-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

This is the last one, I really need to stop!

Uwe replied to Chayse's topic in Leather Sewing Machines

Congratulations on a great find! Well worth the drive, I'd say. It's amazing how well the looks-like-rust oil residue cleans up with just a little TLC. For actual rusty bits (like on the bobbin winder), I've had very good results with Evapo-Rust. Just submerge the rusty parts for an hour or two and rinse/scrub with water, then dry off and buff a little. I have some presser feet for this machine. Kwok Hing makes very nice quality standard presser feet for the Pfaff 335/545/1245 series (Part No. KP1245W, $45) The super-slim left-toe version is also useful (part No. KP-1245-R071, $49) -

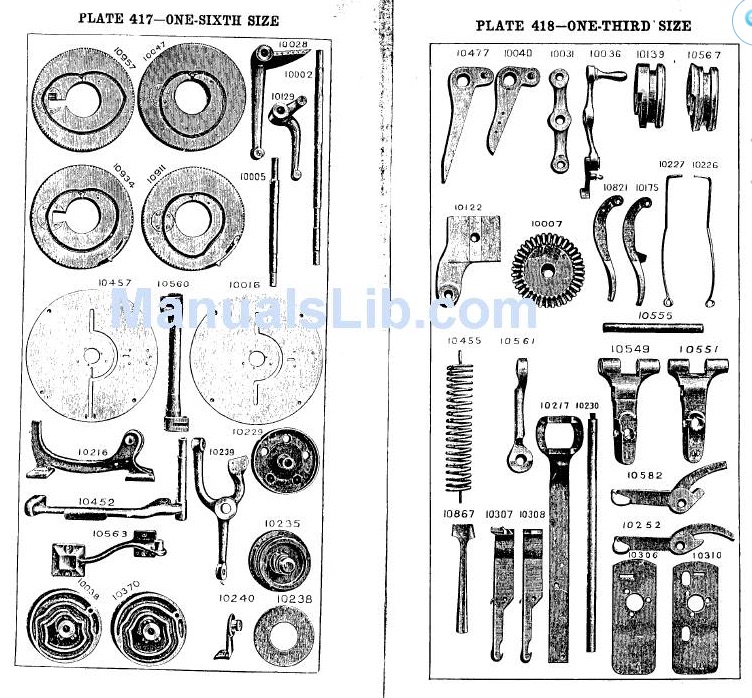

Any machine with a bunch of pattern cam discs in the parts list image plates is probably safe to pass up for a general purpose leather sewing machine.

-

NEW to me... LU-1560n and others - lotsa questions!

Uwe replied to R8R's topic in Leather Sewing Machines

It does seem like a shame to sentence a once-fine machine like that to death by computer, but I'm not sure it serves any useful purpose without that ancient computer. Non-computerized pattern stitchers don't really fare that much better, though - I'll probably end up dragging my half dozen vintage box-x machines to the scrap yard, too. -

It's easy but not necessarily obvious. The machine in the video snippet is an Adler 205, but almost all shuttle hooks work the same way in terms of how to release the latch to pop out the bobbin.

-

I'll have to set aside some time to do some pulley trials on the lathe. Thanks for the workholding tips!

- 5 replies

-

- was not leather

- adler 120

-

(and 2 more)

Tagged with:

-

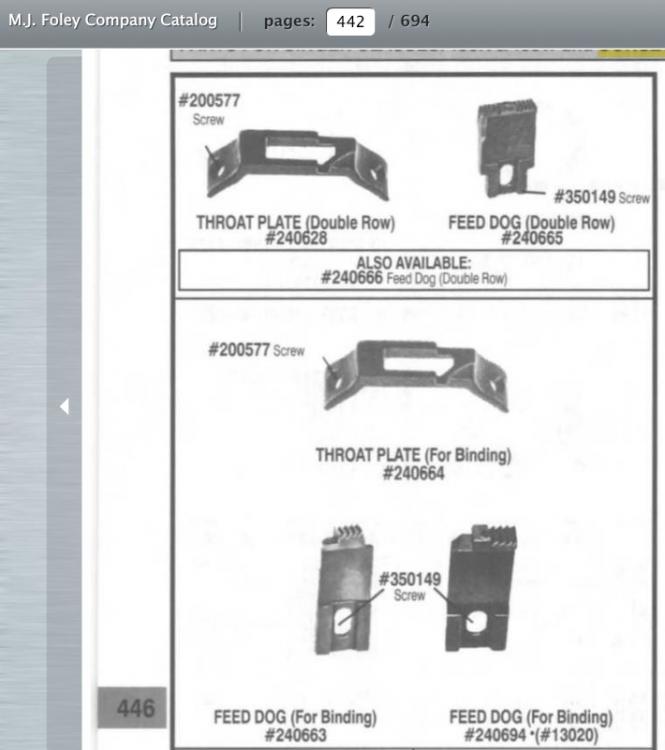

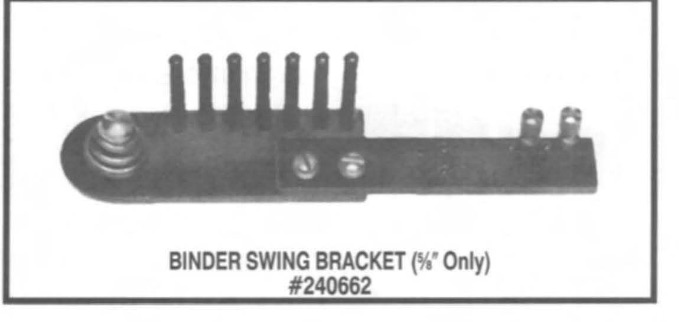

According to the MJ Foley Catalog (requires Flash plug-in), the Singer 153W and Consew 227 generally accept the same parts. They have some special binding feed dogs and throat plates which may be of interest, and also a swivel arm for attaching tape folders. Which parts work with your existing customized parts is hard to tell. Most regular dealers can order these parts for you. Based on the Foley catalog info, my KHF48C 3/4" kit may actually fit your machine, too. It's unused and available for $70 (send me a PM if interested.) Here are some screen shots from the MJ Foley catalog:

-

NEW to me... LU-1560n and others - lotsa questions!

Uwe replied to R8R's topic in Leather Sewing Machines

It's probably not worth bothering with or even possible, as you say, to convert the two-needle machine into a proper single needle machine. You may be better off cleaning up the two needle machine, selling it and putting the proceeds towards the 1508n you really want. The Juki AMS-210C does seem more of a liability than an asset. Nobody wants to deal with decade(s) old computer technology unless they're well paid to do so. -

Small and large are relative and depend on what you are actually referring to. On the KwokHing binder pages, they really mean large diameter vs. small diameter cylinder arms on machines. In that context, the Consew 227 and other vertical axis hook cylinder arm machines ( e.g. Singer 153W102, Juki 341, etc.) are considered large diameter, whereas most horizontal axis hook machines (e.g. Pfaff 335, Adler 69 etc.) are considered small diameter. I have a KHF48C 3/4" binder and the only machine it really fits is my Singer 153W102. I don't have a Consew 227 to test fit. The Consew 227 pictured earlier looks like it may only need a standard tape folder like the one shown below and a short inner binding foot to make it do binding work.

-

NEW to me... LU-1560n and others - lotsa questions!

Uwe replied to R8R's topic in Leather Sewing Machines

Welcome to LW. Juki has a dealer locator on their website https://www.juki.com/distributors-north-america.html . Any Juki dealer should be able to order parts for you. Some of the dealers are here on LW. Online support and ordering options vary. -

The only Adler 104/105 manual I have is an all-in-one affair which covers the common elements up front and then has a bunch of subclass specific supplements. There may not be a standalone manual specifically for the Adler 104-64 subclass. Here's the PDF: Adler-104-105-Manuals.pdf

-

Wow, that is seriously impressive work! There isn't a millimeter to spare anywhere near that reducer pulley. Thank you so much for taking the time to disassemble the parts and document your setup. I had been contemplating mounting a "floating" reducer pulley on a swivel arm, but your solution is way simpler and more elegant than what was bouncing around in my head. I too have a bunch of skate bearings left over from previous projects - time to put them to work. Now I have to figure out workholding for turning my own reducer pulleys. The small pulley seems straightforward enough, but the big pulley stumps me. Is your lathe chuck simply big enough to hold the big pulley on the outside diameter to turn the center hole first? My experience on a lathe is limited and I know just enough to be dangerous and occasionally productive.

- 5 replies

-

- was not leather

- adler 120

-

(and 2 more)

Tagged with:

-

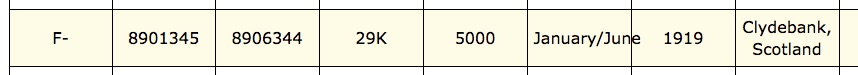

Folks, please include links to sources you use whenever possible. I know it's work and not everybody is up for it, but fact checked and/or referenced info is so much more valuable. According to the ISMACS serial number reference the F-8901955 machine was indeed produced in 1919. The ISMACS model reference list does not provide a production date range for the Singer 29K60. So either it's the a Singer 29K60 with the very rare time travel option, or they started making that particular model earlier than stated above (or the type plaque got swapped or misread.) Photos are super helpful. As for your Adler 67GK373, I'm not aware of any resource for dating Adler machines by serial number. You can narrow it down to within a decade or two by looking at dated documentation like parts lists etc. I'd place an Adler 67GK373 in the mid 70's to late 80's. The earliest mention of the Adler 67-GK373 I know of is January 1976 in a German language service manual (Adler-67-GK373-Justieranleitung.pdf - I don't have an English version and I don't do translations, sorry!) The parts list I have for the Adler 67-GK373 is dated 1982 (Adler 67-GK373 Parts List.pdf) . A photo of the machine and type plate may provide clues to narrow down the date range. It's nice to know when a machine was built, but not the end of the world if you don't.

-

If the metal sheet is thin and soft enough, I doubt the mechanics suffer. Thin copper sheets may work, too. Might be useful for attaching laser-marked or etched name plates or decorative elements. The needle may not be happy for long. Now, what I REALLY want to know is more details on your motor mount and speed reducer pulley. That is probably the cleanest and most compact installation I have ever seen. Can you please make a separate topic on that? I have a few machines with the same form factor I need to motorize.

-

I'm not really familiar with the Consew 220, but if it's a standard industrial garment machine, this may work: This foot looks like what you're describing, a open quilting foot on a regular industrial garment machine: This Youtube video has a bunch of comments, some with sourcing tips (watch it on youtube to see the comments). Perhaps it will be of help to you:

- 7 replies

-

- consew 220

- consew

-

(and 1 more)

Tagged with:

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Uwe replied to Brtz's topic in Leather Sewing Machines

If you knew that why didn't you say that along with with the question? The machine is hard enough to figure out remotely without trick questions. I don't see why Pfaff would make the large lever purposely operate the way you describe. Maybe parts of the feed mechanism are wrong or totally out of adjustment. Maybe the lever cover plate is incorrect. There are dozens of feed mechanism variations and combinations in the Pfaff 145/545/1245 series alone and there's really no guessing exactly which bits they combined for your machine. My Pfaff 545 with extra long stitch length also does not have reverse, but it also has a special cover plate that restricts movement of the large lever to the top half of the normal range of motion (it also has full FWD at the top position instead of the normal bottom.) This machine is just fountain cool weirdness. Since there are apparently no manuals for this exact model and nobody else has direct experience or access to that model, it's all up to you now. Try out all lever combinations and report back. Find out part numbers of your feed mechanism and compare them to existing manuals. Don't rely on your initial assessment of it being a combination of a Pfaff 145 and a Pfaff 4143 being correct, either. It may look that way at first glance, but so far the functionality details and key part numbers (e.g. looper) don't really support either.- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Uwe replied to Brtz's topic in Leather Sewing Machines

Just flip the big stitch length lever all the up and it should sew in reverse.- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Do you know the model number of this machine? It may be an early or transitional Pfaff 571 or Pfaff 474 model where they changed how the stitch length and reverse was controlled (motor controlled bottom wheel drive), and before they got around to changing the casting to remove unused controls. If that's the case there is nothing functional behind that black cover plate. You'll would probably the original Efka controller to set the electronic stitch length control. Here's an example of a Pfaff 474 (the rectangular brown push button in the bed is the reverse button) I found one other example of your machine, which is apparently a Pfaff 1296 model as it came from the factory. Who knows, it may also have a motorized bottom wheel drive.

-

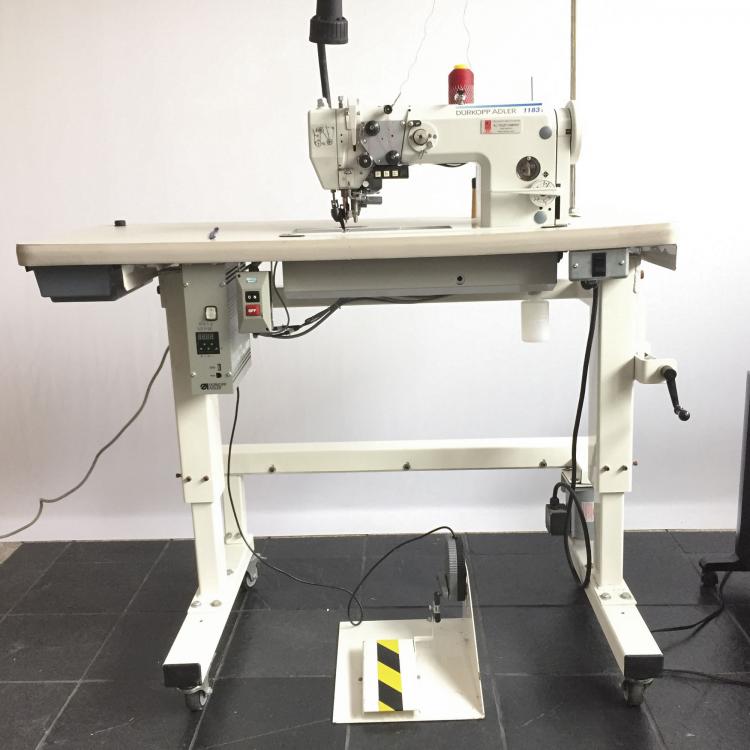

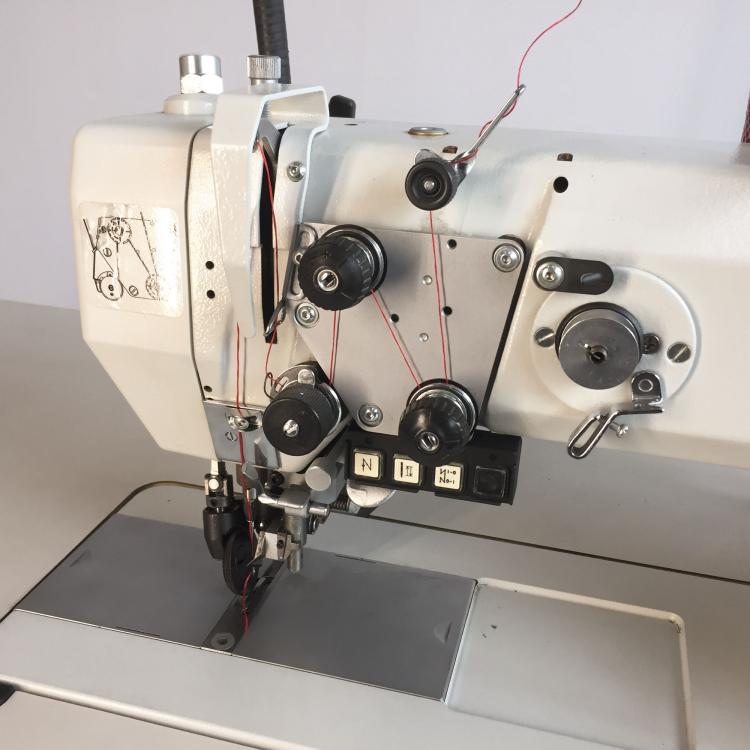

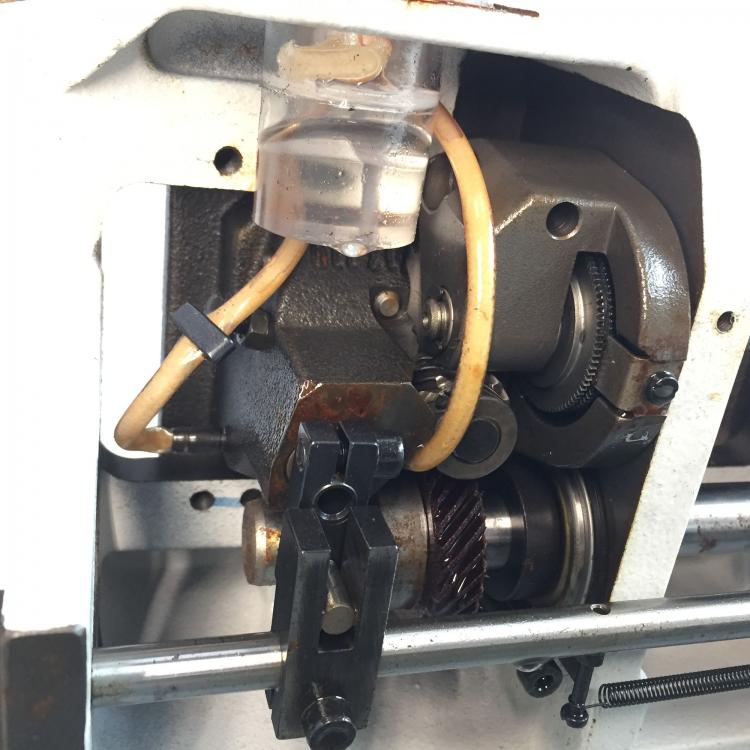

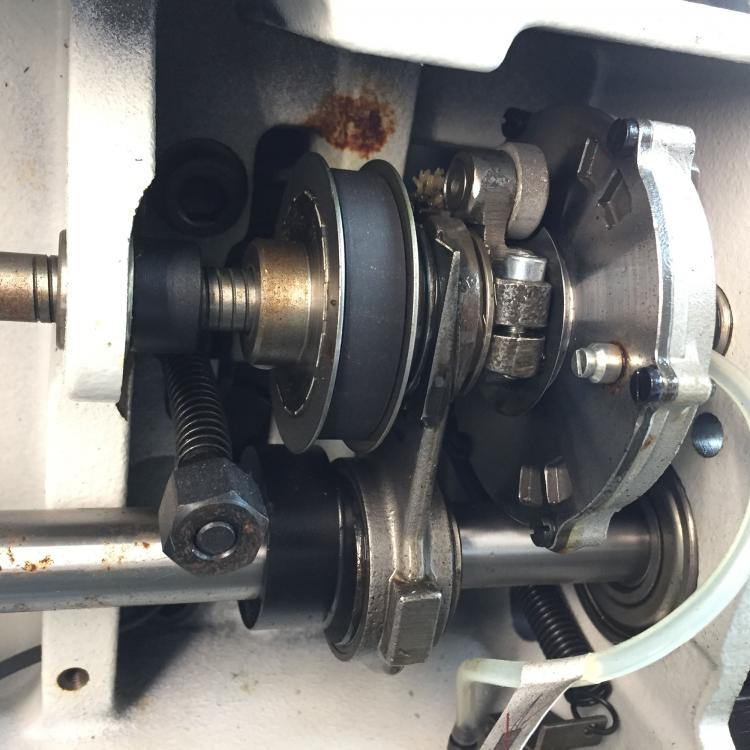

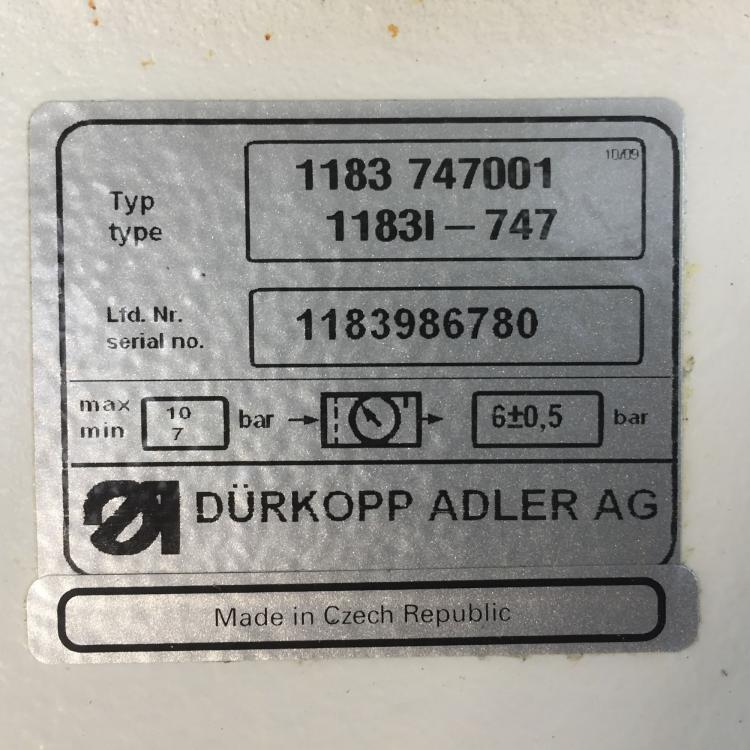

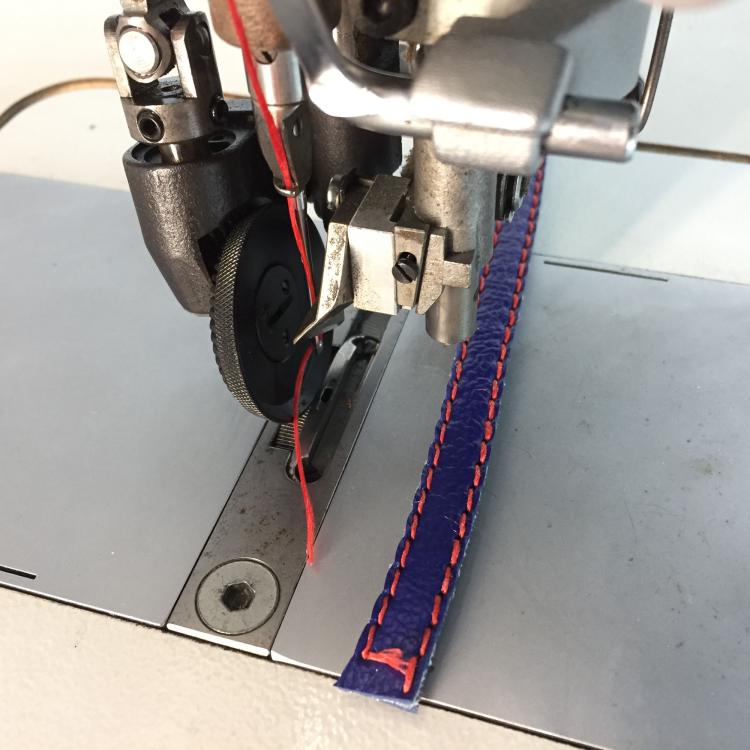

I have a nearly pristine Durkopp Adler 1183i for sale. This package runs over $7K new. I doubt it has ever been used for more than testing and demo sewing. It can be yours for a firm $2,300. The machine has dual driven wheel feed and an edge trimmer that can be engaged as needed. It's an all-electric full-function machine with foot lift, reverse, back-tack, thread trimming. This type of machine is generally used for car upholstery and shoe work, but is also be suitable for light to medium flat work like wallets, watch bands, belts, canvas bags, and the like. It comes with the finest Efka motor and controls (220V single phase, just like an electric oven or dryer). The machine is mounted in a killer table, by far the best I've ever owned. The table is made in Canada and is super sturdy, electrically height adjustable via toggle button, has manual tilt via hand crank, and lockable wheels. Sales flyer, Spec sheets, user and service manuals for the machine can all be downloaded directly from Durkopp Adler. I prefer local pick-up, but may be willing drive to meet you (not driving it across the border, sorry). You'll need a small enclosed U-Haul trailer or similar. Total weight is about 250-300 lbs. I'm working on a little demo video, but it's not ready yet. Meanwhile, here are a few pictures:

-

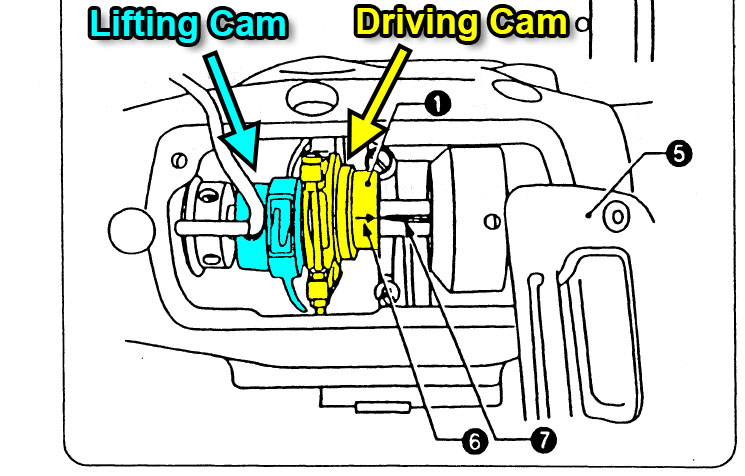

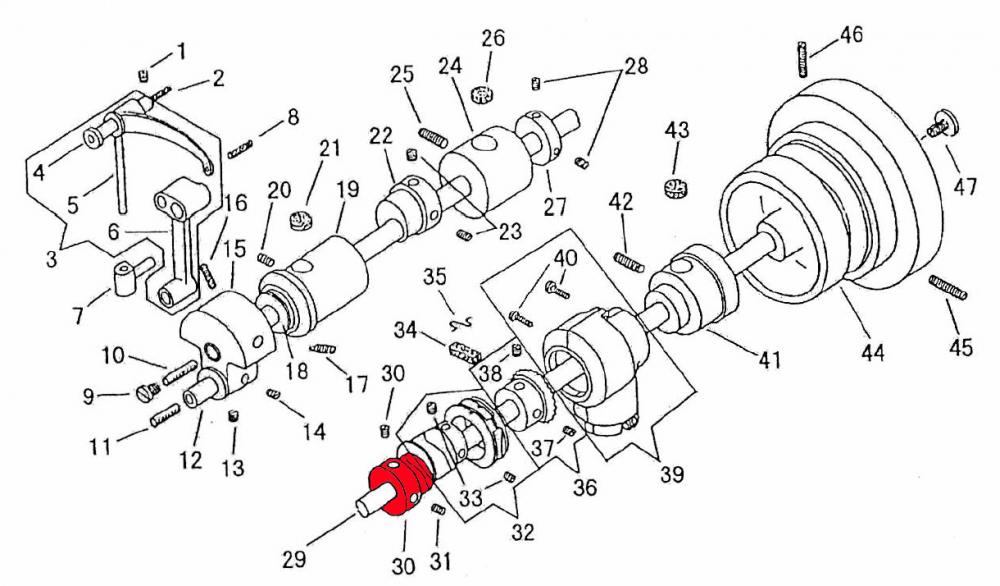

As far as I can tell, the manual only talks about adjusting the feed driving cam. The manual does not talk at all about adjusting the feed lifting cam. The two should be independent and individually adjustable.

