-

Posts

5,247 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Dwight

-

Most likely I too would replace the rivets . . . it is just how "authentic" you want it to look. But if you want one color on top and another color on the bottom . . . saddle stitching is definitely NOT the way to do it. Traditional saddle stitching will cause every other stitch to be the same color . . . with the different color in the stitch next to it. You want to do a loop stitch . . . such as a sewing machine does . . . the top thread is pushed down thru the sheath . . . looped around the bottom thread . . . then the same top thread is pulled back up thru the same hole . . . and the two threads pulled together so that the overlap loop is in the middle between the pieces of leather. This is a 20 dollar tool that will make that a much easier job . . . https://tandyleather.com/products/sewing-awl-kit May God bless, Dwight

-

Carol - looking for a leatherworker in Iowa

Dwight replied to Carol456's topic in Leatherwork Conversation

Is it possible for you to post a picture of one of them . . . or all of them . . . at least one fairly close up view of the affected area? All you do is follow those directions down below . . . where it says "Drag files here...................". Just pick the pictures from your computer. Ideally they should be about 1000 by 1350 or so. May God bless, Dwight -

The first thing I would have looked at is the needle. That rascal cannot be "off kilter" or it and the bobbin will not make that stitch. And the fact that you were hitting . . . then missing . . . would sound like it was close to being installed correctly . . . but just maybe off a tad. Check your needle if you have any more trouble. May God bless, Dwight

-

Carol - looking for a leatherworker in Iowa

Dwight replied to Carol456's topic in Leatherwork Conversation

Tell us what you are looking for . . . Lots of people see this part of the forum as well. May God bless, Dwight -

If you want to have some fun some time . . . go to Ebay . . . look up something costing about 50 bucks . . . then have it sorted by price, lowest to highest. If there are 150 offerings or so . . . invariably there will be one in there for $39.95 . . . but it will be after the ones for $79.95. Reason??? They're also charging you $59.95 shipping. I almost got hung on that one day . . . been super careful ever since. May God bless, Dwight

-

How do you interpret this ad for a Cobra Class 3

Dwight replied to kgg's topic in Leather Sewing Machines

"Something strikes me as just not right with this." is probably an understatement . . . but at the same time . . . there are people who just don't know how to set up an ad or word anything for use out there on the internet. There is a chance it might be a good buy . . . I would certainly try to find out what I could. How far is he from you . . . or do you know where he lives?? May God bless, Dwight -

How do you interpret this ad for a Cobra Class 3

Dwight replied to kgg's topic in Leather Sewing Machines

If you are a mechanic . . . don't mind working on your "stuff" . . . it's about a 40% saving over a brand new one. You can buy a bunch of parts for 40%. I'd pop him a text to find out all of what is wrong with it . . . might even ask him for a video of the machine sewing (taken with a phone . . . transferred to an SD card . . . mailed to you). If he's willing to do that . . . it's most likely well worth it. If he is not . . . I'd run away from it. May God bless, Dwight -

Viking sea serpent holster.

Dwight replied to Viking's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You might also take up a trick I found out about a few years back. Before you dye the project . . . give it a light (emphasis on light) coat of genuine neatsfoot oil (not compound). I brush it on with a 1 inch bristle brush . . . getting it just wet enough to change color . . . like it was wetted with water. I hang i up . . . and the next day it is back to about 95 % the color it was before the oil. Then I dye. I was having a real time with saddle tan especially . . . have zero problems with it now. Not sure what makes it work . . . it just does . . . and I'm happy. May God bless, Dwight -

My attempt to enter the machine sewing world

Dwight replied to Tio's topic in Leather Sewing Machines

Before you buy either . . . check em both out first. I'm not sure I would have bought the Cowboy . . . never used it . . . but have seen them . . . would have to be seriously impressed with the Cowboy and it's sewing before I would buy it. Either way . . . have fun . . . and remember one thing about the Tippmann . . . they are really good people to deal with. I've been there . . . done that. May God bless, Dwight -

My attempt to enter the machine sewing world

Dwight replied to Tio's topic in Leather Sewing Machines

I sewed for years on a Tippmann Boss . . . and did not realize how really slow I did sew with that thing. I finally figured out how to make my Cowboy 4500 go REALLLLLLLY slow . . . and we are doing a lot better together now. I doubt if I'll ever get it up to the fastest setting . . . my sewing ability is just not there. I can watch the needle go down . . . down . . . down . . . down . . . and finally contact the leather . . . then down and down and down . . . I like that kind of control. May God bless, Dwight -

In my years of leather working . . . I've mostly used my Tandy store . . . almost an hour away . . . bad part of town . . . But I got to pick my inventory that I wanted . . . And they are really not good for letting you know something is not in stock if you order something and it isn't there. But my real gripe . . . is one of the "nationally known" leather suppliers . . . about an hour and a half away . . . Weaver Leather. Getting there was a 100 mile trip . . . as I did have another place I wanted to go first. Got to Weaver's . . . walked up to the showroom door . . . it's locked . . . little white paper sign on the door . . . we're closed for remodeling. Apparently was closed in 2020 when covid hit it's stride . . . not one word on any of the Weaver site about the showroom being closed. Today . . . go to their website . . . still not one word about it being closed. You make the trip . . . you are out of luck. I had in mind to purchase a couple hundred dollars worth of stuff plus leather . . . wound up buying one hide . . . and I only did that because I wanted to see if Herman Oak is as good as I've heard . . . or if I'd rather play with the Tandy stuff. On top of it . . . I spoke personally to five different people . . . assured me they would address the closure . . . yeah . . . don't hold your breath. Top if off . . . checked my bill . . . I was overcharged . . . not much . . . but overcharge is overcharge . . . Anyway . . . so much for my gripe . . . May God bless, Dwight

-

I did a bunch of counter tops back "in my day" . . . and Weldwood contact cement was my product. We stuck down pieces 6 ft long by almost 36 inches wide . . . trimmed them . . . and then had lunch or dinner on them. Far as I know . . . some of them are still out there . . . and the first one I did was probably 1970 or so. When I got serious about my leather work . . . it followed me over into it. I don't use glue very often . . . because of the setup time needed . . . to say nothing of "what happens if it moves and you don't see it?" . . . Weldwood does have an odor . . . and just maybe I've gotten used to it . . . but I use it and don't really have a problem with the odor. If I'm doing say several belts . . . as I glue em up . . . they will go hang in the garage . . . or if the weather permits . . . sometimes I'll take the gluing process out into the garage. What I love about it is . . . when I stick something together with Weldwood . . . I can go answer the phone . . . check my UPS guy . . . hit the bathroom . . . go to lunch . . . or any of a hundred other things . . . and when I come back to those pieces I stuck together . . . they are still stuck together and stuck the way I put them. It is my recommendation . . . and the only one other thing I use . . . and it is super rare . . . I've got a bottle of white Elmer's glue . . . and I can't recall when or why I even used it last . . . but I had some kind of project maybe back in 2020 or 2019 where I used it. But that is just me . . . and my story. May God bless, Dwight

-

There is a "button" on the side of the controller box for the motor . . . on mine it is a little chrome button . . . looks like an old volume button where the knob was yanked off the radio. Mine turns clockwise to the last click . . . where it will not go at all. One click counter clockwise and it is really slow . . . the more clicks CCW you go . . . the faster it goes. You may have a different setup than mine . . . but that is the way mine is . . . I can get you pictures if you like. May God bless, Dwight PS: Just a quick compliment . . . Milt Sparks puts out some great stuff . . .

-

Just really beautiful work . . . Wayyyyyy beyond my reach . . . May God bless, Dwight

-

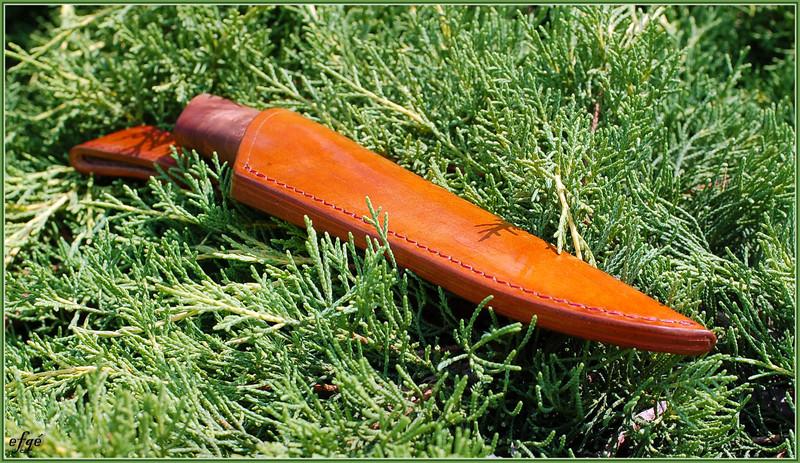

2nd Attempt - Knife Sheath

Dwight replied to Jhunter13's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You need to go to Harbor Freight . . . buy one of these . . . https://www.harborfreight.com/1-in-x-30-in-belt-sander-61728.html It is a little 30 inch belt sander. With it you can sand down the edges of your sheaths . . . so they are perfectly flush . . . no matter how many layers you use. Take off the plastic guard on the top roller . . . and you can do the inside of your curves with it. It's the best 60 bucks you will ever spend as far as finishing tools is concerned. I own two of them . . . AFTER you finish sanding the edges smooth . . . take a stitch guide and set our outside stitch line . . . adjust it and set your inside stitch line . . . or use a set of dividers. I prefer the stitch guide as it actually cuts a little trough for the top stitches to lay in . . . but for a knife sheath it is six of one . . . half dozen of another. The other tool is of course is an edger . . . get a #4 for knife sheaths . . . and you can burnish them with a piece of canvas . . . and a little bit of water. I didn't do this sheath . . . but it gives you an idea of what the edge should look like. Notice he has a full length welt in there as well. May God bless, Dwight -

Let me second his opinion and decision. "With a little help from my friends" . . . mostly on here . . . I made the same decision . . . and am happy that I did. I almost went with the 3200 to save money . . . but just every now and then I need that extra height . . . glad I spent the bucks now. Yes . . . you can do chaps on this machine. Fact is . . . if you pop a few bucks for an accessory plate made in Australia . . . you can go down to some pretty thin leather on this machine . . . mine will be on it's way in a few weeks . . . If you want to make any adjustments to this machine . . . remove both the pedals . . . move them both to the right and to the rear so the back edge of the pedestal and the pedals are even. You'll have to drill and tap the holes . . . but if you do it . . . you can drop the machine into the lowest position . . . and at 6'2" I can sit down on a kitchen stool and sew with it. Beats the heck out of standing up. Get the accessory kit with it . . . money well spent. Toledo Sewing machine in Toledo, Ohio . . . where I got mine. May God bless, Dwight

-

Jennifer . . . check this thread

-

Thanks AzShooter . . . One of the things I really do have fun with. I actually make the pattern on Microsoft Excel . . . Then sit down and bead it up . . . I kinda giggle all the way thru it . . . knowing that Bill Gates would have a fit if he knew what all that coding and programming produced: a beading pattern maker . . . lol May God bless, Dwight

-

I went looking for these the other day . . . took 2 days to find where I'd stashed them. I read once that some of the native Americans used beads to "sort of" depict things from times past . . . part of their personal experiences . . . I took that idea and ran with it . . . will be my left and right sleeve leaders down over each shoulder toward the front. My navy career . . . my ol Navy uncle . . . are on one of them . . . the most important Bible verse is on the other . . . Just need to get the buckskin jacket made so I can put these on it. May God bless, Dwight

-

Mmmm . . . I'd love to get on that ship say in New York . . . sail around to New Orleans or so . . . spent 4 1/2 years in the US Navy . . . and didn't get even a glance at anything with a sail on it. Much to my displeasure . . . always thought I'd a made a great sailor 150 years ago. Anyway . . . thanks for the link . . . it was fun to look at. May God bless, Dwight

-

Thanks, Chuck . . . I had never really done any before . . . first one I did was enough out of proportion that I did not like it . . . so I did it all over again. Would you believe that my pattern maker is Microsoft Excel?? It actually is. But thanks for the compliment . . . it was a fun project. May God bless, Dwight

-

-

Don't be bashful about dressing them up . . . This was my pair up until I quit riding. May God bless, Dwight

-

Didn't see a place there on your web site . . . where we could get hold of you . . . With these stinking electronic boxes . . . always needing some advice . . . not sure we could do that phone number . . . I'm used to not having to pay for any phone calls . . . May God bless, Dwight

-

Just a note . . . I don't know if you can get the product . . . here it is called Resolene . . . it is an acrylic leather finish. Another one we use . . . it is a floor polish . . . called Mop and Glo. Cut either of them 50 / 50 with water . . . and brush the product on your shoes. Might take 4 coats . . . let em dry a couple hours between coats . . . might make those boots last you long enough to work out the cash for better ones. There is a fellow in UK . . . don't recall his name or website . . . makes some of the most beautiful holsters for the old .45 automatic from WW1 and WW2 days. Not sure how he managed to get and hang on to a .45 auto . . . but he shows pictures with it. Good luck. May God bless, Dwight