-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

Pfaff 335 binding attachment on Seiko CW-8b(consew 227)

Uwe replied to Jordanball33's topic in Leather Sewing Machines

Sorry, I don't have any hem attachments. -

Pfaff 335 binding attachment on Seiko CW-8b(consew 227)

Uwe replied to Jordanball33's topic in Leather Sewing Machines

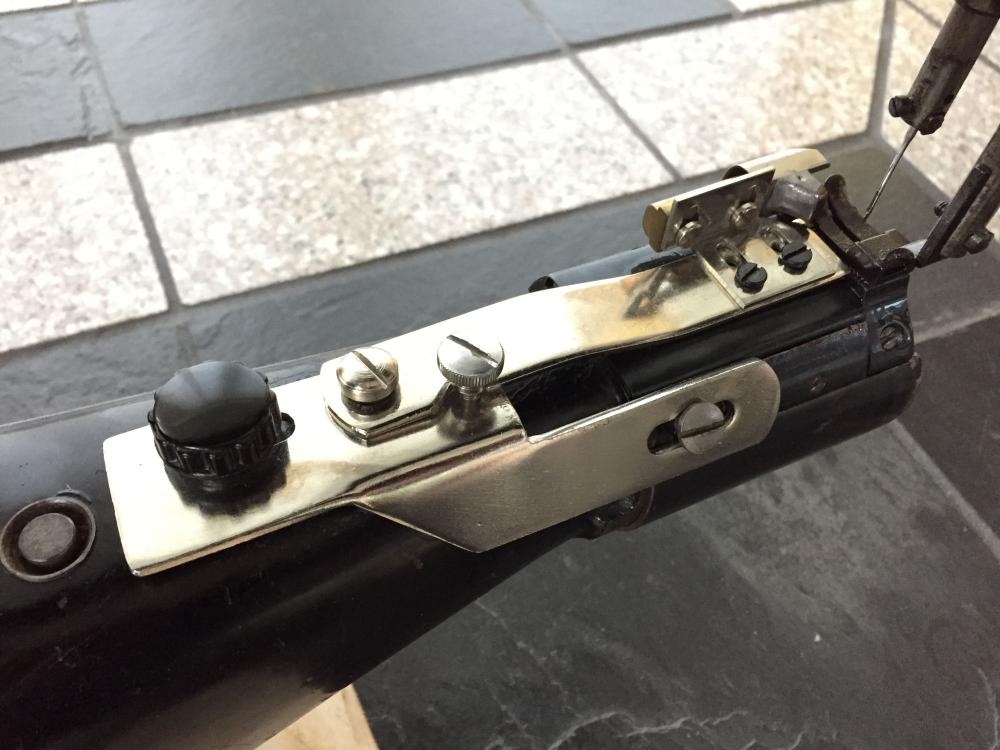

As a follow-up to my earlier post, I ordered a sample of the KHF48 binder kit made by Kwok Hing (retails for around $65 including the tape folder). It fits nicely on my Singer 153W102, so there's a good chance it might also fit a Consew 227 (but it didn't fit my Juki 341 or DA 269). Here are some pictures of the KHF48 installed on the SInger 153W102: -

I just posted a separate topic for the video below. I thought it would make sense to include it here, too, since this thread is what got me going on figuring out my Cowboy 4500's hook timing procedure and reverse stitch issues. Perhaps the video will help some folks who run into similar issues:

-

I spent some quality time with my Cowboy CB-4500 trying to wrap my head around the adjustment procedures for hook timing. Best way to learn is trying to teach somebody else. Which is one reason I make the videos - it helps me understand how things work. Hopefully others will find it useful, too. Here's the video:

-

recomendations for a good heavy duty, walking foot, zig zag

Uwe replied to mixmkr's topic in Leather Sewing Machines

Sergey at SewPro also has a few heavy duty zigzag options that you can actually buy. The SEWPRO 146 RBI seems like a sensible choice. -

recomendations for a good heavy duty, walking foot, zig zag

Uwe replied to mixmkr's topic in Leather Sewing Machines

This Keestar GA204-104A sure looks like a step up from a Singer 107W1 -

recomendations for a good heavy duty, walking foot, zig zag

Uwe replied to mixmkr's topic in Leather Sewing Machines

Seems like we already went over this last December: -

You got some good deals there! My recommendation would be to leave the Quick Rotan on the Imperial Zig-zag and use that setup as it is. It's not really worth the time and aggravation moving that Quick-Rotan setup and it'll just never be the same again once you rip it apart. On the Singer 111, a simple, worthwhile upgrade is to swap the clutch motor for a simple servo motor with a small 50mm pulley. You'll have two very capable machines that will actually sew. Use them for a few month and then decide if you still want to swap motors or make other upgrades.

- 12 replies

-

- 111w155

- quick rotan

-

(and 1 more)

Tagged with:

-

Don't. That's my advice. Buy a rated/tested/approved strap. Logging is deadly enough as it is, without guessing if a home-made strap will hold or not.

-

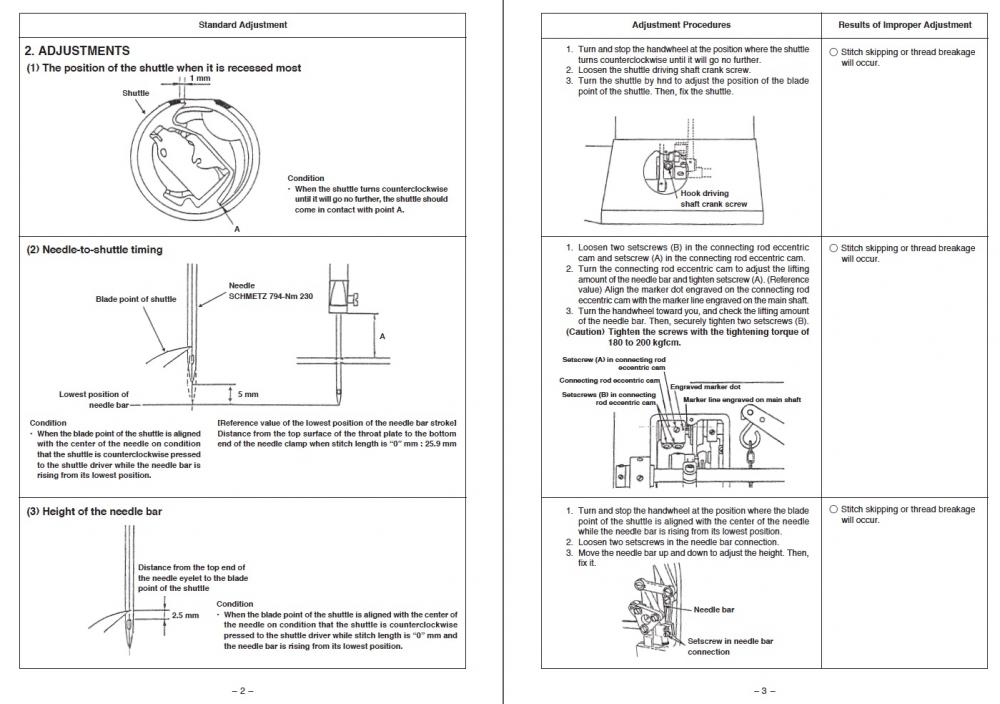

It may seem that way, but the manual states fairly clearly that the 25.9mm distance is the "Reference value of the lowest position of the needle bar stroke." The shuttle driver is supposed to touch the needle slightly - that's what prevents the needle from getting deflected towards the hook (and getting hit by the hook.) The shuttle driver also acts the needle guard. The Juki TSC-441 Engineer's manual can be confusing, especially if you read it on the computer one page at a time. The manual makes (slightly) more sense when viewed as two-page spreads, or printed as a booklet like this: Now you have the target settings on the left, and directly opposite to the right you have instructions on how to change that particular setting. Alas, the adjustment instructions for step 2. on the right side (middle of page 3) still confound me. But I'm determined to figure this out over the weekend.

-

There may not be a "qualified" Cowboy dealer in all of South Africa, since the original dealer/agent didn't really set things up correctly to begin with, according to the original post. Sometimes taking the machine in for service is just not an option. Well over 99% of all people do not live within driving distance of a qualified Cowboy dealer. I'd say certain hook + race combinations just don't work well together. Mixing and matching parts between OEM (Juki) and aftermarket copies (Cowboy and others) does not always yield desired result. If an aftermarket copy is a truly faithful copy of the original, then the OEM parts should work. Some manufacturers make subtle design or manufacturing changes (on purpose or accidentally) that go unnoticed but result in poor parts interchangeability. I have a feeling the issue of thread getting pulled into the race during reverse has, among other things, to do with very subtle differences in the curves and slopes of the shuttle hook tip itself, and also the shape of the right edge of the race and backing ring. Thread material, and how sticky/slippery it is may als affect this issue. If the thread does not want to slide back on the hook during reverse, it is more likely to get dragged into the race. A slight burr on the hook will have the same effect. Aggressive polishing of the hook tip may make things permanently worse. The opposing movement of hook and needle during forward stitches hides many imperfections and timing flaws. Sewing in reverse where both needle and hook move in the same direction, but at different speeds, is much less forgiving. I'm working through the hook timing instructions in the Juki TSC-441 engineering manual (Juki 441 Engineers Manual.pdf). It's not exactly intuitive and some steps don't compute in my head quite yet. Missing reference marks on the machine don't help, either. In the meantime, I made a video showing how my machine's race and shuttle hook fit together and how things come apart. Perhaps it will help others notice some differences, or confirm that theirs is the same as mine in the video.

-

I decided to get to the bottom of my machine's issues in reverse at max stitch length. I now know how it snags the thread and why it occasionally skips a stitch in reverse. Exactly how to fix the issue, I'm still not sure about. I made a needle feed throat plate from clear acrylic so I see could what was going on below. I made a video for the occasion and it might be of interest to folks with a Juki TSC-441 class machine, even if they are not experiencing any issues. On my machine the thread snag is caused by the top thread loop getting pushed into the race channel by the hook. Using thicker thread may actually avoid this issue because the thick thread is less likely to squeeze into the tight gap between the shuttle and race channel. I'm using size 138 thread in the video. I may need to tighten up the race channel a little (not sure how/if that is even possible.) The hook-to-needle timing on my machine looks spot-on to me. Alas the hook does not go back quite far enough to make reliable stitches in reverse at max stitch length. Perhaps retarding the hook a little bit may improve clearance between the needle/thread and the tip of the hook in reverse at max stitch length. Sewing at higher speed may also help, actually, as the hook gets tossed back and forth and is more likely to rest against the shuttle drivers push point. My slow-motion hand turning in the video does not create much momentum to toss the shuttle to the limit stops. Here's the video for your entertainment:

-

You can copy and paste the web address of your video (in this case "https://www.youtube.com/watch?v=EDDnYJoJqH8" ) directly into a reply and it will be automatically embedded for easy access:

-

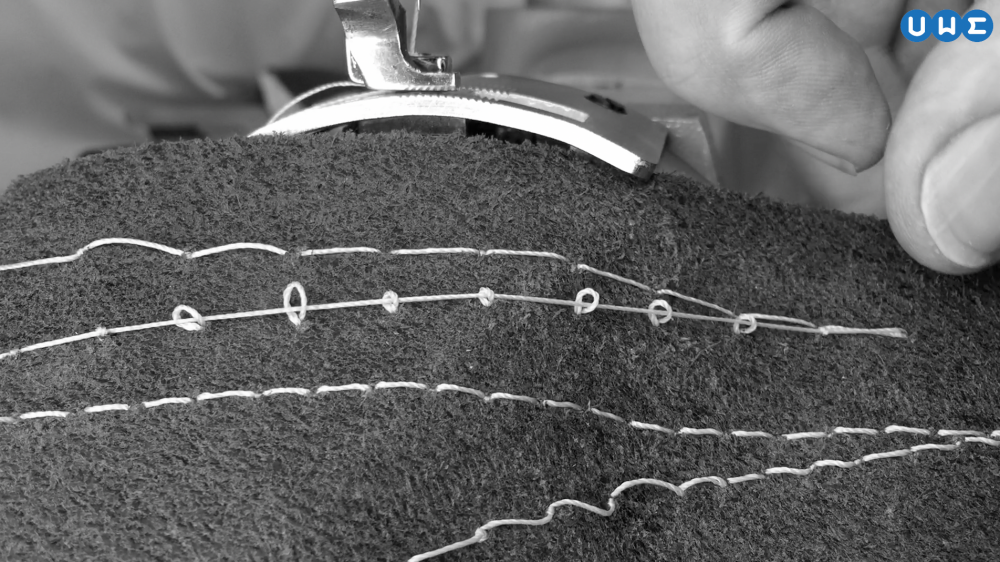

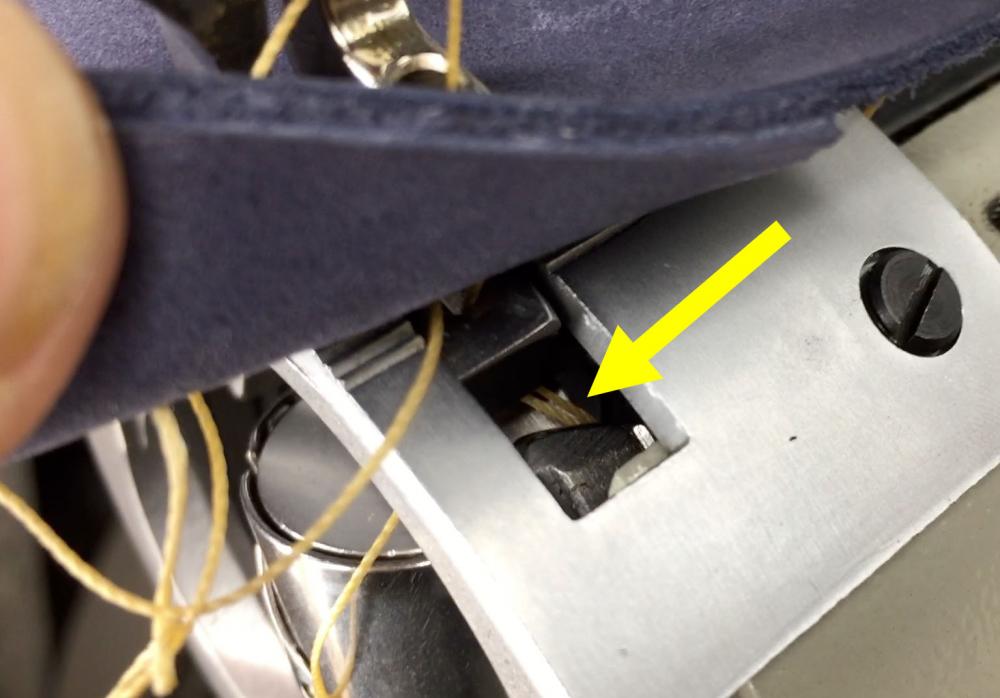

I finally got a few snippets of film catching the machine as the thread gets snagged. It's hard to see and even harder to film, but my machine actually manages to snag thread in two different ways. One is subtle and only causes somewhat loose stitches at the bottom, the other is a major snag and causes big loops of top thread on the underside. The main problem is when the thread gets snagged between the shuttle and the race: The photo below shows four rows: Top: forward Second: reverse with big snag loops Third and fourth rows are forward again with smaller stitch length followed by reverse with moderately loose bottom stitches. I still don't know exactly what causes the snags or how to fix them. I put together a few video snippets showing how my machine catches the thread under certain circumstances. This is not some elaborate how-to-fix-it video, just documenting what can go wrong.

-

The fix was super easy! Just point a camera at the machine and threaten it with public shaming in social media and it'll make perfect stitches in both directions at all stitch lengths!

-

So I was just trying this out on my Cowboy 4500, and, lo and behold, it does the exact same thing when I reverse at maximum stitch length! It sews just fine in both directions when I select a smaller stitch length, but at maximum stitch length in reverse, the thread loop snags momentarily between the shuttle and race, the take-up lever pulls more thread from the spool with a snapping sound in the upper thread path, and leaving a loop at the bottom. I'm not sure yet why the thread snags or how to fix this, actually. I guess it's my turn to take a video snippet of my machine misbehaving and report back.

-

I'd open the hook cover, turn a few stitches very slowly in reverse by hand and closely inspect what's happening as the thread gets wrapped around the hook. Your top thread may snag some place in reverse and pull more thread from the spool, which the take-up lever cannot pull tight anymore. A video snippet uploaded to Youtube is a great tool for remote debugging.

-

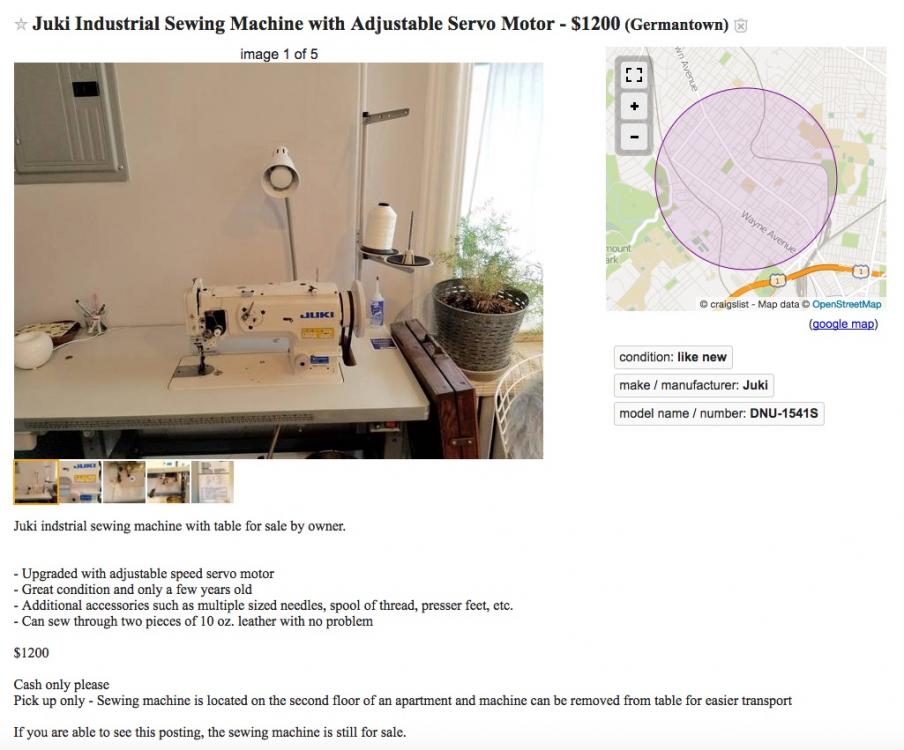

That Juki 1541S in the CL ad came from @Gregg From Keystone Sewing . The machine in the CL Ad looks to be in very nice condition. The price for that machine new from Keystone $1,510. Here's a snapshot of the CL ad for this juki DNU-1541S, just in case anybody's interested:

-

Also make sure you actually pull up the bobbin thread through the feed dog hole. You can't just leave the bobbin thread dangling underneath after changing the bobbin. Hold the top thread and hand-turn one cycle to pick up the bobbin thread and bring it to the top. The hold both threads for the first few stitches to avoid tangles underneath.

-

Looking for a shoe patch machine

Uwe replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

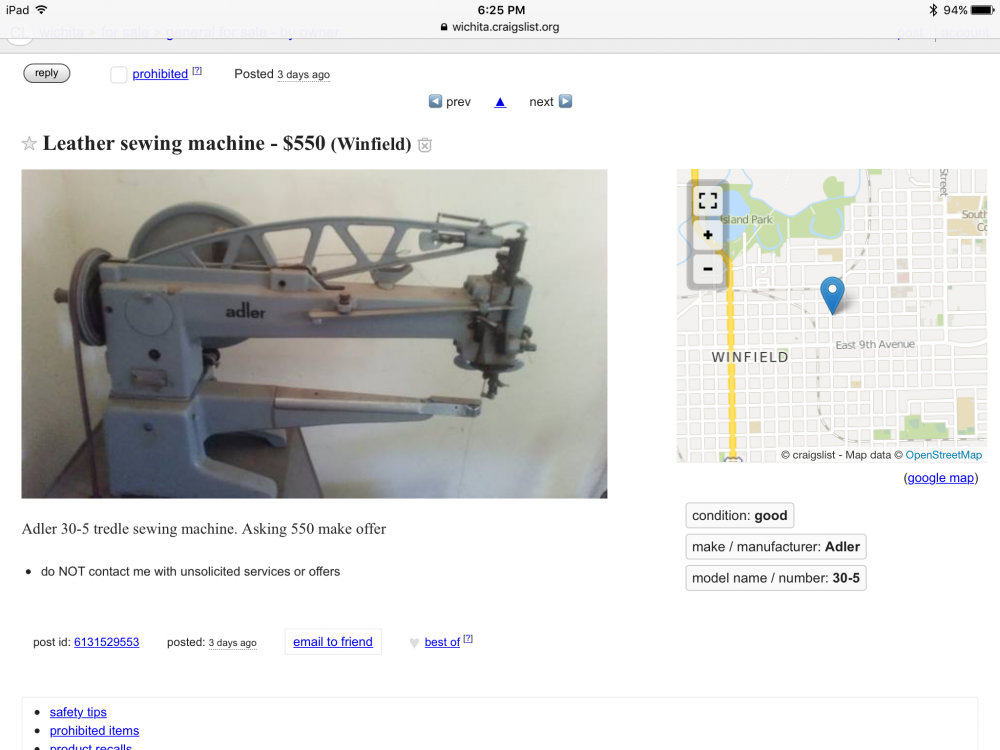

That Adler 30-5 sure looks like it's worth a loooong drive to pick up. If I was within driving distance, my inquiry to them would go like "I'll take it. When's a good time to pick it up?" https://wichita.craigslist.org/for/6131529553.html -

Pfaff 335 binding attachment on Seiko CW-8b(consew 227)

Uwe replied to Jordanball33's topic in Leather Sewing Machines

When you get a chance, please let us know exactly what you ordered and how it worked out. Did the folks at Altanta Attachment offer any insights you care to share? -

Pfaff 335 binding attachment on Seiko CW-8b(consew 227)

Uwe replied to Jordanball33's topic in Leather Sewing Machines

I'm afraid almost nothing form that Pfaff 335 binding kit will fit on a Consew 227. The cylinder arms are totally different. The off-the-shelf binder you're looking for will be similar to this KHF-48 style binder made by Kwok Hing for large diameter cylinder arm swing machines.(http://www.kwokhing.com/KHF/app/app_bi_cy.htm) -

few machines to choose from, which one would you pick

Uwe replied to beltbuckles's topic in Leather Sewing Machines

The Pfaff 138 gets my vote. There's a detailed topic on that machine: -

Many stands in the technical part of the show did indeed have "no cameras" signs plastered all over. The entire Juki stand was off limits for photos and videos. I took only a handful of photos and one video during the show. I may post about a few items here and there as time and motivation allows, but I don't plan to write a detailed trip report.