-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Uwe

-

Atlas is Atlas Levi's house brand. A double needle post bed sounds like a good candidate for making bags with french seams. The Atlas AT20T53 is only $1,200 almost too cheap even for a clone - you'll be hard pressed to find anything cheaper in that configuration that still makes a stitch. The ATlas may work just fine, though - I have no first -hand experience with them. Just for reference, I have a nice used Durkopp Adler 268 double needle post bed that I won't let go for under $2,000. My general rule is that a good used original is worth as much as a decent new clone. The Atlas machines are NOT clones of Durkopp Adler machines, just to make that clear.

-

Well hello there, former almost neighbor! Feet and other common parts are readily available on Ebay and from various vendors. Adler 67, 167, and 267 share the same feet, throat plates and feed dogs, which is nice. I have a few Adler x67 parts in my Ebay store (see link in signature below) made by Kwok Hing, including feet, throat plates, and feed dogs. As for upgrading the hook, it's not quite as simple as swapping out the hook, I'm afraid. There are a few other parts that need to change (e.g. take-up lever) and the larger hook may also be taller, which means you may have to lower the hook carrier frame, which is not an easy thing to do. Compare the parts diagrams and find all the parts that have different part numbers - I'm guessing at least a dozen parts are different. I have a feeling most folks decide against an upgrade because of the complexity involved.

-

Need Needles for my Singer 144WSV37

Uwe replied to DelNeroDesigns's topic in Leather Sewing Machines

Please post some pictures of your machine. I want to see what the 144WSV37 looks like. Is it a long arm machine? Take some pictures with the face cover at left end of the head removed, too. Your needle bar may have two lines marked on it. Those are used to set the needle bar to the correct height. If the lines are present on a normal, well adjusted machine, the upper of the two lines should be just barely visible at the bottom end of the needle bar bushing when the needle bar is at its lowest position during the cycle. Then, if you keep turning the hand wheel until the lower line is just barely visible, that's your hook timing position. If your upper line moves well below the needle bar bushing, that's an indication that the needle bar was lowered to accommodate a needle that is too short. The problem with a too-low needle bar is that it may touch the feet during the cycle and bind or rub, especially when the feet are raised (e.g. for bobbin winding.) Adjusting the needle bar height is not hard to do. Usually there's just one screw (maybe two) to loosen and then you can slide the needle bar up and down. This is an important step during hook timing. You'll want to know how to do that unless you enjoy schlepping that monster to a technician a lot. The Singer 144W103 Manual may be useful, too: 144W103_W203_W303.pdf -

Sometimes the "wick" is not a wick at all, but a protective "filter" pad that keeps dirt and grit out, but lets oil through. Once you remove the pad, any little piece of dirt or grit gets directly to the gears or bearing.

-

There really are no repair manuals for most vintage machines, as far as I know. They just assume that's what you learn in your apprenticeship when you become a sewing machine technician. Once you've taken apart a few dozen machines, things will start to look very familiar in other machines. The closest thing to an actual repair manual with removal and re-installation instructions is this Military training manual: TM10-3530-202-24.pdf . It covers repair instructions for variety of machines, including the Singer 111, which shares certain design elements. with your 153. Having a beater or parts machine to tinker with is really useful, so you know what's going on when you start working on a precious machine. Often you have to get a little creative. In the absence of a manual for a specific machine, documentation for a very close relative can be very useful. In your case of the Singer 153, the Consew 227 is that close relative. Check out the User Manual for the Consew 223/227 (223.pdf). Also, the Consew 227 Parts Manual shows parts in small groups as mini-exploded views where you can tell how things go together, or if something that looks like a screw really is a screw.

-

After cleaning I usually squeeze some grease directly onto the gears before installing the gear covers again. That way I know for sure that the grease is actually ON the gears rather than just inside the box. You can always add more grease through the access holes you mentioned. Tri-Flow grease is what I use on my machines and I like it. One thing to watch out for is that if you separate the gears during cleaning or to make adjustments, make sure they go back together meshing with the same teeth. Some gear sets are matched pairs that are intended to be meshed with specific teeth on both gears. There may be a factory mark on both gears to line them up. You can also add marks yourself with a sharpy pen before separating the gears. The gears should still work even if they're meshed in a different position, but they may be noisy.

-

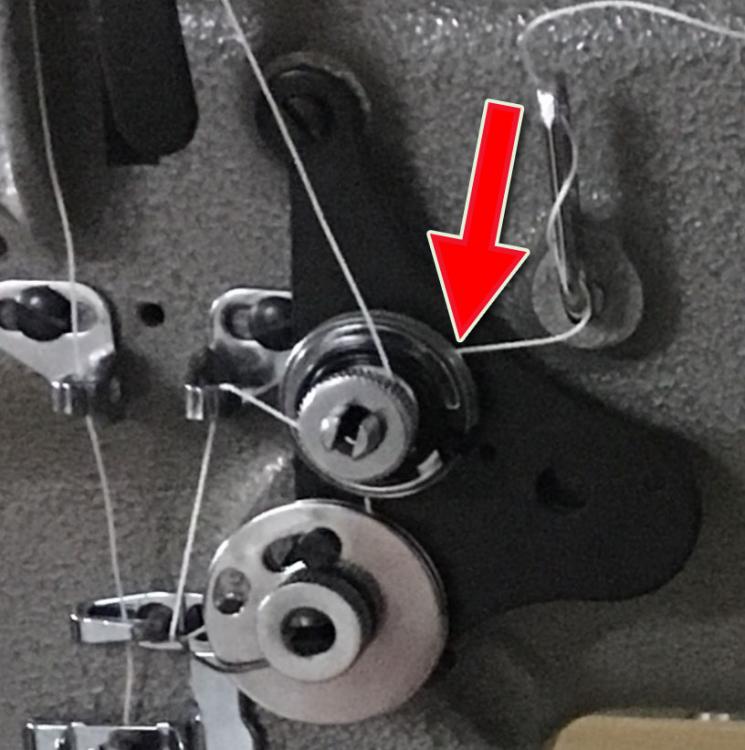

There's a set screw on the bottom right that locks the post of the check spring unit in place (I was so focused on the check spring unit when I made the video a few months ago that I didn't notice that the tension discs weren't threaded)

-

It also looks like the incoming thread is BEHIND the two tension discs instead of BETWEEN the two tension disks. Unless the thread is between the tension disk you'll have no top thread tension at all which all but guarantees loops on the bottom.

-

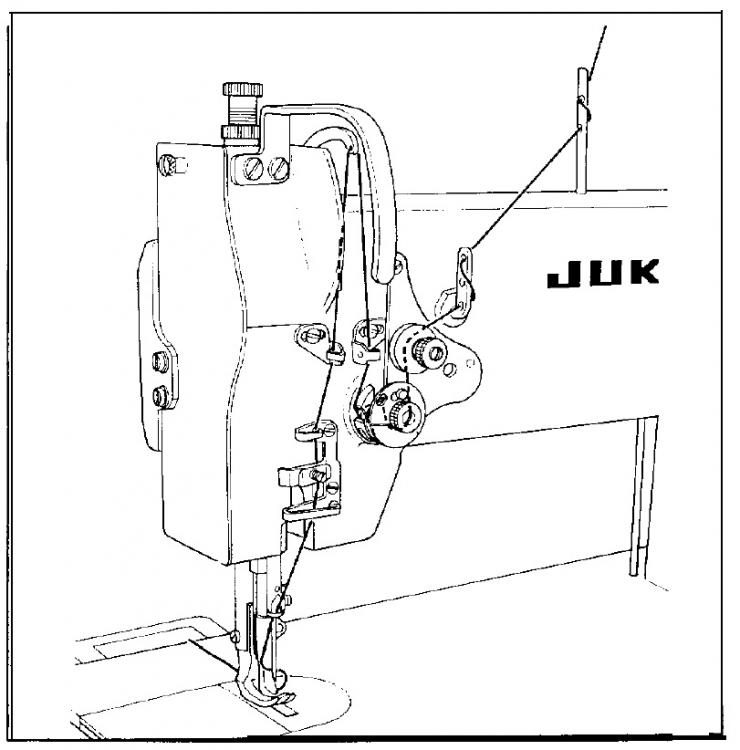

Don't change things there. It may never be the same again. You may not yet be aware of Rule #1 of sewing machine maintenance: Never loosen a screw unless you know what it does. I'm also a little concerned that your Juki DNU-241H looks quite different in the head area from the one that Leif Labs describes in this blog post: Can you please post detailed pictures of your machine's name plate and other identifying marks? Also a few pictures that show the whole machine. Try not to have pictures backlit (strong light in the background) - it' makes it very hard to tell what's going on. Turn the machine around or shine a bright light at the front (or touch and hold the area on thor phone screen you want to be in focus and well exposed.). I know it's a pain to fuss with lighting, but it makes all the difference in the word.

-

All three machines you listed are garment/embroidery machines in the domestic range. The 191-20C appears to be the strongest of the three. The only thing heavy duty about the Singer Heavy Duty 441 is the marketing hype and the paint color. None of them are well suited for sewing leather beyond a layer or two of very thin, soft garment weight leather. Plan for two machines, one that does your light garment work (domestic is fine here), and a second machine to do the leather work properly. Check out this thread to get an idea on the type of sewing machine you need to sew leather:

-

My upload speeds were super slow tonight, so here's a second video I made earlier tonight about using that adjustment screw Bob mentioned to set stitch length.

-

I had to fuss with my Singer 153-W102 quite a bit to get the stitch length adjustment to work right. My thread were broken and jagged, too. I used a Dremel grinder to clean up the threads and make them smooth again - that made a big difference on how smooth the adjustment knob turned.. I had made a video a few months ago that goes in into a little more detail of the mechanism. Hopefully it will help you get your stitch length adjustment knob too cooperate.

-

I'd stay away from Ebay until you know what you're doing - it's a gamble under the best of circumstances. Buy from a reputable dealer or somebody you trust. Most people on Ebay do NOT know how to ship a sewing machine and thousands of machines have died in transit. In general, industrial sewing machines are designed to sew whatever you can fit under the foot. Look for unison feed (bottom+top+needle) machines with at least 10-12mm foot lift. Resist the temptation to change the question every time you get an answer. For sewing multiple layers of leather, a bottom-only feed machine will not make you happy.

-

You may not be able to use your braided waxed thread in a sewing machine, at least not for long. You'll spend two hours cleaning the wax out of the machine every time you use it. Consider not buying from your local dealer, especially if they're all weird about even giving you a price. You're country is part of the EU and the Schengen Zone, which makes for super easy cross-border travel and purchasing. Take advantage of that. Personally, I'd plan an overnight road trip to Bayreuth in Germany (6 hours drive) and visit Sieck. Germany is place to be to get good, used original Durkopp Adler machines. Sieck has lots of nice, original machines both new and used and their prices are very good in my opinion. The Sieck website lists prices for almost everything they sell - it's a great reference. Consider the SIECK 267-373, which is their version of the Durkopp Adler 267-373 for 1.800 Euro with a nice servo motor. They also have the original Durkopp Adler 267-373 machines used for even less.

-

Congratulations on finding a great bargain! The simple thing to do is to get a servo motor with a small 50mm(2") pulley first and see if it is slow enough for you. If you then find you need it to be even slower or have more torque, you can always add a speed reducer pulley later on.

-

Since your budget is limited, you'll probably get a Golden Wheel, the brand of the Chee Siang Sewing Machine company. Luckily, Chee Siang is one of the very big companies that produces high quality copies of many original designs. They make nearly everything, or so it seems. I have yet to find a famous machine design that they don't make. The Golden Wheel brand doesn't have much of a presence in the U.S. But I strongly suspect they are behind many of the aftermarket brands that are sold in North America. Check out the website at http://www.golden-wheel.cn/en/product-2 in the "Heavy Duty" section, either under Flatbed or Cylinder bed. Each of these categories have a "Unison Feed" section. There you will find all the candidates for your work. For example they have cylinder arm machines of Juki TSC-441 (CS-441) , Durkopp Adler 205 (CS-205), and Pfaff 335 (CS-335) designs. That small sample right there covers the majority of machine designs people on this forum use and recommend. On the flatbed side, check out their version of the latest Durkopp Adler 867 design, the CSU-8671 (not cheap, but it's the machine design I would buy new right now - it's bound to be a future classic.) The other flatbed unison feed machines are all designs you'll recognize from discussions on this forum. One other nice part is that Golden Wheel posts most manuals right on their website, which is how it should be. They also make and sell parts for their machines, not all aftermarket companies do. Good luck with finding a nice machine!

-

Sold to a good home in Indiana.

-

Yes, the motor is just a temporary test setup to check stitch speeds and take measurements. I'm building a proper table for the machine to get it ready for demo (and sale.) I'm not sure exactly what parts are involved to add reverse to a Singer Class 7, so I don't know which Singer 7 subclasses are compatible with the retrofit. I know Singer Class 7-31, 7-33, and 7-34 can have reverse, but there may be more.

-

Some Singer Class 7 models can be retro-fitted with reverse. The lever is on the back and usually operated via foot pedal or pneumatic cylinder. With the right motor control you can even program automatic back-tack and other tricks. Adjustment screws at the top and bottom allow to balance forward and reverse stitch length. Here's a picture of my 7-31 that has the retrofit reverse lever:

-

I'm still putting my money on the top thread snagging somewhere below the throat plate. You don't get big loops of top thread underneath like that unless more top thread is pulled from the spool at the wrong time, leaving the take-up lever without a chance to pull the knot tight. I may sound like a broken record to some: Take the belt off the hand wheel and do a few very slow, hand-turned stitches and really look, feel, and listen for anything that is not how it should be. Knowing how things should be is often the hard part. "Smooth and without hang-ups" is a good starting point.

-

The picture may indicate something else in the thread path going on. Your top thread path may not be right. Your top thread may snag somewhere as it wraps around the hook and bobbin. Maybe the bobbin case opener doesn't work right. As for the tail of the bobbin thread after installing, you pull it up through the feed dog hole. Hold the top thread and make one manual turn. Make sure the bobbin thread is under the tension spring of the bobbin case and that you have very light tension as you pull the thread (30-50g) This Juki DNU-241H manual (http://www.raichert.com/adobe/dnubook.pdf) has a little more than the basics.

-

The picture doesn't really tell me much detail about how you're loading the bobbin. For remote debugging, you're going to have to give us little more to work with. What model Juki your machine is and what do you mean by "isn't panning out". Do you have a user manual for the machine? What does the manual say about loading the bobbin? If you don't have a manual, have you looked for one online?

-

Looking for Singer 29k thumb nut #113088/nn88w

Uwe replied to Wizcrafts's topic in Leather Sewing Machines

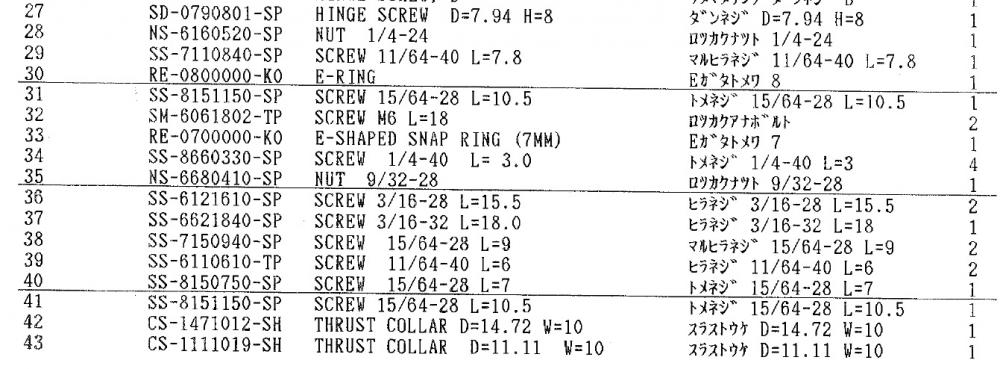

Juki is happily mixing metric, SAE, and specialty Singer threads on their machines. Sometimes they're just messing with you. The 15/64-28 is in the parts list snippet below (from Juki TSC-441). Also note the 3/16-28 and 3/16-32 screws to drive you to the edge of insanity trying to match up threads. 15/64-28 is also dangerously close to an M6-1.0 screw. 15/64"=5.953mm, 1mm pitch is 25.4/inch. Both 1/4-28 and M6 screws will thread a few turns into an 15/64-28 threaded hole before binding. -

Looking for Singer 29k thumb nut #113088/nn88w

Uwe replied to Wizcrafts's topic in Leather Sewing Machines

Thanks for solving my little part mystery, @Evo160K! My part is also a SIMANCO 91436. The thumb nut threads nicely onto a 15/64"-28 bolt from my Juki parts bin. -

Looking for Singer 29k thumb nut #113088/nn88w

Uwe replied to Wizcrafts's topic in Leather Sewing Machines

Just click the link below to pay and then send me a PM with your postal mailing address. http://paypal.me/UweGrosse/12.00