-

Posts

5,250 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

I don't know what kind of tool you are using, . . . mine is an old saddle makers tool, . . . it is a hunk of steel. Using it and an suitable mallet are crucial to getting really good rivet tops. Plus, . . . see the enclosed diagram, . . . it will help your work immensely to have something like this, . . . and get off the kitchen table. May God bless, Dwight

-

You didn't say if it was vegetable tanned leather you are using. That can make all the difference in the world. I know of holster makers who do what you are planning, . . . gluing them flesh side to flesh side, . . . it makes a very pretty and smooth inside and outside for the holster. It is also very rigid. I made one some time ago and got in a hurry with my selection, . . . used 2 pieces of 5/6 for the front and the same for the back, . . . laughed about it later as being the 10th round of the weapon. Shoot all 8 bullets, . . . if that don't work hit em with the gun, . . . if that fails, . . . hit em with the holster . I use weldwood contact cement when I'm doing things like this, . . . cut two pieces, one slightly larger than the other, . . . then after the gluing process, . . . trim the fat one down. You can also "massage" it a bit and it will become somewhat more flexible, . . . but it will almost never become loose and limber. May God bless, Dwight

-

^ ^ ^ What he said, . . . is in most cases going to be the best. May God bless, Dwight

-

You are a fortunate man, . . . grand daughters are always more important than saddles. (AND, . . . that is one good looking rig,........... ) May God bless, Dwight

-

For the last several years, I have used Tandy's 346 white waxed nylon (?) thread, . . . with almost no problems at all. The one situation I cannot fix is the thread will not take dye permanently, . . . it eventually rubs off, . . . and generally turns some color between white and the product dye color. I'd like to find the same thread, . . . in brown and in black. I bought the offering Springfield Leather had to offer, . . . was very much disappointed with their thread (but to my pleasure they offered to take it back, . . . full refund ). Anyway, . . . it is a heavily waxed thread, . . . wonder if you all know where I can get something equivalent. May God bless, Dwight

-

A template for decoration? A template for hole spacing? A template for buckle end? A template for tongue end? A template for a Ranger Belt? Kinda tough when no one knows what it is you want. But at just about any local Tandy shop, . . . they carry books on belts, . . . patterns, . . . layouts, . . . etc. Google up Tandy Leather Works, search for belt book, . . . the Al Stohlman one is $19.99, . . . and you can get it cheaper than that on the internet. May God bless, Dwight

-

After, . . . finish the work, . . . 100% final, clean, done, . . . then put on the Resolene. There may be some other special applications of things done after Resolene, . . . but I don't know what they are, . . . and don't do them. Other than, . . . some extra final wax polishing for certain items. And for the OP question, . . . GranpaJoel pretty well summed up my practice as well. If for some reason you do not want to use a stitch groover, . . . buy a pair of LARGE dividers, . . . dull the points down, . . . and use them to make your line and your groove. In one of his older video's, . . . that is the exact process that was taught by John Bianchi, . . . no groove, . . . just a wetted leather indentation produced by a pair of dividers. I also have used this process, . . . it does preserve the top layer, . . . but generally I only use it on very thin veggie tan stuff. May God bless, Dwight

-

Me, too, Chris, . . . I'd love to have one like the example Tippmann has on its website. Dreamer I guess. May God bless, Dwight

-

And I'm getting a post in here, . . . so I can follow what is going on. I've only made a couple pair, . . . and I can use all the help I can get too. May God bless, Dwight

-

So you are telling me that to conform to the accepted practice of a professional saddler, . . . I need to space 5 holes, 2 inches apart, on my 2 inch wide belts I make for my customers, . . . in order to conform to "belts should have 5 holes space the width of the belt apart." Some stuffed shirt know-it-all may have written down in some dusty old book a hundred or two years ago that this is the "accepted practice", . . . but it just does not make any sense at all. And you can relay that to him for me. My customer's needs, . . . desires, . . . comfort, . . . likes, . . . and dislikes are what drive my production, . . . and the "real" production of the whole profitable trade enterprise. Suggesting that everyone conform to some silly rule like that is beyond silly, . . . May God bless, Dwight

-

I'm really not sure where you came up with this information, . . . but it is just totally incorrect, . . . period. The tongue end of the belt needs to be long enough to go out through the keeper with an extra 1 inch or so, . . . when the buckle is in the first hole. Spacing them the width of the belt is not only silly, . . . but totally defeats the purpose if you have a belt that is wider than 1 inch. And 5 holes or 7 holes is only a function of how the maker wants to do it, . . . there is no "standard formula", . . . at least not on the west side of the Atlantic. May God bless, Dwight

-

Yep, . . . looks really good from here. I'm curious though, . . . how you finished off the beads, . . . or, probably, . . . how you did it in the first place. I could do the loom part, . . . even copy the patterns, . . . but the attachment, . . . haven't figured that one out yet. Have you got the little guy helping you with the beading yet? May God bless, Dwight

-

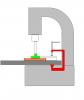

I don't have the fancy one made yet, . . . when I do, . . . it will be square white vinyl tubing, white vinyl angle, . . . the square tubing being bolted to the back of the press, . . . the angle guides being adjusted in and out by 1/4 x 28 threads and springs. I figure when I get time to do it, . . . it'll be a couple hours work, . . . but it will be worth it. Presently, . . . I'd use the "C" clamp set up if I couldn't just eyeball it. I did a leash for a friend over Christmas, . . . name and 10 digit phone number, . . . did it on a 1 inch strap, . . . all by eyeball, . . . turned out AOK, . . . but I wouldn't do that with belts or something I had a lot of other time or material invested in it. Hope this helps. May God bless, Dwight

