toxo

Contributing Member-

Posts

2,261 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by toxo

-

I guess we need a Cobra guy to come along and say if it's right or wrong.

-

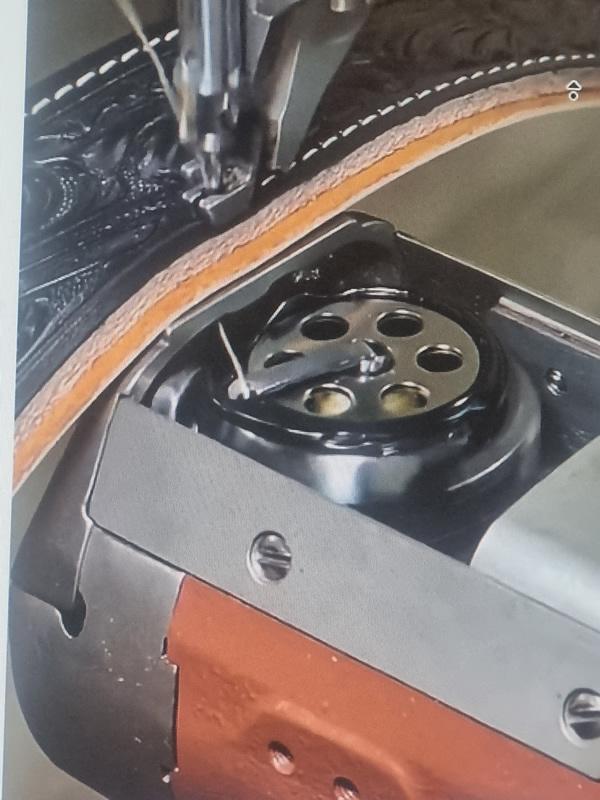

Yes but I don't see a slot on the Cobra. It's where it goes after the tension spring that's got me puzzled? There's no way my thread can double back after coming out of the tension spring and go through the little notch on the bobbin retainer on the top like it is on the Cobra.

-

Saw this on a video short. Guessing it's a Cobra and noticed the thread going through the notch in the thingy that holds the bobbin in place. Is this standard because I don't see any way I could do that on my machine? Of course i could always be missing something.

-

Interesting information. Thanks for sharing.

-

Took me a while to realise that hand sewing works around dissimilar curves because it draws the two halve together gradually. In some cases the stitch holes are different on each side to facilitate. The simplest way when they get too far apart is to go back now and then and use the previous hole twice to even up but doesn't look good if gonna be seen. When machining it's sometimes easier to "V" notch arounf the bends.

-

After watching the Dieselpunk video for the mocs I don't like em so much but the pattern has all the parts so Ill look at adapting it for machining. The slipper pattern will be a breeze to machine and should be quick too.

-

Good job Chuck, I did much the same thing. Got half way through and got fed up trying to work things out so bought a pattern. Easy enough to do and I had a piece of sheepskin. I ran out of sheepskin so used a bit if something else. I have lots of real fur that's just sitting there cos many over here are squeamish about real fur. Turns out I don't like the open back so will prolly put a back on. I'm not keen on the boot type but they look good. I do like the blue ones for something you can go out in in fact, when I bought the slipper pattern I bought this one also which is closer to what I was trying to do in the first place.

-

Well you've already bought the kit now which will serve for a while. As you're finding out, a question like this has a multitude of answers. They all mean well and as in all things, everyone has their own take. I'll just add this. Start with a pattern! Everything will be explained in detail, you'll understand each step and why and will give you confidence to look for the next project. Many pattern sellers provide a step by step video and tell you what leather and how much you'll need. This was my very first project (I'd done some reading of course). It's a Dieselpunkro pattern (Motoko3) and I made it with the minimum of tools. I have no affiliation with Dieselpunkro but from recollection I know he has some mask patterns.

-

You don't say how you're fixing the liner. Does it have to be completely detachable? If not, could it be just glued in? How about this before you spend important money. Presumably the bottom can be just a fold over. the top can be hidden under a turned and stiched leather top seam. That just leaves the sides. If your machine won't do the job after a couple of folds, how about packing it out with a strip of leather welt which can be held in place with double sided or basting tape. Just a thought but I'm a bugger for solving problems with what's to hand before throwing money at it. Of course, if you intend production runs that's a different matter.

-

Have you ground the teeth down on that bandsaw Chuck?

-

Well done!

-

A bit more info in this old thread. Was a 170mm at that time, changed it again later.

-

If I had a memory I'd be dangerous and I did this a few years ago. I'll try to find it but remember I'm in the UK and if IRC I bought it from a local engineers supply unit. They're really easy to use though because it comes in two parts. Each size of center piece is matched up with a series of sizes of the pulley itself. You marry the two with the set screws you can see at the joining point. This one has a 250mm pulley. The Adler 69 that I sold a while back had a 270mm pulley but likely had the same size center.

-

And they're easily available in all sizes and much cheaper than the normal speed reducer. Iirc the whole thing ,pullies and belt cost around £40.

-

With servo motor and replacement handwheel and servo pullies to give speed control and extra torque. Will do a stitch at a time. Forgive the video quality and sketchy use. I haven't touched this machine for a very long time. Located in Chatham, Kent, UK. Pickup only. £850. Price drop; £650 Durkopp 239 with converted handwheel for extra torque and slower speeds..

-

They're generally called 801 skivers and there's no reason why it shouldn't be great. When I made a wallet for myself I skived it to death. It's an eleven pocket bifold and is really thin when fully loaded. They're pretty simple machines and most parts are easy to find.

-

I can't offer much because my 341 came fully built with a speed reducer which of course improves the torque. Also when I asked for confirmation of anything like does it go in the same hole in reverse for instance, it was my actual machine that they videoed

-

Now you're just trying to blind me with science. All I know is my machine works perfectly well with one thread coming from the bobbin. All I'm saying is take the bobbin away. That's all. The bobbin case doesn't move.

-

But NOTHING would change! I'm not talking about changing anything. Imagine no bobbin, just a tube coming up about a half inch from the inside bed of the hook or the bottom of where the bobbin used to sit. now imagine a thread coming out of that tube and going through the same slit and tension spring in the bobbin case as it does now. If you can't see that you have to tell me why because nothing changes.

-

I never professed to be a sewing machine expert. What I said was IF you could get a tube coming from below into the the bobbin space through the center of the revolving hook mechanism without interfering with the hook mechanism it could work. The cone thread would simply relave the bobbin thread. Everything else doesn't change one little bit. I was talking about a normal horizontal bobbin. At no time was I talking about any other mechanism and certainly not moving shuttles. Are you saying that IN PRINCIPLE it couldn't work Wiz?

-

The bit I hate is when you're about to start a decent run. You have to check the bobin and then 9 time out of 10 you waste what's left on there and put in a new one to make sure it's not gonna run out.

-

From a cone sitting somewhere below. It's the principle I'm trying to get across. I know it's possible. The route that the thread takes from the cone is something sewing machine people can work out. I imagine a tube of some kind that's sealed at both ends so as not to interfere with oiling and such.

-

I'm gonna try just once more because I can see what you can't and I know there must be others out there that know I'm right but they're not coming forward so I'm gonna leave it after this post. I'm beginning to think you must be a troll windind me up . Either that or YOUR picture is so strong in your head that you can't see what I'm talking about. Let's get back to basics. The bobbin THREAD, not the bobbin itself comes from the bobbin, goes through the tension mechanism in the bobbin case and is picked up by the hook along with the top thread right? From there the hook carries the top thread and the bobbin thread around the bobbin case and comes back to where we started. Now let's go back to where we started. ie, the bobbin THREAD coming from the slit and the tension mechanism. Now. just humour me and imagine that NONE of that process is changed at all EXCEPT that there's NO bobbin at all. What used to be called the bobbin thread is now called something else because there is no bobbin any more, just a thread coming up from the center of the space that the bobbin used to occupy in the center of the bottom of the hook mechanism and going through the same tension mechanism as usual. If you can't see it now I give in.

-

OMG! You said, "you can't just wrap a single strand of top thread around the bobbin thread without the entire bobbin spool passing thru the loop of the top thread." That's EXACTLY what happens every time a stitch is made. The bobbin doesn't move AT ALL. The only thing that moves is the hook. Show me where the bobbin leaves where it sits and passes through anything? If you're talking about the thread going AROUND the bobbin CASE that also doesn't move, I'm not suggesting that that will change, in fact nothing will change from the way it works now except the thread coming up from the center of the revolving hook.

-

Of course that's relevant and I don't understand what goes on underneath the hook but can you not agree that IF you could get a sealed tube coming from below, going through the center of the hook so it doesn't interfere with it and coming out where the bobbin current sits it at least SEEMS like it would work?

.jpg.d60258221c476480a6e073a8805645bb.jpg)