-

Posts

3,794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by YinTx

-

- 2 comments

-

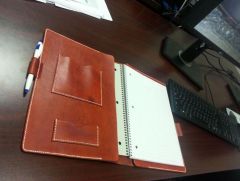

- hand stitched leather

- leather padfolio

-

(and 1 more)

Tagged with:

-

Anthony, I emailed you on Saturday regarding the condition and quality of the leather sides you shipped me. Please respond to my email. Thank you. YinTx

- 4 replies

-

- chromexcel

- horween

-

(and 4 more)

Tagged with:

-

Fancy Pancake For Ruger Sr40C With Inlay

YinTx replied to tclaridge's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That borders on awesome! love the color combinations, really nice stitching, leather finish is great, edges phenomenal. YinTx -

- 2 comments

-

- hand stitched leather

- leather padfolio

-

(and 1 more)

Tagged with:

-

-

- leather padfolio

- yintx

-

(and 1 more)

Tagged with:

-

How Do I Finish Leather But Keep The Leather Smell?

YinTx replied to Chief Filipino's topic in How Do I Do That?

I've been using Aussie to finish the leather, gives it a slight bit of water resistance, a very nice hue, and smells great, at least in my humble opinion. Not as shiny/plasticy as the resolene, which I prefer - not so much into the shiny look on leather myself. You might try it on a small piece and see if you like the results. YinTx -

Oh man I had no idea that the Chromexcel would look so bad after such a short period of time. Will this be bad to use for a footstool or a leather covered seat? I had planned to make some note book padfolios and some totes out of the stuff I had ordered, now I'm afraid customers are going to be bringing all my products back to me in 6 months complaining it is worn out. Anyone have any long term experience with that type of stuff? Thanks for sharing! YinTx

-

Black Dogg, No problem, thanks for sharing and commenting and clarifying! YinTx

-

Re-Lining A Louis Vuitton Bucket Bag

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Yes, I watched that video too while I was trying to figure some things out, very cool. Wish I had matching thread and machine to match the stitch pattern in the LV pieces! Instead, I had to figure out how to do straight stitches where they were supposed to be straight... (not sure how to get this right side up, but this is the top binding leather) And do slanted stitches where they were supposed to be slanted... I think I did ok... learned a few things along the way. I like how they used leather for the lining, and I wanted to, but the customer wanted the material that you see... the original material is not leather, but instead a coated cloth that eventually gets sticky and peels off. YinTx- 6 replies

-

- louis vuitton

- relining purse

-

(and 2 more)

Tagged with:

-

Jarednem, I wish I knew. I bought it from a gentleman in Yoakum, Tx who had a number of items, I also bought my Osborne calipers from him. Perhaps you know which shop closed down around a year or two ago? The next time I'm in Yoakum, I intend to ask him, I forgot to do so when I bought it off of him, I like to know the history of stuff! Hopefully, he remembers... YinTx

-

- 4 comments

-

- stitching irons

- chisels

-

(and 6 more)

Tagged with:

-

Thanks for that, Gmace99. As you know, making a video and posting it takes some time and effort, so I appreciate when others are able to pick up some tid bit from it. I have learned many things from your videos that I have not picked up in the hundreds of other videos I've watched on the subject of leather work! YinTx

-

Re-Lining A Louis Vuitton Bucket Bag

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Considering I had to line up all the original holes to stitch by hand, I did have to fight every stitch, but I think you are on to something there. The original appeared to use basting tape to hold the liner to the bag before stitching, and then the leather binding was added at the end. I did lightly glue the liner to the canvas, then stitched, then had to stitch the binder without glue in order to properly line up the holes. Not sure how I would do it differently, but I wasn't entirely happy with the way the binder seated - not as straight as I would have liked. If I could have figured a good way to glue it into place, I would have. There was a whole lot of trying to hold a lot of things in line prior to stitching, and not a simple task. Definitely a job for a machine and some glue, and not try to retain all the original bits! YinTx- 6 replies

-

- louis vuitton

- relining purse

-

(and 2 more)

Tagged with:

-

Re-Lining A Louis Vuitton Bucket Bag

YinTx replied to YinTx's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I suspect stitching the binding on would do the trick but I attempted to be true to the original construction as much as I could. I suppose it could help take the stress off of the binding stitch, and prevent it from pulling through the thin leather there, but not sure. This was the first one I have done like this too, so I'm no expert. Perhaps someone that does this regularly could chime in? YinTx- 6 replies

-

- louis vuitton

- relining purse

-

(and 2 more)

Tagged with:

-

So a good friend asked me to repair her LV Bucket bag, as the "Alcantara" lining had turned sticky and started peeling, as these purses are apparently apt to do. She wanted to maintain all the original leather pieces so the "patina" on the Vaschetta leather would match, which made repairing difficult. She also wanted a canvas style lining, so I used a cream colored Duck Cloth. all the hardware had to be scrubbed clean of the sticky material that came off of the lining. I used Fil Au Chinois 532 Jaune thread, saddle stitched. For the lining to LV canvas, I used 138 Bonded Poly thread, stitched by hand again. Comments and suggestions welcomed! YinTx

- 6 replies

-

- louis vuitton

- relining purse

-

(and 2 more)

Tagged with:

-

Black Dogg, I'm fully aware of Mr. Armitage's excellent videos, and have enjoyed them thoroughly and learned from them immensely. Never had any intention to upstage any of his teachings, but there were some requests to see how I was doing my stitching; so I made a brief video to share. Nothing more, nothing less, thanks for watching it! YinTx

-

And then there's the other dimension: the width. Had a recent customer want a 1.5" belt width, I asked twice to make sure, yeppers, he wanted that 1.5" width. So I spent time and effort to hand stitch it all nice, delivered it, punched the hole onsite custom to the customer's request. Called back 1 week later to see how it was working out... lo and behold, he can't get it to fit any of his other pants. Turns out he's wearing dress slacks all the time, and 1.5" just wont pass through the loops! So he hasn't used it at all. The buckle didn't make any difference at all in that instance! Might be making that one over again, but 1.25" instead. YinTx

-

- 8 comments

-

- yintx

- black leather belt

-

(and 1 more)

Tagged with:

-

Just a quick video for those asking how I am stitching my leather. Just one of many techniques I have learned in the last year I have been doing leather work. I am using Coats Barbour 18/3 Ecru linen thread. This is a 3.38mm stitching iron making the marks, and using a 35mm Vergez Blanchard Awl. I get a very nice separated angled stitch with this technique. For straight stitches or angled stitches that the thread stays touching, I use different methods. Hopefully the link works. YinTx

-

From the album: Straps, Belts, Watches

work in progress, new stitching irons, blue crystals, .8mm Tiger thread.. stepping out of my comfort zone! YinTx© YinTx

-

- blue crystal belt

- red belt

-

(and 1 more)

Tagged with:

-

Knights Templar Inspired Holster

YinTx replied to Boriqua's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Wow, that rocks. Just sayin. Thanks for sharing! YinTx -

JLS, I'm a little confused. I think your downloadable instructions say "For most holsters, we like a total of about 8 or 9 ounce leather thickness. Our patterns state the weight of leather used for the model shown. This is the total thickness desired, and can be single-ply piece that thick, or some combination of thinner pieces adding up to that thickness..." Your comment says 7 or 8 oz, so is that total, or each ply? I ask only because I am contemplating a holster, and when I went to a gun show this past weekend, I picked up a number of them. The 7 oz total weight holsters seemed pretty flimsy to me, like they might not hold the gun for very long or very effectively. I can understand not wanting to haul around a thick holster IWB all day, and trying to avoid printing, but it still seemed inadequate. Photos I see on this site of holsters I've admired appear significantly thicker, like 8 oz per ply. I think I only saw one remotely close to that, and the gentleman was asking $140 for it, vs. the $65 for the others. Build quality warranted his price point, especially sitting on a table next to the other vendor's er... stuff. I also must say the attention to details on even the most modest of holsters I have seen on this site blow away everything I saw for sale there. Including some NOS Bianchi holsters still in the package - I was frankly disappointed, considering the name and reputation, I had expected something on an entirely different level. Thanks also for providing the templates gratis. I have other templates, but its nice to have choices! and instructions. YinTx

-

It is a regular saddle stitch as far as I know, I use two needles and an awl. Not sure what a half stitch is. I think the biggest thing for me to get the separation is size and angle of the hole relative to the size of the thread. I think folks consider this a "French" style stitch, as compared to the "British" style stitch where the threads touch but maintain the angled aesthetic. The "American" stitch seems to be set in a groove and have a straight lay. I've been working to get any of the three looks, and maintain the same look on the backside of the stitch. Has not been easy to figure out without some direct instruction - an apprenticeship would have probably made things much easier! I have tried making a video, with varying degrees of success. When I get an opportunity, I will try to post one, it may be a few weeks... YinTx

- 8 comments

-

- yintx

- black leather belt

-

(and 1 more)

Tagged with: