-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Stitch Length Regulator on Consew 226r-1

Constabulary replied to BelleH's topic in Leather Sewing Machines

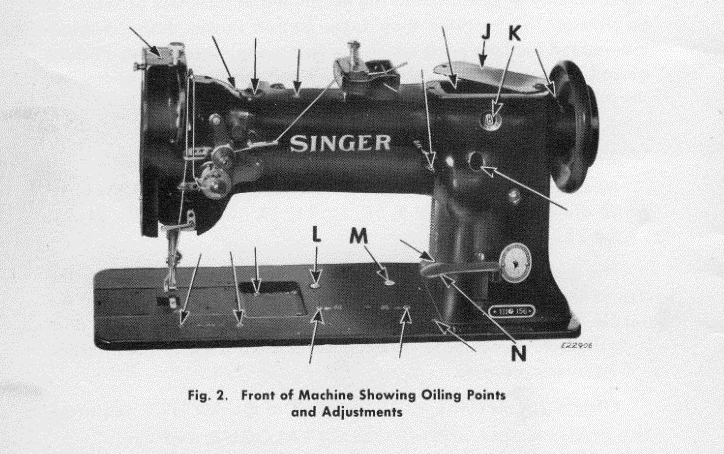

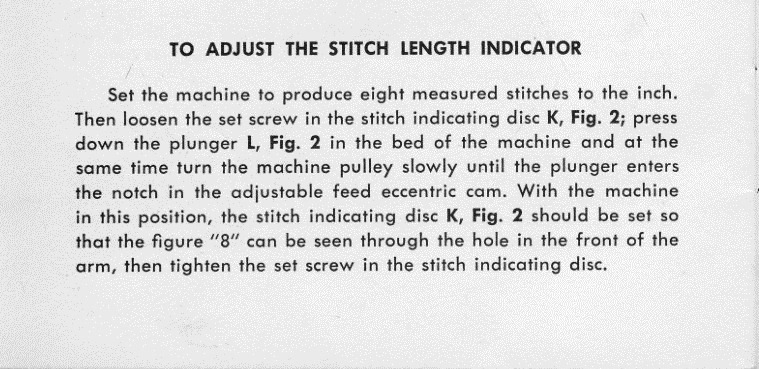

The stitch length dial is held on the top shaft by a set screws. Dial in the longest stitch length (5SPI) open the top cover then loosen this set screw and rotate the dial until you see the "5" in the window then tighten the screw again. This does not change any settings on the machine or so it is just the position of the dial you alter to match the dial with the stitch length. But as you can imagine the dial is not necessarily 100% precise cause the window gives quite some room for displaying the number on the stitch length dial. Just play with it a little bit with the dial position. I think Singer says in the 111 manual you should do this with 8 SPI. Let me check the manual... EDIT: Yeah, 8SPI - this most likely is because you can reach the set screw in this position. This is from the Singer 111 manual: -

Maybe you like to show us some pictures of your machine. And a video will probably better explain the issue. regarding timing - I think the post #3 in this thread will help you with the timing:

-

Important Customs news for UK/Eu leatherworkers

Constabulary replied to fredk's topic in Marketing and Advertising

@Klara Not a leather supplier - CS is short for College Sewing Machine Parts Just got a response form another UK supplier - quote: -

The Singer 7 came with (at least) 2 different hook sizes / bobbin sizes so when looking for a hook compare the bobbin sizes too or you may end up with an way to large or way to small hook. F.i. the 7-10 has smaller hook than the 7-33. I have a German language Adler 20 (predecessor of the 120 and similar to Singer 7) spare parts list and the larger hook has parts number 20195 (parts list explicit says Large Shuttle) and the smaller hook has parts number 20319 (closed frame) and 20315 (open frame). I think they are the same as for the 120. I assume the 120/8 is using the smaller hook but I´m not 100% sure. Can you find a spare parts number on your hook or on the shuttle race so maybe we can figure out more when comparing the parts numbers.

-

Important Customs news for UK/Eu leatherworkers

Constabulary replied to fredk's topic in Marketing and Advertising

CS still does not ship to the EU. They said since January all packages they sent to the EU have been returned (that was in May) by the carriers (UPS & DPD) so they do not ship to the EU until this is solved. Unbelievable. Feels like I want to plutonium from the Russians - thats probably easier meanwhile. Today I sent a request to Trojan Sewing asking if they have successfully delivered package to the EU but yet no reply. -

Be careful with removing shafts - you may damage parts and there are no spares available except someone rips apart his broke machine. If it was my machine I would not do it. But it´s of course up to you. There are no service manuals for these machines. However - the closest nowadays available machine is the Seiko TF-6 I have attached a parts lists. Maybe it will help you. PARTS_TF-6_6B.pdf

- 2 replies

-

- singer18

- singer 18-3

-

(and 4 more)

Tagged with:

-

I assume you have the needle all the way down when turning around the material, right? Try this, rise the needle bar until only the needle tip remains in the material and then turn around the material. What thread size and needle size are you using? Any specific leather tip needle that you are using?

