-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

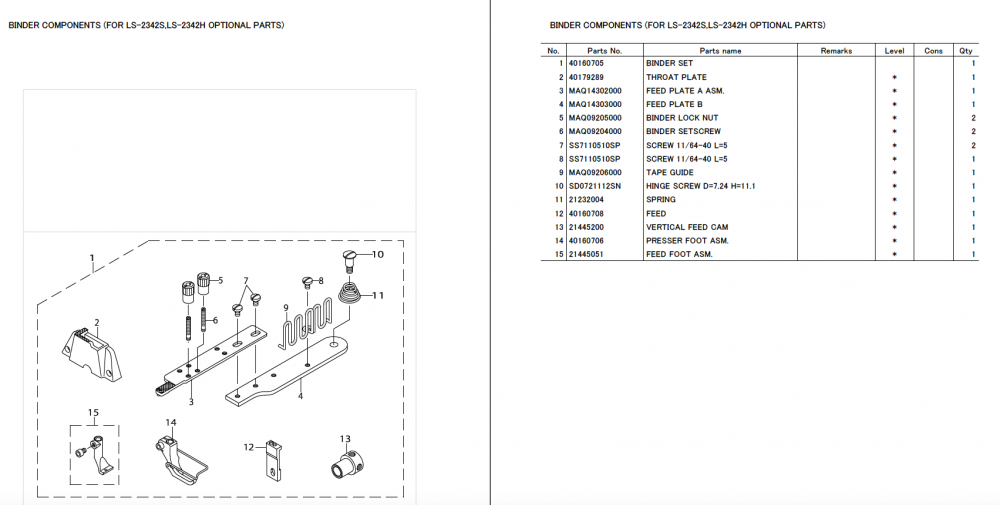

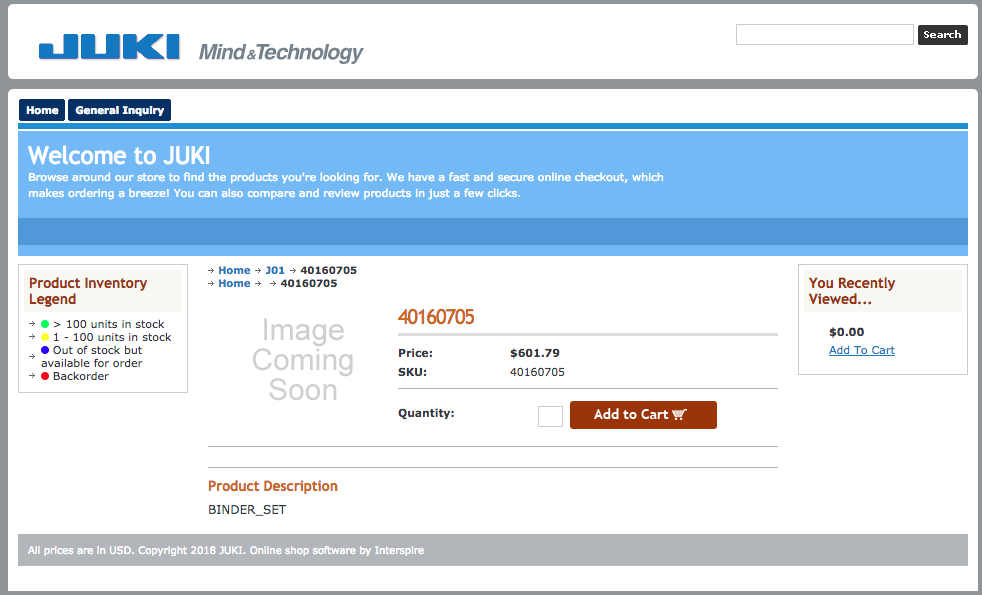

For what it's worth, the Juki LS-2342 Parts List (Juki LS-2342 Parts List.pdf) does show a set of synchronized binder parts on Page 57: Notably, the set of parts includes a vertical feed cam, apparently to "turn off" the vertical feed dog movement for binding mode. Second notable detail is that the Feed Plate A arm (part #3) rests on top of the feed dog (with a registration pin) and has a knurled tip, which acts as the actual bottom feeding surface. Looks like they put some thought into this. Cost of the Juki LS-2342 binder parts set is $601 on the Juki Americas online parts store:

-

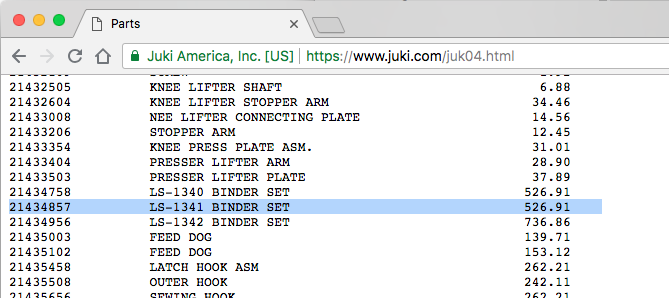

I have a feeling they didn't sell many kits and it just wasn't worth bothering. At $526.91 ten years ago, it wasn't exactly cheap. Even today with more machines and clones in circulation, I'm estimating the potential customer base among the LW crowd who are willing to fork over that kind of money for a binder kit is in the very low single digits. Most people in the business of binding don't bother trying to make off-the-shelf binders work. They just have a custom binder made that is perfect for one single application. Juki may still make and sell some individual items in the kit, I'm not sure. Here's a screenshot of the Juki 2008 parts price list:

-

That’s quite impressive! Thanks for sharing some real world evidence of what the machine can do at the limits.

-

We need somebody who has an actual machine to check if the machine can still make 7mm tall steps even if you put 12mm of material under the feet. Often machines can make full size steps on top of the maximum material they can take under feet.

-

No, it means the machine can walk with 7mm high steps on top of the material, no matter how thick the material is. In theory, if you put 14mm of felt material under the feet, the feet should still be able to walk with 7mm high steps on top of the 14mm of material.

-

Converting triple feed machine to needle feed

Uwe replied to raWorkshope's topic in Leather Sewing Machines

Yes, the rear foot will stay down. It only lifts if the front foot presses against something. $150 is indeed a lot for a Singer style presser foot, it seems. They may have some New-Old-Stock that, when it's gone, it'll be gone for good. I'd better store my precious Singer 240029 foot in a safe until I can find a buyer who can secure financing. I found one more alternative in my stash: an original Simanco USA two-part foot with top No. 93813 and bottom No. 203013, but they seem to be just as rare as the other foot. If I find any more I'll be able to retire early. I'm willing to let go of one of my super precious presser feet for $50 shipped within the US (send me a PM if interested.) Here's the picture of the second candidate (I have two, rear is new-old-stock, front is slightly used.) -

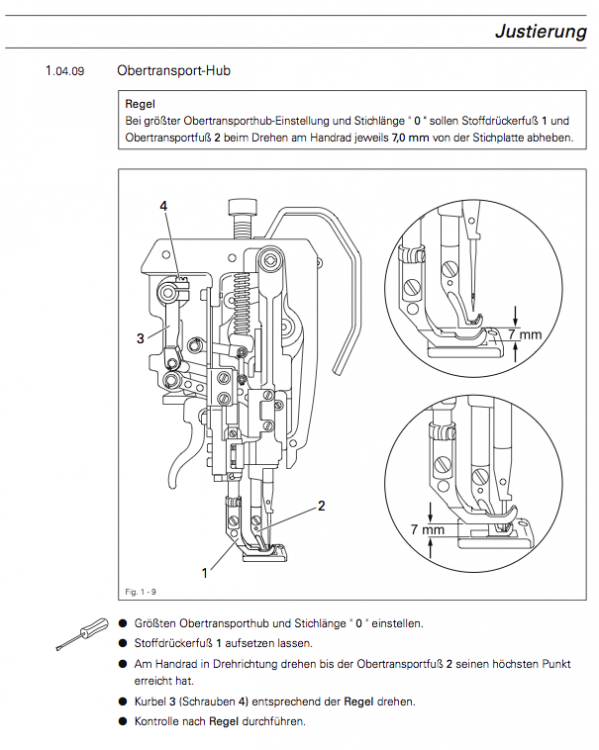

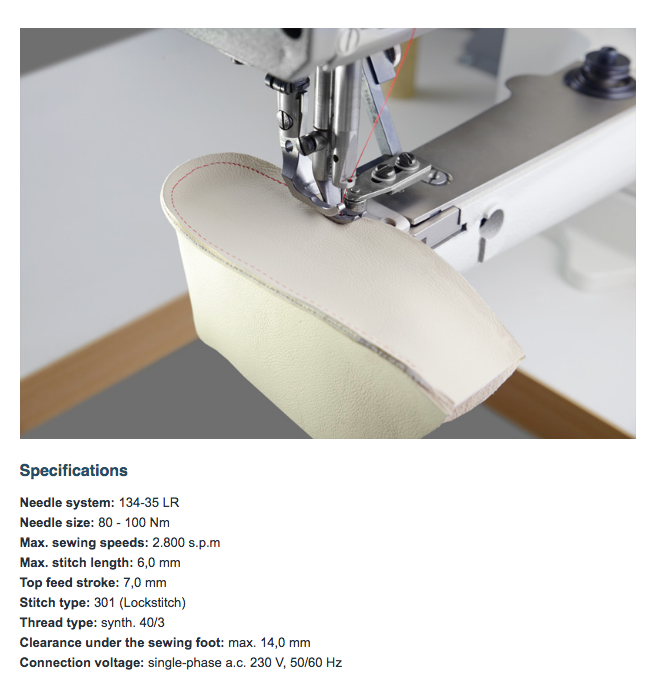

I think the 7mm figure is referring to the maximum walking height of the feet as they walk (called "top feed stroke" in the specs below.) The Service manual shows this: The old casting of the Pfaff 335 was built with four different foot lift heights (maximum clearance under the feet): H1, H2, H3, and H4 . I don't see any such differentiation for the new casting of the Paff 335. They list just one figure for maximum clearance under the foot: 14mm (https://www.pfaff-industrial.com/en/portfolio/sewing-machines/cylinder-arm/pfaff335) .

-

If there's LocTite (a variation on Superglue or Cyanoacrylate) involved, the heat from a torch will soften the glue - which is what Wiz was referring to, I think. Lacking a torch, Acetone (nail polish remover) may be worth a try. Just pour some into the threaded hole and let it sit overnight. It may dissolve the glue enough to let the screw go.

-

Converting triple feed machine to needle feed

Uwe replied to raWorkshope's topic in Leather Sewing Machines

You should be able to just remove the front walking (or vibrating) foot and install a slotted needle feed presser foot on the rear presser bar. They come in two styles, so you don't really have to rotate the presser bar. Below are pictures of two Singer style needle feed feet I have, showing the two different mounting orientation. The left foot is one example of a slotted needle feed foot that can be installed on a Singer 111W155 without rotating the presser bar (Singer Part No. 240029, this one's made in W. Germany) -

Very few of the normal pricing guidelines apply to Hawaii. Some things are cheaper because you're much closer to the Asian manufacturers, but many things get the very-remote-island markup. You probably know best what new machines cost in Hawaii. Take a third off and you have fair deal on a good used machine, half off is a very good deal, two thirds off is a bargain. Much depends on the condition of the machine, as always.

-

100 years ago most people bought new industrial sewing machines from the companies that designed AND built them. There was a small cobbler or shoe repair shop in most villages or neighborhoods, which accounted for a good portion of new machine sales. The needs of those small shops that needed versatile machines entered into the design of the machines back then. Nowadays, I suspect that cobblers, small custom shops and hobbyists account for well below 1% of new industrial machine sales from Juki, Durkopp Adler, or any of the other OEM manufacturers who still develop new machine designs. It makes no economic sense for them to spend effort on design requirements of such a tiny demographic. They design for the big companies who set up production facilities with hundreds of single-purpose machines. Those companies do not want table attachments. They want a separate workstation for every production step. If they need a flatbed for one production step, they just use a flatbed machine. The old-but-not-ancient cylinder arm machine designs like the Juki TSC-441, Juki LS-341, Durkopp Adler 205, and several others actually DO have one or more accessory mount points integrated into the cylinder arm. The OEM companies just never designed or produced a flatbed table attachment for those machines, at least to my knowledge. I highly doubt Juki was involved in the design of the standard, table-mounted flatbed table that you can buy from the 441 clone dealers.

-

Thanks for the endorsment @Joon1911! Below is the installation video for my UT-441 flatbed attachment (I'm working on another batch and they'll be in stock again next week.) The flatbed attachment may look simple and obvious now, but it was a bit of an engineering challenge to come up with a design that uses existing mount points while making it functional, solid, and easy to mount.

-

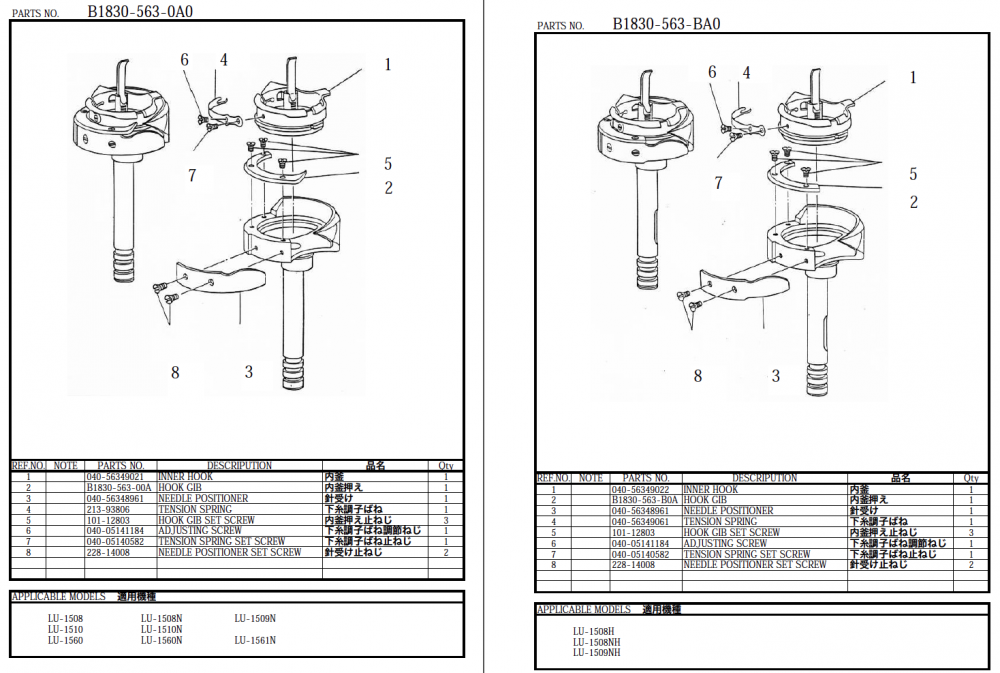

Here's the side-by-side parts list of the two hooks you can install in a Juki LU-563: Standard: B1830-563-0A0 Thick Thread: B1830-563-BA0 Both hooks were carried over to the later Juki LU-1500 Series of machines.

-

The feed eccentric unit may bind up due to dried oil or dirt before it reaches the limits of its adjustment travel, which could limit stitch length. I'm working on a video on how to take the feed eccentric assembly apart for cleaning and how to adjust the friction gib - hopefully i'll get it done soon.

- 10 replies

-

- juki

- adjustment

-

(and 1 more)

Tagged with:

-

Juki 341 clone thread path felted wool pad

Uwe replied to HardenGoods's topic in Leather Sewing Machines

My Juki LS-341 has a felt pad. The purpose is likely to soak the felt with Silicone or similar lubricant to coat the thread as it passes by. I have a feeling this pad goes missing on a lot of used machines, but new ones should definitely have it. -

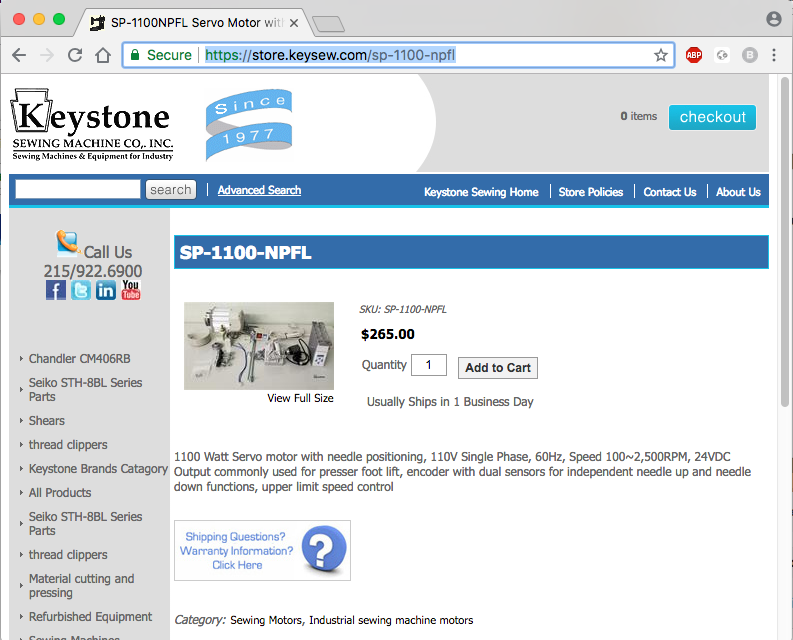

I believe that is the slowest maximum speed you can dial in. In other news, just realized that the SP-1100 motor is also available from @Gregg From Keystone Sewing with quick and easy online ordering. I'm glad to see that type of motor offered by additional vendors.

-

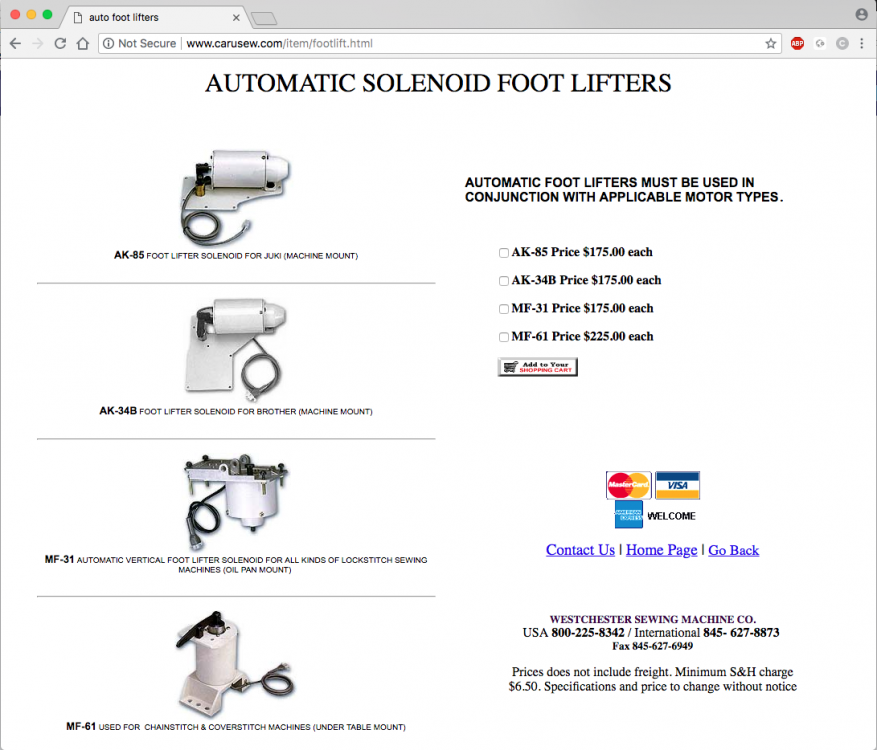

Turns out foot lift solenoids are actually a thing and readily available. I should have Googled "foot lift solenoid" a year ago. Here's one example of commercially available units:

-

I'd love to find out more about that solenoid you're using, @Gregg From Keystone Sewing! Is that solenoid an industry standard part that one can buy at Grainger or McMaster-Carr, or is it some specialized part that you by chance sell separately? I experimented once with an electric solenoid to make an electric foot lift but failed miserably. My solenoid was a 110V door latching solenoid. It closed with a BANG but wasn't nearly strong enough to move the foot lift lever directly. It didn't even occur to me that a 24V output in the controller box could directly drive a solenoid strong enough to actuate the foot lift lever. Perhaps the linkage levers increase the pulling power just enough. We should probably spin off the recent foot lift discussion into a separate topic if it's not too late.

