-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Uwe replied to Brtz's topic in Leather Sewing Machines

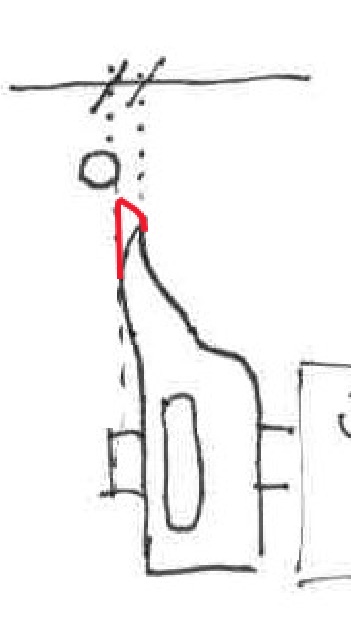

I suspect the tip of your looper is worn from touching the needle. In your diagram the tip of looper is pointing away from the needle. I think it used to point towards the needle before it was worn off. In the video, the looper is deflecting the needle a lot. I'm guessing as the lopper tip wore off over time, it was adjusted towards the needle to make it pick up the thread at all, causing even more wear on the looper. The only part number reference I could find is Pfaff 102025 (In the Pfaff 4143 Parts Manual: Pfaff 4143.pdf) . Alas, that part does not appear to exist anywhere online or physically from what I can tell. With a little luck, you may be able to regrind and polish your existing lopper tip a bit, or perhaps a looper from another machine will be compatible .- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

singer 111w155 Singer 111w155 feed lifting cam slop

Uwe replied to kiddcaprix's topic in Leather Sewing Machines

The clearance on my Singer 111W155 is about two sheets of paper. I don't think this is an area that warrants major expenses or work unless things are way off or worn down. If things are well oiled and moving freely, the cam will barely touch the bottom of that fork if at all. On my machine the underside of the upper arm of the fork is well glazed from constant contact with the lifting cam, the bottom shows almost no wear marks at all. I made a video taking the fork off my machine and inspecting it. If nothing else, it may give you a reference point to compare your machine against. -

singer 111w155 Singer 111w155 feed lifting cam slop

Uwe replied to kiddcaprix's topic in Leather Sewing Machines

Personally, I'm waiting for a picture with an arrow. I don't think you all are talking about the same part. -

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Uwe replied to Brtz's topic in Leather Sewing Machines

This is turning out to be such a cool machine, I'm getting envious! I'm not sure I've ever seen a walking foot chain stitch machine with a rotating looper like that before. When you get a chance, please post a link to or upload the manual you found for the machine. As for the small lever and the connected push bar, I'm guessing it's for temporarily adjusting the stitch length to be longer than the one dialed in with the large lever. This is very useful because you can only temporarily shorten the stitch length with the large lever by lifting up. To increase the stitch length temporarily with the large lever, you'd have to turn the adjustment knob and then you'd loose your set stitch length. Both levers together give you quick single step stitch length adjustments in both directions to line up with existing stitch holes, turn a precise corner, or to step over something. The push bar with the brass block at the bottom is likely intended for use with a knee lift mechanism so that you can keep your hands on the project while you fine-tune the stitch length for a specific stitch. Using the small lever to override stitch length does not override the maximum stitch length in the rear set by the mechanical limits. I'm guessing you let go of the small lever again before the feet get to the very rear of the movement, especially if you're overriding the longest normal stitch length to be even longer for just one stitch. Letting go of the small lever sets things up again for a normal length next stitch. Since the movement of the small lever / push-up rod is adjustable in its travel limit, you can also use this feature as a quick-select alternate stitch length setting. You can then quickly switch between the two pre-selected stitch lengths by pushing up on the small lever. The knee lever especially would be useful to switch to a longer stitch length for a short run during part of the seam. I can't wait to see a demo video of this machine stitching!- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

You can also raise the presser foot bar up to where it's supposed to be.

-

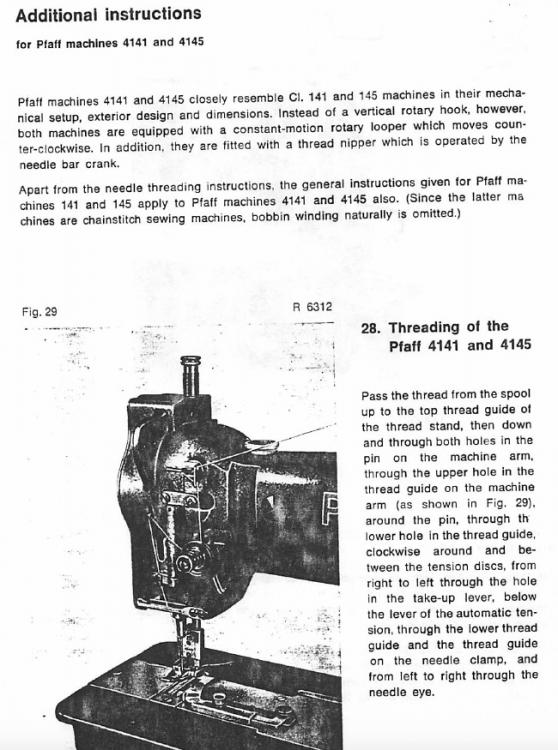

Welcome to LW, Bert! And congratulation for figuring out how to resize and post pictures - it's one of the main challenges for newcomers! So the Pfaff 4145 appears to be a chain stitch variation of the Pfaff 145 design. I had never heard of it before your post - thanks for sharing! It seems like a very rare machine indeed. Hopefully it's complete and doesn't need parts - they may be very hard to find. Can you please post some additional pictures looking into the head from the left, and also pictures of the underside with a close-up of the rotating looper would be interesting. I wonder if the looper design is similar to the Cornely embroidery machines. I came across a reference for the Pfaff 4145 in a regular Pfaff 145 manual :

-

I'm not a LW moderator, but if I was one, I'd give you a vendor neutral answer that you should look at Juki TSC-441 class machines as an upgrade in capability to your Consew 227r. Juki TSC-441 class machines are still sold as originals by Juki dealers, and also as copies under various brand names (THOR GA 441, Cowboy 4500, Cobra Class 4, Techsew 5100, and many others) by several vendors, some of which advertise in the banner ads or support the LW community in other ways. Because as a LW moderator, I'd be extra careful not to give the impression that I'm consistently generating leads for any particular vendor. But that's all hypothetical, of course, because I'm not a LW moderator.

-

Congratulations on scoring a free Adler 30-7! The downside is that everything will seem super expensive from now on. Post a few "before" pictures when you get a chance. Remote internet-based support works best if you can document your story or problem really well. It looks like the part with the gears is part number 030-10-010-0, at least according to the Adler 30-1/-5/-7 parts diagram ( Adler 30-1.pdf) Chances of finding that part new are slim, I'm afraid. Your best hope may be that it's a somewhat generic part that was used in a couple of other machines, or copied from or by others. Or make friends with gifted, bored machinist. On the bright side, that same part/number was carried over into the newer Adler 30-10/-50/-70 models, increasing your chance of finding a replacement. If the newer models aren't dramatically different, the Adler 30 service manual ( adler30servicemanualpdf.pdf) may be of help.

-

Inline Cowboy presser feet on Cowboy CB4500

Uwe replied to Wizcrafts's topic in Leather Sewing Machines

The first few of my new batch of UP441-ILSS inline feet are ready and I've updated my Ebay listing (http://r.ebay.com/UhCM8M) for folks outside the U.S. -

Looking for the ideal sewing machine to stitch thin/soft leather

Uwe replied to UKRay's topic in Leather Sewing Machines

This Durkopp Adler 69-572 manual request should really have its own, new topic and not be tacked onto the end of an 8 year old thread. The only thing I have is a brochure that describes the different models of the Durkopp Adler 69 class of sewing machines (Durkopp Adler 69 Brochure.pdf). For the person in Brazil: Here's the link for the Google Translate service between English and Portuguese: https://translate.google.com/#en/pt/ Esta solicitação manual Durkopp Adler 69-572 deve realmente ter seu próprio tópico novo e não ser aderido no final de um segmento de 8 anos. O único que tenho é uma brochura que descreve os diferentes modelos da classe Durkopp Adler 69 de máquinas de costura (Durkopp Adler 69 Brochure.pdf). Para a pessoa no Brasil: Aqui está o link para o serviço Google Translate entre inglês e português: https://translate.google.com/#en/pt/ -

Inline Cowboy presser feet on Cowboy CB4500

Uwe replied to Wizcrafts's topic in Leather Sewing Machines

I'm working on another batch. They'll be ready shortly.. -

You can also remove the brake pad on those FamilySew style motors. Personally I strongly dislike those brakes. In my experience I was much more likely to accidentally start the motor while depressing the pedal just so while leaning in to position something. For me it's actually safer to remove the brake pad and keep the foot off the pedal as I turn the handwheel and manipulate the workpiece. This machine will stop quickly when you let go of the pedal, brake or not. It's a different story on racehorse garment machines galloping along at 3000 stitches per minute. It's also a different story on a car. Even without brake pads the handwheel will be somewhat hard to turn due to the speed reducer pulley.