-

2 Gun Buscadero

Dwight replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks good, Josh, . . . any old outlaw (or peace officer) would have been proud to wear that into Dodge City. One of these days, . . . I'm going to waste a bunch of leather, . . . time, . . . etc. and make a "somewhat" copy of Roy Rogers' double rig. That is, . . . unless I change my mind and do a Lone Ranger, . . . I always liked both. Whichever I do, . . . I hope it turns out as well as yours did. May God bless, Dwight -

1911 Pattern For Browning Hi Power?

Dwight replied to mrfixit's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Show us a picture of the holster you now want to duplicate. Most likely, . . . it will be a simple process, . . . but I hate to start trying to give advice: if it is this one, do this, . . . if it is that one do that, . . . but if the other one, gotta do the other thing. The 1911 is one of the thinnest of the big bore auto's, . . . so to start with the pattern will have to be somewhat bigger, . . . but again, . . . pop up the pics and one of us can probably point you in the correct direction. May God bless, Dwight -

Redhairing, . . . while I do not do a lot of hand stitching, . . . as often as not, . . . it is done without a clam or stitching pony. Yeah, . . . it's a little tougher to do, . . . but I get it done, . . . mostly putting it between my knees or laying it off the edge of my work desk. You follow the same procedure, . . . it just takes a bit longer. But, . . . in all honesty, . . if you have a machine available, . . . that would most likely be a lot quicker and easier. May God bless, Dwight

-

Just Started Making Holsters Let Me Know

Dwight replied to thayn61's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I cannot tell a lot from the pictures, . . . they're a bit dark, . . . but for the most part, . . . everything looks fairly nice for your first ones. The only two things that kinda "jumped out" would be the suicide strap on the black one, . . . when you make those, . . . leave a tongue below the snap, . . . something to lift it with beside a fingernail. That one looked like you cut it real close to the snap. On the brown one, . . . you were probably attempting to be "artistic" with the little bumb in the sewn edge below the trigger guard, . . . and down at the tip end of the barrel. Those little cuts like that do lend an artistic flair to some things, . . . but to holsters, they will usually just become a frayed and raggedy piece of fluff leather a dingle dangling off the edge of the holster. Strive for more flowing and even lines, . . . avoid square corners worse than you would avoid a female skunk on PMS. But, . . . you started out good. May God bless, Dwight -

I have a compass, . . . RARELY ever use it, . . . simply because there are too many rolls of masking tape, plates, saucers, coffee can lids, coffee cups, drinking glasses, pill bottles, etc, . . . which are perfectly round, . . . AND, . . . I can lean on with my left hand while scribing with my right. It don't move, . . . I get a good scribe, . . . and we're off to the races. When I do use the compass, . . . it has to be done from the back side so the "point" doesn't mar the good piece. You may also want to be sure to have one that opens and closes with a turn screw, . . . not one of those sliders like kids use in school. It'll slide on you every time and frustrate you worse than a dull beak on a woodpecker's head. May God bless, Dwight

-

If you want to make an actual groove, removing leather, . . . a stitch groover is hard to beat. You can get one that is pretty much fixed, . . . or adjustable, . . . or freehand. The freehand one is a hoot, . . . works great, . . . just take your time using it. Google up Tandy, . . . put in the search word: groover. I've got all three, . . . they work well for me. The cheap one with the wooden handle, . . . is my "fixed" one as I cut off the excess of the arm, . . . locked it into position, . . . never have any problem with my stitch borders not being the same from item to item. If you do not want to remove leather, . . . but just make a line, . . . an old pair of dividers works wonders. Just take em to the sandpaper and dull em real good first, . . . or they will cut the leather. John Bianchi in an older set of videos, . . . used the dividers to lay out his stitches on a belt and holster he made for demo. May God bless, Dwight

-

Cowboy Holster Tutorial

Dwight replied to Jim's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I use the hammer handle instead of a dowel, . . . because it starts out pretty small, . . . and goes up to pretty big, . . . AND, . . . they come pre-finished so all you gotta do is cut off the part that would go into the hammer head, . . . sand down the very end nice & smooth, . . . you've got a tool. It then works for lots of different sizes of holsters. May God bless, Dwight -

Cowboy Holster Tutorial

Dwight replied to Jim's topic in Gun Holsters, Rifle Slings and Knife Sheathes

It looks like there might be a welt in the holster, . . . can't see for sure. But the scratches seem to be on the outside half of the holster away from the leg. That would indicate to me that the ejector rod is probably hanging up, . . . or scraping badly. In John Bianchi's holster making videos, . . . he shows opening up the barrel end of the holster with a hammer handle. Yessir, . . . it works. I got mine at a yard sale, . . . sanded it all down, . . . smoothed it out, . . . greatest tool in the world for SAA holsters. It will open up that bottom where the ejector rod is, . . . make it smooth and non-catching. I recommend that tool to anyone making SAA holsters. May God bless, Dwight -

How Do I Put A Cap On A Socket Straight For A Snap

Dwight replied to leathervan's topic in How Do I Do That?

Not sure I understand, . . . can you post a pic? That would sure help, . . . several would be ideal. May God bless, Dwight -

The only difference, . . . I will sew down one side first, . . . sight track side mostly, . . . then only wet the "front", . . . which gives most of my hosters a flatter if not flat back, . . . which to me is more comfortable (I'm a bony old rascal with not much padding ). On my "fold overs", . . . I just wet the front piece, . . . when it's all dry, . . . complete it. May God bless, Dwight

-

Actually that is the process I have always used, . . . it has never failed me yet. When it is dry, . . . I cement the pieces together, . . . re-test the fit, . . . sew, . . . and finish. But that is just one way to do it, . . . kinda like making soup, . . . all kinds of recipes. May God bless, Dwight