-

Posts

961 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by BDAZ

-

Yup, Started on Photoshop beta in the 80s.

- 26 replies

-

- bevelingislife

- celtic

-

(and 1 more)

Tagged with:

-

I did almost the identical graphic in this tutorial the other day, which I downloaded via Google. First I drop it into Photoshop. Next I eliminate any background, usually white. If it is a .png it may already be on a transparent background. The I select the remaining image and create a new layer. I fill the layer with white and stroke it with a 3 pixel stroke. Could be wider, but 3 pixels is the width of a knife cut. Then I reverse the image and print it on standard paper. I apply it to the leather and either iron it (at least 260F) on or use my press or saturate the paper with alcohol and use a creaser. If it was sa a photograph, I would trace it on a new layer in photoshop and then print as above.

- 26 replies

-

- bevelingislife

- celtic

-

(and 1 more)

Tagged with:

-

While blowing mesquite fronds off my xeriscape front yard (crushed rock) I stumbled into a small prickly pear cactus. I nailed both ankles with tiny hairlike spines. I tried tweezers but I can's get close enough to see them. Getting the side of my ankle next to my face is a talent I have long not been able to do, if ever. I noticed the barge cement on my shelf, pained a couple coats on the affected areas. Once dried I peeled the cement off and wala! All the spines went with it. If you live in the NE/SE/NW disregard this thread! Bob

-

Not sure what you mean? I just finished a piece and the lines of toner are obliterated by the cuts. I make my lines 3 pixels. BTW I like your idea of using the bevel first. I used small modeling spoon instead and made the actual beveling much easier, faster and smoother. Thanks! Always a new tweak in this business!

- 26 replies

-

- bevelingislife

- celtic

-

(and 1 more)

Tagged with:

-

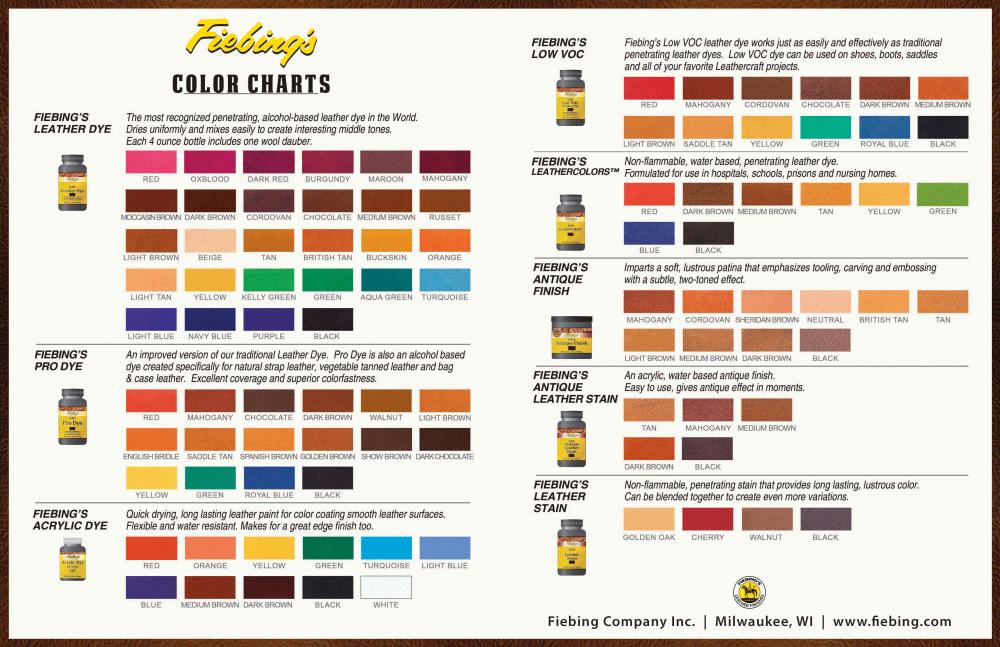

What I would do is test the standard dark brown against what you already have dyed. I ran both colors through Photoshop and Med Brown is really close to Pro Dark Brown. Here are the RGB numbers for both: Pro 135-61-32 Dark Brown Dye 136-63-31 Medium Brown Dye 82-30-17 Dark Brown If the color chart is accurate, then medium brown should give you an almost identical brown to the Pro Dark Brown. Bob

-

IMHO a walking foot machine is essential for leatherwork, unless you are doing garments or upholstery. There's a reason that 99% of leather workers use walking foot machines. My former CEO when I was based in London used to say that only the poor or uniformed can afford to buy twice. I learned that lesson long ago. I bought my 3200 when I really couldn't imagine I would need the capacity, but I also new I could recoup my investment if I decided to sell it, since walking foot machines are so much in demand. If you are a hobbyist, then stick with hand stitching, time spend is immaterial and it's cheap. If you intend to make items commercially, go with a 3200 or 4500 or similar machines from Cobra. Reliable, affordable and proven technology. Bob

