-

Posts

807 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by LumpenDoodle2

-

I have also considered using a full log, but I have limited space, so needed something a bit more flexible. Also a nice solid workbench just wasn't going to fit anywhere. My dear hubby made me a 1 foot square by about 2 foot tall table out of 4" x 4" square fence posts (you could balance an elephant on it without fear of damage, if you are into balancing elephants). Then a very nice tree feller fella handed in two wood 'rounds' about 20+" diameter, by 8+" deep, and I use one of them on top of my little table. I can pound away on it, and nothing moves, unless I want it to. I also have my bit of granite on it for stamping, and just swivel the round, round when I need to use it. I have little racks fitted around the table underneath for my most used tools and mauls. As to drying, my logs were pretty well sodden when I got them, so I experimented a bit. One of them I placed in a warm dry area, and when it dried out, it split enough for me to get a fist into the crack. The other one I left under a dry porch in my garden for several months, and no problem so far with it.

-

For the less able diy'ers among us, this is what I did. I bought a lovely handmade maul from a chap in Italy. (18oz I believe). The red polymer used seemed to have a bit too much 'bounce' to it for my liking, and seemed to soak up some of the impact. I had a bit of a think, then I bought a length of white polymer about 2cm diameter wider than the original. I also cut the polymer about 1cm longer, then I drilled it out, and fitted it to my new maul. It was easy to do, using the hubby's chop saw, and piller drill. The extra weight and bigger size is now perfect for me.

-

Youtube has been a very useful learning tool for me. Even some longwinded vids have proved their use for that little gem of info. On the downside, is the 'witterers', who take 15 minutes to tell me their thoughts on life, and three minutes showing me 'how to'. Sometimes even that's ok, as long as they can string a sentence together that has a meaning/purpose. The coughing/wheazing/choked sinus/ummm/eerrr group who don't realise the microphone pick up everything, "gonnie no dae that" (she said, with meaning). Everything (especially bodily produced noises) in moderation please. And now the biggie. I can turn down the volume. I can fast forward. What I cannot do, is make an out of focus, off subject vid watchable. Nothing worse than someone showing me how to do something, while the camera is pointing up their left nostril, or it's bouncing about so much. I feel motion sickness coming on. (rant over, I'll go and have a lie down now).

-

You haven't lived until you visit Scotland, we cram a lot of variety into one small place. The Brother Innovis 750, is the equivalent of the Brother 770 in the US. It costs about the £900 mark new, and can take a bit of getting used to, but when you get the hang of it, it's a good bit of kit. £900 is still a lot of money for something you are pushing to its limits from day one, though. As to making your money back on the machine through items to sell, I know I haven't yet, maybe never will in the lifetime of the machine, but I still wouldn't be without it. As to being noisy, even when not under the additional strain of embroidering thick material, it clatters away to itself. I make finds pouches with personalised embroidery on them, so treated myself to the Embird digitising software. A bit of a steep learning curve, but pretty good, and you can buy the software in modules so doesn't hurt the bank balance too much. At £90-£150, per unit, not too cheap, but the alternative is £1,000+ for commercial software.

-

Advice for a nooby please guys

LumpenDoodle2 replied to sparky20006's topic in Leather Sewing Machines

Wot Mikesc says. I think the Highlead GC3108 is the same as the Joy Pf5318 (correct me if I'm wrong). I bought the Joy pretty cheap from an upholsterer, and although it has limitations when working with leather, it does the job for me (at least until I can afford/have the space for a better machine). I also fitted a servo motor, and it changed the machine for me. It also remove the embarassment of seeing a grown woman hanging onto the end of a piece of material, screaming "Mummy! Mummy!" as the material she is clinging to dissapears through the machine at the speed of light. As to what you can sew, I use mine over a range of materials and thicknesses, from thin pvc covers, to veg tan belts (3.5mm-4mm max, but do-able. So, I know there are better machines out there, but out of your selection, I can vouch for the Highlead as well useable, but be careful with the price, as to me, £400 without a servo motor might be considered as on the higher side, price wise. -

Can I volunteer to provide the neccessary storage in between 'loan outs' for it. Honest, it will be well looked after until someone else needs it. and y'all can come out and collect it from Scotland anytime.

-

5oz does seem quite a weight. Main thing to keep in mind is that even a domestic embroidery machine like my Brother will do 650 stitches a minute, and being computer controlled, when goes wrong, it really goes wrong. I embroider pvc backed canvas, and single thickness webbing without worry, but thick suede is definitely pushing it. I think it would be too problematic correcting the stitch density, and tension, never mind the strain on your machine. It's not just the needle bar timing which could be knocked out, that could be quite a weight for the hoop positioning mechanism to be dragging about.

-

I have a Brother embroidery machine, and you can embroider thin leather (1mm), and I've seen some lovely work via google. You'll probibly need quite a thick stabaliser to stop the thread puckering (embroidery thread has quite a stretch to it), and play with the top tension a bit. As for the needle, I'm not too sure what type would be best, as a leather point might encourage the needle holes to run into each other. Such thin leather may handle a standard embroidery needle better, and you may find you have to replace the needle at the start of each job due to it being blunted. Certainly aim for low stitch density patterns. Are you using software to create patterns, or buying pre-made ones. Just to add, the 1mm thichness refers to veg tan or 'bookbinding' leather, you can embroider thicker chrome leather, but be careful, as you will be pushing the limits of your machine, and could knock the timing out.

-

I have the walnut dye on back order from Abbey England. Apparently, it's on its way on a slow boat from the US, and can't be had anywhere here, even for ready money. I was told on enquirely, that the arrival of this boat is affected by the weather, good weather, and it takes but a few weeks. Bad weather, and it will take months, as the boat sort of hangs about sheltering from the rain, or something. Hence image of European leatherworkers en masse praying for good weather over the Pond.

-

Tandy now carries the Tippmann Boss

LumpenDoodle2 replied to veedub3's topic in Leather Sewing Machines

Oh, if only I could by a Tippman Boss for $1,600, instead of £1,600. It appears that when Tandy send me a mail drop, all they've done is Tippex out the dollar sign, and replace it with a pound sign........... -

How should I sequence these operations ?

LumpenDoodle2 replied to ToddB 68's topic in How Do I Do That?

Another Detectorist here. I'd definitely leave a little gap at the bottom of the sheath. It saves on the build up of dirt in the sheath, and is easier to keep clean. -

If you get stuck, try contacting a local or internet based belt maker. If you have the measurements, they may be able to supply an off the shelf cam/timing/pulley belt with the same dimensions that will do the job. Or even make one for you.

-

Just to say, if you can get another outlet other than fleabay, do it. I sell about 60% of my stuff on fleabay, and once I get a bit time, will be pushing my own little webshop more. About 95% of my customers are lovely people who I've had many a good blether on the phone, and emails with, but it also attracts the weirdyboys. At least with your own shop, you can politely, but firmly deal with the bampots in your own way. On fleabay, there are so many policy rules and a 'customer is always right' attitude, it can too easily suck the fun out of your day. But, there again, that's the payoff for selling your stuff to strangers.

-

I have a very small workshop, and have been using the same two 15 year old dinky flat pack desks as work/cutting surfaces. Got fed up 2 weeks ago, and bought two cheap Ikea table tops, and fitted them on top of my desks. I now have a greatly increased, and even work surface, and didn't break the bank doing it. Maybe that would be an idea for you? (Does Ikea 'do' where you live?)

-

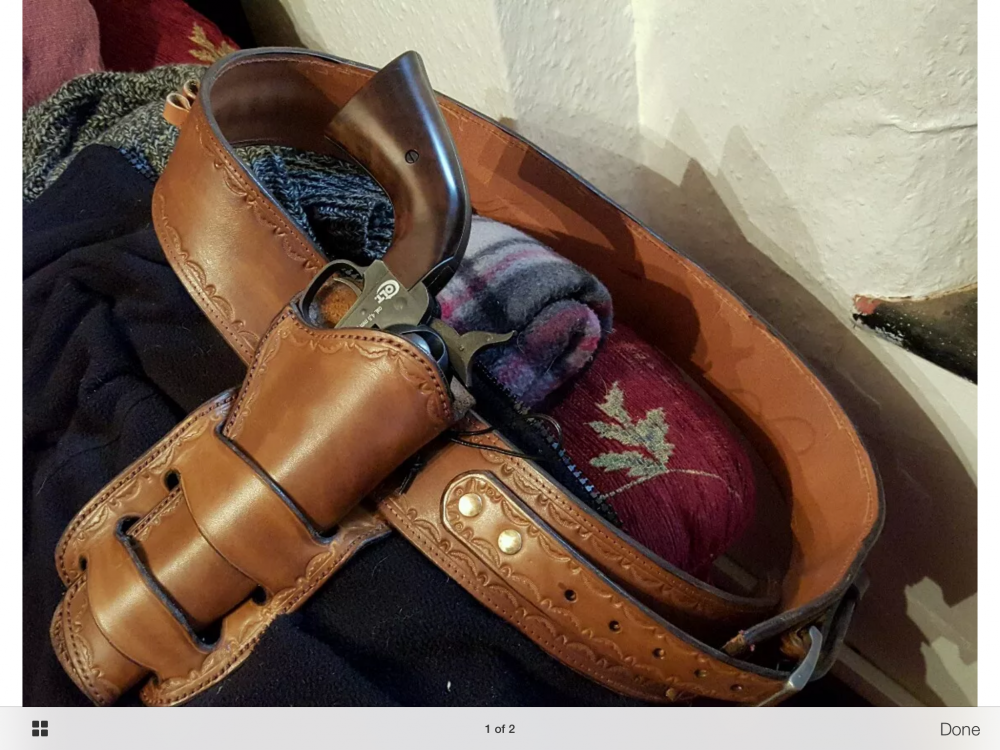

Hi many thanks for the reply (and the compliment). Being from Scotland, there isn't many opportunities to get my hands on a 'proper' rig. Photographs and vids are fine, but just not the same holding a real holster, and feeling how it is constructed. I have been very fortunate in that one of my customers is extremely experienced in competition gun shooting. He has very generously just sent me a couple of competition holsters to look at. Bit of an eye opener, and will certainly make me 'up my game' as they say. As to customers after soft holsters, well, each to their own, I suppose, and it will be another bit of experience for me.

-

Teaching your son leathercraft will at the very least, get him to appreciate craftwork, and the difference between throwaway tat, and something that someone has put their heart into. Maybe a carear at the end of it, but probibly self-employed, rather than an employee. I think the biggest thing to me about this leather working, is to try to not get stuck in one market or product (unless it's paying you to do so). You have to be open to new ideas and methods. Like RockyAussie, I have a 3D printer, but I'm just starting to work out how it can make life easier for me. anyhoo, a good grounding in art and craft, and you can do (almost) anything.

-

By gum, that looks fun..... I think the hubby would be a bit upset if I came home with that big chap. I have only seen pictures/vidoes of that model, and none of it actually sewing.

-

I'm still very much an apprentice in this leather making thing, but have been fortunate to sell a number of my Western style holsters to folk. A great way to learn, and earn money. But, I have had two people not happy with how stiff/tough my finished holsters are. That set me wondering about how to get the affect they want. I figure that although I can't see any advantage to softening a holster, if that's what a customer wants, fair 'nuff. So, what would be the best way soften up a holster after the stamping, and shaping of 3mm+ has left it hardened. I use Aussie conditioner as a finish, but would a good coating of Neatsfoot oil both inside and out do the trick. Maybe saddle soap first? I am moving somewhat out of my territory here, so any advice would be gratefully received (I've added a picture of one of my rigs just to give you an idea of what I'm making).

-

I use the gum trag for the more 'loose' flesh side, and aussie conditioner for the rest. Works for me.

-

When I first got my arbor, I rigged up a chuck from an old electric drill. Although it had a lot of potential for using with stamps and dies, the chuck did take up a lot of the limited height on the arbour.

- 20 replies

-

- arbor press

- dies

-

(and 2 more)

Tagged with:

-

0.5 tonne press okay for stamping?

LumpenDoodle2 replied to Artificial Intelligence's topic in Leatherwork Conversation

I have a 1/2 tonne press I bought from machine mart. Does the job for me, and up until I treated mysef to a 'proper' stud setter thingy, it did all my rivets and studs too, no problem. You probibly use a bit more grunt to get there though. I agree that the handle could do with being about 2" longer. -

Cutting Leather With Laser Questions

LumpenDoodle2 replied to pillpusher's topic in Leatherwork Conversation

Wonder if the folk who used to cut leather with flints criticised the ones using those new fangled bronze knives. Nothing wrong with purely hand made using old techniques , hand made with modern tools, or machine made. As long as you don't try to claim otherwise to a customer.