-

Posts

3,794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by YinTx

-

nice write up. enjoy the wallet. Looks distinctly like a '68 Ford pickup.

-

Few beginner questions about making a hoslter

YinTx replied to RadekSkylark's topic in How Do I Do That?

Thank you Skylark. Also, Capt., the black belt was done with Vinegaroon. No bleeding issues to be concerned with. I did a red belt, it has not bled at all. Or you could do the lining leather without dye, again no worries with bleeding. But I suspect it would discolor over time. YinTx -

Few beginner questions about making a hoslter

YinTx replied to RadekSkylark's topic in How Do I Do That?

Thank you for that. I have seen folks learn how to get that look after stitching for a few weeks/months, me, it took nearly a year to figure out what made that look happen! In the interest of saving anyone else time, the essence is using the right type of pricking iron (European Slanted) and appropriately sized thread - if it's too big, the slant seems to go away. Of course, which needle in first/second, etc has an impact. I won't carry on, lots of folks have done videos, and tutorials, so I won't bore you with the finer details. Just sayin, took me long enough to figure it out, so don't feel bad. YinTx -

Few beginner questions about making a hoslter

YinTx replied to RadekSkylark's topic in How Do I Do That?

Heh. No way I can finish a belt in one day. For me it is more like this: Cut blanks. Clean leather. Dye leather. set aside, go to sleep, go to work. Come home, put neatsfoot oil on leather. do other work, leave overnight while sleeping. Go to work. Come home, put leather conditioner/sealer on leather. do other work, leave overnight while sleeping. Go to work. Come home, punch buckle hole in leather. Skive ends. Dye buckle hole. do other work, leave overnight while sleeping. Go to work. Come home, mark stitch lines in keeper. Edge, sand and burnish keeper. Stitch keeper. Go to bed. Go to work. Come home, mark stitch lines in belt. Contact cement keeper into belt, contact cement back layer to belt. Leave overnight while sleeping. Its Saturday. Edge belt, sand, dye edges, burnish. Now, start stitching, 12-14 inches per hour hand stitching. Which, for a 44 inch belt is 88 inches of stitching, so 6-8 hours of uninterrupted work, which means usually Tuesday or so to be finished. I like the end result, but they do take a long time, and hard to sell one to make it worth my while. Maybe with practice and retirement I could make one in a couple of days! YinTx -

I made a video about making a watch strap

YinTx replied to udol leather's topic in Leatherwork Conversation

Really informative and very detailed. Thank you for making this, I've been wanting to make a strap for some time, even have the buckles and all, but haven't had the nerve to start yet. Your video helped me think through some of the details. Much appreciated! YinTx -

I've recieved around 10 sides of Hermann Oak from them, some were marked down mis-splits, all were great quality, actually, some of the better leather I have. Only thing I have that is any better is top grade W&C. I have been really happy with the service, don't recall shipping, but that means it didn't break the bank. I'll be ordering from them again when I need something. YinTx

-

I have a pile of Tandy Rivets that will go in the recycle bin. I can tear them in half with my hands, hardly quality material that I would expect to last in a customer's hands, and I don't want my hard work coming back to me for repairs on account of low rent rivets. When I need rivets, I've used solid rivets, unfortunately I don't recall where I picked them up from, and I need to get more. If I remember, I'll post. YinTx

-

Are you referring to Maverick leather? YinTx

-

Wdfd908, It is available for now, PM sent. YinTx

- 11 replies

-

- sole bend

- 15 oz leather

-

(and 5 more)

Tagged with:

-

or linoleum...

-

Awesome, I've always been wondering how I could get the damaged punches I received into better shape! thanks so much for posting this. But also, what I want to know, is what is your floor made from? I'm guessing wood? YinTx

-

- 2 replies

-

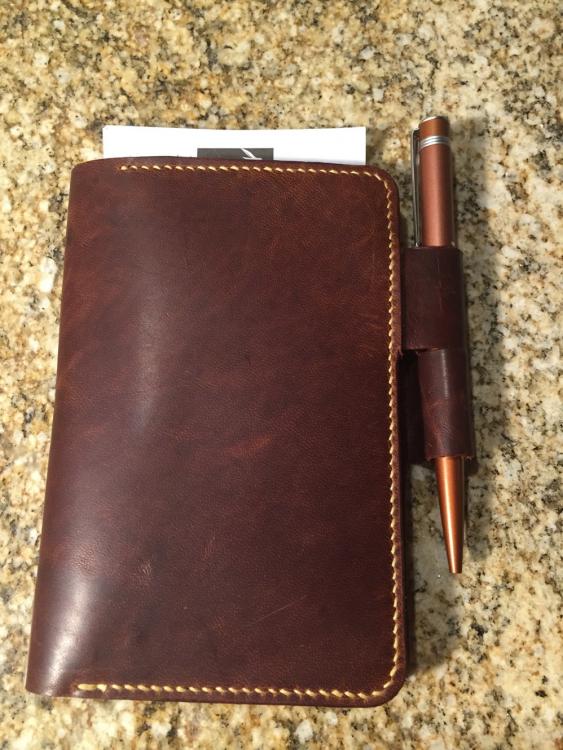

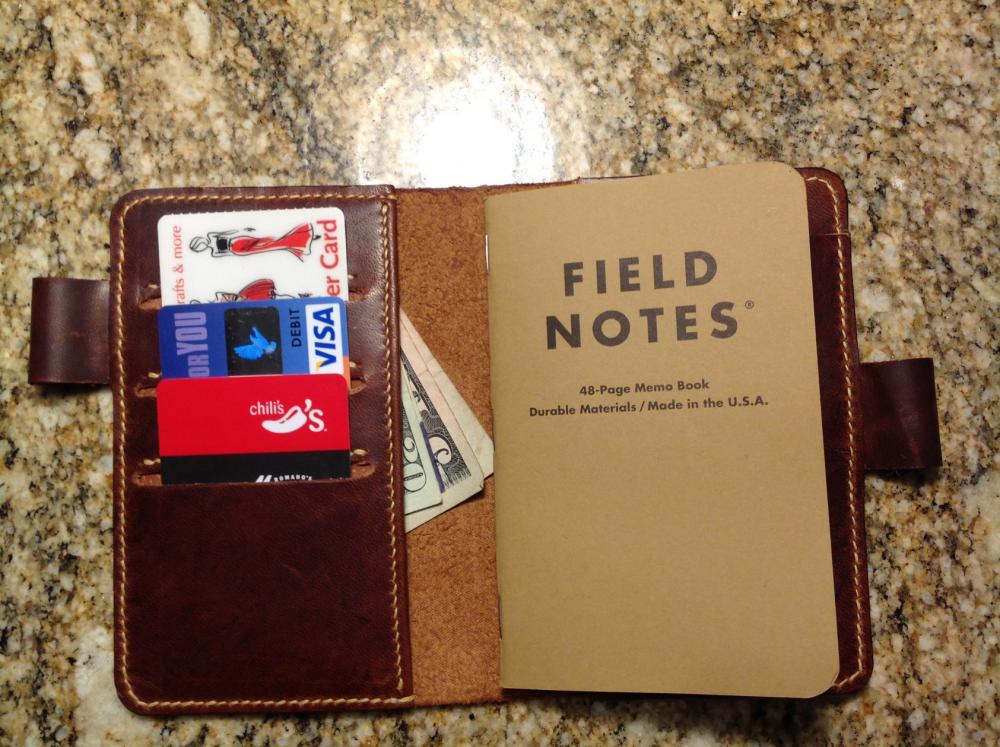

- passport cover

- leather field notes journal

-

(and 1 more)

Tagged with:

-

Does anyone have up close photos that illustrate this phenomenon of twist going in the right direction vs. twist going in the wrong direction? This is a detail I have not noted myself, maybe I've been lucky and used the correct twist for my particular stitching style, or maybe I just didn't know what I should be looking for... Thanks! YinTx

- 18 replies

-

Heh, my bad. Just an oversight, thanks for noticing. I am in Texas (YinTx). And if it doesn't sell, I'll have plenty to make a case or two, and some shoes, great ideas. YinTx

- 11 replies

-

- sole bend

- 15 oz leather

-

(and 5 more)

Tagged with:

-

Not too much into the armor thing, but if it doesn't sell, I may make a case out of it. A small one, have to be able to carry it! Already have a design in my mind... Thanks for the reality check... YinTx

- 11 replies

-

- sole bend

- 15 oz leather

-

(and 5 more)

Tagged with:

-

Ran it across the strop tonight, night and day difference! Thanks for the pointer, Matt! YinTx

- 11 replies

-

- rotary blade sharpening

- rotary blade

-

(and 1 more)

Tagged with:

-

I wish I knew. I have purchased a couple of lots of leather, and this was one of the sides I ended up with. And there is only one side of this color in the lot! So I won't be able to make too many things with it. There was a nice blue side in there too, and I made a similar style tote with it, see this thread: Sorry I couldn't be more help! YinTx

-

Thats quite an undertaking, and it looks like it turned out really well! Certainly the recipient is all smiles! Well done! Would be interested in seeing some close ups of the details... YinTx

-

No takers? Is the price off or does no one else use heavy leather? I'm open to offers! YinTx

- 11 replies

-

- sole bend

- 15 oz leather

-

(and 5 more)

Tagged with:

-

So, after a year and a half at this, I finally feel like I can post something in the Show Off section! I know it isn't perfect, has some things I can do better next time like skive the side where the binder covers the stitched section, and I will still reburnish the handles (got ahead of myself taking pics...) and still haven't perfected the binder overlap, but overall I am pretty happy with this one. Hermann Oak leather for the straps and binder. Waxy pullup green leather for the body, hand painted liner (No, I did not do the hand painting myself.. ) More Posted photos here: Please let me know what you all think! YinTx

-

-

From the album: Totes and Purses

© YinTx

-

-

-

- yintx

- leather purse

-

(and 1 more)

Tagged with: