-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

Textima/Claes 230 or DDR Clone of Pfaff 335

Uwe replied to alexitbe's topic in Leather Sewing Machines

Interesting machine, Alex! That looks like a surprisingly big bobbin in that machine. I'm wondering if the feed dog goes up and down as it moves, or if it is only a horizontal movement. You're mixing up walking foot lift height with total foot lift. Your total foot lift height determines how much material you can put under the feet, and how thick your machine can sew (7mm in your case) The walking foot lift height is the up-down movement the feet make as they walk. That determines how big of a step up or down they can take, but it does not determine how thick a material they can sew. The design of your machine has very little in common with a Pfaff 335, though. Your machine is a very close relative to the Singer 108W20: I have a similar flatbed version of that design, a Singer 151W1 -

Can anybody help me with detail of this machine?

Uwe replied to Rockoboy's topic in Leather Sewing Machines

These feed-off-the-arm chainstitch machines are normally used for side seams on jeans, attaching tape, or similar operations. For $100, you can't really go wrong, though - it'll be good entertainment and learning experience no matter how it turns out. It's a gamble, though, especially if you can't find a service manual for it. I imagine it takes advanced sewing mechanic skills to keep these machines with three needles and six thread paths happy. Do a picture search and find a machine that looks very similar and has manuals available (e.g Brother DT6-926), then hope that the machines are very similar. -

The mounting screw thread is a regular/weird 9/64"-40 thread, same size and pitch as the Juki LU-562 foot mount screw. Upon closer inspection, my adapter may actually be home-made from an existing foot, by cutting/filing it just so. Hmmm, looks like a useful little CNC mill project to me. I'd probably give the mounting hole a standard metric thread size, though (M4 or M3.5).

-

Careening my Land Rover away from the cliff and back towards the topic, I stumbled across a little adapter that looks much like what @Chayse considered making. It allows installing low-shank feet on the big boys.

-

According to the Singer 111W155 manual (Singer 111W155 Manual print.pdf), these machines use System 135x17 needles (for fabric, also called DPx17 or SY3355) or System 135x16 needles (for leather, also called DPx16 or SY3378). If you type "135x17 needles" into the Ebay search field, you get 1,700 results. Any of our trusty banner vendors have these in stock, I'm pretty sure. You just have to ask for the right thing.

-

Adler 205-370 kicking out of gear

Uwe replied to ScarlettStarlett's topic in Leather Sewing Machines

I second the Youtube approach - it's THE place made for sharing videos. You can share them as "unlisted" so only the people you tell about the video will see it (as opposed to the whole world.) Many of these trouble shooting tasks come down to three general steps: 1. You need to know how things SHOULD be (and how things should move) 2. Notice which particular detail is NOT how it should be 3. Make a correction so that everything is again how it should be Step one is actually the hard part - it takes time, observational skills and lots of experience. The best way to start is to look at a machine that works exactly as it should. Then compare that to your machine and figure out how yours is different (easier said than done - put on your Sherlock Holmes hat for that step.) To help get you started I made a short video showing how my Adler 205 moves to make a stitch. Compare it to yours - pay attention to the range of motions and also the sequence of motions. Your adler may have a cover of the take-up lever. I'm also referencing two other videos that should help with step 1 - knowing how things should be. Here's the video (filmed on my iPhone 6 using a $10 selfie stick clamped to a chair. I uploaded it to Youtube in "unlisted" mode. You can upload to Youtube directly from your phone, too.) For a general operation guide to the Adler 205 you can watch this video. (Make sure your threading is correct) Lastly here's another video showing how the Adler 205 makes a stitch -

Your machine looks like a very close relative to a Brother DB2-B755. Check out the Brother DB2-B755 manual (db2b755.pdf ) and see how closely it matches up with your machine. Also, most industrial needles of this general machine class have a round shank, only domestic sewing needles have a flat side on the shank. The two types are not interchangeable. Since the needle shank is round, you have to pay attention as to how you insert it. The manual will tell you how.

-

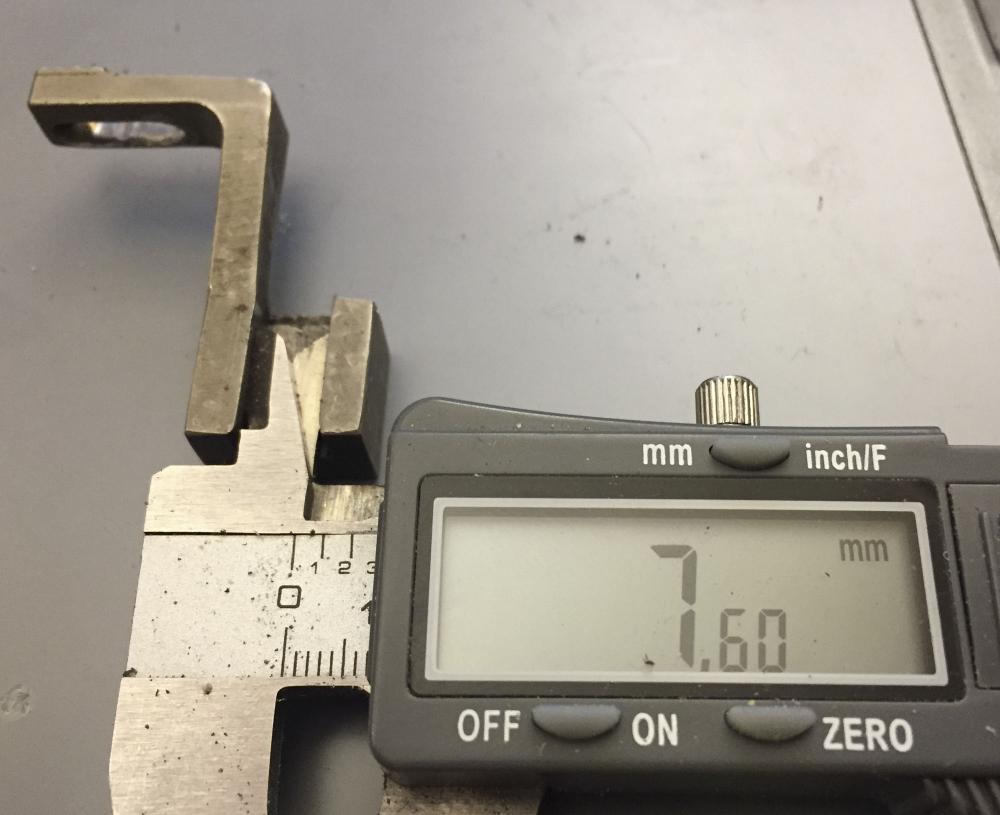

I think you might be able to use non-Adler feet on your machine, including some Singer feet. You always have the option to buy a second presser foot bar (generally inexpensive and often interchangeable with other machines) and modify it to make it fit other feet, but that may not be necessary. A quick survey of my stash yielded a small collection of feet that may be candidates. The all have the same width mounting channel (7.6mm or 19/64") and all are very close in height (about 35mm hole center to bottom). The hole for the mounting screw on some is a tad smaller (4mm instead of 4.6mm), but that's easy to correct with a simple drill. The center four feet in the bottom row are original Adler feet (onePart #0055840 and three Part# 105220010) that mount on the right side of the presser bar and have teeth. Those four original Adler feet are the only ones I'm positive which machine they belong to (the 105220010 feet appear in the Adler 105-RM25 parts diagram.) The bottom right foot is very close to what you currently have. All the others have smooth bottoms for bottom (and needle feed) machines like yours. I don't know which machines they go with, but very likely some Singer model. The feet with round holes are for machines without needle feed, since there's no room for the needle to move. In any case, I think you have some options to move towards presser foot nirvana on your Chandler 305-64. All the feet in the picture are for sale, by the way. The original Adler feet are $80, all the others are $40 each.

-

I doubt anybody stocks and sells these cast rawlings. Usually they only exist in the factory between two processing steps. You can have your own made by various chinese suppliers if you're willing to order a few dozen or a few hundred. I have some cast rawlings in my parts drawers, but I have no idea where they originated. I don't even know which machines mine are intended for. I'm pretty sure, though, that they're of no use to you, sorry!

- 16 replies

-

- feed dogs

- walking foot

-

(and 2 more)

Tagged with:

-

Thanks for the update, @HatoriKun! The Anker website sure uses a nearly identical factory image that is on my machine in their scrolling banner images on their Anker history page. That settles at least my portion of the mystery machine. Yay!

-

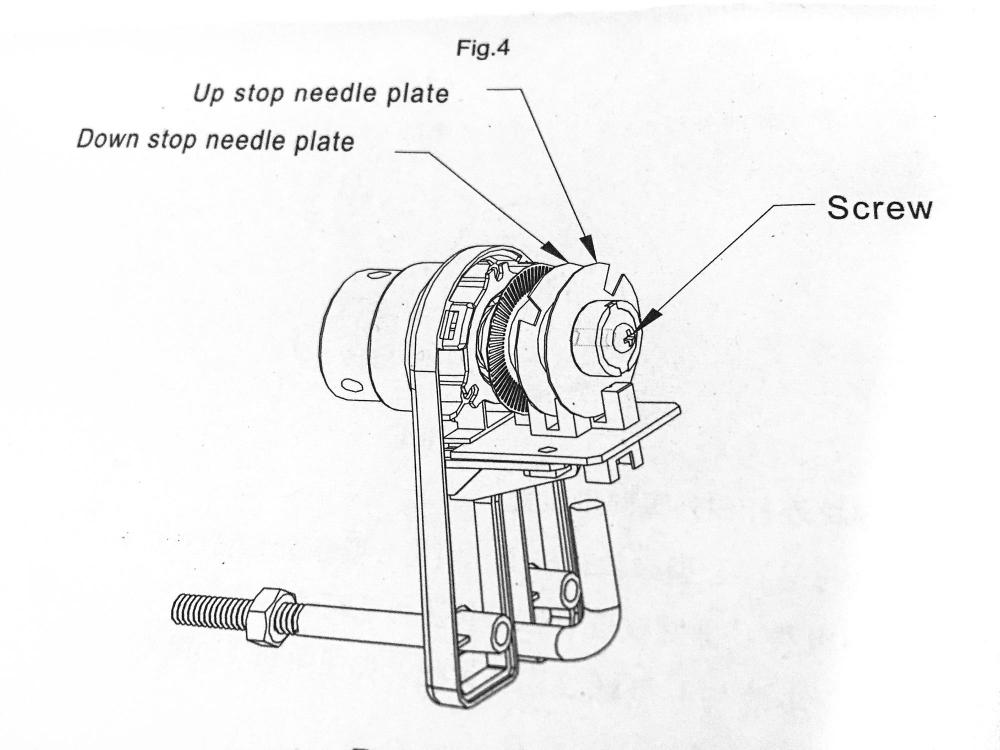

Many synchronizers have two discs inside that you can rotate individually to adjust position for UP and DOWN. When I set up a machine with needle positioning, I usually set the DOWN position to when the needle is rising, but still in the material (don't make it stop in the hook timing position unless you enjoy skipped stitches.) For UP position I set it to when the thread take-up lever is at its highest point. With a little luck your position sensor will look like the graphic below on the inside. It's the notch in the disc that signals STOP when it reaches the light sensors at the bottom. Loosen the "screw" to turn the disc that needs adjusting while holding the other discs in place. It take a little practice but it's not too hard. Don't forget to tighten that screw again.

-

I got motivated and connected my SewPro servo motor to my Singer 7 Class in a test setup, just to check speeds and take measurements for the real table. I'm planning to mount the motor to the top of the table, rather than cutting a slot and mounting it underneath. This mounting concept would also work if you want to have the machine just sitting on top of the table. Here's a video of my test setup - just for reference since you're looking at motor options. The real test will be sewing a thick stack of webbing, but speed control looks quite suitable and slow enough to me, even without a separate speed reducer pulley.

-

The shaft itself is the same, it's the hook driver that's different. We'll "just" swap hook drivers and all should be well.

- 22 replies

-

I was in Frankfurt in May for the Techtextil and Texprocess trade fairs. It's the place to be to keep up with modern sewing technology. The Frankfurt show floor was nearly ten times the size of the show in Atlanta last year. I'm working on getting a Singer 7 class motorized and I also plan to mount a servo motor directly to the base frame like they did in the video. The motor in the video is an Efka system, I think. I'll have a go using my 1,100 W SewPro servo motor and see how well it works without a speed reducer pulley. I also have a new Consew 733 class machine still in the crate that will be next up for big boy work.

