-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Uwe

-

I've never even heard of this machine until just now, but it looks like a very nice - and very complex - machine. You'll need to spend some quality time with the service manual for Durkopp Adler 8967 (8967_instructions_for_service.pdf) I'm not an expert on thread cutting mechanisms, but I was just working on the thread cutting mechanism on my Adler 467 yesterday. It also did not want to cut the thread reliably - I had to advance the hand wheel a quarter turn to complete the cut. On my machine the fix ended up being an adjustment inside the needle position sensor. My NP sensor has one disc that is used for positioning during thread cutting operation. I had to rotate this disc a little to change how far the knife moves during the cutting cycle.

-

The Cowboy CB227R seems like a fine machine and would probably do most of what you want to. I think you should also pay a visit to your local industrial sewing machine vendor South West Sewing Machines in Houston. See if you get good vibes talking to them. Having a local resource for machines, parts, and service is a big deal. Shipping these little monsters across the country is not cheap.

-

As for screws, there is a mix of imperial, metric, and specialty xx/64 screws in many machines. Most Juki parts manuals, including the Juki TSC-441 Parts manual (Juki 441 parts List.pdf) list screw sizes, which is super useful. You don't want the screw material to be too strong. If you're going to cross thread or strip some threads, you want the screw to die, not the threaded hole. It's MUCH cheaper and MUCH easier to replace a screw than it is to re-drill and re-tap a threaded hole.

-

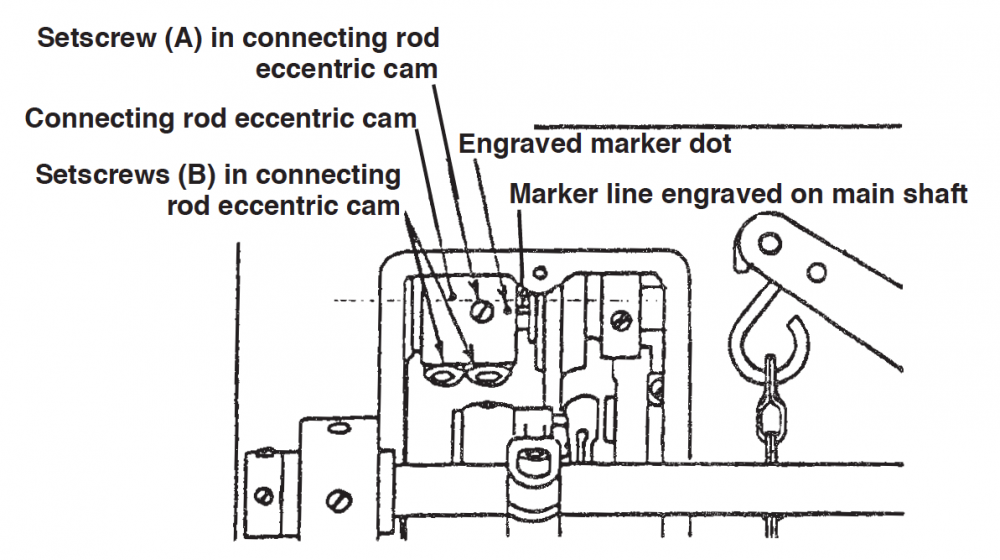

For the 441 class machines, the original Juki TSC-441 Engineer's Manual (Juki 441 Engineers Manual.pdf) manual is your best option. I see two references to alignment marks in the manual, both refer to the same area: Unfortunately, my Cowboy 4500 (a Juki TSC-441 clone manufactured by HighTex and sold in the USA under the Cowboy brand) ) does not have these timing marks:

-

Absolutely love this Pearson #6

Uwe replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

Actually (and somewhat surprising to me,) currently neither Android nor Apple iOS have built-in image resize functionality (they both have cropping, but that's not the same.) I'm guessing both platforms do this on purpose to encourage app developers a to improve app store revenue streams. A simple, free Android app like Photo & Picture Resizer may be your best bet. -

Let's also take a moment to appreciate that beautiful paint job on the Cobra Class 26 in Al Bane's video above.

-

Edge Guide for Consew 225 (and clones)

Uwe replied to KeithHideWorks's topic in Leather Sewing Machines

Nice one, DC! I like the simplicity and the brassy steam punk look of it. A tight screw beats a magnet most of the time. -

There is a video by Al Bane about the Cobra Class 26. Al Bane has some good videos but this isn't one of them. He make so many wrong statements that it's obvious he didn't do his homework before talking about this machine. But at least you can see what the machine looks like. Just don't believe most of what he says in this video.

-

On most machines the knee lift does not have a hold function. The hand-lift lever's first detent is the one you use during normal sewing. This first detent can usually be released again with the knee-lift. The hand lever will fall back down if knee lift raises the feet above first detent level, allowing you to have both hands on the material and lower the feet with your knee to start sewing again. On some machines the second detent does NOT automatically release when the knee lever is pressed. There's probably a good reason for that, but I can't think of it right now. Perhaps it's just for extra clearance when changing feet etc.

-

Good choice! The Cobra Class 26 appears to be a copy of the Juki LS-341 design, one of my favorite sewing machine designs. You should be in good hands with local support and expertise. I posted some image resizing instructions recently in this topic: I do wish the administrators would create a pinned topic or send new members some instructions on how to deal with image uploads in a welcome message. We have several instances every week with new members facing the image upload gauntlet. I found exactly one image of a Cobra Class 26 online. Cobra Class 26 Juki LS-341

-

Edge Guide for Consew 225 (and clones)

Uwe replied to KeithHideWorks's topic in Leather Sewing Machines

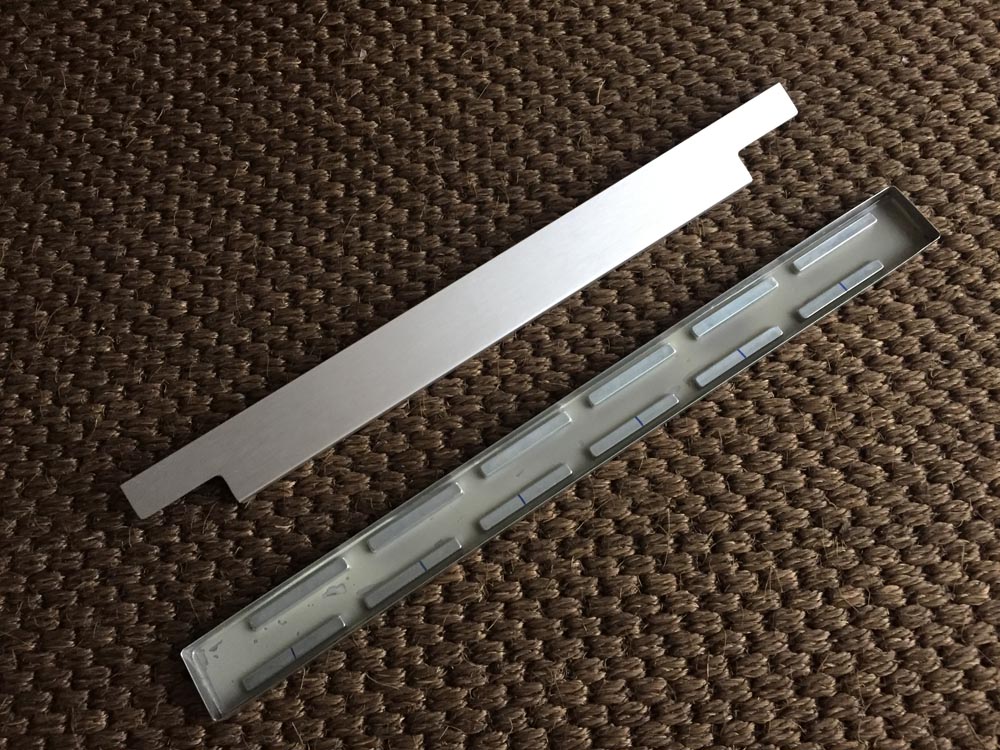

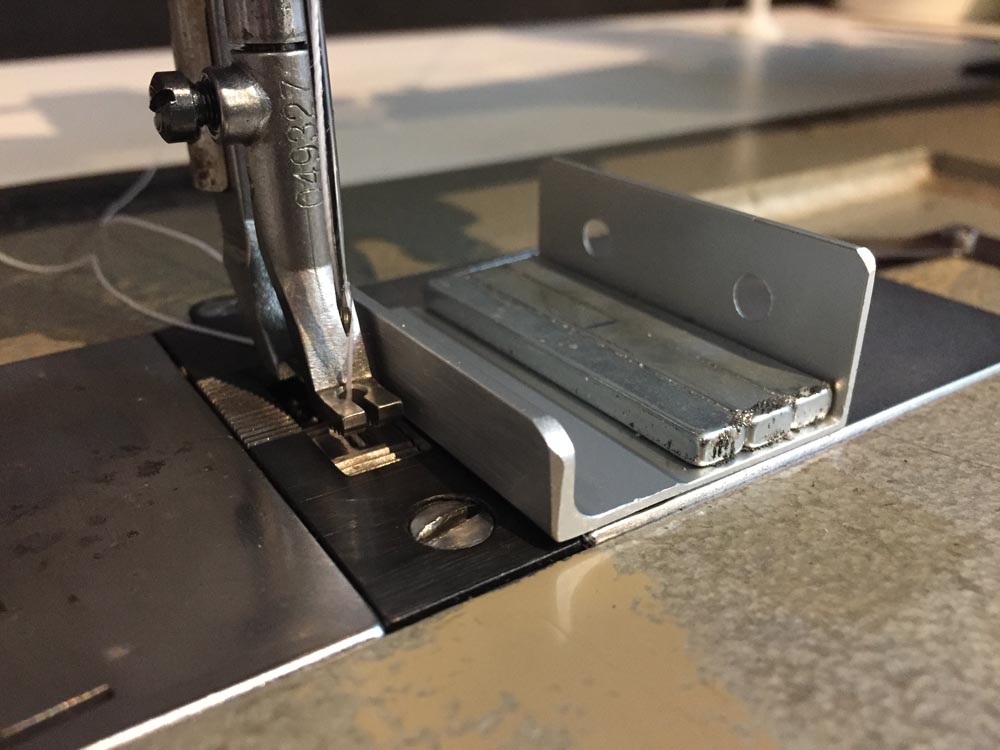

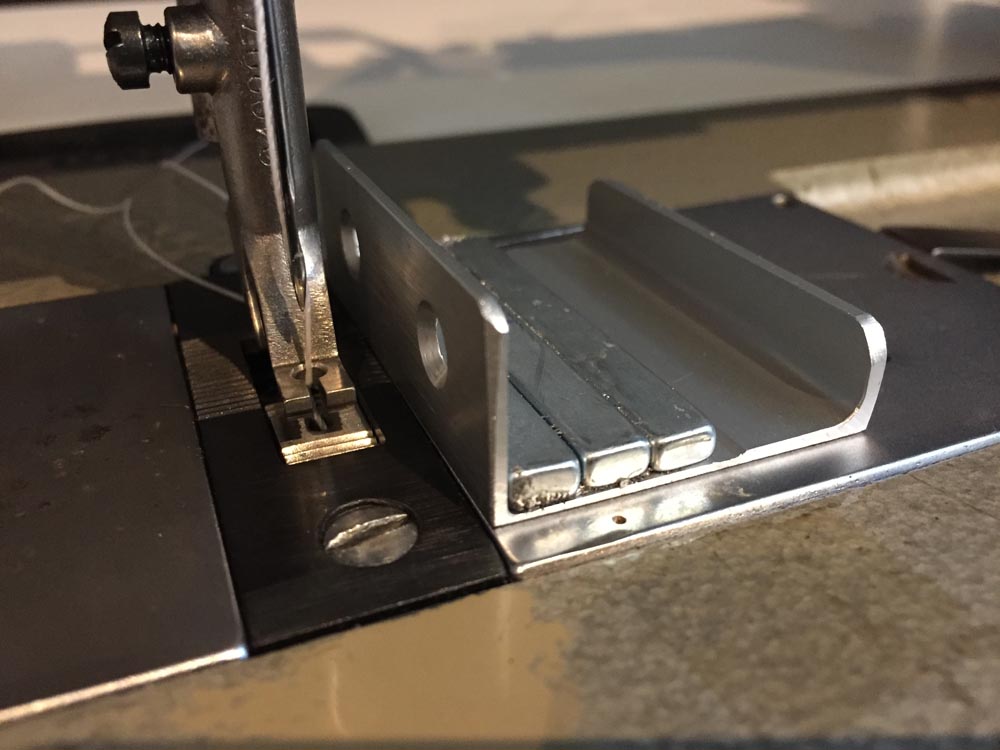

Since this topic is sorta-kinda morphing into a show&tell of DIY magnetic edge guides, I started tinkering. I live near an IKEA and IKEA hacks are one of my favorite things. I made a magnetic edge guide based on an IKEA $9 GRUNDTAL magnetic knife rack bar and a small $4 BLANKETT handle (longer ones cost more). Each knife rack has twelve rare earth magnet bars glued to the back. The magnets can be removed carefully (the magnets are brittle, I broke one out of the twelve.) The BLANKETT handle comes in different lengths, has a low and a high guide edge and a nice, smooth anodized brush finish. The small version of the handle is just the right size for a set of three of the magnet bars and fits on the slide plate. I cut a longer handle to size to fit nine magnet bars for a stronger hold and longer guide edge. Simple double sided adhesive tape a or a few drops of glue will hold the magnets to the handles. The handles are big enough to grab with your fingers when pulling the guide off and the holding force can be adjusted by adding/removing magnets. I didn't spend quite enough time to scrape the glue residue off the magnets to make it look super pretty, but it's functional and can be made to look nice. I'm attaching a few pictures. -

Yes, that is one example of the kind of machine you need. Those Juki LU-562 or 563 machine are great machines and this particular one looks to be in very nice condition.

-

If that's a criteria, you're better off skipping this particular machine. It's a cool sewing machine, actually, mainly because it's ancient and it says "Modern Age" right on it - how cool is that! But for sewing "pretty thick stuff" you really do need a proper industrial machine, not a sturdy domestic machine. Being a newbie is actually a really good reason to drop $1,500 on a very good new machine that does exactly what you want to do, from a reputable vendor (check the banner ads). Once you get get the hang of it, you can start gambling on vintage machines on Ebay or Craigslist for your second, third,etc. .... machine. Resistance is futile. As for that particular Ebay seller, I ordered one machine from them about two years ago and it wasn't really a good experience - missing parts, lots of grief and very poor packaging.

-

You can embed/link Youtube videos by copy/pasting the full Youtube URL into a post (the link you paste should look something like this https://www.youtube.com/watch?v=Z1QX4nL65L0 , not the abbreviated versions)

-

Singer 153W103 Cylinder Repair and Timing - Pics

Uwe replied to Ian1783's topic in Leather Sewing Machines

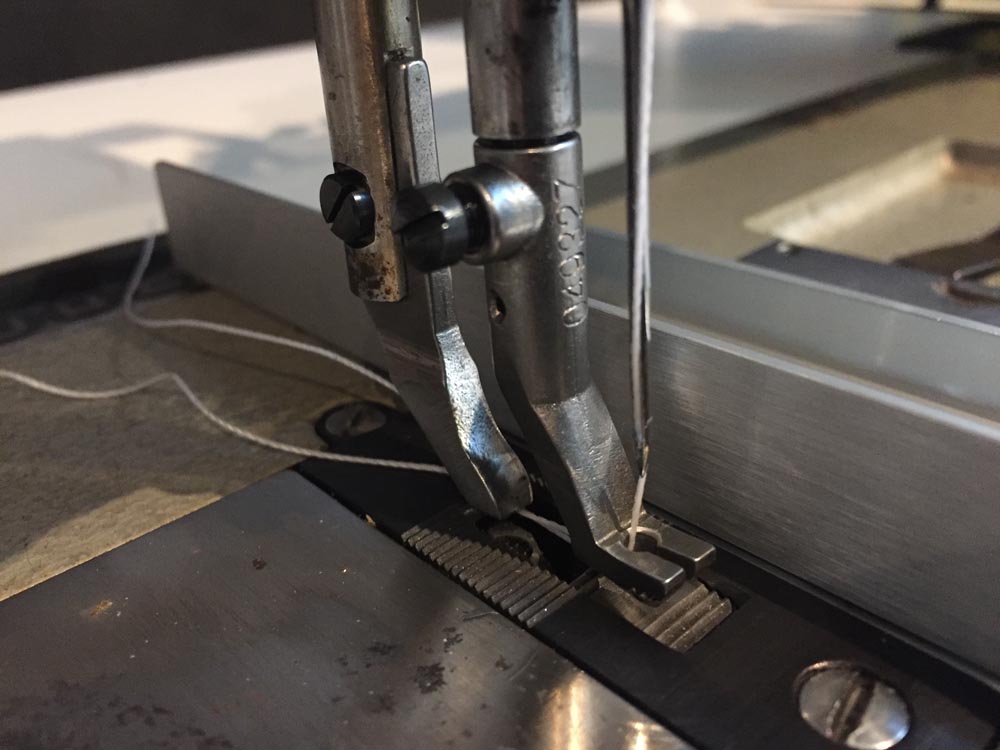

One way to get back to a reasonable starting pojnt is to turn the wheel towards you until the needle reaches the top of the material. Then loosen screw "A" to make both feet rest on top of the material. Then tighten screw '"A" again. That should bring things back into a normal state. The outer foot will start to lift up the moment the inner foot presses against something (material or feed dog). You need both feet and feed dog installed and ideally some material under the foot to check/adjust this. My Juki LU-563 adjustment video below shows this particular step at the 4-minute mark. The lever "B" gets actuated by an excenter that sits on the upper shaft inside the head. That excenter can (but very rarely needs to) be rotated on the shaft to change the timing of when arm "B" is being pushed out and pulled back in to create the up/down walking motion of the feet. I have yet to encounter a machine where that excenter needed adjustment. Keep in mind one of the main rules of sewing machine maintenance: Don't loosen a screw unless you know what it does. Here's the video I mentioned above (the equalizing of the walking foot lift shown at the 4-minute mark is one of the few things in the video that applies directly to the Singer 153W103): -

There is actually a manual for Singer 153K103: 153k101 (1).pdf I too recommend replacing that 3-phase motor with a simple servo motor.

-

Welcome to Leatherworker.net Mr. JeepishGrin! Post some pictures of your machine when you get a chance. I actually have no idea what it even looks like and there seems to be absolutely nothing online about your machine. In the absence of an original manual, sometimes your best bet is a manual of a machine that is very similar. Check out the Sutton Rapid-E Outsole Stitcher Manual and see if the Sutton is a similar design to yours. If yes, you may be able to thread yours the same way, or you may be able to figure out how yours should be threaded just using the Rapid-E threading as a starting point.

-

Singer 153W103 Cylinder Repair and Timing - Pics

Uwe replied to Ian1783's topic in Leather Sewing Machines

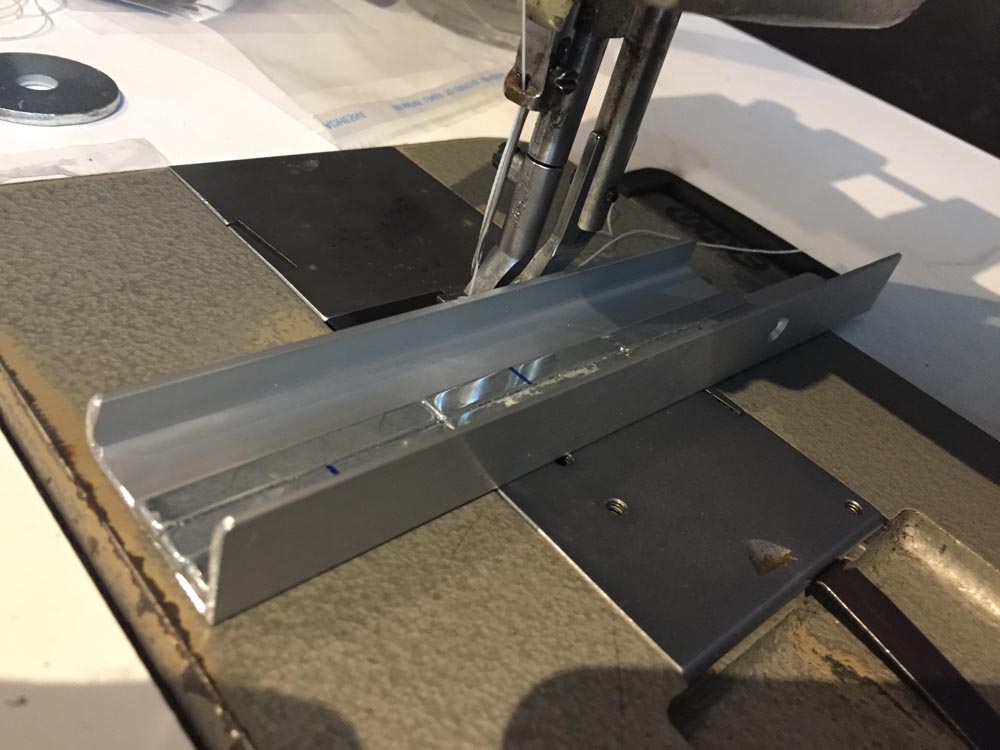

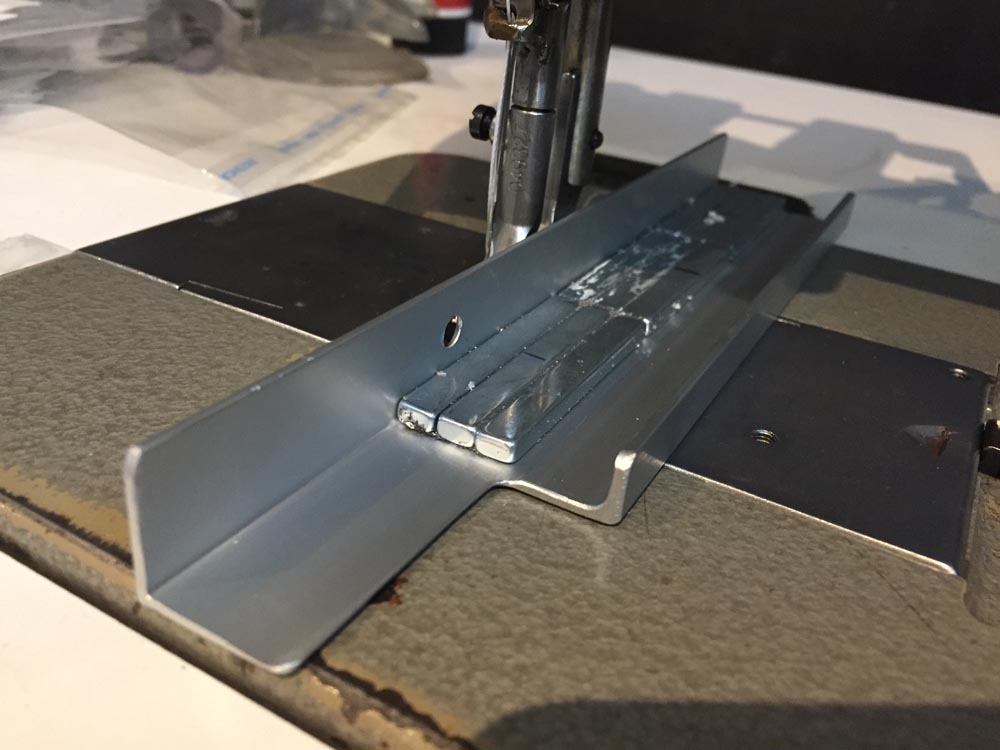

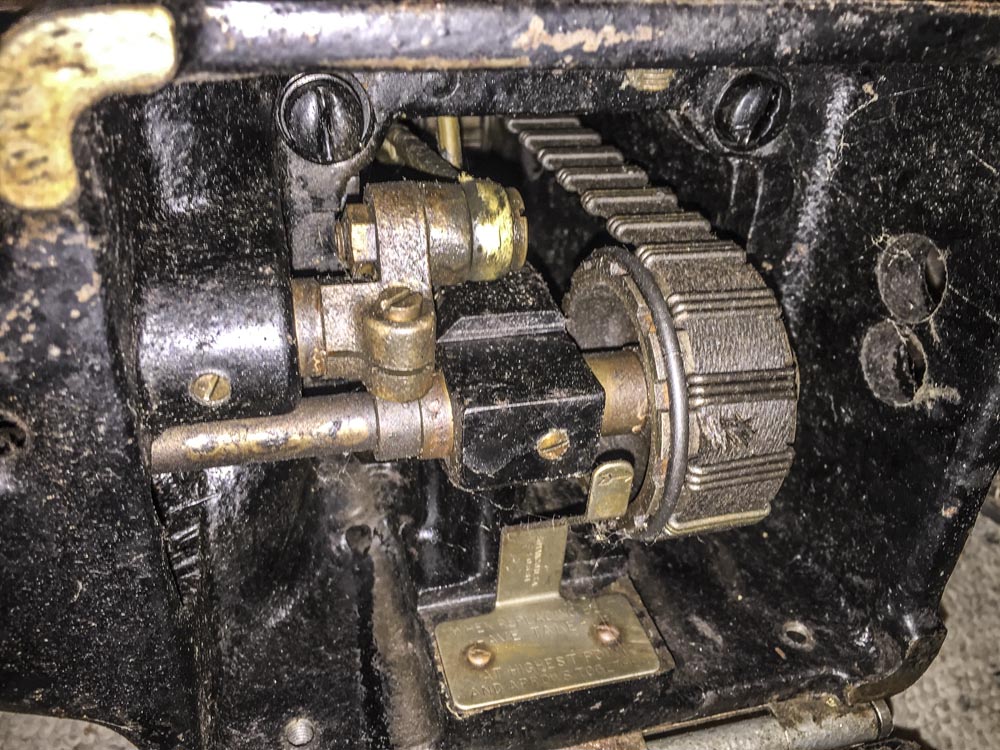

The timing belt synchronization should be one of the very first steps in the timing sequence. If that is out of synch, none of the other adjustments will make much sense. I have a Singer 153W102, which is the bottom+needle feed version. The bottom feed and arm design should be identical to your Singer 153W103. Mine has instructions right on the part they talk about in the manual: First you have to turn the handwheel so that your thread take-up lever is as it's highest position. Then make sure the marks align like this: In case your machine doesn't have the part with the arrow and the instructions, the mark on the safety clutch cog wheel points straight down when properly aligned. If the marks don't align, you may have to take the belt off the safety clutch, align the marks, and then put the belt back on the safety clutch. That may be tricky if your belt is a fabric belt like mine - the newer rubbery belts are easier to pull off after warming them up with a hairdryer. -

Singer 153W103 Cylinder Repair and Timing - Pics

Uwe replied to Ian1783's topic in Leather Sewing Machines

Nice photos! The Singer 153W103 Manual has some "Instructions for adjusters and Machinists" starting on page 15. That would be a good starting point. I'd take a close look at the timing belt synchronization first (page 23) - it may just be all you need to do to get feed dog motion back to normal. -

Female Hinges for a Singer 112w139 Sewing Machine

Uwe replied to tmitch's topic in Leather Sewing Machines

Hopefully Bob will find some, or other trusty banner vendors will jump in (or just contact them directly). They probably have them in stock in a neatly labeled drawer. The hinge hooks are readily available new from the usual supplier suspects. I'll probably order a dozen sets with my next order, just to have some new hook sets on hand for my own vintage machines. The new hooks are too cheap to even bother looking for old, used ones in my not-yet-organized vintage parts stash. -

[Jedi voice:] "The Cobra 3 is not the machine you're looking for" For the sake of marital bliss I'd strongly recommend two machines. Get two used ones for about the same or just a little more than one new Cobra 3. For your wife's bags, a medium duty cylinder arm machine in the Juki 341 or Pfaff 345 class would be a good fit. For your own flat workpieces, a nice vintage flatbed like a Juki 563 or a newer Consew 206RB will make you a happy sewer. Check out your local brick and mortar vendors in the LA area (Atlas Levi, Alberoni, etc.) to see what they might have in their used corner. If you must have a Cobra for the manliness factor, they're fine machines, too. Trying to sew all the things you both want to do with just one Cobra 3 is like like hiring an army drill sergeant to recite your poems - he'll do it but it won't sound quite right. If you must make do with just one machine, I think a Juki LS-1341 clone like the AtlasUSA AT3341 is a much better fit for your range of projects than the Cobra 3. Our banner vendors also sell similar versions of that class machine (e.g. TechSew 2750), but having a local, no-shipping, carry-in-service option is a BIG advantage.

-

Binding and tape folding is an art and science in my experience. If your binding setup worked flawlessly, you got lucky by using the right combination of mount angle , alignment and height, tape folder width and thickness, tape width and thickness, material thickness, and a few other factors. Change one thing and all bets are off.

-

Edge Guide for Consew 225 (and clones)

Uwe replied to KeithHideWorks's topic in Leather Sewing Machines

Please report back after you get it. I enjoyed reading the Amazon review of the football player who struggled to get this magnet off his fridge. -

machine for handbags... possible singer153

Uwe replied to beltbuckles's topic in Leather Sewing Machines

I'd recommend spending a day for little road trip to visit Gregg and his showroom - it may save you weeks of frustration and is very likely your best bet for getting off on the right foot with the right machine (in good working condition.) After you know a little more you can start playing the CraigsList roulette for your second machine.