-

Pfaff 545 bobbin case opener jams the catch hook

Constabulary replied to John D's topic in Leather Sewing Machines

yeah - that can happen and often owners do not what to do and sell the machine as broke. This is what I found on my 107w1 between bobbin case and hook when I received it. The thread and oil have built up to a really compact piece. There were 4 or 5 colors of thread in this thread "cookie". They just did not care about the machine until the bitter end (all of a sudden, of course) and then did not know what to do. Machine cost me 1€ + shipping back then Conclusion - better know your machine and be able to help your self. -

Piping Feet Seiko STW 28 B / Consew 226

Constabulary replied to Handstitched's topic in Leather Sewing Machines

Your dealer is right. You cannot use singe needle piping foot set on a double needle machine! You can try to modify a foot set but that requires cutting and welding / brazing. Maybe a cheap drop feed machine will work better. Like Juki 127, 555 or a Singer 31K, 331K, 95K, 96K or the like. Accessories are rather cheap for these machine. You sometimes can buy industrial plain drop feed machines for a bargain but depends on your sewing machine market... Note the list of machines in the description: https://www.ebay.com/itm/143446313333 -

45K´s sometimes have round belt groves and sometime V groves (newer machines rather have V groves) and yes considering the size of the machine the grooves seem to be quite narrow sometimes. Mine has V groves and I´m using a 10mm 10/Z belt (metric world) or X10 (toothed) belts - no problems. Yes the belts seem to bee a bit too wide but thats not really an issue. So it really depends on your machine pulley. https://www.zahnriemen24.de/a/40051-keilriemen-z-10 https://www.zahnriemen24.de/a/40059-keilriemen-x10 Alternatively on some of my machines I´m using green PU round belts with rough surface in 8mm like this: https://www.ebay.de/itm/133659334890

-

Price range of domestic machines

Constabulary replied to chrisash's topic in Leather Sewing Machines

What domestic machine costs 4000? New computerized or vintage? It´s one thing that someone is asking that kind of money for what ever machine the other thing is finding someone who is willing (or able) to pay that money. Often (vintage) domestic machines are more a collectible rather than a machine people are actually using. Of course there are a lot of shades of grey between collecting and using but IMO most domestic machines are overpriced. But vintage industrial machine are sometimes way overpriced too especially on Ebay.com. -

Singer 51W SV 2 Post Bed Machine Restoration

Constabulary replied to Constabulary's topic in Leather Sewing Machines

@Jholden0 maybe a longer bottom bushing will do the job too. I just noticed the later model 51w seems to have a bottom bushing only so maybe a longer one will work w/o installing a top bushing. I only can guess but looks like a good solution w/o drilling and gluing in a top bushing. Of course diameter of old and new bushing have to match. See below thread: -

Yours appears to be the 2nd model of the 51w and to me it looks like it has a smaller diameter needle bar than the 1st model (which I own). Looks like you have a fairly long bottom bushing but no top bushing (due to short needle bar). I only can judge from pictures as I never have touched a 2nd model 51w. I guess the NB on your 51w has a 6.35mm diameter. Therefore you could use a Singer 107w / 143w or Singer 111w needle bar. Take a measure on your 226R - I assume it has a needle bar with the same diameter as the 51w shown. If that's the case it will be an easy task. You probably have to shorten the new NB.

-

IMO oil the open gears - grease tends to collect dust, lint, dirt (broken needle tips sometimes) more than oil. When you apply new oil it can wash off some dirt, lint... thats what the oil drip pan is for. No matter what clean the machine regularly. I only use grease or sticky synthetic lubricant in capsuled gear boxes. But as always opinions are different.

-

Nylon or polyester thread

Constabulary replied to ps0303's topic in Gun Holsters, Rifle Slings and Knife Sheathes

https://www.ebay.com/sch/hotheart10/m.html?_nkw=&_armrs=1&_ipg=&_from= -

Pfaff 545 bobbin case opener jams the catch hook

Constabulary replied to John D's topic in Leather Sewing Machines

You have no needle plate installed - never run your machine without needle plate. Install needle plate and make sure the small tab #4 sits in the gap in the needle plate as show in the encircled picture. -

Misread - forget what I wrote - looks like you want to ship a machine + table...

-

CB 105 forward reverse stitch length dont match

Constabulary replied to RockyAussie's topic in Leather Sewing Machines

Instructions are always welcome - please share! -

I use heavy double wave carton and on the in inside to each side min. 1.5" stick Styrofoam plates (the thicker the better). Fill all (really ALL) free spaces with cut pieces of the Styrofoam plates the way that the machine cannot move inside the package. I prefer UPS - never had issues with them.

-

Pfaff 545 bobbin case opener jams the catch hook

Constabulary replied to John D's topic in Leather Sewing Machines

Please post pictures and a video of your own machine so we can evaluate the issue better. Are you sure #4 is in the notch of the needle plate as shown in the encircled picture? For adjusting the bobbin case opener loosen #2 adjust #1 the way thread keeps not hanging between #1 and #3 and in the gap between #4 and the needle plate (encircled picture) and tighten #2 again. But that should be mentioned in the manual I think. -

Singer 51W SV 2 Post Bed Machine Restoration

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Bitten by the buck - there is no cure Very good choice! You will have no problems finding parts! -

Singer 51W SV 2 Post Bed Machine Restoration

Constabulary replied to Constabulary's topic in Leather Sewing Machines

ouuuh - indeed a very special color! Does it glow in the dark? I wouldn´t want to look at it all day but it of course it is a personal choice. I´m sure folks here would have crucified me for "destroying" the original floral decals on my machine (and maybe for other things). But I just do not like it though it looks good but its not what I like to look at when working with the machine. Personal choice... But please don´t put Hello Kitty or My little Pony stickers on your machine **kidding** -

you need 380/400Volts and an air compressor to run this machine with it´s "Bells & Whistles" - keep that in mind.

-

Michiel - his picture shows the 212 not the 239. 239 is a nice machine when properly set up. Very similar tot he Singer 111G156 presser feet are the same as for the 111 series also the bobbins an several other parts. If it is a 239-531 it even has a large hook (bobbin size like Adler 167)

-

most likely for sewing shoe upper or for decorative stitching. I haven´t sewn seat covers but a flat bed machine would probably the better choice for this work.