stw 8 / consew 225 what to adjust?

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

I don´t know your tension spring but maybe a heavier type beehive spring could help too. Juki parts is # B3114-232-000. You should get them from most industrial sewing machine dealers. They usually cost 2 bucks or so. Maybe worth trying. Or try a larger needle size . Stitches on most needle feed / triple feed machines become shorter the thicker the material. That's the pendulum effect of the needle bar. Add another layer and stitches will be even shorter. -

Consew 118 needle bar height and timing

Constabulary replied to Pianoguy's topic in Leather Sewing Machines

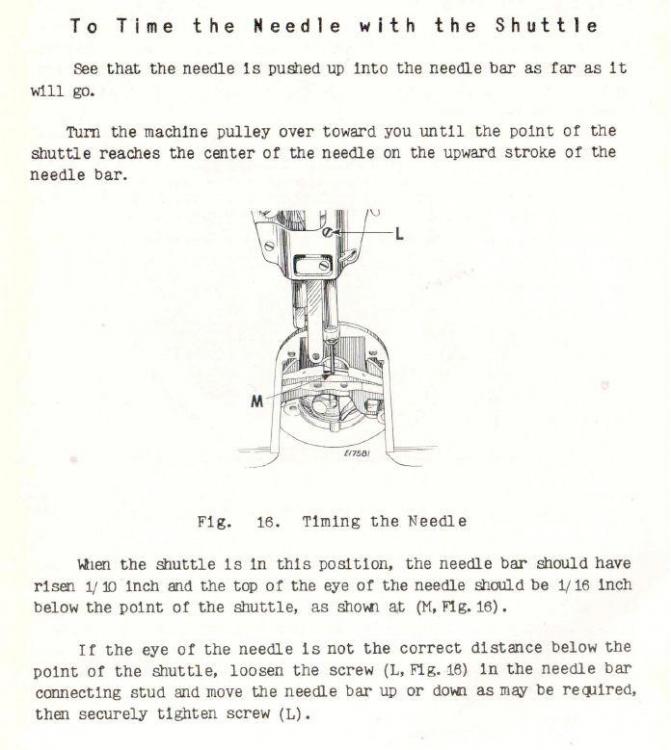

Needle hook timing should be the same as for the Singer 16 Class machines cause it has a CB hook and is using sys. 16 needles as well. Try this: -

Who said that - the Chinese seller? Thats quite unlikely but could be possible if they ship to a EU based distribution warehouse run by the Chinese (or whom ever) and they do the import custom work and pay the duties (which is prepaid in one or another way by the seller) and from there they ship to your address but I honestly would not expect that! In worst case If you (as an importer) do not have a receipt showing that you or someone else paid the import duties + VAT for this shipment then it could be Zollhinterziehung / Steuerbetrug (not kidding). And saying "but the sellers said so" does not prevent you. Make sure you have your self informed in terms of "Wertgrenzen". AFAIK you have to make an electronic import declaration for goods above 1000€. So be careful!

-

Again - it was just a brain fart. The idea was that the above linked soft start module possibly could add some sort of acceleration ramp to a servo motor without speed reducer. I´m not meaning the lowest rpm a servo starts with I mean a slightly smoother start / rpm acceleration when you hit the pedal. I personally don´t have the need cause I´m using speed reducers. It was just an idea because I´m in process of adding this module to my table saw and thought it possibly could add some comfort to one or another servo motor. Again - just a wild idea and I though someone else here probably had a similar brain fart or maybe has some experience with this module in general - you never know. EDIT: My idea was just a softer start of certain (not all) servo motors and not preventing from tripping fuses and so on... Just a softer start, no RPM reduction... So boobies can explain it better than I (different module - but same effect I was thinking to achieve) https://www.youtube.com/watch?v=oSrz3GaaDO8 This was the table saw soft start module (or similar) I was thinking of: https://www.youtube.com/watch?v=iWr0B2U-QT8 Note the difference when the motor starts.

-

Brass Line 24 Snaps. A losing venture?

Constabulary replied to JerseyFirefighter's topic in Hardware and Accessories

I´m using CS Osborne brass snaps until I find a proper supplier for DOT black brass snaps on my end. DOT so far and in IMO worked best. -

Depends on what parts you need. Some may work others wont. But don´t expect to find too many parts. The parts I found was just trial and error - I just bought them to find out if they work or not. I also swapped out the needle bar and foot bar so my machine now can use common needles like 135x17 and the common Singer type feet (check my above linked thread for that). I also installed a "foreign" brand hook so I can use the bobbins of my 111G156 machine. But I have a single needle machine and yours is a double needle machine - thats a different story (at least partially).

-

Need help on value of a Pearson No 6 bobbin winder

Constabulary replied to mogwild's topic in Leather Sewing Machines

depends on what gunk you have there, I´d scrape it off and I´m usually using paint thinner for cleaning off the reaming gunk. -

In case you will order it - keep in mind you have to pay import taxes and then 19% Einfuhrumsatzsteuer on top. If the machine goes with DHL standard you probably have to make a trip to your local customs office (which is maybe close to you or maybe 100km away - check that on Zoll.de or call them) to provide your payment details. If they ship with DHL Express or UPS you most likely have to pay your duties on delivery at your door. DHL Express and UPS (or other forwarding companies) may charge some fees as well for handling your package (meaning doing the customs work).