-

Posts

844 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Tim Schroeder

-

Finally finished my daughters boots. I have made a few pair of lace up boots but these are my first pair of Cowboy style boots. Made a lot of mistakes but learned a lot. Can't wait to start myself a pair.

-

Looking To Hire Someone Experienced With Holsters.

Tim Schroeder replied to onder's topic in Old/Sold

Hi, I not an expert but have built a few molded holsters. If you want to call we can talk about what you are looking for. 214-505=8400 Thanks Tim -

The rubber tire on the motor is a bobbin winder tire off any home sewing machine. Any sewing machine shop or Ebay will have one. A standard home sewing machine motor. Mine is an AlphaSew. You will need a pulley for the tire to fit on. Any sewing machine shop or Ebay.

-

Hi Machine head, I really haven't had time to mess with it yet. I have talked to Harris at Pilgrim Shoe and he sounds like he will be very helpful. He has an adjustable edge guide that will make it possible to run two rows of stitching. I am making a pair of boots for my daughter that were suppose to be done for Christmas. I will take them to a local shoe repair man to sew them up when finished. Hoping to get my Landis going after these boots.

-

Still trying to find out what size thread and what kind of thread is used for sewing soles on cowboy boots. Any info would be greatly appreciated. Thanks Tim

-

Just bought a Landis 12 and need to find out what size thread is used for sewing soles to the welt of Cowboy boots. I need to order a new needle and awl. Also what kind of thread. Thanks Tim

-

Well I managed to get the machine home and unloaded without to much trouble. She definitely likes to lead whether you want her to or not. Looks like everything is working but it needs a good cleaning. The Auction guys opened the top cover and let it fall in the back and broke a big junk out of the back of the top cover and then shoved the giant broken piece in the middle of the machine. Any suggestions on how to go about cleaning 60 to 70 years of oil and dirt. I would like to know what size thread and what kind of thread is used for sewing the soles on Cowboy boots. I am going to buy a new awl and needle and need to know what size to order. Another question will be how to sew two rows of stitching since there is not any adjustment in the edge guide. Thanks for any help, Tim

-

Thanks Machine Head and Glenn, Appreciate the info. Thought I was going to have to take dance lessons there for awhile. Hope she likes Willie, Waylon, Merle and Johnny. Thanks Again Tim

-

Thanks for the warning/advice. I am a wannabe boot maker. I am hoping this machine works since I was not at the auction to check it out.

-

This machine just has Landis 12. No letter. I paid $610 and I will have to drive 3 1/2 hours to go pick it up. Figured I could drive there and back next Sat. In the picture it was threaded so I hope it is in working condition. It was from a boot shop auction. My mistake. Looking at the pictures closer I can see MODEL F on the base.

-

First Time Tooling

Tim Schroeder replied to barbedwireboutique's topic in Floral and Sheridan Carving

I use Hidepounders theory on casing. Look at his gallery. I slide the piece thru a sink full of water until the bubbles are coming out. Not until they quit coming out. Then place on flat water proof surface and cover with a piece of glass or plastic for at least a 1/2 a day. Then uncover and wait for it to start to turn back to normal color. I have all my patterns copied at Staples on thick paper and put the pattern on the leather and put my glass on it for 5 minutes or so. If the leather is to wet your paper will get wet. IThe paper should not get wet a tear when tracing with a pen. If the pen is trying to tear the paper then the leather was to wet. The lines on the leather should be dark when you remove the paper. That will help you tell how long to wait before starting. You can cut with it pretty moist (not mushy, the leather should feel a little firm) and bevel but it should be getting back to normal color when you do all the decorative stuff. Backgrounding looks best when you wait until it is back to normal color. If you need to add moisture to keep tooling I spray from the backside a let it sit for a few minutes. If you are leaving natural after tooling you should have a dark burnished look to the impressions especially the shading and beveling. Adding more moisture seems to make a little of the color away. If you can't tool all of it without adding moisture I cover halve the piece with plastic and tool all but the background then uncover the other halve finish tooling and start backgrounding in the area you tooled first. I get the most color in the impressions when I let it set under glass or a piece of plastic for at least 24 hours before uncovering. You can see where I sprayed around the edges on the backside after I cut this piece because the outside will try to dry first. In this tooling you can tell I beveled it with it a little moist. A lot of the beveling doesn't have the color it should. I dye and antique finish everything so the color isn't as noticeable as if you wanted to leave it natural. Tim -

I just bought a Landis 12 from an auction. I think the price is probably right if it works. My question is: Are all Landis 12 machines curved needle. This is just a landis 12 no letter. Thanks for any help.

-

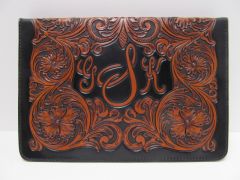

A Few Drawings And The Tooling

Tim Schroeder replied to Tim Schroeder's topic in Floral and Sheridan Carving

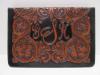

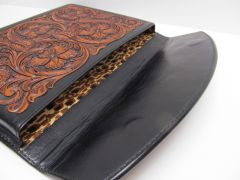

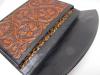

I also put this piece on her suitcase and a luggage tag. Makes it really easy to identify her suitcase quickly. She travels a bit for work. I made this stuff 2 yrs ago and my tooling has improved quiet a bit since. -

From the album: computer case

-

A Few Drawings And The Tooling

Tim Schroeder replied to Tim Schroeder's topic in Floral and Sheridan Carving

I use all Fiebing's dyes and antique finish. I started using a damp t-shirt wrapped around a block of wood to wipe the excess antique finish off so it only wipes off where there is no tool impression. Thanks Tim -

Boberg Stuff

Tim Schroeder replied to JLSleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice looking work. I love the the look of all black with tooling. -

A Few Drawings And The Tooling

Tim Schroeder replied to Tim Schroeder's topic in Floral and Sheridan Carving

Finished in time for my wife to take to a big meeting in New York tomorrow. Everything she has is this same color. Wallet, checkbook cover, make up bag and phone case. There is also a tote bag to match.The tooling is a little different color. I sprayed to much Wyo-sheen and the med brown antique finish didn't tint the tooling like the the rest of her stuff. Everything is dyed with 50/50 light brown and chocolate mix with med brown antique finish. The stitching on the computer case is 346 bonded nylon using Tandy's diamond hole punches. The black ones, not there new pro line. The holes are a little big but my machines only sew 207 and it looks kind of small on a case this big. IMO I bought Bob Parks (Hidepounder) book on drawing patterns and it has really helped a lot but still have a long way to go. Thanks for looking and the positive comments. Have a great New Year, Tim -

A Few Drawings And The Tooling

Tim Schroeder replied to Tim Schroeder's topic in Floral and Sheridan Carving

They are they pieces to a molded computer case for my wife. So it will be black with brown or tan tooling. I will post some pictures Tuesday or Wednesday. Thanks Tim