-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

I'm not sure. Some of the Ferdinand Bull machines are modified original Juki TSC-441 machines which may accept this plate, but other Ferdinand machines are not compatible.

- 12 replies

-

- adler 205

- juki tsc-441

-

(and 3 more)

Tagged with:

-

Sewing machine for up to 14oz of leather

Uwe replied to ClassicBlock's topic in Leather Sewing Machines

That Durkopp Adler 272 is a fine machine for its intended purpose, but being a good starter machine for sewing leather is not its intended purpose. The 3-phase power requirement alone rules it out for nearly all domestic settings. This Juki LU-563 is an example of what many people here on LW want to own and work with: https://miami.craigslist.org/pbc/hvo/6013897271.html These machines are very capable and well made, cheap parts are readily available and the servo motor provides good low speed control. -

I finally found some screws (Juki part number SS-6121050-SP) to install this throat plate on 441 class machines without requiring washers:

- 12 replies

-

- adler 205

- juki tsc-441

-

(and 3 more)

Tagged with:

-

Now I'm curious how you defied gravity on your machine! Would you mind starting a new show-and-tell topic in the leather sewing machine forum telling us what you did?

-

Nice work 1CJK, looks very solid! One drawback with having the lever point down when the feet are up is that you can't lower the feet again using the foot pedal (while holding the material in position with both hands), because the lever won't "fall" back up to the normal position. But that matters only if you're even using the foot pedal release method. There are many options, you just have to pick one that works for you. Thanks for sharing your solution!

-

I made a small batch of the extension lever that replaces the original manual foot lift lever on the Juki TSC-441 class of machines, which include Cobra Class 4, Cowboy CB4500, Techsew 5100, and many others in that same class. The main advantage is that you can use it along with a swing-down edge guide like a KG-967 or KG-867. The original lever gets in the way. I call it UX441 and I'm selling it to the general public on Ebay for $59 (http://r.ebay.com/sVhPDU) LW members get $10 off, just send me a question through the Ebay listing and tell me your LW member name. You can also contact me via personal message (PM) right here on LW to avoid Ebay. For folks outside the U.S., shipping really is cheaper if you go through Ebay. Of course you can make one of these yourself if you're handy and motivated. Here's a picture of my UX441 version with fancy packaging and a cute red dot. Here's the promo video I made for the extension lever:

-

It's unlikely that thread tension is the culprit. Normal polyester or nylon thread doesn't usually break the thread guides. Some specialty threads like Kevlar on the other hand will saw right through metal guides and take-up levers over time. Sometimes the needle bar height is set too low and it may touch the presser foot when the foot is raised. I've worked on several machines where the needle bar was set too low. It happens if hook timing is a little late and the needle bar is lowered to compensate. Most machines have a sweet spot where hook timing is spot-on and the needle bar clears the raised foot by a fraction of a millimeter. Using the wrong or a poorly made foot may also cause the needle bar to touch the raised foot even if the needle bar height is set correctly. If the needle bar touches the raised foot, running the machine at thigh speed with the presser foot raised up (e.g. to wind a bobbin) will slam the bottom of the needle bar against the presser foot repeatedly. That can cause the thread guide, which often extends a tiny bit below the bottom end of the needle bar to get fractured and break over time. Make sure your needle bar does not touch the raised presser foot before you install the new thread guide.

-

I really do think the fix was a normal adjustment and I don't see any indication of some major flaw that needs to be worried about.

- 21 replies

-

- presser foot

- cobra

-

(and 1 more)

Tagged with:

-

I vote for letting the man enjoy his stutter-free machine.

- 21 replies

-

- presser foot

- cobra

-

(and 1 more)

Tagged with:

-

I think the vertical plate adjustment is just a normal adjustment for this machine's design and does not indicate a loose bushing or some other defect. The bearing wheel presses against the vertical surface as it rolls up and down. That vertical surface needs to be in the right plane to keep things aligned properly and provide a leverage surface for the bearing wheel. If the vertical surface is too far away the linkages put horizontal pressure on the presser foot bar and deflect it or press it sideways against the upper and lower bushing walls, rather than guide it straight up and down without sideways deflection or pressure.

- 21 replies

-

- presser foot

- cobra

-

(and 1 more)

Tagged with:

-

As a follow-up, I actually caused a similar problem on my Adler 205 once, where the foot lift linkage started making odd clicking noises. I took me a while to realise where the noise came from and that I myself had caused the machine to make these noises after adjusting the manual foot lift height. A very subtle tweak to lower the manual foot lift height a small amount brought the machine back to silky smoothness and banished the clicking noise. In my case the clicking noise was caused by an internal sliding block that was stuttering as it moved on the shaft. The Adler's mechanism is different enough from your 441 class machine to not be of help in debugging your case. I'm just mentioning it to illustrate that small adjustments can have unintended side-effects, and that some issues only manifest themselves at very slow speeds and could easily be missed during initial setup. The clicking noise actually went away when speeding up the machine. No off-center holes or lemon castings, just plain old user error was the root cause in my case. Here's a video snippet of my Adler 205 making the clicking sound:

- 21 replies

-

- presser foot

- cobra

-

(and 1 more)

Tagged with:

-

I'd take the faceplate off and carefully observe how everything moves as you slowly turn the hand wheel. Give it a good oiling while you're at it. You might be able to tell where it catches and causes a stutter. Sometimes the foot lift linkage needs to be adjusted a little to line things up just so for smooth movements. Also check if a screw may have worked itself loose during the break-in period, which happens on occasion with new machines no matter how careful the technician is. The vendor's tech support is your first line of problem solving, be sure to keep trying to give him a shot a fixing your problem. The dealers keep saying that it's their setup work, initial adjustments, and after-sale support that makes the difference between all these virtually identical clone machines. If you're going to end up doing the work yourself, you might as well order a machine on alibaba.com and save a chunk of money up front. At the same time, even the best vendor has absolutely no control over which screws the user turns, which may cause issues. It's not yet time to lose sleep over potential off-center holes and lemonade. But it is time to break out the camera phone, dust off your youtube account (or get one) and post a video snippet of the problem. The only thing that's certain is that this won't be the last time words alone will not sufficiently describe a problem.

- 21 replies

-

- presser foot

- cobra

-

(and 1 more)

Tagged with:

-

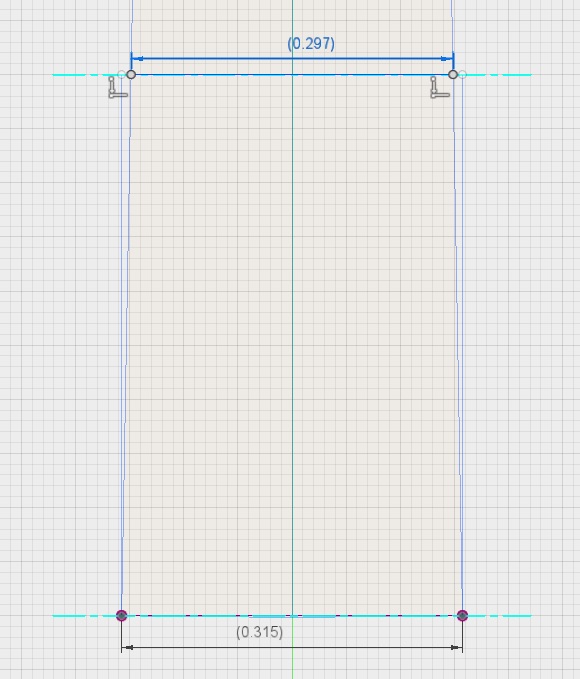

A variety of factors may affect stitch length as material thickness changes.The pendulum effect by itself accounts for less than 0.5mm of the 2mm you're losing. Sometimes the feed dog movement isn't quite right and it only manifests itself with thick material. If the feed dog descends too early or rises too late, it may affect stitch length. With thin material it may be less noticeable since the material gets pressed into the throat plate opening to make contact with the feed dog even if it's a little off. If there's significant drag or friction at one or both ends of the material feed movement, it will affect stitch length. Ideally, the inner presser foot arrives at the material at the same time as the tip of the needle. If it's far off, it may affect stitch length. That inner presser foot timing may also need to be adjusted a little if you sew very different material thicknesses. How squishy or stretchy the material is also plays a role. A little high school geometry math (or a CAD program) will let you figure out what the pendulum effect itself may contribute to the theoretical change in stitch length. It contributes surprisingly little, actually. On a 562 class the needle bar pendulum is roughly 9" long. If the needle "swings" an 8mm (0.315") stitch length at the throat plate level, it will swing a 7.54mm (0.297") stitch length at 12.7mm (1/2") above the throat plate. So theoretically the pendulum effect accounts for less than 0.5mm in shorter stitch length if your material is 1/2" thick. This image is a screenshot of the very bottom of the pendulum in my CAD program, showing the two stitch length measurements at throat plate level and 1/2" above:

-

The only time I really noticed the lack of vertical feed dog movement on my Pfaff 335 was when the material had a step on the underside due to a fold. The feed dog would catch on the step as it moved towards the front and push the material towards the front as well, resulting in short stitches.

-

If you can't find brochures, manuals, or documentation that list specs and describes how the thing works, don't buy the machine.

-

Look for trusted standards like Singer 111W155, Consew 225 or 226, or Juki LU-562 or 563. These machines come up for sale in on CraigsList every so often and some vendors (check the banner ads) may have them in stock, too. $400-600 is not much to work with in terms of a functional, well adjusted industrial sewing machine with a proper motor. If you're patient, you may get lucky, but if you need something soon, you may end paying more. For sewing fire helmet shields, there's no need for reverse or big bobbins, which run up the price quickly. Being able to sew slowly with good low speed control, however, is very important for your application, I think. So plan on getting a servo motor ($130) and potentially an optional speed reducer pulley ($150). A few folks here on LW are doing fire helmet shields. Check out what they have done by doing a google search like "site:leatherworker.net fire helmet" One lady who makes fire helmet shields ended up buying a Consew 225 from me and it suited her work well.

-

-

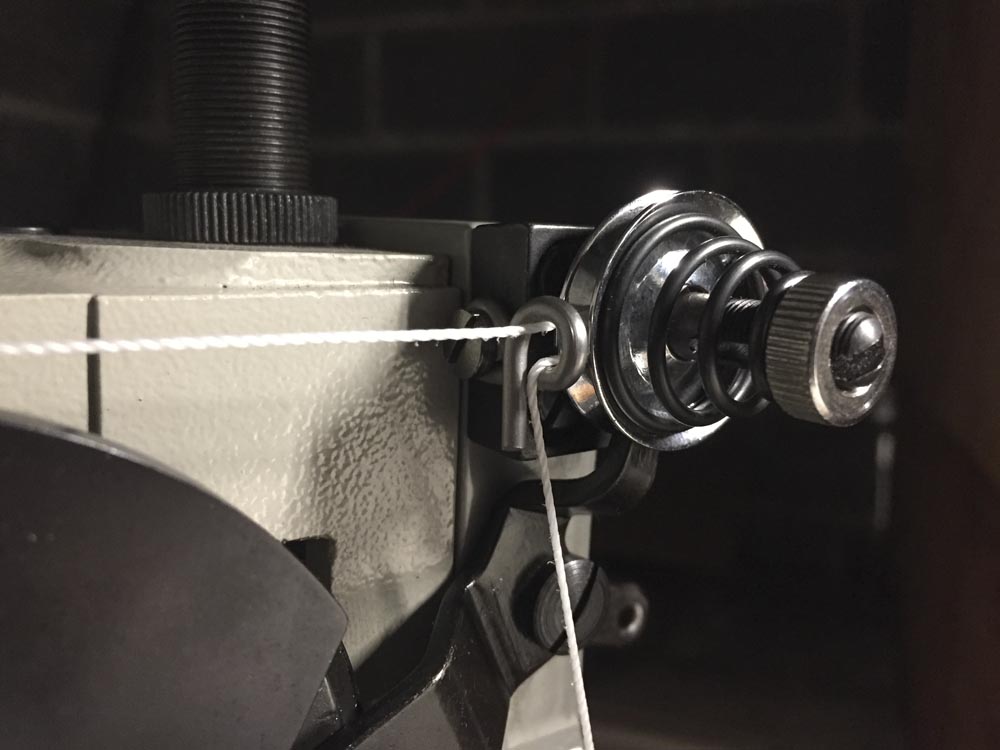

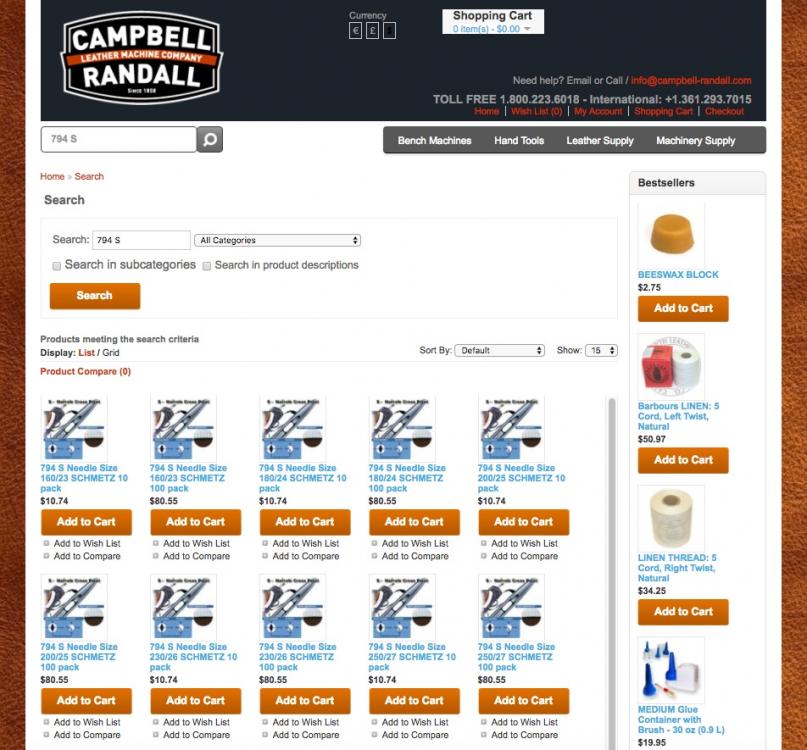

Groz Beckert (the green guys) published a brochure with a nice visual guide of industrial leather needles: http://thethreadexchange.com/downloads/gb014.pdf Our friendly banner advertisers are just a click or a phone call away. But it doesn't hurt to know what you're looking for before you call and have price reference in mind. When you type "794S" into the search box at Universal Sewing, they show Schmetz needles (the blue guys) available in sizes from 130Nm-250Nm The folks at Campell-Randall folks also list a range of sizes for Schmetz 794 S needles in size 160Nm-250Nm:

-

If I were living in Japan, I'd look for a nice Juki LS-341/1341 or any of the other highly regarded made-in-Japan brands. Just like there a plenty of used Pfaffs and Adlers around in Germany, it seems there should be a good number of used Juki machines available in Japan. Maybe Juki has a factory outlet?

-

One of the commonly used drop-down (or swing-down) guides is the KG-867. There's an extended version of that edge guide available called KG-967, which has about 20mm (3/4") more reach. The two guides overlap in the range of motion, and the overlap range places the roller guide right next to the needle on the 441 class machines. If you have a need to place the guide in front of the needle (e.g. for holding a tape folder or binder), you'd want to get the extended KG-967 version. The Cobra Class 4 (also TechSew 5100, I think) already have mounting holes drilled and tapped on the back of the machine, so that makes installation easier. If your machine does not have pre-drilled holes you'll have to drill and tap mounting holes. Either way, you'll need an adapter bracket like a KB-205 for a proper installation. The only real issue with using the swing-down edge guide on a 441 class machines is that the standard manual foot lift handle gets in the way. I made an extension handle to get around that. Just something to keep in mind. Here's a short video showing what the installation might look like on a Cowboy 4500:

-

I've only bought from their remnants section (https://www.filzfelt.com/index.php?/shop/categories/category/remnants) , where they have less-than-full-width pieces in limited colors for a reasonable price. The remnants are great for experimenting and smaller projects like iPad or phone sleeves and the like. Good point on that wax coating, Cory! I had to take a loser look at that aspect. I have two kinds of colors of felt that I got from FilzFelt. I did some testing and one of them readily absorbs oil, on the other the oil droplets just sit on top. I don't know how you can tell on their website which version has the coating and which doesn't. The one type of felt I have that absorbs oil readily and would make a good wick material is a 5mm thick "200 Natur". I'm guessing "200 Natur" color is untreated and all-natural, which is why it absorbs oil more readily. Here's a short video that shows how different the oil absorption of the two colors of felt is:

-

I guess Australia needs to save a few more sheep from becoming UGG boots to make a few yards of wool felt. The sheep would appreciate it, too, no doubt. Here in the U.S. I buy my wool felt at Filzfelt (https://www.filzfelt.com/index.php?/shop/categories/). It's a great material to combine with leather.

-

I probably should have included the rather long list of Juki TSC-441 clones that this plate will work on, just to get caught on a few keyword searches. Juki TSC-441 clones include HighTex/Cowboy CB3200/3500/4500/5500, Cobra Class 4, TechSew 5100/5100SE, Keestar 441, Thor GA-441, Dematron GA-441 , Typical TW3-441/TW3-441S, SewPro 441-PRO, Reliable MSK-441, Nick-O Sew NKS-441, TopEagle TCB-441, FoxSew FX-441, EconoSew 441S, SEWLINE SL-441, and perhaps a dozen or more lesser known brands.

- 12 replies

-

- adler 205

- juki tsc-441

-

(and 3 more)

Tagged with:

-

We'll have to be a bit more precise with wording to make progress. It's not totally clear to me which exact parts you are referring to when you say "that gauge" and "that button". It's obvious to you because you're looking at the parts, but we have to interpret the words and try figure out the details. Pictures with a little arrow always help. Most smart phones allow to to annotate pictures with arrows and words that you can then upload here. I made a video describing the feed adjustment mechanism on my Singer 153W102, which should be identical to what you have on your Singer 111W103. Hopefully the video will help you understand how the feed (stitch length) adjustment functions and perhaps identify why yours does not work right.

-

I used thin strips of wool felt to replace my missing oil wicks and it worked fine from what I could tell. I've not replaced any wicks inside of plastic tubes, so I can't make any recommendations on that.