-

Posts

4,513 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by TwinOaks

-

It sounds like the dye you're using isn't 'light fast'. My suggestion is to find a similar color in Fiebing's Oil Dyes, recolor, and then seal with Resolene. Resolene is an acrylic based sealer that also has a UV blocker in it. So, use one of the better dyes and then protect the dye from sun bleaching.

-

Go with the machine for which you can get the most info, accessories, and parts. Sewing-wise, either should be fine for light to medium work.

-

can we get a pic of the top piece with the bottom of the tool facing the camera?

-

'being square' is just a term I've picked up from lots of building/repairing of things- it means that one surface is perpendicular to the other. In this case, if the stamping tool is vertical, the maul/mallet face should be horizontal at the time of the blow. If you hold the maul at an angle, either it or the stamping tool will deflect to the side when the strike is made. There is a smaller 'sweet spot' with a round mallet face, but I've found that to be a good thing. It made me learn to control my strikes and hit the tool properly, as opposed to looking like I was playing 'whack-a-mole'. Even with my wooden mallets (with flat faces), I started to get a hole in the center of the face. That just means that you're consistent in how you hold and strike with the tool.

-

Wallet Strap....stitching Is Deforming The Edge Of The Strap..

TwinOaks replied to thekid77's topic in How Do I Do That?

The needle is pushing leather out of the way when it goes through, so if it's deforming the edge, there are two easy options- move the needle further in, or move the edge further out. On the second suggestion....what I mean is make the strap and complete your sewing before trimming the final edge width. Just make it slightly over sized. You might also look at how the edge is being supported. If the leather is 'floppy' then, yes, it's too soft for the way you're stitching. you'll just have to change the way you're holding the leather. It might also be the stitch spacing, or the tension on the stitches. -

Billfold And Question

TwinOaks replied to Avion's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

First you need to be absolutely sure of the type of leather you're using. Only veg-tan leather will tool correctly with hand tools. Your plan on making the pattern/design is spot on and should look just fine. I suggest practicing the design WITH backgrounding a few times so you can see what the options are. -

Patent Infringement: Shotgun Concho Dog Collar

TwinOaks replied to HellcatLeathers's topic in Patterns and Templates

Karma definitely ran over his dogma -

Vertical Holster Press - Kydex / Leather Former

TwinOaks replied to RMB Custom Leather's topic in Suppliers

product link is dead -

Keeping It Natural

TwinOaks replied to novaroper's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

You can apply a sealer as a resist over everything, then carefully strip it from the tooling, or you can apply a mask over everything else and carefully use a brush or spray. Or, you could simply color the tooled area without masking off everything else, but be wary of drips as you move over the areas you don't want any color. -

If you'll double check the last post, Oxalic acid is also used in cleaning agents, and in wood bleach. As you are in Germany, I don't know what the equivalent terms would be. Acetone will probably NOT work, as the spots are caused by a chemical reaction between the metal and the leather. You can spend several hours reading up on this in several of the "vinegaroon" topics. The use of a mild acid to clean the spots most likely results in another chemical reaction - between the acid and the products of the reaction that caused the spots in the first place.

-

Neeedles & Awls For Champion Peerless 30 Stitcher

TwinOaks replied to Blade 1's topic in Leatherwork Conversation

Welcome to the best site on the internet! Here's one source you can check http://www.campbell-randall.com/ -

Local hardware store- You'll need a t-nut, a bolt, a finish washer (aka 'cup washer'), and about 1/2" of rubber hose from the plumbing section.

-

Help Sharpening Vergez Blanchard L'indispensable Knife

TwinOaks replied to apriori's topic in How Do I Do That?

It might be the 'pulling back' that's the issue. When you get the edge extremely thin it will actually bend to the side while sharpening. That's called a 'burr'. The edge will just kinda flop back and forth, but on a veeeeeeery small scale. Then, when you try to cut something, that edge rolls right over and you're trying to cut with a rounded edge. Try pushing the blade forward, which remove the burr, then strop at an angle.....as in don't pull the blade straight back on the strop, pull like you're slicing something. That will have the strop polishing across the grind marks. And if you do have the curved blade...just pull along the curve, like stropping a round knife. -

Recommendations For Cylinder Bed Walking Foot Machines

TwinOaks replied to Vikefan's topic in Leatherwork Conversation

Short answer- it depends on what you want to sew. Long-ish answer - If you're going to be sewing extra heavy duty leather...oh, say right at an inch thick...I'd say a campbell-randall. If you'll be sewing a wider range of fairly heavy duty things - holsters, belts, saddles, you might want to look at one of the big cylinder arm machines from Adler, Cobra, Cowboy, or Techsew (Adler 205, Cobra class 3 or 4, Cowboy 3200, 3500, 4500, Techsew 5100). While the stated range of these machines is one thing, most user reports on here say that anything less than 6oz is below the useable range for these machines. So, consider them a med. to heavy duty machine. If you'll be sewing light to medium weight things- bags, chaps, some belts, etc., then you'll want to look at some of the medum weight stitchers - Adler, Consew, Pfaff, Juki...they all have a machine in that range. Check out the sewing machine dealers in the ads at the top of the page. Cobra and Cowboy have a long running reputation among our members, and Nick-o-sew is fairly new to the site....not the business. However, I've personally spoken with Nick about a type of machine for the work I want to do, and the conversation gives me a lot of confidence that he knows what he's doing with the machines. (Sorry Steve, he offers a type that Cobra doesn't currently carry) Once you haver narrowed down the type of machine you want, call and talk to the dealers or their staff to see how much machine you can get for the money, and go with the dealer that can offer you the best deal. Also consider their location, as shipping will likely effect the price. -

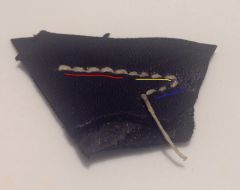

From the album: D.M.DeLoach Custom Leather

-

D.M.DeLoach Custom Leather

Images added to a gallery album owned by TwinOaks in Our Leatherwork Galleries

-

From the album: D.M.DeLoach Custom Leather

-

This thread explains what you should be looking for http://leatherworker.net/forum/index.php?showtopic=25239 There IS a "walking foot" attachment that can be put on a straight stitch machine but it is NOT the same thing- it only mimics a true walking foot. If you're going to be sewing leather, just get a walking foot or jumpfoot to begin with.

-

6 or 8 plait round, or 10-12 plait flat or half round in Roo, with paracord as the core. For flat straps, lay two strips of paracord side by side and secure with some small tie strings. For adjustment, how about an eye braided into the end of the cross piece, and a few small buttons braided onto the ends of the larger piece? The nose band ends would sit between the buttons, but could be worked up/over the buttons to adjust the size. The paracord core should give plenty of strength, as each one of them has a 550lb tensile strength.

-

that was from 'uship.com'. But notice, that they are only listing freight companies. You might do better contacting one of them directly. check into freight shippers, and if at all possible, put it on a small pallet. You can build the 'crate' around it out of OSB and 1x2s. You should be able to get a small pallet from just about any large box store, or even from some drink vendors. Placing it on the pallet will keep you in the good graces of the people who have to move it around.

-

I'd like to suggest re-checking some of your sources for products. I just pulled up Zelikovitz's website and compared prices with Tandy. Wow, it was a bit of a surprise that the same product from Zeli is about 20% LESS expensive....and that's for Fiebing's Pro Oil Dyes. For the water based dye, which I presume is akin to the Pro Waterstain retail prices are closer, but Zeli sells in smaller bottles. For the same amount it's (Z) $13.98 for 8oz vs. (T)$15.99 for 8.5oz. And since Zeli is already in Canada (Ottowa, Ontario), you don't have those pesky import tarrifs to deal with. Now, since you've got the VAT, the prices actually come out about equal. The way to get the prices down is to become a business and buy at wholesale. "But that requires $$ for a business license, more accounting, quarterly taxes, yada, yada, yada...." What? You thought that becoming a manufacturer with a couple of hundred (thousand?) hides in the back yard, a warehouse full of chemical vats, and 55 gallon drums of homemade dye was going to be cheap??? I commend you for wanting to know how to do things yourself. I think knowledge is one of the most valuable/important things you can have. But you also need to know your own limitations.

-

From the album: D.M.DeLoach Custom Leather

-

From the album: D.M.DeLoach Custom Leather