-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

Heck, if it's free just get it and report back! Don't overthink it. It'll be a great machine to learn with no matter what. Chances are good that it's a really nice machine. I'm voting for the the Taking TK-8BL being a clone of the Seiko STH-8BL:

-

Compression spring for Ferdco Pro 2000

Uwe replied to BaroqueLeatherGal's topic in Leather Sewing Machines

You'll have to find out which machine your Ferdco is based on. I'm guessing it's either a Juki or Seiko. Knowing the original make and model opens up your parts sourcing options a great deal. Post a few pictures of your machine so we can narrow down the make and model of the original machine. -

This belongs in the Leather Machinery section (http://leatherworker.net/forum/forum/222-leather-machinery/) . Perhaps one of the moderators like @Northmount can move it there.

-

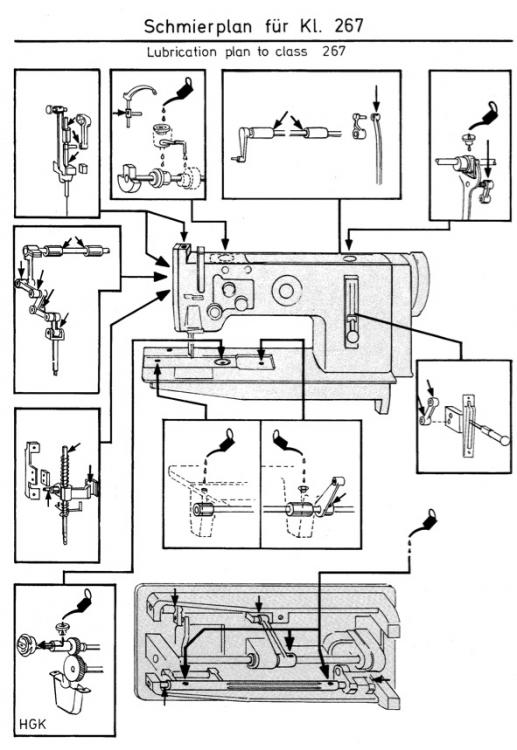

The Durkopp Adler is a manually oiled machine according to the Durkopp Adler 267 Parts list ( adler-267-parts.pdf): The Durkopp Adler 267 Brochure ( Leaflets_Adler_class_267_part1.pdf) has all the specs you need.

-

The window of opportunity on these machines has closed. They may be for sale again in the future at a price point closer to their real value (2017 wholesale pricing for this model starts at $3,400 for just the head with a minimum order quantity of 10 and before shipping from Taiwan.) I'll keep them in my permanent collection until market conditions improve.

-

For $200 just buy and explore it and learn. It'll be worth $200 for the rest of your life unless you destroy it. Singer 29-4 and close relatives have been discussed so many times here on LW people may not be enthusiastic to repeat the whole thing here as a convenience. Do a LW specific search (google "site:leatherworker.net singer 29") and read though some of the topics.

-

The Seiko SK-2B Parts lists (and actual parts) are available here: http://www.industrialsewingmachineparts.co.uk/parts_seiko_sk2b.htm For LW archival purposes I attached the files here too: Seiko SK-2B Parts file 1 (PARTS_SK-2B-1_1.pdf ) and Seiko SK-2B Parts file 2 (PARTS_SK-2B-1_2.pdf )

- 3 replies

-

- rogerds

- 12/3/20017

-

(and 1 more)

Tagged with:

-

I have one other variation on Singer 111W binding feet (part 13246 and 13249), just for reference. The inner foot on this is a little wider (and outer left toe is thinner) than on your standard foot . This provides a little more room for the binder to align the tape edge with the needle.

-

A Singer 111W style binder foot set isn't very expensive at less than $20. You can also cut off your existing feet to achieve a similar result.

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Uwe replied to Brtz's topic in Leather Sewing Machines

Thanks for the update! I'm glad to see you got the machine to work well. It makes a beautiful stitch now.- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Singer industrial machine model 281-24

Uwe replied to hollyobrien's topic in Leather Sewing Machines

The Singer 281 Service Manual ( Singer 281-5, -6, -20, -22, -23, -24 Service Manual.pdf) was printed in 1964, so your machine is likely from the mid '60s. Singer serial numbers can be used for more precise dating of many Singer models. Servo motors are discussed in many topics here on LW. Check one of the recent ones: -

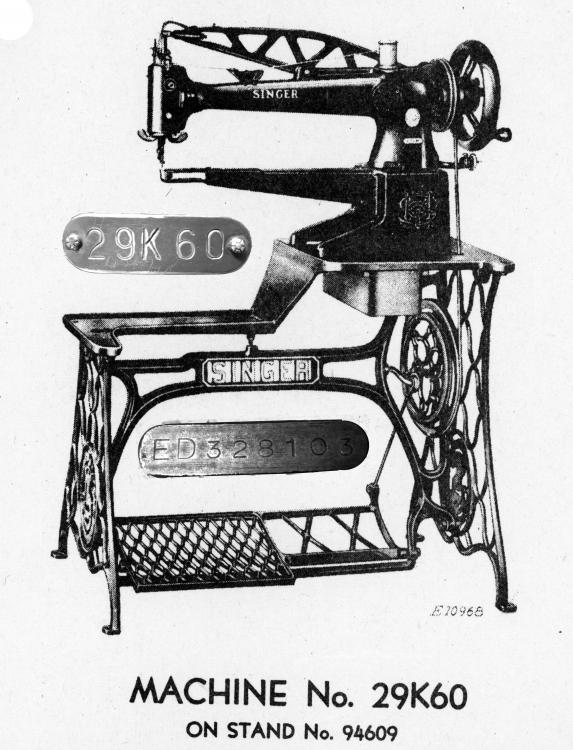

While you're taking pictures, please also post a close-up picture of your Singer 29K60 model type plate and serial number. We're investigating a different issue on another Singer 29K60 in a separate topic and could use another reference picture.

-

I think the "GK" (Greifer Kupplung, i.e. hook clutch) models were a later addition to the family of Adler 67 machines.

-

I'll have to add escutcheon pins to my vocabulary (the eustachian tube connects your middle ear to your throat.) The type plate and pins do look a little suspect. Here's one reference I found of a Singer 29K60 with a detailed, original looking type plate with decorative pins and a modern, sans serif font used for marking (that machine's serial number points to 1945)

-

I stumbled across an original, vintage manual booklet from 1933 titled "The Regular Lock Stitch Wax Thread Machine Instructions". The machine is more commonly referred to as the Landis #1. Since I couldn't find any PDF versions of this manual online, I scanned it to PDF for fellow LW folks: Landis_1_Manual_1933.pdf I decided to format this PDF for digital viewing only - I added a watermark and disabled printing. High quality printed booklets without watermark ($10) and the original ($50) are for sale, send me a PM if you are interested.

-

Contemplating A Puritan Stitcher: Vamping, Staying, Fairstitch ?

Uwe replied to Uwe's topic in Leather Sewing Machines

Mike @leathersmyth was kind enough to scan his Puritan documentation. Thank you Mike! I cleaned up and shrunk Mike's Puritan PDF: Puritan-Catalog-Manual-Parts-newer.pdf I also discovered an older version of the Puritan catalog/manual/parts list in my archives. The two catalogs have a decade or two between them and show some common information, but they differ in which machines were in production at the time and some other details, like pricing info for parts. I miss the days when a dozen Puritan needles cost $0.75 ! ($0.75 in 1917 is over $15 in 2017) Here's my older Puritan catalog: Puritan-Catalog-Manual-Parts-older.pdf -

Part of the learning process is resolving apparently contradictory information. No doubt @shoepatcher knows his stuff, but I for one am always looking for verifiable facts that support a statement, especially if it contradicts other information. In the grand scheme of things dating a sewing machine is not a super important issue, but since we already started down that rabbit hole, we may as well figure out where it leads. I think we need exhibit A: the close-up photo of the actual serial number and type plate on @chase97's Singer 29K

-

Contemplating A Puritan Stitcher: Vamping, Staying, Fairstitch ?

Uwe replied to Uwe's topic in Leather Sewing Machines

@leathersmyth I did end up buying a set of ten #2 needles and ten #3 awls directly from Puritan last year (for an eye watering $173.30!) so I'm good for basic testing. My Puritan indeed uses small shank (0.086") needles and awls. 91 pages Puritan manual goodness is definitely worth the effort to produce a state of the art PDF version. -

Contemplating A Puritan Stitcher: Vamping, Staying, Fairstitch ?

Uwe replied to Uwe's topic in Leather Sewing Machines

It would be very cool to produce good quality PDF of your Puritan manual. I'd be happy to help you do that. If you don't have a scanner, a series of full resolution photos would be a good starting point. I have software to build a good quality PDF files that is not huge. You can message me here on LW, or email me at uwe@uwe.net - you can email me image files that are too big to post here. I'll upload the finished PDF here. -

Contemplating A Puritan Stitcher: Vamping, Staying, Fairstitch ?

Uwe replied to Uwe's topic in Leather Sewing Machines

Not yet, but when I do get her to cooperate I will be sure to let everybody know about it -

The control box circuitry usually runs on single phase 220V. It's the motors that are often true 3-phase affairs. There may be a separate type plate on the motor. A four conductor power cord hints very strongly at 3-phase power. Alas, you may be able to run the whole affair on single phase power. On my 3-Phase Durkopp Adler 467 Efka setup all three power wires connect to the motor, but only two of the three power wires continue on to the controller box to supply single phase power. On other machines it is less obvious what's going on. A three phase motor will continue to run just fine with only two power wires connected once it starts rotating (but with a lower horsepower rating.) I just bought a rotary phase converter from a guy who said had it connected to his three-phase Adler 467 sewing machine (same as mine.) One day he forgot to turn on the rotary phase converter before he turned on the machine, and, lo and behold, everything worked just fine without the rotary phase converter turned on. He was lucky in that he had (by chance) the power wires connected just right - the two original incoming single phase power wires have to be the ones that continue on to the controller (you have a one in three chance of getting it right by accident.) The "proper" way to connect three phase equipment to single phase power supply is to use a rotary phase converter. They normally consist of a control box and a special 3-phase generator motor. A two HP rotary phase converter should be fine to run a single sewing machine. They cost about $250-$400. In any case, make sure you are comfortable doing electrical work or get some somebody who is.

-

The business end of the cylinder arm on your Ferdinand actually looks identical to the Adler 205 design, but it's unclear if Ferdinand modified the hook driver in any way. Your shuttle hook may actually be compatible with the Adler 204/205 shuttle hooks. Chances are good you can find a decent aftermarket shuttle hook, but exactly which one is the right one is still unclear. Aside from the obvious critical dimensions of diameter and thickness of the shuttle hook frame, the other important dimensions are distance from tip to butt of the shuttle hoot, measured along the outer circumference of the hook. The length of the hook tip itself must also be match the original. The bobbin case itself, the tension mechanism and what's going on inside the bobbin case is less critical. The bobbin case tension springs can sometimes be bent a little make it work better. I once removed the spring metal part and bent it slight down in the middle, so it would make better contact with the size 92 thread my customer wanted to work with. The tension spring may also buckle or arch upward in the middle if you tighten it too strong, because once the spring blade rests on the bobbin case body near the tension screw, the mechanics change. That's probably why tension increased when you backed up the tension screw a little from the over-tightened position. (as Bob also just said seconds ago.) One other option is to fill in the worn channel on the bobbin case with silver solder or brass, but that may be a little tricky to get right.

- 16 replies

-

- bobbin case

- hook

-

(and 1 more)

Tagged with:

-

Consew doesn't manufacture anything as far as I know, they just put a Consew badge on things others make for them. Your Ferdco may be made by Seiko, sold as a Consew, then modified by Ferdco. Your best bet may be to find out which OEM manufactured the machine that Ferdco modified. Only then will you be able to find out which parts may or may not be compatible. Pictures always help determine the true ancestry of a machine. Please post some of yours. You'd want to replace the entire shuttle hook, no point in trying to replace just the bobbin case. Have you tried the 441 style shuttle in your Ferdco? Personally I'm betting on a Seiko CH-8B, in which case you'd have to reference the Seiko CH-8B Parts Manual. An original Seiko hook (Part# 28901C) runs about $350. Consew 754R:

- 16 replies

-

- bobbin case

- hook

-

(and 1 more)

Tagged with:

-

Looking for advice on a leather sewing machine

Uwe replied to Pip's topic in Leather Sewing Machines

I'd recommend making a day trip to College Sewing , just North of Manchester and check out their brand new showroom with demo machines. It's only an hour drive from Liverpool. Talk to them, tell them what you want to sew, bring some materials you want to work with and have them demo a few machines for you. Chances are they'll give you good advice and good service. You're bound to come away with very good idea as to what machine might fit your needs. -

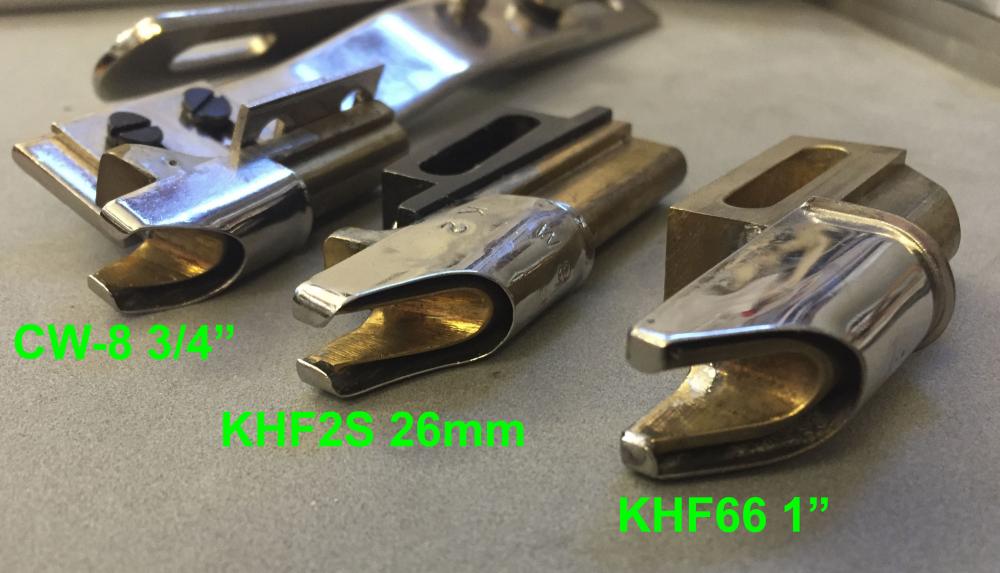

I tried it on my Juki LS-341 and it unfortunately did not quite fit - mounting slot on the back does not line up with the threaded hole and the angle of the rear arm is different. I don't have a Juki LS1341 to test with. @R8R, @TheRuggedProject: For 1" tape folder options, I have the KHF2S 26mm ($45) and the KHF66 1" ($59) versions on hand. Compared to the CW-8, the KHF2S and KHF66 tape folders are quite a bit larger and have a different mounting scheme. They might work, especially if you make a custom bracket. They definitely do fit the Pfaff 335 binder bracket. These are well made tape folders and I've heard good feedback from folks who bought them. Here are some photos for comparison: