toxo

Contributing Member-

Posts

2,261 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by toxo

-

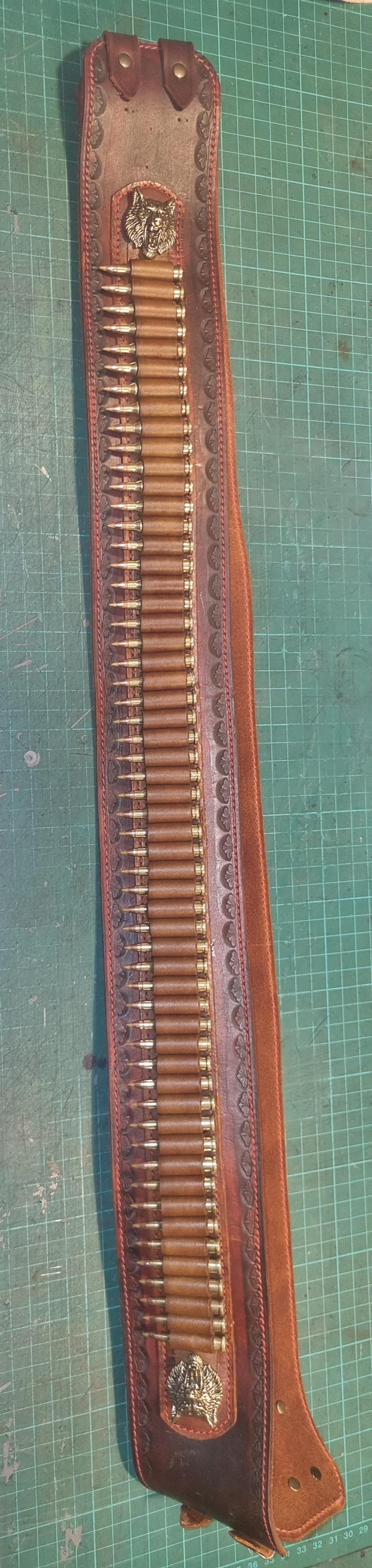

Almost finished. Far more work than I'd bargained for and my hands didn't thank for making the loops a bit tight. Quite happy with the result though. I haven't seen any for sale that include cartridges and these are ballistic tipped, our laws over hre are pretty strict even on components for making so I had to make sure they definitely couldn't be re used.

-

Stapler! Not the office type, the plier type. Use anywhere the holes are not seen. Simply remove after they've done their job. Office/Work/Home Stapler - Foska Plier Grip Stapler ST0512 - Black | eBay UK

-

Don't have first hand knowledge but from what I've seen you could do it with a straight fabric strap. One end around the wrist a couple times (maybe velcro) then wrap around the bar a couple times. The grip is only to hold the strap in place. You're lifting with the wrist. Ask any boatman. A round turn and a half hitch could almost hold the Titanic.

-

Help with square corners on wet molded pouch

toxo replied to bigsig11010's topic in How Do I Do That?

Where's the bottom "wing"? You need to unfold the bottom, then trim oversize all round so you can re wet it and clamp all round. Then force it around the corners with a bone folder or similar. Got to be wet. After drying and stitching, trim to final size. -

Don't use it as much as some do but it hasn't given a moments worry and I love that I can switch it on at any time and use it without worry whether be it a serious project or to mend one of the dogs squeaky toys. Gives me more confidence than I've ever had.

-

Thanks for the thought H but when I do stuff like this I tend to go with what I have to work with and what's practical. The main strap has to be thick enough to last and do it's job. It has to be wide enough to not only take the bullet loops but also any embossing or stitching you have in mind. The bullet loop strap is governed by the length of the bullet case and needs to be be robust enough but supple enough to wrap around the bullets. I'll decide on thread colour later. I like a contrast but the cosplay and re-enactment peeps might not like it. Looking ahead now, do I incorporate an angle in the shoulder? (Might depend on how wide the main strap is), And if so and I go on to make two, do I make them handed, i.e. the bullets facing each other? Depending on the length of the overall belt and the amount of bullets on each side I could make them universal without the shoulder angle. This'll give you some idea of how my brain works 24/7, I'm tortured.

-

Found the heads. Now to think about it seriously. Since it'll only be for play I'll not worry about doing things "Properly".The heads are a nice tight push fit so I'll glue em in. Likewise with the cases. Whilst I'll make sure they're tight, a dab of glue will ensure they don't fall out. Fred, if you think those patterns will help I'd be grateful for them. Can never have too much learning. Does anyone have a simple brass pickle recipe?

-

A Chinese dustman knocked on the door and a bronzed hunk of a man answered. "Where you bin?" Says the Chinaman? Hunk Says "I've been on holiday, d'you like the tan?". "Naw naw naw, where you wheelie bin?" Says the Chinaman. Hunk Says " OK, I lied. I've been on the sunbed".

-

Welcome Jacqui and congratulations on getting an 801 skiver. It's an amazing piece of kit but be prepared to waste a lot of scrap learning how to use it properly. It might be a strange thing to say but I enjoyed that learning process immensely. You'll learn about different types of feed roller/presser feet/what speed to use and how things change when switching to a different thickness of material. When you think you've got it right it might not work as good on a different TYPE of leather/vinyl so the most important piece of advice I can give you is ALWAYS ALWAYS get it perfect on scrap before putting hours of work through it. Good luck with it and send a message if you need help.

-

I acquired a large carboy and a few demi-johns as well as the rest of the paraphernalia needed for this journey. I now have three mash bins full of de-stemmed grapes and water and yeast that was put in two days ago and the must is almost at the top of the bins. I haven't adhered strictly to the recipe due to lack of equipment at the right time. I'm told online that I shouldn't have added water despite the recipe calling for it. Time will tell. This post is about the large carboy. I bought it from my new French friend who brought it from France years ago. To say the basket is very fragile is a huge understatement. I know I don't really need the basket but I'd like to know you guys thoughts on how easy it would be to restore it. I will make a leather bottom and lace it to something around the top but I will oil it and look for some wicker? I think it's worth saving. Your thoughts guys?

-

Tips/advice for 1st craft market tent?

toxo replied to ThisIsMyFirstRodeo's topic in Marketing and Advertising

Big step. First of all, what's your weather like? Over here in the UK the outdoor show season finishes around October time. Rain can ruin a weekend and can be a big factor over here, less of a problem where you are. If you intend to do it full time you might consider paying the extra cost of indoor shows in which case gazebos are less of a consideration. I've seen many cheap ones in the bins after a windy weekend but the good ones are very expensive. If it's to cover three pitches it'll need to be a big one which will make your eyes water. As is often quoted on here, "buy once, cry once". As for the display itself, try for an open fronted "U" shape which is more welcoming than a straight table. Fabricate some vertical tiers, especially at the back where you can put the bigger items especially some brightly coloured stuff. People walking past won't see stuff that are on a flat table. Lighting is a must and raises you to a different level. Use it to spotlight your more expensive or more interesting items and it will attract a lot more than those stalls that don't have it. When choosing what shows to book your first consideration should be footfall. Don't imagine for a second that everyone will like your stuff as much as you do. Only a small percentage of your stuff will appeal to MOST people. Now, after looking at the total footfall you have to face some facts. The promoters will lie about the total footfall because they want your $. Now take out the number that are only making a day of it and have no intention of buying anything. Then take out the number that would be a customer if only they had some money including the tyre kickers. You can think of many more that won't be giving you their money. The number that's left is where you'll make your money. So the higher the footfall, the more chance of making some money. Unfortunately these are the shows that will cost the most. Another important factor might be the type of show. I've paid £40 for a weekend at a steam rally (not with leather) and took well over £1000. I've also paid £600 at an air show with a huge footfall and didn't get the pitch money back because I booked too late and had a lousy position. Lesson learned, when you have all your ducks in a row you'll book your shows for the year just after the new year to guarantee a good pitch. Over here there's a publication called "The Showman's Directory", it lists every show through the year with footfall and contact details. Although primarily a UK thing there was a lot of international shows as well. Maybe there's a US version. Good luck. -

Saying well done to you is getting tiresome. Do something wrong for God's sake man.

-

That's the only thing I'm envious of in the US,the space. Must be great. Thanks for the cool on the hat.

-

I applaud your skills Chuck but I do wish you guys would talk English. Wots a burb?

-

Welcome neighbour! Website looking good. Lots of friends here.

-

Thanks Mr Black. It's all veg tan, yes there's wire in the brim and it's not lined. Didn't make it for constant wearing. Of course a lining could be installed at any time.

-

Have been out and about today picking free grapes. Now have loads. On the journey for sure now.

-

Are you referring to my wizard hat Fred?

-

I've got one of those sharpened hole saws somewhere. Don't think I've ever used it. That mini rolling mill makes it so easy to do circles. I would have thought that even the soft part of the hole saw would do the job if the edge wasn't so fine to make it fold over i.e a blunter edge. Even mild steel is much harder than leather.

-

Fool that I am have decided to have a go this year. Know nothing about it except picking up bits through life. Only been here for 3 yrs and last year there was so few bunches that I didn't bother but this year there's about 5 times more. There's still not enough to make it worthwhile so I'll have to supplement with either more grapes from somewhere or some concentrate. A couple peeps on facebook don't want theirs so I'm going tomorrow to see what's left. A whole new learning curve coming up and equipment to buy but two of my daughters will no doubt push me to get it done.

-

Thanks Bob. Took a while though. Ordered the red and black cord cos wasn't sure which one would have the most impact but I think the black is right.