-

Just a tip. I take my design, reverse print it on a laser printer then place it on the piece toner side down, saturate the design with acetone, then either use a creaser or even better a hot iron or press at 250F, which will transfer the toner onto the leather. I also use this on suede when someone wants some text on a piece or a signature. Bob

- 26 replies

-

- bevelingislife

- celtic

-

(and 1 more)

Tagged with:

-

From Cowboy Bob's Wesite: The Cowboy CB2500 has feed dogs to move the material, against a fixed, or roller presser foot. This may leave visible tooth marks in the bottom layer of leather. These marks can usually be rubbed out with a smoothing tool, or hammered out by laying the back layer on a smooth hard surface, covering the top with a 10-12 oz piece of hard veg-tan leather, and tapping along the stitch line with a mallet or hammer. If this sounds like too much work, you may want to consider buying one of our triple feed machines, with a smooth feed dog and walking feet. IMHO, give it a miss!

-

Just to further Hanna's comments, cost should NOT be the deciding factor. Decide what machine you NEED and then figure out how to pay for it. Bob

-

Consulting the MSDS of bothe the Pro and Regular, I see little difference, which may be in the percentages used of various alcohols in each formulation, Maybe the ingredients in the Pro cost more so can add the word pro and charge more. I'd test dye a piece of scrap and see how close it is to the original Pro color. I use the standard Feibings dyes. Bob

-

It's all about training. So that's why you have the basenji!

-

I thought you would have an Elkhund or Buhund. I have been watching a number of Norwegian TV series and always keep an eye out for local dog breeds. I used to own a German Spitz and my last girlfriend has 6 border collies. I gave up on leather for the collies and went with BioThane® Coated Webbing. Bob

-

Well I sell all my items so a balance of durability, aesthetics and cost (man hours) are critical. If it's a hobby for you, then go to town. I had a boss once who gave me some really good advice: "never love anything that can't love you back."

-

Bad logic! A bounce means that the energy is being deflected and not doubled. A dead blow transfers all of the energy to the work precisely because it doesn't bounce. I have a 2 lb and a 4lb and use them primarily for hole and slot punches. I use a 2 ton arbor for all my 3D stamping and a poly mallet for stamping. For rivets I use a short handles steel hammer. Best source for dead blows in Harbor Freight Bob

-

I would beg to differ from my neighbor to the North and laminate the goat and cow together and then trim to get a perfect edge which can be edged and finished with dye and waxed. A dog collar is going to get some heavy use and I would worry about the glue delaminating at the centers. I have made a number of lined dog collars for a breeder and trainer and they really took a beating, especially playing fetchit at the river (in NC ot Tucson). Might work for a ladies belt but I would go with a simpler, tougher solution. Bob

-

I was in a similar situation and went for the Cowboy 3200 and it was one of the best investments i have made. Based on having that machine, I was able to turn my hobby into a business and have paid for the machine many times over. The efficiency and timesaving a high quality machine is tough to beat and the 3200 is well priced and will do almost everything the larger machines will do. The 3200 is only $400 more than the Outlaw. If you wanted to work in an environment that had no electricity like maybe craft shows, ren fests or Syria, it would be a great choice, but there are some quirks including having to lift the needle to turn the work, and using one hand to guide the work and the other to stitch. I often need both hands. Bob

-

-

Just finished an order for a name in Hebrew.. I cut the letters, bevel all cut edges and then use a backgrounder to "lower the background and add texture. In this case the textured background is painted black with USMC Blach,and the letters are painted metallic gold. Bob

-

I competed nationally in FITA and I would have been very pleased to have a rig like that! Well done! Bob

-

Not yet. I don't believe edge paint would stick to the silicone but if the silicone could be used as a combination filler/edge dressing, that could be the business. To that end I am playing with a slot with a small rounded end that can be used to run a perfect bead of silicone across the top of the edge producing a perfect rounded silicone edge and fill. Black silicone would be perfect. Will definitely try the corn starch as well. Thanks! Bob

- 48 replies

-

Thanks for the input but a quick set solution is essential. Bob

- 48 replies

-

You wont be sorry. Get a batch of snaps too.

- 11 replies

-

- arbor press

- stamping

-

(and 4 more)

Tagged with:

-

I only use #24 snaps and use both Gold Star's and Tandy and all are perfect! I position a 4 ton jack next to the rear and set up the press so that the fully extended handle is resting on the jack at a low angle. Then I simple crank the jack to the level I want . The 2 ton arbor press is definitely overbuilt but I don't push it. I generally use it for smaller embossing plates when I want to maintain pressure for a while to get a good impression. Bob

- 11 replies

-

- arbor press

- stamping

-

(and 4 more)

Tagged with:

-

My first impression after seeing the photograph was Cobra. I have seen a number of cobras, in situ, when I lived in Africa. The most common was the spitting cobra, but there are many varieties that are marked with patterns, etc. This is definitely a snake you don't want hanging around in your backyard. Bob