-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

Unsticking stitch length regulator on Consew 227 (not R)

Uwe replied to SheltathaLore's topic in Leather Sewing Machines

That knob should turn clockwise to come out. It's the opposite rotation of what you'd expect. I made a video some time ago about that stitch length adjustment mechanism on a Singer 153W102, which should be the same as your Consew 227: -

That depends on what features you care about. The Juki DSU-145 or Juki DSU-245 may be candidates with similar capabilities and price point. Pfaff 335 is the old school standard bearer for small diameter cylinder arm machines.

-

Unsticking stitch length regulator on Consew 227 (not R)

Uwe replied to SheltathaLore's topic in Leather Sewing Machines

Call @Gregg From Keystone Sewing , I'm sure he's interested in you being able to change the stitch length on that machine. That knob may also not turn in the direction you think it should turn. Otherwise post some pictures. It's hard to guess exactly what your stitch length mechanism looks like. -

Yes, that broken bobbin case opener is a problem, I think, especially if the broken-off piece finds its way into some gear teeth. Here's what mine looks like on my Singer 153W102: That finger needs to be able to pull back the bobbin basket to open up the thread path around the tab in the throat plate cutout. When you adjust that case opener finger position, make sure it doesn't bind in the far open position. The basket should still have a tiny bit of wiggle room when pulled all way to the right. Ideally the tab inside the throat plate cutout gets pulled just into the center of the cutout, not all the way to the other side. It's easy to accidentally adjust the finger position too far without checking for a bind. Then you have a hard bind with every turn of the hook, and the finder will just fatigue and break off eventually (or the tab on the bobbin basket.)

-

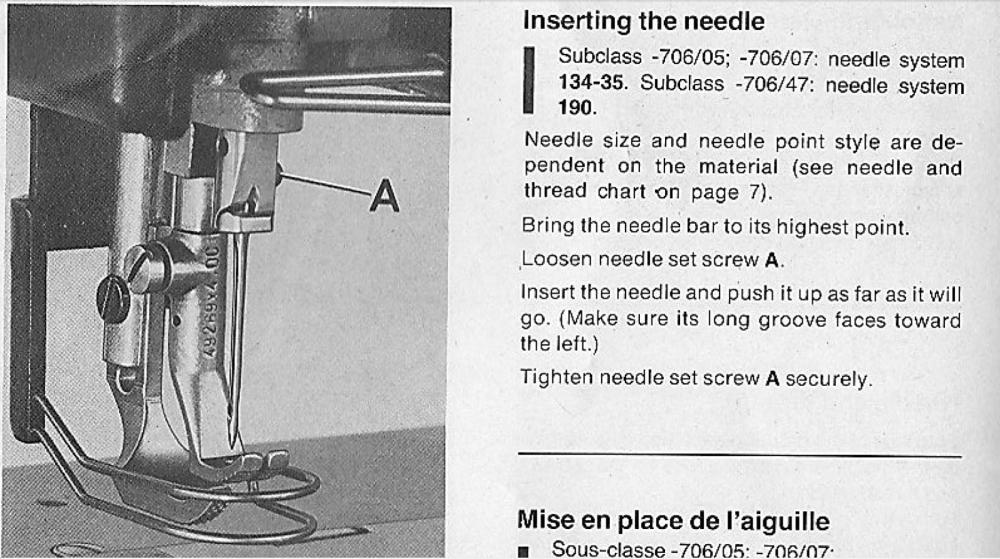

That machine looks to be in very nice shape overall. Great find! That needle bar on your machine looks different than the ones on my Pfaff 145/545. Perhaps your needle bar got replaced at some point. Yours looks like it was designed for use with a separate, tiny thread guide part. That wire is a homemade fix, I think. That wire or screw may actually get in the way between the needle bar and the inner presser foot. It's a tight fit, depending on the foot. Usually, out of the three holes, one is for the thread guide screw, one is for the needle screw, and the top hole is just a sight hole to see if the needle was inserted all the way. On my Pfaffs 145/545 machines the thread guide is built into the tip of the needle bar (and it is often broken on old machines). I have two replacement needle bars for the Pfaff 145/545 that I got some time ago but haven' t used yet. They're readily available and relatively cheap (Pfaff Part no. 91-710650-92.) Both of mine are aftermarket versions. Here's are the photos of my Pfaff needle bars, just for reference. Here's a picture from a Pfaff 545 manual I have:

-

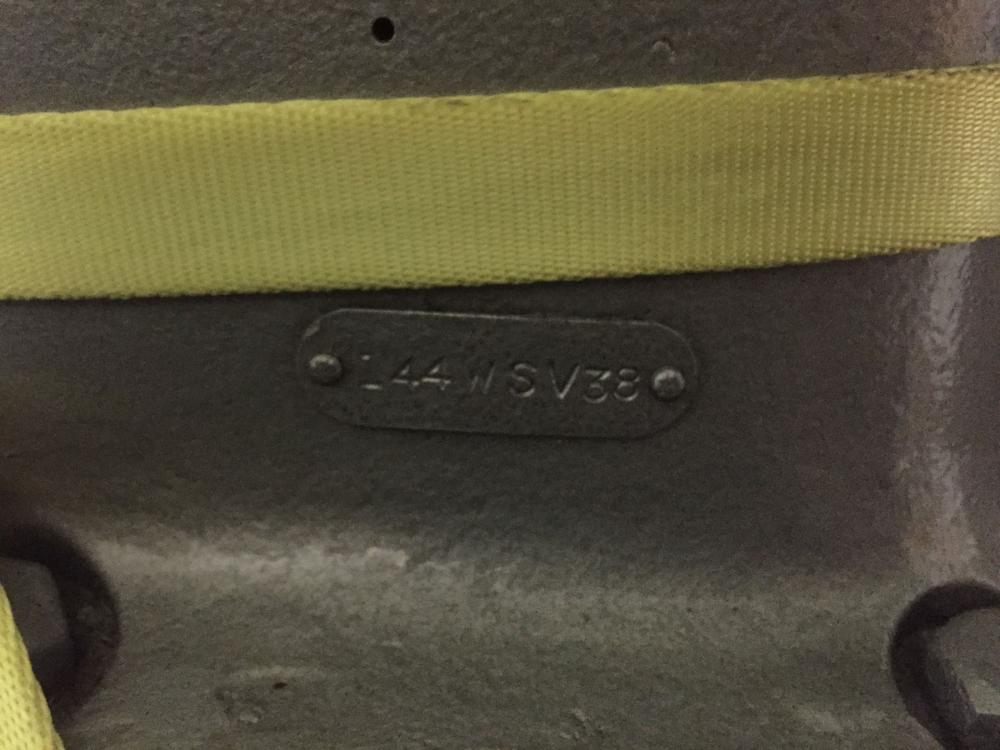

So it turns out this machine is actually a Singer 144WSV38. The tag was hiding under the yellow strap. I have no idea what the difference is between this special version and the standard one. It may just be a delete option because there's no gear on the shaft for the front hand wheel, so you'd better have long arms. On the plus side I found most of the missing bits for the thread control check spring unit. Price drop to $600 and last call for LW members until year-end. A few more pictures:

-

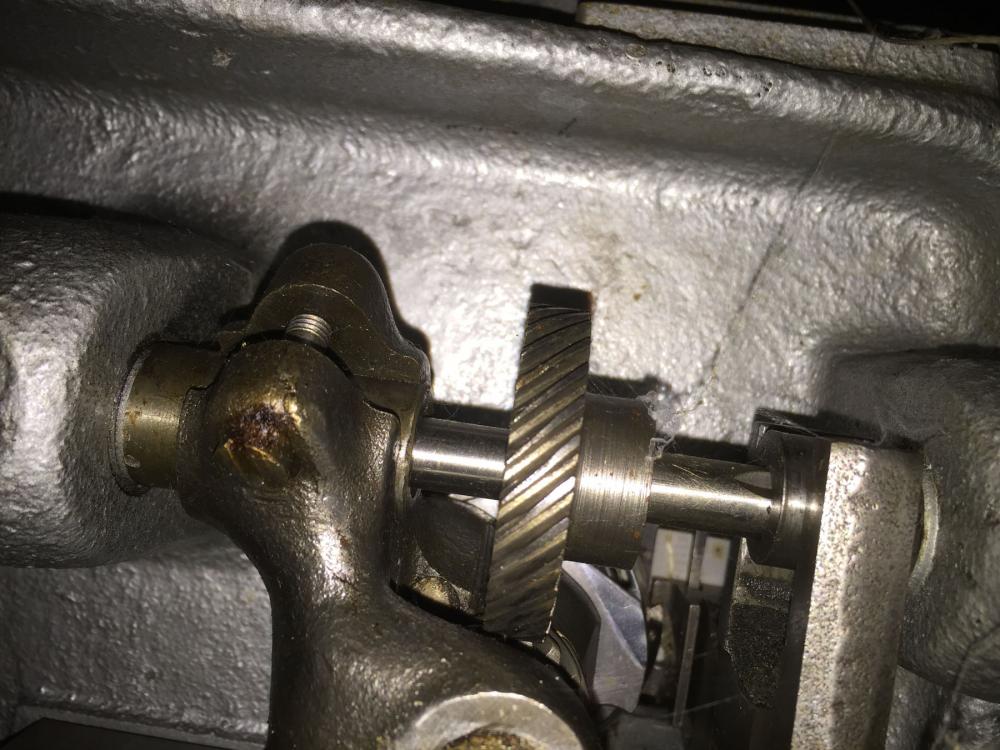

I'm guessing if the gears aren't meshed properly and there's too much play the teeth will catch on the edges on occasion and chip a little.

-

Does the set screw your Cx3 arrow points to normally stick out like that? If it did it may have touched/rubbed/hit the cone gear above and cause the "wear" you are seeing. I had one machine of similar design and it had the wrong length set screw on one of the holes on the hook driving gear. It was sticking out too much and touching the cone gear under the hook. It didn't sound good and I could feel resistance when turning over by hand. It took me a while to figure out what the problem was. I ended up filing down the too-long set screw and cutting a new top slot with my Dremel. If the set screw on your machine worked itself loose and stuck out, then you'll have problems before too long. For adjusting the "mesh" between the hook driving gear and the cone gear under the hook, it really is the hook driving gear (that Cx3 holds on the hook driving shaft) that needs to move to the right (instead of moving the hook saddle to the left). The hook driving gear (Cx3) needs to be able to rotate and slide on the hook driving shaft when the Cx3 set screws are loose. That's how you time the hook on his machine. The gear may be stuck to the shaft because it's rusted in place or stuck due to oil varnish. I'd remove the set screws and drip some kerosene oil or WD-40 in the holes and warm whole thing up with a hair dryer. The crusty oil varnish will dissolve or soften and the hook driving gear will start to move on the shaft eventually. Then you can make proper adjustments.

-

If you can get a new Sunstar with table and servo motor for £600, then your budget may dictate to check that one out first. I'm just a little concerned that after subtracting cost of table, motor, and shipping from Korea, there's really not much left to build the actual sewing machine. Sometimes new things are too cheap to be sustainable or ethical. But then again, I'm guilty of buying that $3 bottle of wine and I forget all my ethical dilemmas by the time I'm done with it.

-

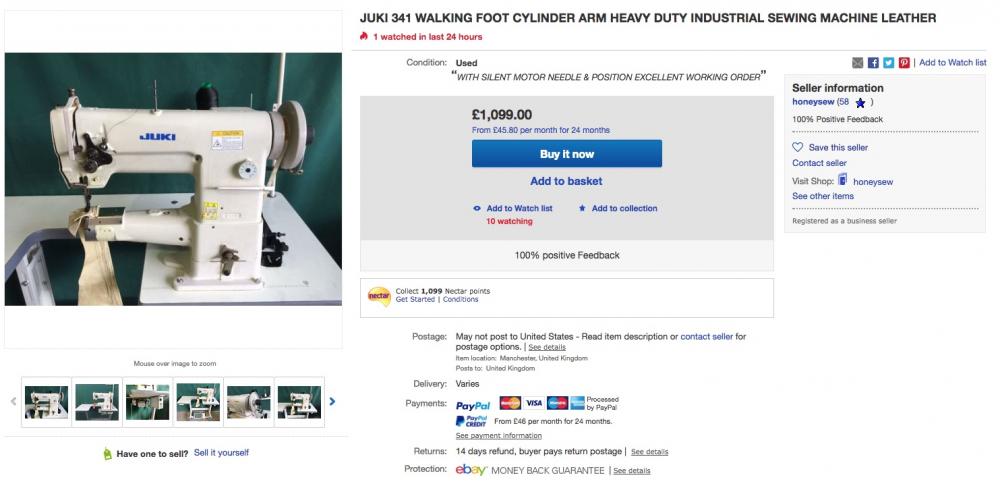

I can't vouch for the seller. Don't just click buy-it-now. I'd talk to the seller and then decide if it's worth spending an afternoon to go check out the machine in person. It's only a two-hour drive to Manchester. Avoid shipping if at all possible. There isn't much overlap between "good cylinder arm machine" and "less than 1,100 GBP".

-

The Sunstar is probably a fine machine, but a used original may be a better choice in terms of long term parts availability and general support. I'd recommend considering a used Juki LS-341 instead. You'll have an easier time finding parts and accessories for the Juki compared to the Sunstar. You also have College Sewing not too far from you near Manchester - they support Juki in a big way. College Sewing may also have some used machines, who knows. Here's an example of a nice Juki LS-341 on Ebay in your general area that looks like a really good candidate to me:

-

Machine Recommendations & Attachments for Leather Binding

Uwe replied to BoulevardEast's topic in Leather Sewing Machines

Just call or email Sergey at SewPro directly. He's a nice guy and best source for pricing info, since he's the only one selling the SewPro line. Weaver sells Adler 205-370 clones for around $4,650 (or considerably less if you sign up for their wholesale program). The Adler 205 synchronized binder kit by itself runs about $500. Cowboy/Hightex also make a Adler 205 clone, but they cost more than the Cowboy 4500. A good industrial sewing machine will last decades in caring hands. Lease and utility payments for a retail shop is money you will never see again. Pretend you already have a retail shop, sell some bags through your current sales channels set that "retail shop" money aside. You'll be able to afford a good machine every couple of months.- 34 replies

-

- sewing machine

- binding

-

(and 1 more)

Tagged with:

-

Machine Recommendations & Attachments for Leather Binding

Uwe replied to BoulevardEast's topic in Leather Sewing Machines

Any Cowboy dealer should be able to order Cowboy or Hightex parts. Otherwise, what's the point of being a Cowboy dealer? Neal's Saddlery is apparently the authorised distributor for Cowboy products in the U.S. - check with them if your favorite dealer can't get the parts you need. Cowboy 4500 with fixed binder: Cowboy 4500 with synchronized binder: The synchronized movement of the binder seems exaggerated on the Cowboy 4500 - it moves much more than the needle. On the Adler 205, a hole in the arm allows installation of a "finger" that does the synchronized movement:- 34 replies

-

- sewing machine

- binding

-

(and 1 more)

Tagged with:

-

Machine Recommendations & Attachments for Leather Binding

Uwe replied to BoulevardEast's topic in Leather Sewing Machines

The Cowboy 3200 and Cobra Class 4 are both variations on the Juki TSC-441 design. Both are fine machines, but neither of them will do binding as well as the Adler 205 design. They rank about the same on the monster scale, the Cowboy 3200 being more of a stubby monster. If money is no object, consider the new Juki LS-2372 (around $7K), less of a monster but only slightly less intimidating when you sit in front of it. The next step down on the monster scale are Juki LS-1341 or Adler 269 class machines, which also have many aftermarket copies floating about. Here's a video that show three different Durkopp Adler machines (205, 269, 69) doing binding work. The Durkopp Adler 269 may actually be a good candidate for range of work.- 34 replies

-

- sewing machine

- binding

-

(and 1 more)

Tagged with:

-

Spring Loaded Edge Guide Presser Feet / Compensating Guides

Uwe replied to CustomDoug's topic in Leather Sewing Machines

I have the swing down edge guide parts available, send me PM for details. Here's a photo of the edge guide presser foot Kwok Hing makes, but I don't have these in stock right right now: -

Spring Loaded Edge Guide Presser Feet / Compensating Guides

Uwe replied to CustomDoug's topic in Leather Sewing Machines

The feet in that ebay listing above are standard Singer 111 class feet and will not fit your Cobra. You can also use a swing-down edge guide to guide along an edge of a layer on top of another material. The edge guide roller can "float" above the bottom layer and follow the edge of the top layer. You'll need the edge guide (KG-867 or KG967), and mounting adapter (KB205), and a hand lever extension (UX441). -

Machine Recommendations & Attachments for Leather Binding

Uwe replied to BoulevardEast's topic in Leather Sewing Machines

One of the very few machines I know of that excels at heavy duty leather sewing AND binding is the Durkopp Adler 205 class with a synchronized binder. Durkopp Adler stopped making the originals a few years back, but aftermarket copies are readily available, e.g. the SewPro 205-420 with the binder setup shown in the video below. Weaver and other vendors also sell Adler 205 clones. The Juki TSC-441 class is more popular, but when it comes to binding, the Adler 205 is the superior design.- 34 replies

-

- sewing machine

- binding

-

(and 1 more)

Tagged with:

-

Pfaff 145 H4 upper tension won't loosen, too tight

Uwe replied to seamsperfect's topic in Leather Sewing Machines

...and the thread tension discs should NOT open during normal sewing. If they do, something is not right. Normal walking foot movement during sewing should not actuate the tension release mechanism. -

One of my videos shows how to reset the safety clutch at the 1:20 mark https://youtu.be/1wNBPX8i524?t=1m20s

-

And as soon as we get the perfect belt installed, the "how do I slow it down" saga begins. Perhaps a new servo motor that is adjustable both in position and speed would be prudent investment right now, especially since the whole setup itself was free to begin with.

-

Most motors have an adjustable mount that allows you to move motor position and adjust belt tension. Belts are available in 1 inch increments over a large range. Just get the right size belt so that you adjust belt tension via the motor pivot. That's what everybody else does, or should be doing.

-

Compression spring for Ferdco Pro 2000

Uwe replied to BaroqueLeatherGal's topic in Leather Sewing Machines

Nothing super special about the spring, really. Juki Part No. 210-50802, should be less than $10. This is what a new spring looks like: -

Here's a Pfaff model number and subclass decoder document: In Introduction To The Pfaff Numbering System.pdf

-

Compression spring for Ferdco Pro 2000

Uwe replied to BaroqueLeatherGal's topic in Leather Sewing Machines

Bob's number shows up twice in the signature at the bottom of his post. You'll know which machine it's based off if you give us a chance to tell you after we get a look at it.