-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Uwe

-

The cheapest and perfectly adequate option is a "Family Sew" style servo motor. They're available for around $120-$150 under various model names (e.g. Family FESM-550S) from many vendors, including some that advertise in the banner ads here. It's usually a direct swap for the clutch motor and easy to install. You may need a new, different size belt, but you won't know exactly what size until you install the new motor. Try to get a 50mm pulley (search for "SM50 pulley") with it for best low speed control. You may also want to remove the cork brake pad. The motor looks like this: The SM50 pulley kit looks like this:

-

The 3/4" tape folder itself is a CW8 model and has a 7.5mm (19/64" or 19oz.) wide throat and accepts up to 2mm (5/64" or 5oz.) thick tape material.

-

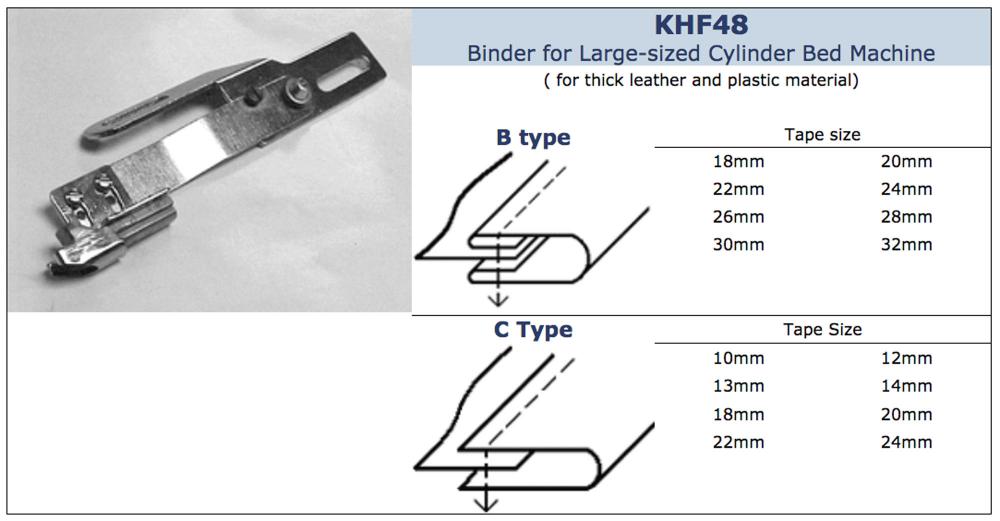

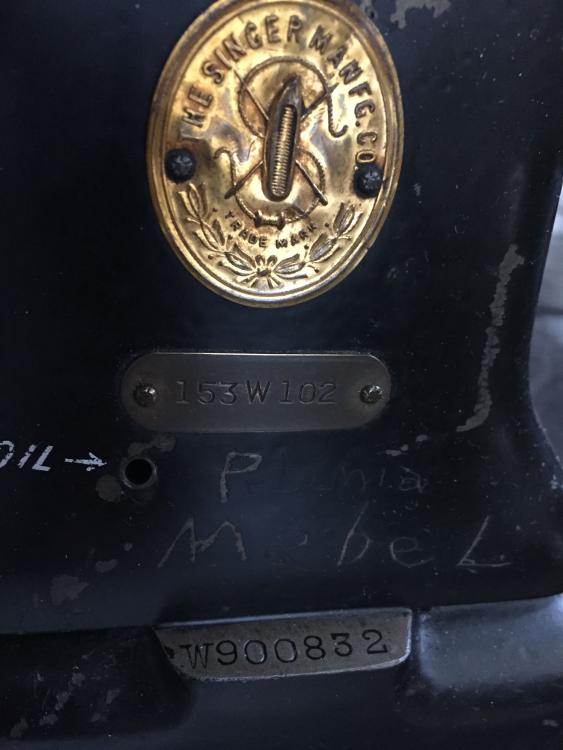

The KHF48C binder kit from Kwok Hing fits my Singer 153W102 perfectly. I bought the kit for testing to see which of my large diameter cylinder arm machines it would actually fit. It has a 3/4" tape folder, is unused and can be yours for $70.

-

The machine is sold.

-

That's a great idea @Darren Brosowski and a simple "hack" of sorts. Those Pfaff 335 binder brackets are on Ebay for $30 or less, certainly cheap enough to experiment with.

-

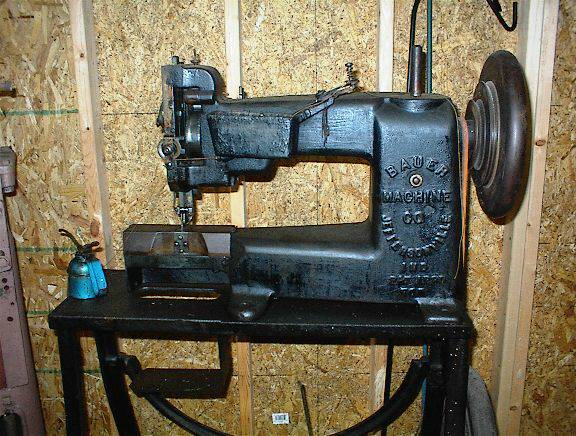

Can you please scan the Bauer manual to PDF and post it here? A series of photos would work, too. We can help make the PDF.

-

The Adler 467-FA373 uses internal air cylinders to actuate levers for functions like reverse, foot lift, walking height, and thread trimming. The buttons you press (or the Efka controller) send electric signals to open or close air valves that supply compressed air to the cylinders to do the work. I used a CAT- 4610AC-B compressor from California air tools which works great and doesn't wake up the neighbors when it kicks in. Some machines (e.g. the Durkopp Adler 1183i) use electric solenoids instead of air cylinders to move levers and don't require an air line.

-

Here's the Patent US822337 about the thread controlling device:

-

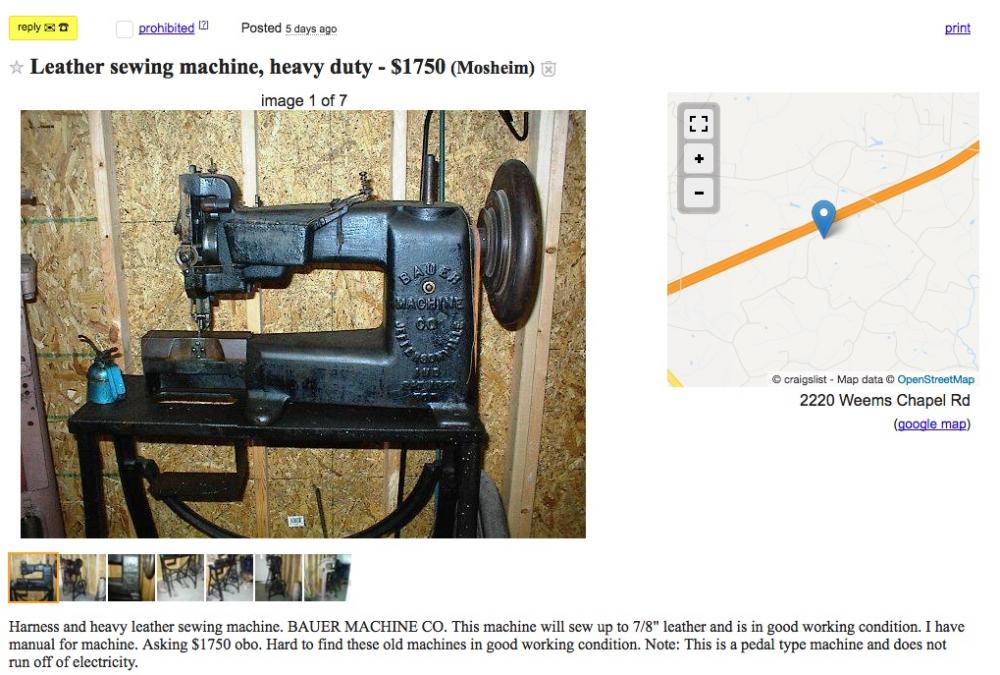

Just a screenshot and the images from that CL ad referenced above, just to preserve it for posterity here on LW. Love that pedal drive!

-

The guy in that Craigslist posting above says he has a manual for it. What are the chances of him being willing to scan it to PDF for the greater good?

-

That is some machine, wow! Unfortunately that threading video appears to be the only bit of documentation available online. I did find an Advertisement for an earlier version of the machine on the last page of the 1909 issue of "Harness" (the thread tension mechanism is a little different - it only has one tension disc). Sometimes patent application drawings and descriptions can be helpful. With a needle that long, there's going to a minimum thickness that makes sense and likely will only be manufactured in a limited size range. Do you know what system needle you have in your machine right now? If not, can you take some measurement like diameter of butt, butt to top of the eye of needle distance, and overall length (ideally in mm). It may narrow down the possible needle system choices. There's only a handful of needle systems that are that long. I was organizing a few parts bins yesterday and came across a few Landis (I think) parts. The bobbins sure look a lot like the Bauer bobbins, but the shuttle boats are quite different, at least in the thread tension mechanism.

-

Good deal? Cowboy CB 29 18” arm

Uwe replied to WoodsHollowLeather's topic in Leather Sewing Machines

Well, if it works then $1,000 is a good deal compared a new one at $2,300 right? It may still be worth $1,000 five years from now if you take care of it. Having access to a machine like that for five years for free is a good deal, most people would agree. It's really one of many copies of the Singer 29K class of machines, not sure exactly which sub-class, likely a 29K72 or something like that. Do a general (or LW specific) search for "Singer 29K" and you'll be overwhelmed with demos, opinions and testimonials about that class of machine. You will find almost nothing for "Cowboy 29", because for every Cowboy 29, there are hundreds if not thousands of Singer 29K machines out there. Tired old Singer 29K originals can be found less than $1,000, but that doesn't means those machines are a better deal. -

I've never even heard of that brand. Can you please post some pictures? You may know more about the machine than most people on this forum.

-

The Adler 104-64 has bottom+needle feed and is designed for the heavy duty range with needle size range 160-230 and thread size range Tex 207-348. You can go one size beyond the top and bottom of that range, but after that it gets dicey. Here's the PDF brochure for Adler 104-64: Leaflet_Adler_Class_104-64.pdf . Overall a desirable machine, at least in my book. No one machine does everything perfectly. If you get a smaller sibling like an Adler 169, Juki LU-563 or similar to keep this one company, they will cover a very large range of applications between the two of them.

-

Black Friday + Black Wednesday Special. Black Friday because of Thanksgiving week. Black Wednesday because my makerspace TechShop unexpectedly went bankrupt last Wednesday and I had to move all my stuff home on a day's notice, including a large CNC mill I was refurbishing there. I now really have no room to turn around in my garage and something's gotta give or go. So here goes ... This Durkopp Adler 467 is a full function machine with automatic back tack, reverse via thumb toggle switch, alternate walking foot height via knee switch, and thread cutter. Efka motor and controls are nice and smooth. All you need is a 3-phase converter and an air line. Oil pump works nicely, even at slow count-along speeds. I verified this by taking the top off and observing the oil dropping at various speeds. No shipping, sorry. Pick up only in the Detroit area. I made a sewing demo video a few months ago:

-

Black Friday + Black Wednesday Special. Black Friday because of Thanksgiving week. Black Wednesday because my makerspace TechShop unexpectedly went bankrupt last Wednesday and I had to move all my stuff home on a day's notice, including a large CNC mill I was refurbishing there. I now really have no room to turn around in my garage and something's gotta give or go. So here goes ... Price dropped to $1,500. Now you can afford to fly in, rent a van and drive it back home.

-

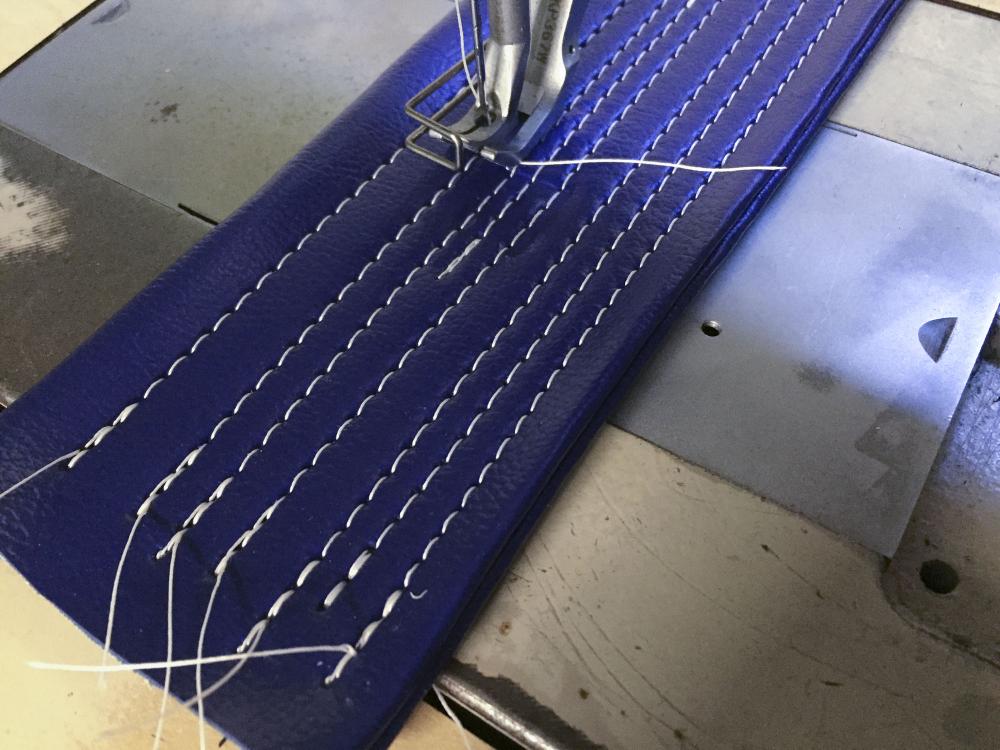

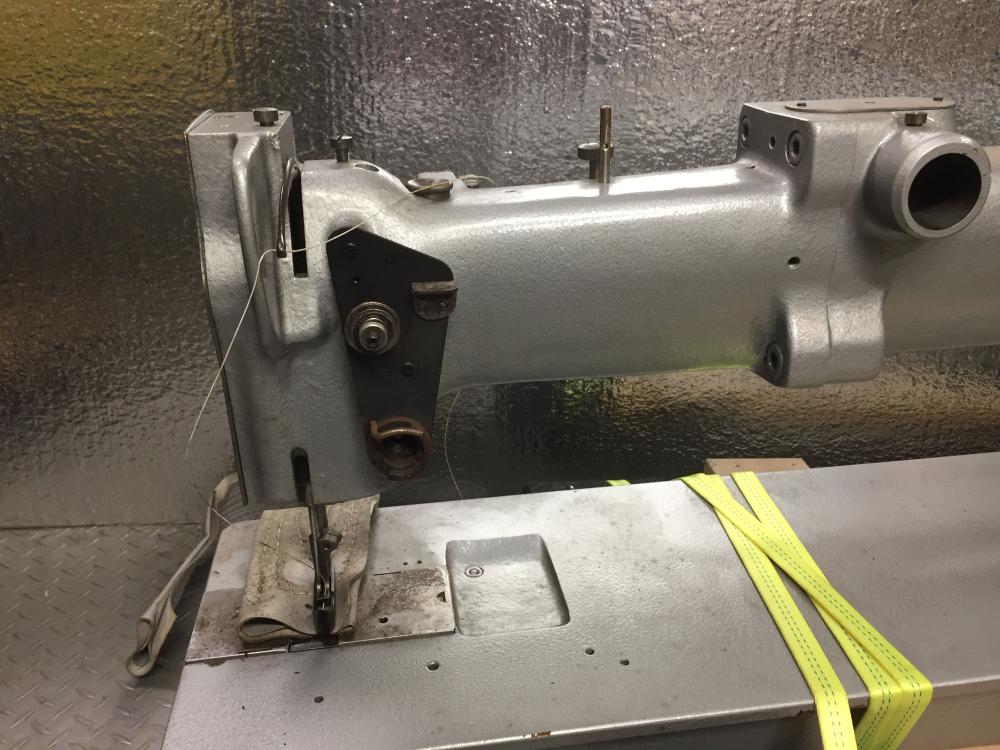

Black Friday + Black Wednesday Special. Black Friday because of Thanksgiving week. Black Wednesday because my makerspace TechShop unexpectedly went bankrupt last Wednesday and I had to move all my stuff home on a day's notice, including a large CNC mill I was refurbishing there. I now really have no room to turn around in my garage and something's gotta give or go. So here goes ... This is a refurbished Singer 144W302 head available for $900. No shipping, sorry. Pick-up only in the Detroit area. It is exactly as I acquired it last year. It's sewn to piece of Vinyl. The check spring assembly bits are missing on the thread tension unit - I'm looking to see if I have a spare one. I have a box full of hand wheels - one of them may fit.

-

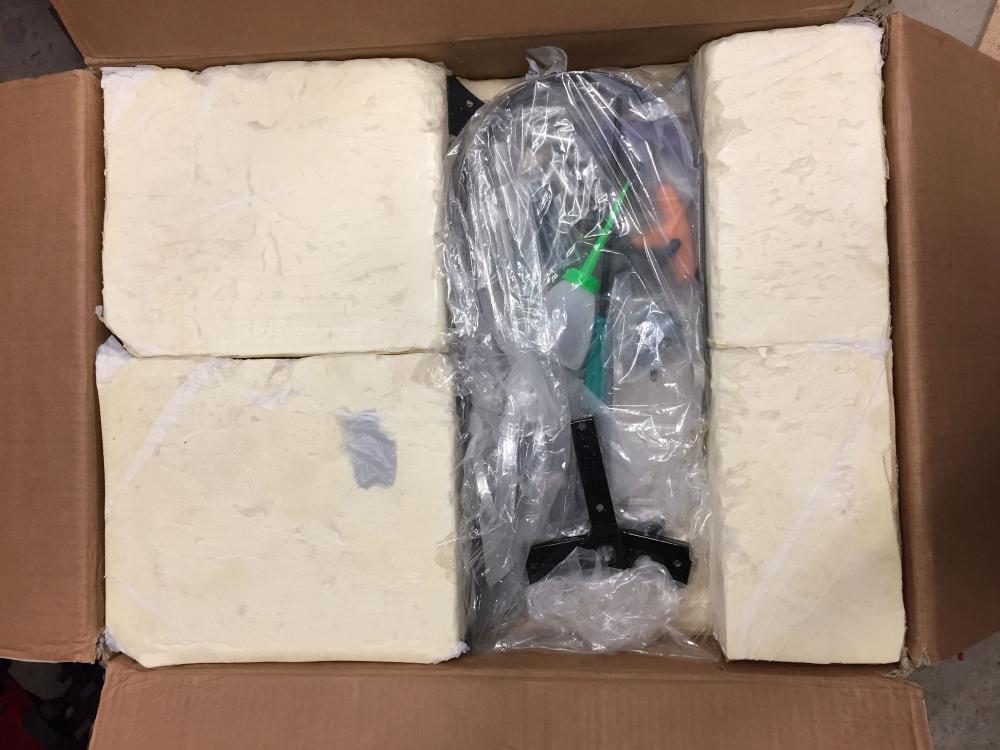

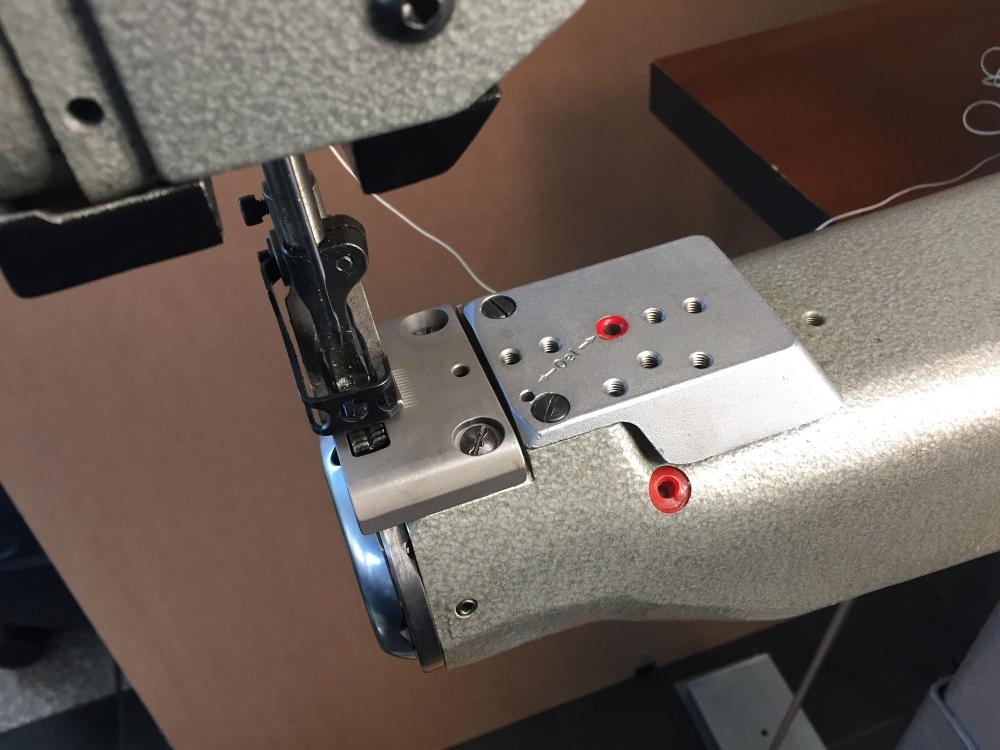

Black Friday + Black Wednesday Special. Black Friday because of Thanksgiving week. Black Wednesday because my makerspace TechShop unexpectedly went bankrupt last Wednesday and I had to move all my stuff home on a day's notice, including a large CNC mill I was refurbishing there. I now really have no room to turn around in my garage and something's gotta give or go. So here goes ... I have two new GF205-370 sewing machines. They are very nice quality clones of the Durkopp Adler 205-370 design. One is still in the box, the other is mounted on a refurbished stand made by Weaver, with 220V servo motor and custom speed reducer. Both machine heads are new and unused, but were stored in a warehouse for a few years before I acquired them last year. The machines are manufactured by Jason Sewing in Taiwan and are still in production. The machine in the box was sewn to a piece of leather at the factory, so I would expect it to take minimal setup effort to put into service. This one is $1,400. The machine on the stand is ready to sew and demo. This one is $1,900.

-

Pfaff 1245 vs. Mitsubishi 3300? Which one for what I sew?

Uwe replied to BrownChicken's topic in Leather Sewing Machines

-

Pfaff 1245 vs. Mitsubishi 3300? Which one for what I sew?

Uwe replied to BrownChicken's topic in Leather Sewing Machines

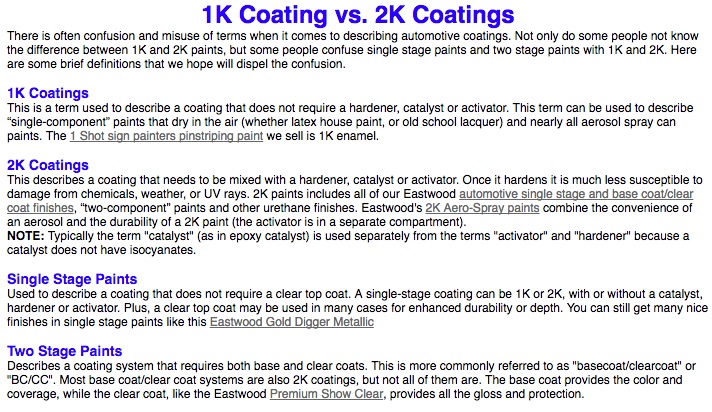

I'd never even heard of 2K paint before today. Got an early start on meeting my daily learning quota today. Interesting paint - I'll have to give it a try sometime. Downsides are the paint is not cheap at around $20 for one aerosol can, and it's a one-shot deal - once you release the hardener, the clock starts ticking and any unused paint will harden inside the can. Your restoration of this Singer 111W155 deserves its own topic. Here's a screenshot from the Eastwood Website with a nice glossary that describes the various paint options: -

Pfaff 1245 vs. Mitsubishi 3300? Which one for what I sew?

Uwe replied to BrownChicken's topic in Leather Sewing Machines

My goodness, yes, please do keep that Singer 111W155! Put it in a hermetically sealed glass dome and upgrade your home insurance. I don't think I've ever seen one as pretty as yours. I was expecting the typical, tired old Singer 111W155. I'd be afraid to actually use your museum piece. -

Pfaff 1245 vs. Mitsubishi 3300? Which one for what I sew?

Uwe replied to BrownChicken's topic in Leather Sewing Machines

Personally I'd keep the Pfaff 1245 and sell all the others. I can't think of anything the Singers or Mitsubishi can do that the Pfaff can't. Cheap presser feet are overrated, in my opinion - it's a race to the bottom in terms of quality. -

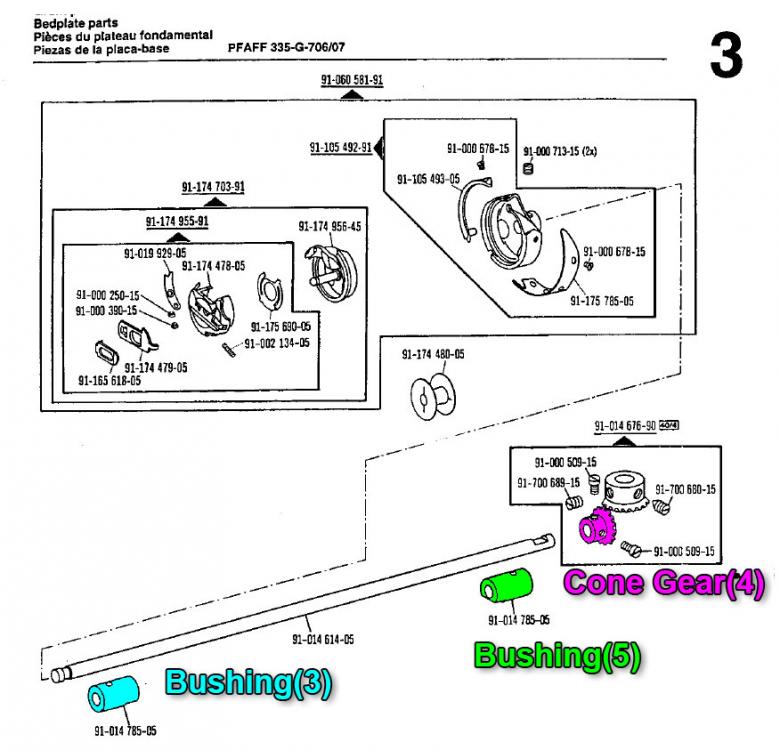

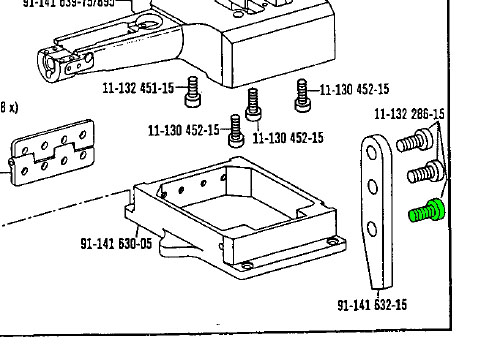

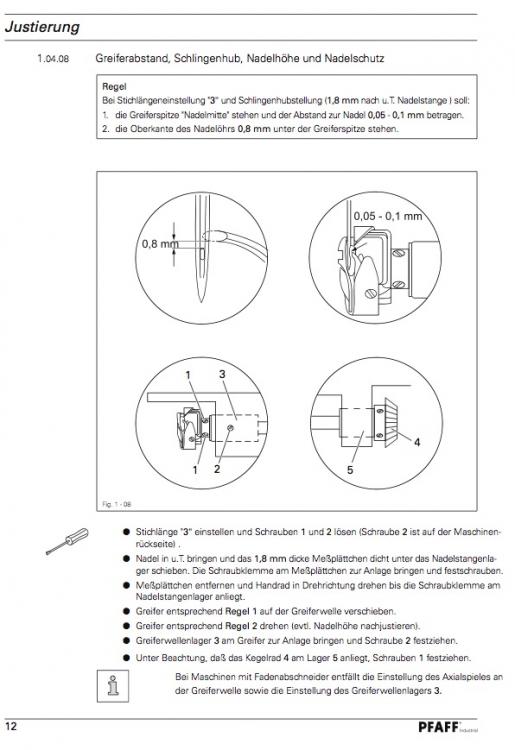

Items 4 and 5 in the adjustment diagram are at the other end of the hook driving shaft (see the second colored diagram.) You'll have to tilt the machine back to see it. In order to tilt the machine back, you have to remove the bottom (green) screw in the guide finger on the right side of the body where top and bottom separate. The plastic belt cover may hide that guide finger and screws. Item 3 and 5 in the adjustment diagram are the bearing bushings. The bushings can be shifted (after loosening the set screw) within their casting tunnels to make them touch the hook on the left and the cone gear on the right. By doing so you ensure that the hook driving shaft and hook can't move axially, because the bushings limit movement in both directions. But that also means that in order to move the hook (and shaft) axially for adjustments you need to loosen all the screws indicated in the adjustment diagram. A few things to watch out for: The bushings have holes in the top that allow oil to reach the shaft - don't rotate the bushings or shaft oiling may not work properly. Make sure the top set screw on the cone gear (4) stays on the flat spot of the shaft (loosen it just a little., and make sure you tighten this screw before the other one) The flat spot is wide enough to allow axial movement for adjustments. I color coded the diagram below. Perhaps it will make more sense that way.

-

According to the Pfaff 335 Service Manual (I only have the German language version for the modern casting Pfaff 335), you loosen two screws marked 1 and the screw marked 2 (on the back side). Then you can rotate and shift the hook to the correct position to line up with your needle in the hook timing position (1.8mm rise after bottom dead center). Make sure cone gear (4) meshes nicely, then tighten screws again.

-

I'd recommend a complete set of piping feet to match various piping tasks. The Juki DSC-245 shares feet with the very common Juki LU-563 (and Singer 111W155, etc.) A complete set of six different size piping feet is available for under $50 in the U.S. Our resident LW vendors may have some, too. Piping feet work best when they're the right size for the task at hand. For example, making just the piping from scratch with cord and material strips takes a smaller foot than when you assemble the piping project with several layers of material. When the piping foot is the right size, it works like magic. When you're trying to use one size piping foot for all piping tasks, you will be very frustrated. One of my clients was trying to make piping-edged boat seat covers with just the one piping foot that came with the machine. When I finally convinced her to buy a full set, it was like an angel choir was singing above her head when she was sewing.