-

Posts

328 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by rawcustom

-

SV-90 Fillet Knife with Mammoth Ivory Handle

rawcustom posted a gallery image in Gallery- Our Leatherwork

From the album: Knives and Sheaths

-

SV-90 Fillet Knife with Mammoth Ivory Handle

rawcustom posted a gallery image in Gallery- Our Leatherwork

From the album: Knives and Sheaths

-

Trinity Knot Notebook

rawcustom replied to Bob Blea's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice, I really like it.- 19 replies

-

- celtic knot

- padfolio

-

(and 1 more)

Tagged with:

-

Thank you. Spring time I get more requests for the fishing knives, but usually my smaller neck knives. The scandinavian style sheath has some distinct advantages for the the longer thin fillet knives with the carved wooden insert. About to start the next one that is about twice the size of the fillet knife on this thread, so glad I got in some practice first. Thanks again for all the comments.

-

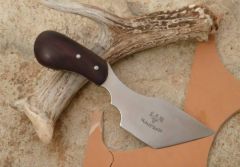

Head Knife Vs. Skiving Knife

rawcustom replied to MonicaJacobson's topic in Leatherwork Conversation

-

Head Knife Vs. Skiving Knife

rawcustom replied to MonicaJacobson's topic in Leatherwork Conversation

Monica, I make skiving knives as well as many others and I can tell you that I like my skiving knife in equal parts to my head knife. You can skive easily with a well sharpened head knife, but there are tasks my skiving knife can perform more easily than my head knife. One of my most common skiving tasks is tapering belt loops on knife sheaths, and I find the straight edge of my skiver is easier to use than the rounded head knife. I also use mine for cutting bevels on sheath welts or acting as an edger and the sharp point can double for a trim knife on reaching tight corners, although I have my own trim knife as well. There is a lot of conjecture on different steels and uses. High speed tool steels should not be demonized as some make excellent knife blades. Steel performance will be based off of how the steel is made (homogenous dispersion of alloys and impurities), what the steel is made of (wear resistant alloys, or corrosion resistant alloys) and lastly how the steel is heat treated. As a knifemaker I use and test many different alloys for many different applications, and each have a place and more is personal taste. Better steels from good makers will cost more, because the steel costs more, it's much more difficult to work, and most of us pay a professional service to heat treat and hardness test the blade to ensure it meets our required specifications. Simple steel AKA "High Carbon" is cheap, abundant, easy to heat treat, and easier to work. A big myth is finding steel that will "sharpen easy" and also "hold an edge". The exact properties that will allow a knife to hold it's edge (wear resistance) will resist sharpening efforts since this is just a directed wear effect. There is some truth on the finished grind angle coming into play, that would change the amount of steel required to be removed to sharpen, i.e. thin edges will have less steel and therefore sharpen faster than a thick chisel edge. The main thing with leather tools is maintenance. Since your tools work best sharp, you should be in the habit of stropping everything before, during and even after use. The more you stay on top, the less problems you will have with trying to sharpen a severely dull knife later. The best knife steels I have found for leather are the high alloyed steels, some classified as high speed steel. The wear resistant alloys keep them sharper much longer, their higher hardness allows them to become sharper than that possible of simple steels, and the ones made correctly can do all of this without being edge chippy or brittle. I love sharp edges that stay sharp, so I'm not a fan of the high carbon simple steels in my leather work. I have played with them a lot, but they just require a lot more breaks for stropping, or stoning to keep that surgical edge. -

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools

-

From the album: Custom Leatherworking Knives and Tools