-

Now I know which machine the guy at the trade show was talking about when he said that the new H-Type 967 fills the void left when the "Adler One Twenty Two" model was discontinued. I'd been searching for "Adler 122". "Adler 120-2" makes more sense. Nice finds, congratulations!

-

Wrinkle alert! I just noticed that the shuttle driver on my shaft is mirrored from yours. I've been wondering why my shuttle driver is marked "Left". I'm guessing it's for special "left handed" versions of Singer 45K machines where the arm points to the right. That means you can't use my shaft+driver assembly as it is in your machine. You'd have to move your shuttle drivers to my shaft. I may have a "right" shaft hiding in my drawers, too. I'll let you know if I come across one. Uwe

- 22 replies

-

I found a nice, straight original 91171 SIMANCO shaft with shuttle driver for Singer 45K in my parts drawers. $70 plus shipping.

- 22 replies

-

-

Inline Cowboy presser feet on Cowboy CB4500

Uwe replied to Wizcrafts's topic in Leather Sewing Machines

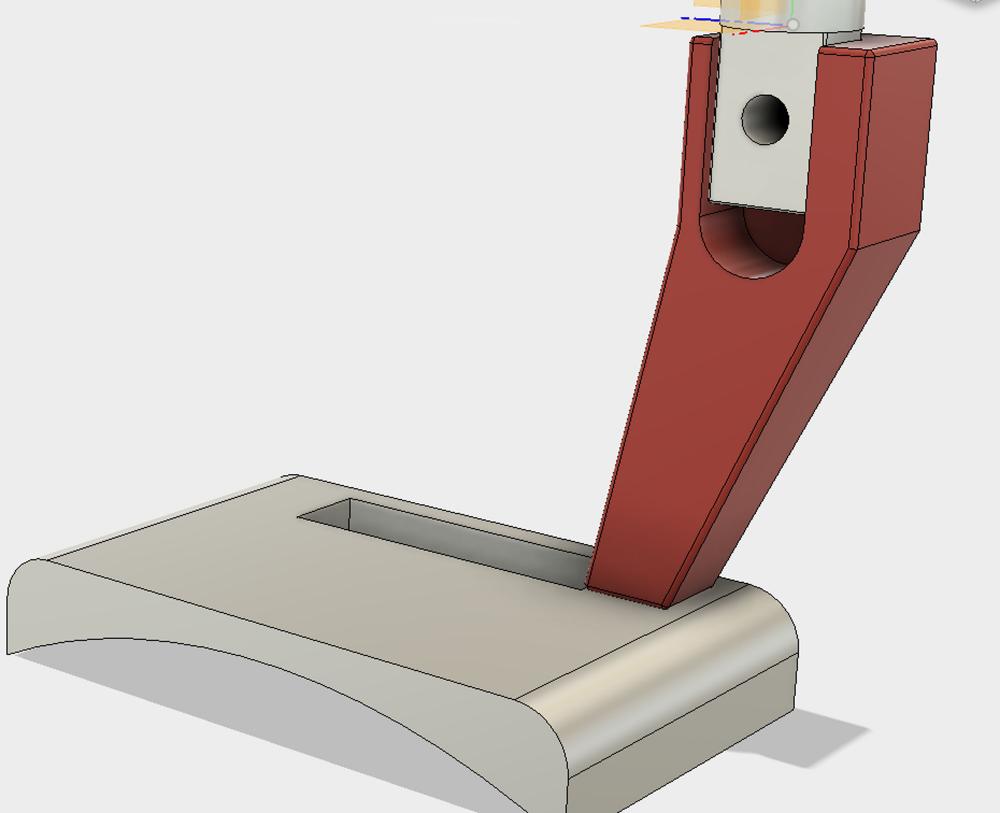

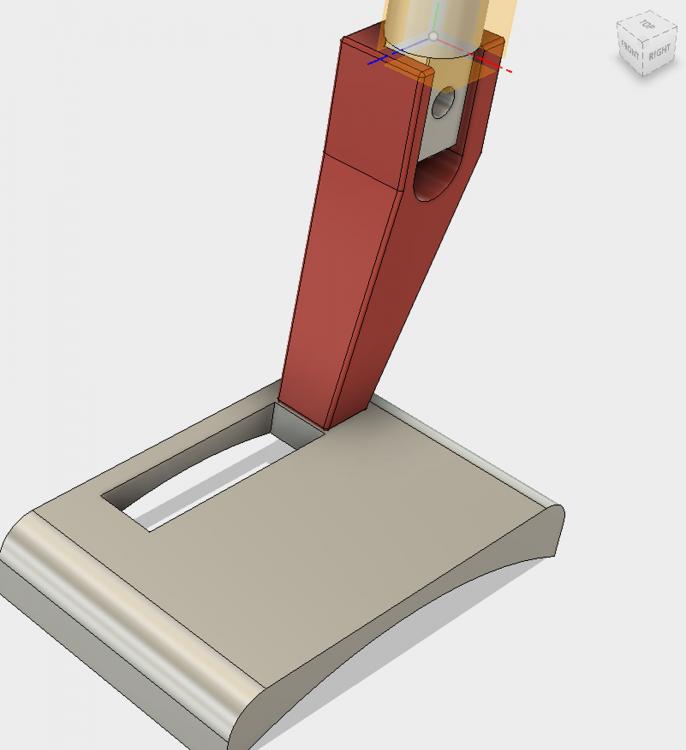

My version is designed to work with the flat harness maker throat plate. I'll have to work with somebody for testing since I just sold my Cowboy 4500. -

Inline Cowboy presser feet on Cowboy CB4500

Uwe replied to Wizcrafts's topic in Leather Sewing Machines

A tripod and pre-focus will make a world of difference for videos. On the topic of in-line feet for 441 class machines, the make-it-yourself option is available to those who have un-used blanket feet in their parts drawer. I made a set a few month ago for the make-your-own-feet type discussion: I was planning to make some from scratch on my CNC mill, but so far I've only come as far modeling it up in my CAD software and buying some stainless steel stock. Maybe I'll give this little project another push. -

How about a picture or model number of the machine? "Omega industrial" is pretty vague. This is like a game of "What's my stitch" where we have to ask a series questions to guess what machine you really have. The pictures that pop on google image search for that term are Sailrite type clones. If your machine looks like the picture below, you can go the sailrite website (http://www.sailrite.com/) and order all your parts and supplies from them.

-

Recommend vintage textile machine with reverse

Uwe replied to Dave4's topic in Leather Sewing Machines

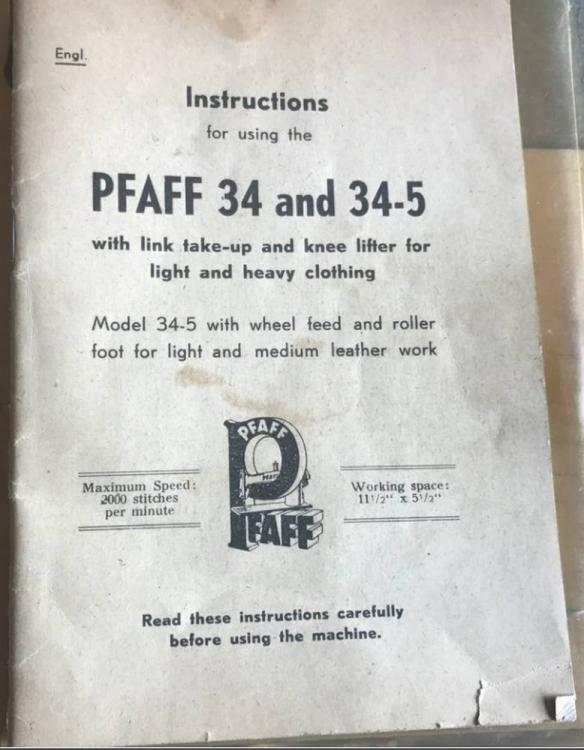

One more vintage Pfaff garment candidate. A beautiful Pfaff 134 popped up on CraigsList radar today. Back from the days when companies cared about what their thread stand looked like! -

Recommend vintage textile machine with reverse

Uwe replied to Dave4's topic in Leather Sewing Machines

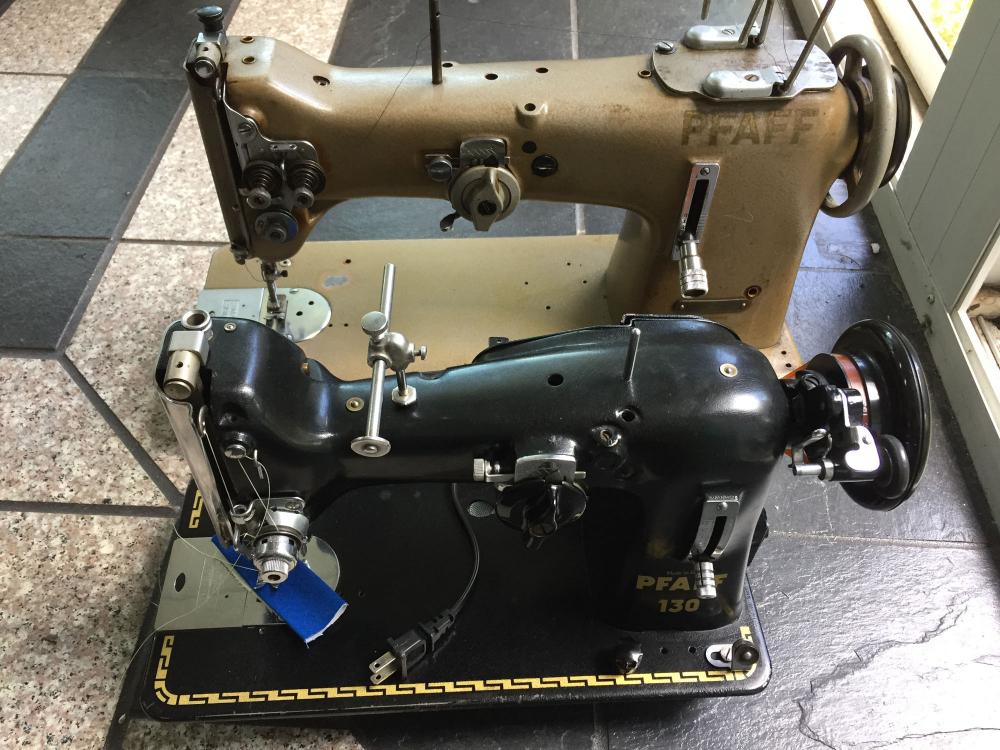

You might also want to consider a Pfaff 138 - a very nice, full size industrial garment machine with reverse (and zig-zag, which may come in handy at times working with fabrics.) I'm estimating these at around $400 for a nice head. I'd also recommend looking at the little brother of the Pfaff 138, the Pfaff 130. It's a surprisingly capable and tough little machine. I made an external sunshade with sunbrella fabric with my Pfaff 130. Many Pfaff 130 use a domestic motor, but they are also comfortable mounted in a table with a nice servo motor. Pfaff 130 is somewhat common and relatively cheap at around $100-200 for decent head (buy two, one for spare parts) -

In-line presser foot for Pfaff 335, 1245, etc.

Uwe replied to Uwe's topic in Leather Sewing Machines

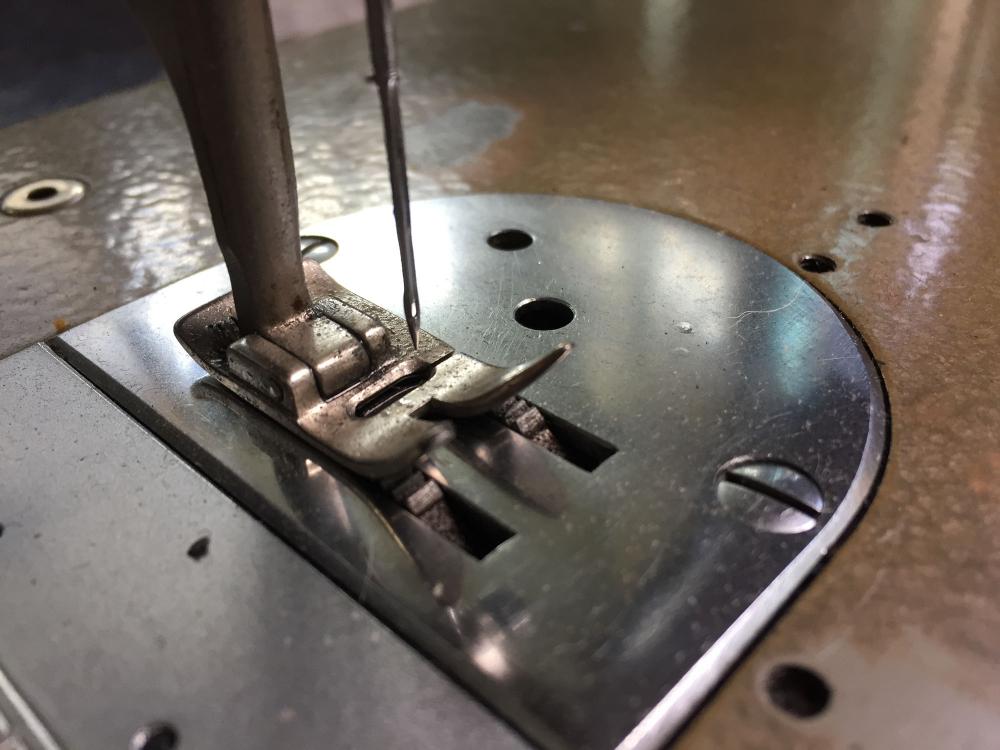

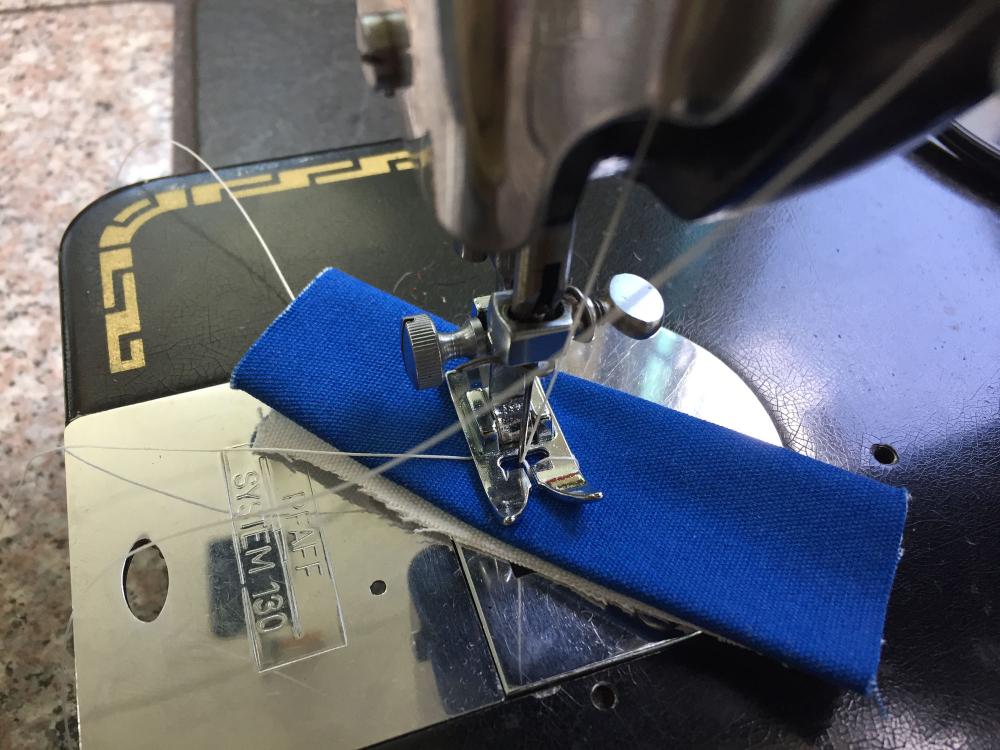

Any of the usual suspects among the flatbed walking foot machines would be a good candidate for making dog collars and leashes. Vintage machines include Consew 226, Pfaff 145, Adler 67, Juki 562 in the $500-900 range. Modern machines include Consew 206Rb5, Juki 1541, Pfaff 1245, prices for new machines ranging anywhere from $1,300-$2,500. It's best to start a new topic for a detailed discussion on what machine might suit your particular needs. It helps keep the topics, well, on topic. -

This listing is for the complete setup with servo motor and tall table. If you need just the head, the price is $200 less.