jimi

Members-

Posts

1,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jimi

-

I would imagine it was just a design change, nothing else. remember at one point they were OBSOLETE in the parts manuals. if you look at a manual you will almost always find the illustrations in pairs. one hook for thin thread and one hook for thick thread. this can be seen when you compare the heel, they are slightly different. try and trace one then compare to the other beside it and there should be one with the heel slightly smaller. in this case the #91044. here are two open shuttles, one for thick and the other for thin? just my opinion..

-

Yes it smelled of new paint on the web!

-

Great job Folker! turned out like new! did you keep the part 91023 from the old broken machine?? (needle bar connection link)

-

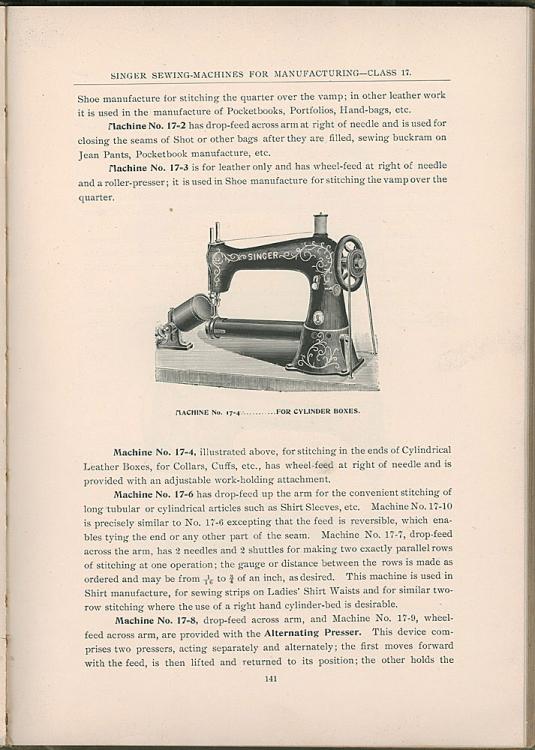

Thanks Tom for uploading. Here is a list of machines and varieties of the various classes, which states its needle type, and the SV models are included. so you can get an idea of just how many there were!!. it does not list all of them. as you can see it says for example "for all sv models except......." but it does not give the list of all these models. but anyway it is a little bit closer to finding out a bit more about the SV models. Enjoy!

-

Hi again, i have found an interesting list of sv machines but it is in pdf, how can i upload it here?? Singer Needles by Machine Class chart.pdf

-

Parts for old Singer Industrial sewing machines - where?

jimi replied to customizer's topic in Leather Sewing Machines

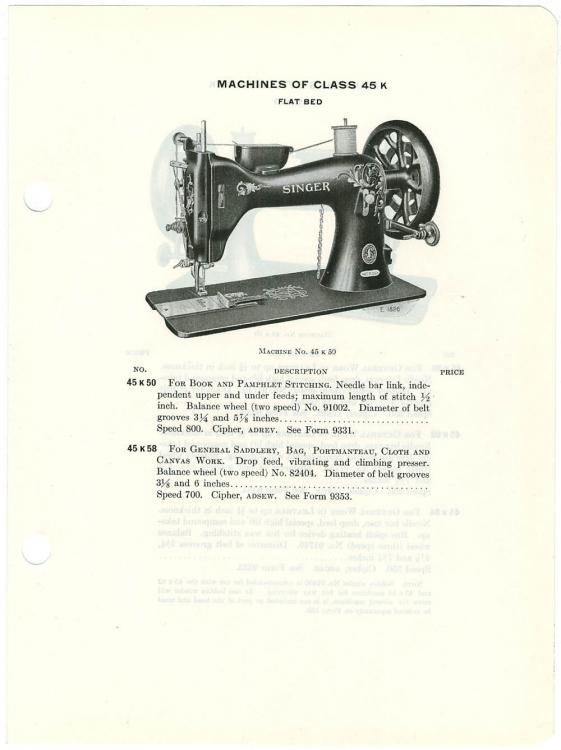

Hi, i think you got the wrong spring number maybe?? here is a link for the #82525 spring https://www.college-sewing.co.uk/store/Singer45KSewingMachineParts and if it is the shuttle you are looking for then i think one for a singer 17 should fit. http://www.ebay.com/itm/SINGER-17-18-ADLER-48-CONSEW-SEIKO-SHUTTLE-HOOK-6028-/290739289023 i dont think you will find the feed dog ring or tiny needle plate anywhere?? try where it says parts-singer- then the model. be sure to upload a picture of the machines for us knuckleheads who like the old iron regards jimi. -

Original Price Of Singer/adler Shoe Patch Machines?

jimi replied to PonyEdwards's topic in Leather Sewing Machines

your welcome, the prices seem to be from 1907.- 11 replies

-

- singer shoe patch

- 29k

-

(and 1 more)

Tagged with:

-

your welcome. there is a topic started on the forum about the SV machines if you are interested.

-

Mystery nut comes out of machine while sewing??!! Singer 153

jimi replied to helena's topic in Leather Sewing Machines

Hi Helena, do you have an illustrated parts manual for your machine?? http://dixiesewingmachine.tzo.com/MANUALS/SINGERPARTS10/153W103.pdf on the first page of the parts (the one opposite the illustration of the machine), there are two arms. one short and one long #240126 and #264112 which is the small arm on the long shaft. it could possibly come from there. this screw is the typical one that is used on these moving arms. there should be a nut that goes on the back, but iam not sure because this parts book does not show a lot of detail. -

HI, in the PDF it says that it is a needle feed, maybe you could make a jig to hold your work similar to the 17k one and see how it goes? having a 97 then it is just a case of trying it out? you may have to make a slanted needle plate but iam almost sure if you had the right fittings you could do it?? the 45ksv100 has no foot, instead it has an arm that goes into your work. i imagine this will be to hold it while the needle pulls through? tell me how you get on and good luck. jimi

-

http://needlebar.org/cm/displayimage.php?album=243&pid=3328#top_display_media Hi There, in the posts above you have some pictures of the 45kSV100 corner stitcher and in the topic there is a PDF explaining a little about the machine. these were designed to do this kind of work but there were very few made. i saw one on ebay a few months back in the states so keep a look out. but it could break your bank! and this is a singer class 17 with the ring feed dog and a support to do this corner stitch. i have never seen one of these supports but iam sure you could make one. you just need to find out if you could sew it with a normal feed dog and what kind of foot they used. the 45kSV 100 is a needle feed machine, that can make a big difference meaning it will not leave teeth marks on the leather. hope this helps, regards jimi.

-

well that 45ksv99 looks no different from a normal 45k??? maybe it is just the reverse that makes it different??. and it has a normal hinged foot not the stepped one??? these SV machines are begining to be a pain in the ass!

-

Thanks for the bulletin folker, very interesting... never thought it was a needle feed???? as for the 34k?? that seems to be fit for another topic on its own?. i have seen these for sale several times and they seem to have an array of heads. it looks as if they have used 16k,17k and 45k heads on this class of machine. so with so many different heads to this class how can you possibly find the difference between a normal 34k (none seem to be normal) and an SV one???

-

Thanks dikman and Mike, junk sail?? maybe it was for this purpose?? good to know? that would make sense about the presser foot. if you see your friend mike you could maybe ask him? @Constabularydid you ever find out if the holes on the arm of your 29ksv3 were for the 2 big bobbins for binding? here is a video of an SV model:

-

45K58 #F1015426, courtesy of John Langdon. For general saddlery, bag, portmanteau, cloth or canvas work. Drop feed, vibrating & climbing presser. Diameter of belt grooves 3 1/8” and 6”. Speed 700 s.p.m. Formerly known as 45KSV51 (and replaced 45K33 & 45K35). 45K54 #F1015426, courtesy of John Langdon. This treadle base came with a 45K54. The legs are 32" apart. The flywheel has a 1¾” diameter section and is 16” in diameter. Two belt pulleys: 11” & 14” dia. http://needlebar.org/cm/displayimage.php?album=243&pid=3328#top_display_media so, this is from the needle bar page. some info on the SV models here. and the treadle base ,as seen above, for the 45k54 was standard, so no bigger flywheel with the 45kSV99 according to this description. that leaves just the presser foot.

-

-

OK, Here is some info in the way of pictures. if anybody needs any more pictures then just ask. MODEL: 45KSV 99,S/N ES580643 - MAY 2nd 1961. lot of 200 made (stopped production of the 45k 1964) NOTABLE DIFFERENCES: Presser foot with part# SK35594. The other possible difference is the mass on the flywheel. measures 45mm wide compared to the 45k21 flywheel which is 30mm wide. i did not manage to weigh them but as you can see by the picture the flywheel is heavier on the SV99. this is notable due to the fact that both are treadle powered and moving the SV flywheel by foot you can feel the difference.if anybody has a similar treadle maybe they can compare?. the presser foot has been worked on by the previous owner. so i think it has only had the area where the needle had been hitting welded or brazed but not 100% sure. what was it used for?? i dont know. the previous owner fixed sails but this is not the best machine for sail makers as it does not have a zig zag stitch, which i believe is what the sail makers use. the small step on the bottom of the foot would probably indicate it was used for making some kind of overlap or hem?? feed dog,shuttle and needle plate are standard 45k1 etc.. parts.

-

Yes Folker, it would be interesting to find out about the SV machines. i am willing to donate my machine in the name of science! haha (i mean photos!)

-

Exactly Matt, if you want to sell your machine being someone who works or sells sewing machines the first thing you do is to get it up and running to show people how it sews. if not maybe it is not worthwhile?? i bought one similar a while back and it was a bit more rusty looking, it had no shuttle or race and the tension spring was a botch up job. the needle bar is worn and wiggles but i put the parts from my other 45 in to test it and it sews! it is from 1894 and cost me €50 with transport included. so it was no big loss if it was totally gone. old machines are a risk, i personally like to risk it and take on a challenge - but at the right price??

-

Here is the description Matt. i would say this type is better than the 45k1 or 5 as the foot moves with the material unlike the 45k1 etc so you would probably get a little less marking on the bottom side. but remember that this machine could be very worn? you might have to replace more parts than you think and some are not that easy to find, not impossible to find but could be expensive. so hammer that price down as far as possible matt if you are going for it. i personally think it is not worth that money with all of the missing parts and the fact you cannot try it out.

-

No Matt, that is a 45k58. it has what they call a jump foot action. here is a video of one. one guy is selling feet for this class on ebay for 45 quid!, you can see them all chromed up looking. you would need the screw for holding the foot on also i think. the feed dogs and needle plates etc can be found here: https://www.college-sewing.co.uk/store/Singer45KSewingMachineParts . also ask the owner if it has a shuttle?

-

Hi Everyone, Matt, it wouldnt be this one on ebay you are looking at without the foot and class nº plate would it?? if it is this one is not a 45k 5??