-

To me it does look like the feed dog lifting timing is off. The feed dog comes up much too late. Normally, the feed dog is coming up and level with the throat plate at the same time it is in the very front-most position. It then starts lifting above the throat plate and start moving towards the back immediately after this point. The front-to-back movement of the feed dog looks just right to me. I don't have a Consew 206 or Seiko version machine on hand for testing, but looking at the Seiko parts diagram, I'd focus on the feed lifting cam (30) on the main shaft. Mark where it is now, and then rotate it a little one way or the other to see which direction gives you the correct feed dog lift timing. Can you please post the Seiko Service manual here? It's missing from my manual library. Ask a moderator or admin for help if the PDF is too big for posting. They can post any size document.

-

What is the correct bobbin size for Pfaff 335?

Uwe replied to DrmCa's topic in Leather Sewing Machines

Pfaff 335 machines come with different hook sizes depending on vintage and subclass. Modern Pfaff 335 machines have a 40% larger hook. Just get whatever is in your machine now. Shop by part number if possible, based on the parts diagram for your specific machine subclass and vintage. -

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Uwe replied to Brtz's topic in Leather Sewing Machines

That 233 094 looper sure looks like it was designed to pick up the thread on the left side of the needle. It might be worth a try to turn the needle around 180˚ to have the scarf face towards the left, and then adjusting the position of the looper to also pass the needle on the left. With a little luck, it'll just work. That's some fancy laser marked number on your part - it may actually be an original Pfaff looper part number 91-233094-05. Not sure which machine it's intended for, though. There's also a good chance that your looper is actually the original, correct Pfaff looper. Perhaps the needle just got turned around at some point by accident. Your looper is an expensive part, too. It shows up in my vendor database for over $120 wholesale - and that's for the generic, non-Pfaff version.- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

This looks fine to me. Does it not work that way? The spring needs just enough tension to keep the knee pad pushed to the left. Position the movable blocks on the main shaft so that the main shaft has just little play front to back inside the "A"-brackets. The main shaft should have enough play to rotate freely, but not enough play to pop out of the "A"-shaped brackets when you push it towards the back or front. If the "A"-brackets are too far apart, you may have to move one of them. Installing these knee-lift brackets is kind of a pain in the neck (literally).

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Uwe replied to Brtz's topic in Leather Sewing Machines

Are we even sure this is the correct original Pfaff looper? Do we even know what the correct looper looks like? Many Pfaff parts have part numbers on them. The looper may already have been replaced by one that only sorta-kinda works. The geometry of the looper likely determines how big of a loop it holds and how much thread it pulls off the spool. If the loop size is different from what the thread take-up lever is designed to pull tight, then the stitches may be tight or loose no matter what your thread tension settings are. I suspect it's similar to how the thread take up lever has to match the hook size on lockstitch machines. The 102025 looper in the parts diagram looks quite different from the one on your machine.- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

I'm curious how that Ferdco 2000 got started down path of short feet. I have a feeling that the short foot that came with the Ferdco 2000 was not designed for a 441 class machine. I have a bunch of Singer presser feet (36K class, I think) that will mount nicely on my Ferdco Pro 2000 presser bar. Alas, I'd have to lower the rear presser bar about 1/4" for the feet to actually touch the throat plate. Might be a fine and cheap(er) way to go if you run the machine in Bottom+Needle feed configuration. You just have to decide whether you want to retire that one short foot and raise the presser bar to be compatible with all unmodified 441 style feet again, or if you want to commit to modifying every 441 style foot you buy going forward to make them all match that one not-so-original short foot. At this point you probably already have three short feet and they may be all you ever need and work perfectly on your machine.