- 16 replies

-

- toledo industrial sewing

- bob kovar

-

(and 2 more)

Tagged with:

-

I'd recommend taking time to read the manual for the machine and checking the specs. Trying to make the machine do things it wasn't designed for isn't a path to a happy place. Installing stronger springs doesn't make the machine more capable.

-

"Good", "affordable" and "post" don't often go together. Machines that meet two out of the three criteria are readily available.

-

OP edited post and added the price after my comment. Now we know.

-

This belongs in the Market Place forum section for sewing machines (http://leatherworker.net/forum/forum/84-used/) . Maybe one of the admins like @northmount or @Wizcrafts can move it there. You'll have to state a price and hopefully upload some pictures, too, per LW Marketplace rules. Location info is important.

-

Beautiful machine! You need to state a price per LW marketplace rules.

-

I have a feeling the diagram is intended as installation instructions, not adjustment. There is apparently precisely one correct alignment for these parts and it should never change once assembled. However, if the alignment does change due to some forceful crash, part replacement, or a well-meaning tinkerer with a screwdriver, these parts need to be brought back into alignment in order for the rest of the machine to make sense.

-

New (to me) machine for skate tongues

Uwe replied to Hockeymender's topic in Leather Sewing Machines

I really want to see a video of it sewing a skate tongue. -

consew 206RB-5 thread tension issue

Uwe replied to alpine luddite's topic in Leather Sewing Machines

You have to pull the thread up past the little hook on the check spring unit.- 10 replies

-

consew 206RB-5 thread tension issue

Uwe replied to alpine luddite's topic in Leather Sewing Machines

Thanks and yes, the Pfaff 145 has reverse.- 10 replies

-

consew 206RB-5 thread tension issue

Uwe replied to alpine luddite's topic in Leather Sewing Machines

Closely inspect your top thread path, or better yet, pull out the top thread and thread it again perfectly.- 10 replies

-

I don't have a Pfaff 463, but from what I can tell it's a very different design from the common walking foot machines we often talk about. The reason the service manual doesn't talk about the timing belt synchronization is because the adjustment happens in the link between the top shaft and the needle bar driver. On many machines the link between top shaft , thread-take-up lever linkage, and needle bar driver is locked in place and not adjustable. That is why the synchronization marks are used. This Pfaff 463 design is very different. The linkage in the head is adjustable and that's why it doesn't make sense to talk about synchronizing the upper and lower shaft. Instead, you adjust the relative position of take-up lever and needle bar, and then you adjust hook and feed timing based on the needle bar position. The relative positions of the top and bottom timing belt cogs are not really a factor in this. I came across the diagram below as a loose leaf insert in another Pfaff service manual. Your machines may work the same way, but I'm not positive. In any case, it's a quick visual check to see if your machine is aligned like the diagram below shows. If it isn't, that may be a good starting point for investigation. Why that diagram is not part of the service manuals, I have no idea.

-

New (to me) machine for skate tongues

Uwe replied to Hockeymender's topic in Leather Sewing Machines

That sure is a beautiful machine! Congratulations on your new addition! -

Why Does My Consew 226 Need so Much Upper Tension?

Uwe replied to Pintodeluxe's topic in Leather Sewing Machines

One other thing to check is to make sure your top and bottom shafts are synchronized properly. The thread take-up lever needs to be in the very bottom position precisely when the thread is being wrapped around the farthest point around the hook. It's an easy visual check, just remove the hook cover plate and turn the machine slowly by hand. If the take-up lever timing is late due to incorrect timing belt position it will not provide enough slack and more top thread will be pulled from the spool as the thread gets forced around the hook. In this case the thread take-up lever will never get a chance to pull the knot tight, regardless of thread tension settings.- 11 replies

-

- consew 226

- upper tension

-

(and 1 more)

Tagged with: