-

Posts

941 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by gottaknow

-

Something Different....a Singer 172K

gottaknow replied to alexitbe's topic in Leather Sewing Machines

There's a glove manufacturer here in Idaho that has a couple of those. They are funny looking for sure. I have a pdf of the parts book if you need it. Regards, Eric -

It followed me home....New to me Singer 111w

gottaknow replied to Chayse's topic in Leather Sewing Machines

Looks like a great find to me! Have fun. Regards, Eric -

You will want to cut off the needle bar, but you won't be able to use it for the standard needle holder. Good news is the needle bars are cheap. I did price out the NBRF for a 112W116 the other day and it was $104 us$. Regards, Eric

-

I should add that on my Juki LH-512's, the NBRF is much shorter and wouldn't require modifying. The needle bar threads are the same as the larger Singer needle bars as well. Regards, Eric

-

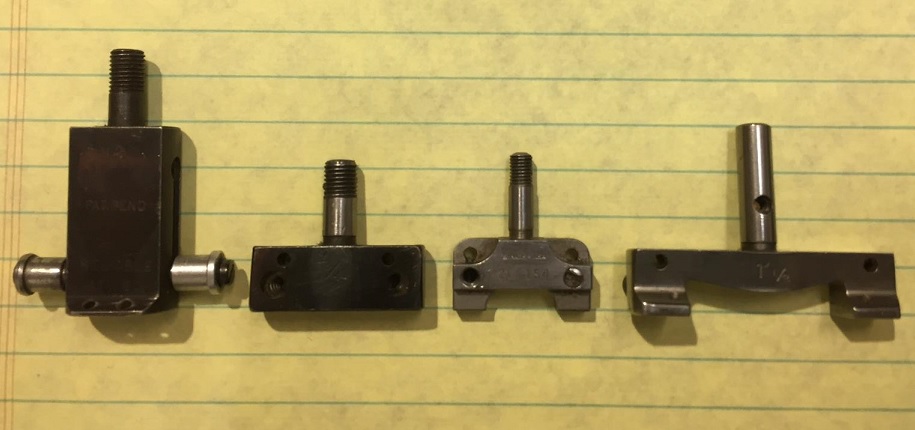

Singer made a shorter NBRF during the years these split needle adapters were popular. I have a couple of them but they don't have part numbers on them like most Singer parts. I'm thinking they had someone make them and were sold by Singer. I've searched through all my parts books to see if I could have written down the number. The 212's and 112's use different NBRF's and the two short ones I have are in 212G140's. The lower bushing however is plenty long enough to cut off. If I remember, the difference is about 20mm give or take. You may want to consider retiming to 135x7 needles. Also, there's a lot of casting to the right of the needle bar that you can safely cut out to accommodate your 3/8" gauge. Cut the needle bar off as needed at the top of course. I say go for it. FYI, here's a picture of the 3 different needle holders. The large and small thread-in style, (the smaller ones are rare) and the screw mounted. I dislike the threaded ones because they tend to wobble. I usually solder the hole and screw to prevent this, and it can be unsoldered when needed. Regards, Eric

-

What seems to be a pattern from the Juki factories is that the build quality is quite good. The loose screws have all been ones that would have been loosened by a tech during the final sew off. Like those clamp screws, feed dog screws, needle bar clamp screws and such. Their new direct drive machines are great, but they all have a rubber LoveJoy coupler between the motor and the top shaft. Very smooth....for now. Tons of torque, which tends to find the loose screws. I'm also still leary of their new "dry head" lube system. Time will tell. On the other side of the coin is I still have a bunch of Singer 300w's I'm using as well as 2 112's. They just won't die. Regards, Eric

-

I looked in a parts book, and there are 3 locations where it may have slipped. The one with your arrow, one on the right end of the top shaft and the one on the lower shaft I mentioned. If you do one that didn't slip, the one that did will slip again. On all of my 9010's and 5410's as well as my 2 ndl. 3578's I leave the lower one looser than the others so it's the one I always know is loose. FYI, I've bought 30 or so Juki's in the last 2 years and several have had loose clamp screws. Regards, Eric

-

Bigdave, What's the full model number? There are several variations of this machine. Does it have the new Juki direct drive motor by chance? Regards, Eric

-

On most Juki lockstitch machines there is a clamp screw located underneath the machine on the right side, towards the front edge. It clamps a shaft that goes from the clamp on the lower shaft up to the upper shaft. It's usually what slips. It will be a fairly large clamp and screw. Loosen it a bit then tap the needle bar back until it's center again. If you have a parts book, you should be able to locate it based on how it connects between the top and bottom shafts. Have fun! Regards, Eric

-

Down and dirty fix if all else fails. Remove the hook and grind off a wee bit of the hub so it goes farther in. Shouldn't take much. Just make sure you know how to re-time the hook to the needle. Your hook won't last long if it's hitting the needle. Regards, Eric

-

Great chart Gregg. A&E thread is really decent thread as well. Regards, Eric

-

Yeah Ferg, they are super picky about the stuff they spec. Forget about even trying to get anything changed. Obviously the suppliers of the military spec stuff know they have you over a barrel as far as price goes. It could get very frustrating. Some of the textile stuff would be impossible to trace once in the product. Not that we ever substituted anything.........heh. Regards, Eric

-

singer 20u for non leather sewing

gottaknow replied to beltbuckles's topic in Leather Sewing Machines

It would work fine for your linings. Regards, Eric -

I worked for a contract sewing factory for many years. We did a lot of contract sewing for the DOD including military uniforms, tactical gear, and a 5 year contract for the official Internment Burial Flag. We made 60,000 5'x9' flags per year. The government standardized many technical aspects of the textile business. Everything that goes into it has a military spec., right down to how the fabric is woven, to how it's packaged, even the pallets used for shipping have to meet a certain standard. It was a real learning experience. One of their first big undertakings was establishing stitch type designations. A lockstitch is Federal Stitch Type 301. If you said well a lockstitch is the same no matter what, it gets confusing because a zig-zag is also a lockstitch, but it gets the designation of FST 304, then it tells you exactly what machine you'll need. Same with a chainstitch machine. The single thread chainstitch is FST 101. A two thread chainstitch is FST 401. Zippers, elastic, thread, buttons, snaps, and all sewing notions have a military spec designation. As you can imagine, it gets very confusing. It does however prevent a lot of mistakes. Regards, Eric

-

Try this. http://www.consew.com/Resources/ Regards, Eric

-

Cleaning feed dogs after sewing waxed canvas

gottaknow replied to Willie0's topic in Leather Sewing Machines

I do this everyday. I spray the feed dogs with TriFlow then use a brush. Repeat. Some people use WD-40, but I wouldn't do that. The TriFlow won't affect the oil already on/in your machine. Regards, Eric -

Here is a step by step guide as to how a lockstitch machine with a horizontal rotary hook forms each stitch. The best way to read this, is if you have a machine with a hook oriented on a horizontal shaft, is to follow along with a machine. This explanation was priceless when I was a new mechanic. I've made all my apprentices remember this cycle and explain it to me on a machine without a book. It takes 3-5 years to train a mechanic to the point where you don't have to babysit them. Even after 3 1/2 years I will make my apprentice sit down on a machine and explain this cycle. It helps with trouble shooting. Even though it was published by Union Special many decades ago, the cycle hasn't changed. It's not something you can just read once and understand it, I remember it taking me a while and seeing it in practice. A big part of being competent on machine repairs is understanding the why. Many people can make the adjustments, but few really get into it deep enough to understand everything that's happening and why. I've always said I can teach anyone to turn screwdrivers, but if you want to be an accomplished mechanic, you need to learn how to visualize things in your head to the point where it's almost like watching a video. Our human brains are capable of so much more than most people challenge themselves with. Sewing machines definitely force you to learn how to think. I know from spending time on the forum over the years, many hobbyists get frustrated because they just want to do their projects and not fuss with a machine. The best way to be able to do that is to learn your machine(s) and what they're supposed to do. I've know several folks that have given up on the hobby because of industrial machine frustration. I try to remind people that it's complicated! Ok, now I'm rambling. Here's the link. Regards, Eric Horizontal hook cycle.pdf

-

And some feeding information. Feeding Problems.pdf

-

Another decent troubleshooting guide. Troubleshooting2.pdf

-

And another. Loopers and hooks.pdf Last one for now. Feeding mechanisms.pdf

-

I have a large collection of educational material for sewing machine mechanics. Singer did a fine job back in the 70's making this information available for training purposes. Somewhere I even have a letter from the old Singer Co. allowing us to freely use the information for non-profit purposes, (training mechanics and such). It's a shame to just let this information sit around collecting dust in my archives. I still refer to things even though I've been a mechanic a long time, I continue to learn. So here is the first file. I hope some here will find it informative and useful. Regards, Eric Troubleshooting.pdf

-

I buy from Atlanta Attachment and Tennessee Attachment. Their prices are pretty close. Both companies make premium folders and are great to work with. Tennessee Attachment has a better machine shop if you need something custom for a foot or feed dogs. They do really quality work. I had them make me a custom gauge set for a Singer 300W chainstitch. it was $1,400, but was as accurate as an original set made by Singer. Both companies have great customer support. Regards, Eric

-

Big Folders for Leather Handles?

gottaknow replied to Constabulary's topic in Leather Sewing Machines

No, that catalog has 492 pages in it. Regards, Eric -

Big Folders for Leather Handles?

gottaknow replied to Constabulary's topic in Leather Sewing Machines

If you look at the attached .pdf, the folder in the lower right hand corner, 404-D Version A, is what you have. You can also make a continuous strap sewn on just the open side or both with a double needle. You could also sew the second side by just turning it around. Regards, Eric Straight folders.pdf -

Big Folders for Leather Handles?

gottaknow replied to Constabulary's topic in Leather Sewing Machines

New from a quality builder, probably $200-$300 US$. On the used market, you might get $20-$50 depending on how bad someone wanted them. Regards, Eric