-

I know it's been well over a year, but that output is used to control a solenoid air valve to pressurize a foot lift air cylinder when you heel the pedal.

-

There are a few modern servo motors out there that have very high power and torque and a very slow starting speed of 100 RPM (most servos start around 300 RPM). But these motors are hard to find. One US based vendor is SewPro, who sells the SP-1100, check this topic for details: I was looking for an alternative to the SewPro motors and eventually ordered some 1,000 W servo motors directly from a manufacturer on Alibaba earlier this year for testing. Turns out the motors are very nice and they even installed small 50mm pulleys for me at the factory. My main requirements were: 1KW power, separate motor, controller, and speed input components for flexible mounting, 100 RPM starting speed, 50mm pulley, needle position sensor option, intuitive keypad with quick and direct speed control buttons and a dedicated needle position button with Up/Down/Off modes. It took me months to find this one. I'm NOT planning to re-sell these motors, which is why I'm sharing the sourcing info here. Downside of sorts is you have to buy them in multiples of four motors. Shipping via air express was quick but pricey and a bit sketchy - DHL is just as bad as the other guys. Luckily all four motors survived the rough handling. Next time I'll order enough motors to ship them on a pallet via ocean freight. I have plenty of machines that need motors. Alibaba is really a Businees-to-Business marketplace and not geared towards end users. It's definitely not like Amazon. Alibaba works best if you have a sense of adventure, enjoy the occasional gamble, and have patience communicating with folks who's English may be spotty but is still way better than your Chinese.

-

I highly doubt there's a plastic tool box sturdy or big enough to ship a Singer 7 Class. I have a modern version of the Singer 7 that's still in the shipping crate. Here's a picture of it just to give you an idea of how to ship them if you care about the machine's survival. It's really forklift territory. No human will lift or move this by hand.

-

Need some explaining did please. Singer 111-151

Uwe replied to Stetson912's topic in Leather Sewing Machines

If the bill you're trying to fit is holsters and gun belts, then the Singer 111W151 isn't quite the right candidate. These kind of topics nearly always end up with recommendations of a Juki TSC-441 class machine like Cowboy CB-4500/Cobra Class 4/Techsew 5100 and other clones. -

Just to clarify, the machines in the picture above and the CL ad are Singer 97-10 models, not 95-10. The Singer 95-10 looks like this:

-

Those are Singer 291 bobbin cases, not Durkopp 291 bobbin case caps. College Sewing in the U.K. has the caps: https://www.college-sewing.co.uk/store/295001426-B_CASE-CAP-DURKOPP-N291-GENUINE The Durkopp 291 bobbin case cap issue should be a separate topic as it has little to do with 3-phase converters.

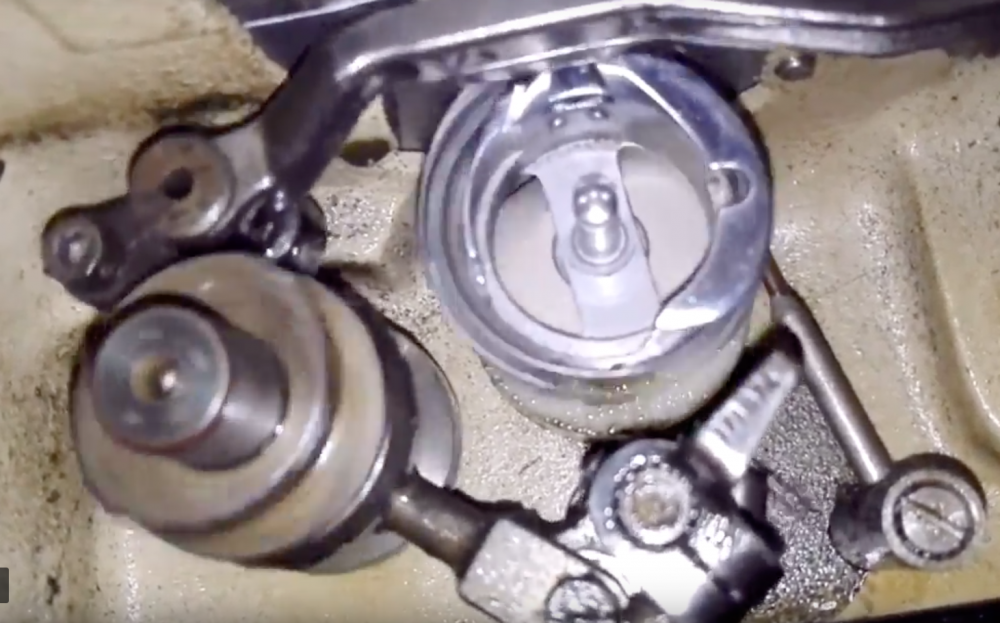

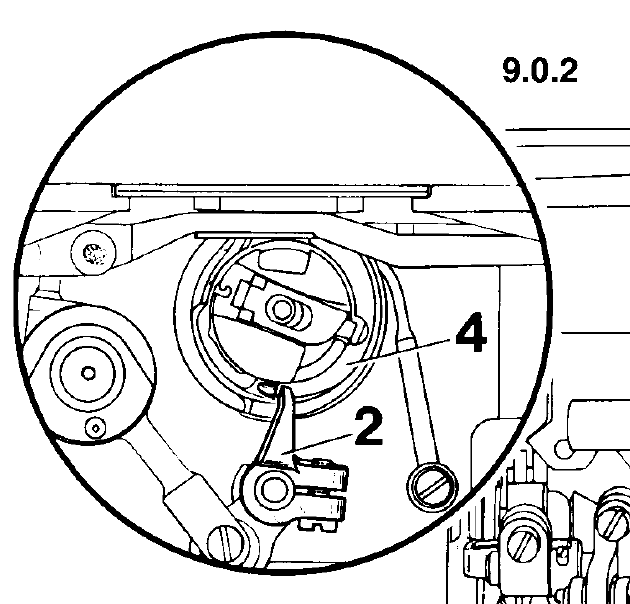

-

The Pfaff 463 Service manual ( 463 463H(3-86.pdf ) generally provides all the information you need to verify proper adjustments and make changes if necessary. Often the diagrams tell most of the story and the text just provides some specifics. Google translate often makes just as much sense as the official translated manuals. You may be able to fill in some details or replace words yourself because you know what part they are talking about by the number reference in the diagram. Then again, after reading the adjustment procedure for the bobbin case opener in English just now, I feel your pain! Even the original German version is probably painful to read and the English translation does not make it better. Translating the already translated English to Spanish via Google may not make any sense whatsoever. We have a few Spanish speaking members who may be able to help with a few specifics or explain an adjustment in a sentence or two. Just don't ask them to translate the whole manual. Your bobbin case opener is definitely out of position: Service Manual diagram: Here's the Google translate version of my own post, just to save you a few mouse clicks: El manual de servicio de Pfaff 463 (463 463H (3-86.pdf) generalmente proporciona toda la información que necesita para verificar los ajustes adecuados y realizar cambios si es necesario. A menudo, los diagramas cuentan la mayor parte de la historia y el texto solo proporciona algunos detalles. a menudo tiene tanto sentido como los manuales traducidos oficiales. Puede completar algunos detalles o reemplazar palabras usted mismo porque sabe de qué parte están hablando por la referencia de número en el diagrama. Por otra parte, después de leer el procedimiento de ajuste para el abre-cajas de la bobina en inglés, siento su dolor. Incluso la versión original en alemán es probablemente dolorosa de leer y la traducción al inglés no lo hace mejor. Traducir la traducción del inglés al español a través de Google puede no tener ningún sentido. Tenemos algunos miembros de habla hispana que pueden ayudar con algunos detalles o explicar un ajuste en una oración o dos. Simplemente no les pidas que traduzcan todo el manual. El abridor de su caja de canillas está definitivamente fuera de posición: Diagrama de servicio manual: Video Still: