jimi

Members-

Posts

1,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by jimi

-

Thanks for sharing Hendreforgan, was just wondering why the owner did not just take off the belts and use the hand crank?? you don´t have both hands holding the work but at least you can still use your machine?? They are very nice machines and a gr8 solution for a small workshop, the small knob was probably for changing over with the large handle for when being used with the motor as it would be pretty dangerous that big handle sticking out and flying around. I have one here in the corner, hand crank and without pedestal, it is the slightly older model. I also have a PDF somewhere of the manual if anyone is interested by Gritzner in English and Frobana in German. Frobana.pdf Gritzner-Manual.pdf

- 4 replies

-

- side sole stitcher

- german

-

(and 2 more)

Tagged with:

-

-

Hi Rickard, did you try not going around the tension disk 1 1/2 times??? this helped me on a 45k.

-

The purpose of left stand sewing machines

jimi replied to Constabulary's topic in Leather Sewing Machines

...I think wiz is on the right track but i have no clue either, what i do know is if you want to treadle one then better hope it has the original treadle base with it -

Hi There, have a look at this post Brissy you might find something?

-

-

Nice work Woehlk! well done, its coming along gr8....

-

I tend to do the minimum in that sense because if things get stuck and the casting breaks then you start thinking.. why did i want to take that part off if it was working Ok!!!

-

Thanks....The worst part was getting the box with the black 335 with all the parts rattling inside and full of holes!!! the rest is just taking lots of pictures and trial and error, but i did not take the main shaft out so you will have to remember where it all goes afterwards its looking good!.... and they are great machines for wallets!

-

Hi Woehlk and welcome, very nice machine there, the paint looks very good on your machine, if it was mine i would not repaint it but that is just my opinion. Have a look at this post, this could maybe help a little.

-

Pfaff 335-H3. Broken eccentric, not walking

jimi replied to TheMortgageGuy's topic in Leather Sewing Machines

You might get some images here of the parts? -

Yeah these are monsters!! I imagine parts would be hard to find and needles probably expensive too?

- 31 replies

-

- stitch

- identify the stitching

- (and 3 more)

-

Yes Silvered, I think they had the 1,2 and 3 needle option, there was a catlouge i think somewhere on here with the models? Great job on the case by the way...looks amazing

- 31 replies

-

- stitch

- identify the stitching

- (and 3 more)

-

Great to hear you got it going again

-

HELP! Skiver presser foot lifter keeps springing up!

jimi replied to LOM's topic in Leather Machinery

That´s a pity, this seller in the link has a few parts for that type of machine by the looks of it so if you find out what parts is failing or worn etc you could probably find one here. It could be the lever is worn and with a file it could work again but i am just guessing?? https://es.aliexpress.com/item/33007431081.html?spm=a2g0o.detail.0.0.1da03bbdYPb8uN&gps-id=pcDetailBottomMoreThisSeller&scm=1007.13339.169870.0&scm_id=1007.13339.169870.0&scm-url=1007.13339.169870.0&pvid=fa0a5ab2-8c8d-4373-ae60-c4956eb54720&_t=gps-id:pcDetailBottomMoreThisSeller,scm-url:1007.13339.169870.0,pvid:fa0a5ab2-8c8d-4373-ae60-c4956eb54720,tpp_buckets:668%232846%238115%232000&pdp_ext_f={"sceneId":"3339","sku_id":"67002099300"}- 6 replies

-

- skiver

- troubleshooting

-

(and 1 more)

Tagged with:

-

HELP! Skiver presser foot lifter keeps springing up!

jimi replied to LOM's topic in Leather Machinery

if it is new, I would say if it is still in guarantee then have them fix it??- 6 replies

-

- skiver

- troubleshooting

-

(and 1 more)

Tagged with:

-

Hi There, I had a issue on a 171, when i got it the thread would just mangle under the needle plate, in the end i put the old shuttle carrier back on, which had a corner broken and the previous owner swapped out with a non original, and problem solved!

-

Sorry, just as i thought, none in my lot here i am afraid toxo.

-

Hi There, Just a guess.....it looks to me like the thread it pretty thick for that machine so you might be at it´s limit?? I would try another thread a little smaller and see if you get the same results. I have a Pfaff 335 and used nº20 thread to see if it would sew it and it did but i felt it was at it´s limit and it was soft leather.

-

I have NO space left in this room so some reclaimed gutters came in handy for me.....Yeah i know....i could have painted little animals on them or something but.....nah next time maybe...

-

-

Yes they are all the same one and a knife from Ali costs about €20 i think, maybe someone here has this 801 type model and can say what they are like performance wise??

-

Hi Glenn, I have a plain drawer on the 29k171 also and have seen a few of them on the newer 29k´s, you must have missed them

-

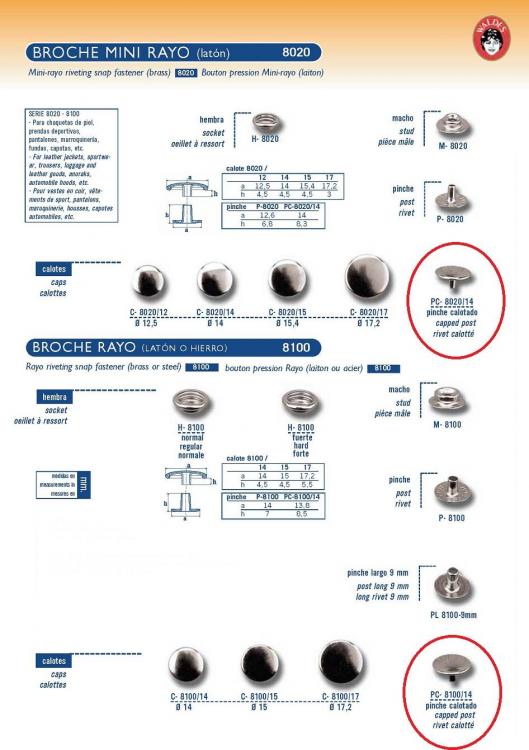

Check out Waldes fredK!!

-

Hi Toxo...Yes....Here in Spain there is a well known maker called Waldes...yes the Koh-i-noor one....the lady with the button on her eye logo... They have been in Barcelona since 1928 i think and are still making snaps, rivets etc but they only sell boxes of Min 1000, I use them but don´t think i have any capped posts, i will have a look. You can download their catalouge from their website. For example a box of 8100/5 14mm diameter is approx....€42-46 and the 8020 the same...add Vat, postage etc..