bladegrinder

Members-

Posts

514 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by bladegrinder

-

Treadmill motor for a sewing machine??

bladegrinder replied to AlZilla's topic in Leather Sewing Machines

Another thing about tread mill motors is they can be used as DC generators. The first one I got years ago I was going to make a windmill with a voltage regulator to charge an RV battery. That didn’t happen though, I built a homemade solar panel instead. I’ve got a 75’ ham radio tower I need to put up first. Connecting a drill to the shaft of the motor I was getting 19 volts for as fast as that drill would go. Also, anyone messing with these you’ll see two blue wires coming out, they can be cut and capped, they go to an over temperature sensor inside the motor. -

I have to throw you a "good job" too! man those leaves look great!!

-

Treadmill motor for a sewing machine??

bladegrinder replied to AlZilla's topic in Leather Sewing Machines

While it's out in left field, I think it's a pretty good comparison. I think it kind of applies to what were talking about here... He could have bought-built one like the guy on National Geographic that's made a bunch of dives with no implosions, but he obviously had lots of extra time and I'm pretty sure saving money was on the top of his mind verses producing a proven design. I'm retired and have a lot of electrical and mechanical background and have a lot going on and not much free time and a lot of folks have one or two jobs, kids and little free time to monkey around with tread mill motors, let alone not knowing which way to turn a left hand screw driver. I just posted a tread mill motor project I did here so I'm not trying to put a negative light on using them but like I said I'm still waiting to see someone do it to a sewing machine. Like Quade said, you can pretty much plug and play a servo motor in 15 min. and be done without going in the poor house there's lots of fun ways to save money but there not all for everyone. -

Treadmill motor for a sewing machine??

bladegrinder replied to AlZilla's topic in Leather Sewing Machines

The guy that built the submersible that went down to the Titanic saved a lot of money too by doing a lot of his own engineering and building that thing himself, although I don’t know if he used old tread mill motors or not, but he obviously had time on his hands to do it…and saved lots of money. -

That's beautiful! great work!

-

Treadmill motor for a sewing machine??

bladegrinder replied to AlZilla's topic in Leather Sewing Machines

That would depend on a persons capabilities to first get the free treadmill motor then install it in a way that works and doesn't look or work like a rube goldberg job. -

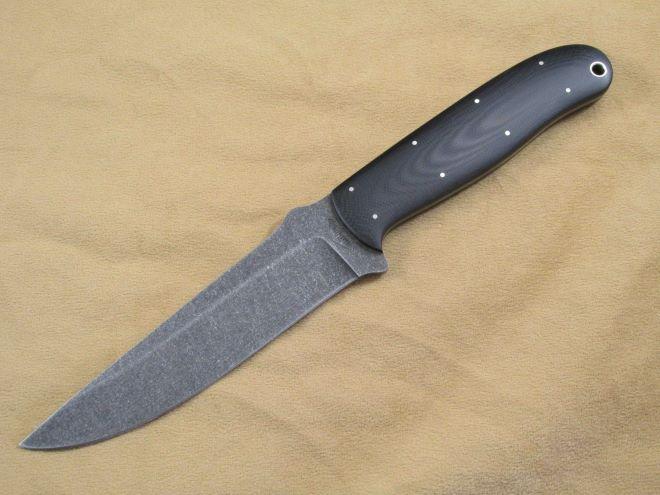

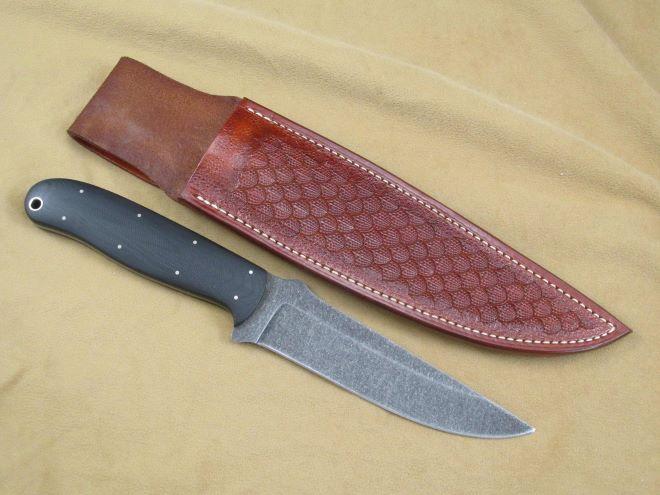

Thanks, the second knife is stabilized Black Palm, the first is Desert Ironwood.

-

I have one similar to the Badger at top with a water separator on the hose end that connects to my pancake compressor which is big and loud but I use it out in my shop. I run about #40-#60 thru mine but those pressures could be way off, it's just what that regulator says. I have a small glass jar that connects to the bottom of the brush verse's the open container, I can see making a huge mess with an open container. I use mine mostly for applying resolene but I also use it for shading around borders of sheaths and holsters. when I do shading the piece has already been traditionally dyed then brushed with a darker color. just brushing with dye will take A LOT of coats because it goes on so thin, sometimes just brushing then scratching the leather will show un-dyed leather. for maintenance I only use denatured alcohol and run it thru with air after using, sometimes I'll take the front sections off to clean the front of the needle and the mixing ports coming from the jar. be careful if you take it completely apart they can be tricky getting the needle back in right. these have really small O rings in them and if their really old you may have some leaks, hook er up and give it a run, it takes some practice to get comfortable with it. the other bigger one's you have pictured I have no experience with.

-

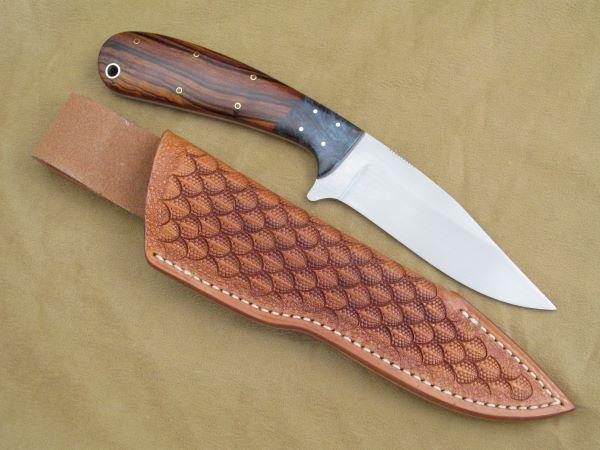

Here's a couple knife sheaths I just finished with dragon scale stamping. first a pic of the knife, then the sheaths. One is done in natural Herman Oak, and one with Fiebings light brown. Thanks for looking!

-

Nice little holster, no matter what I'm carrying I also always have a .380 in my front pocket.

-

For starters I’d try a few good rubbings with saddle soap.

-

Treadmill motor for a sewing machine??

bladegrinder replied to AlZilla's topic in Leather Sewing Machines

When those stainless steel pins came out for tumbling brass I jumped right in, wow was that a good move. Pricey getting into them but no comparison to corncob. -

Treadmill motor for a sewing machine??

bladegrinder replied to AlZilla's topic in Leather Sewing Machines

I agree, I have a pretty well set up shop and a some of my equipment was built in my shop. I like fabricating anything I can myself. I had two treadmill motors laying around and the only thing I had to pay for for that tumbler build was the rectifier, the wood and the end caps for the pvc, but like Chuck said those motors aren’t just laying around. Both of mine came from treadmills on the side of the road and from what I remember it was kind of a fight to get them out, on eBay their averaging $80.00. So after you get a motor you have to figure out how to mount it, get a ac to dc converter controller and mount that somewhere where you can somehow connect a foot pedal to it in some fashion. While I’m sure it can and has been done I think realistically in the end a person would stand back looking at what he just built and think to himself…hell, I could have just bought a servo motor and been done with it. However, I do look forward to seeing a treadmill motor powered sewing machine posted up here. -

Treadmill motor for a sewing machine??

bladegrinder replied to AlZilla's topic in Leather Sewing Machines

I built a ceramic tumbler for putting stone wash finishes on knives with a treadmill motor. there is a DC rectifier it the junction box shown and it's powered by a variac, the red gismo on the left. I'm sure one could be used for a sewing machine...but...there would be a lot of tinkering on mounting it and powering it. in the end I don't know if it would be worth it over just rigging up a servo motor. -

Belt knife sheath...

bladegrinder replied to bladegrinder's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks folks! -

Belt knife sheath...

bladegrinder replied to bladegrinder's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Gezzer, I love making this stuff. I feel lucky to be able to do this. -

Just finished this sheath, first time use of one of Sergey's dragon scale stamps. the front was going to be natural but while dyeing inside the throat it leached thru to the front so I just dyed the whole sheath, natural next time!

-

I don't know much about horses, other then they can throw you...but that looks GREAT!

-

Couple of knife sheaths...

bladegrinder replied to bladegrinder's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks gregintenn, the blade is CPM154 stainless. the handle is stabilized blue dyed Box Elder burl with brass and red fiber optic pins and a nickel silver lanyard hole. it also has red G10 liners between the scales and blade. -

Oil tanned leather - bad for knives ..

bladegrinder replied to SUP's topic in Leatherwork Conversation

I use mostly stainless steel for my knives and have never had any corrosion issues using veg tanned leather. I’ve never used chrome tanned leather so I can’t comment on that. I’m in Florida and right now the humidity is 90% and the feels like temp is over 100. The high carbon steels I use will rust here if you look at them cross eyed, that’s why I don’t use much of it where I’m at. I always coat my high carbon blades with a good wax to help prevent it. Your problem might not be the type of leather your using but where it’s coming from. Do you know what kind of steel the blade is made if? -

That is uber cool!

-

What I do is cut my patterns out for whatever I'm making and apply a light to moderate amount of neatsfoot oil with a piece of sponge prior to any stamping, carving or dyeing and let it set overnight. the next day it's ready to go. I know that's a lot of drawn out time, sometimes I'll do it in the morning and it looks ready hours later. I just wait until it looks like it did before I oiled it before I do anything to it. this seems to work good for me.

-

Couple of knife sheaths...

bladegrinder replied to bladegrinder's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks folks. Tugadude, I have a website. millerknives.com