-

Posts

502 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Techsew Ron

-

Our customers who use the 810 or 830-R post bed machines for shoe reconstruction typically use size 69 thread with 18 needle or 92 thread with 20 needle. Patchers are more common when sewing patches onto pre-constructed shoes but a post bed machine with roller foot is preferred for piecing together the various parts of the upper.

-

Techsew 2600 table came damaged, repair ideas?

Techsew Ron replied to JC2019's topic in Leather Sewing Machines

Hi Jason, sorry to hear what happened to the table in shipping. As of the end of day Friday we were still waiting for you to do a full inspection to make sure no other parts of the table or machine were damaged. We still have not gotten a reply from you. This morning I'll make sure the replacement legs get shipped to you immediately at no cost. regards, Ron -

Sewing Machine for Sewing Custom Sneakers

Techsew Ron replied to JohnG305's topic in Leather Sewing Machines

Yes you can simply remove one of the needles.- 40 replies

-

Sewing Machine for Sewing Custom Sneakers

Techsew Ron replied to JohnG305's topic in Leather Sewing Machines

The second shoe was constructed piece by piece, it looks like a double needle post bed machine was used on most of it. The first shoe was most likely modified with a patcher.- 40 replies

-

Sewing Machine for Sewing Custom Sneakers

Techsew Ron replied to JohnG305's topic in Leather Sewing Machines

For customization and sewing patches onto existing shoes a patching machine would be the most popular choice. This type of machine allows you to sew into hard to reach areas and you can rotate the presser foot to sew in different directions. For shoe construction from scratch, you'll need a post bed, roller foot machine (preferably with reverse). The 810 type machines have a lower feed mechanism which feeds the material into the machine, with a roller foot to help guide and compress the material while sewing. You can sew 2-3 layers of thin/medium shoe leather with this type of machine. Maximum thread size on this type of machine is 92. For sewing thicker and more multi-layered materials you may want to look into a top and bottom feed machine with a gear driven roller feed. As others have mentioned, a side wall sole stitcher is needed for sewing the upper to the sole. Ron- 40 replies

-

Hi Ava, we received your email and our technician will be in touch with you to resolve this. Ron

-

New Tandy Craftool Pro Stitch Master made by Sailrite

Techsew Ron replied to Treesner's topic in Leather Sewing Machines

well said Gregg ! Right machine for the right customer. Everyone has different needs. -

oops - re-sent the correct manual. Ron

-

Hi, yes we have the Techsew 3650HD in stock. We just sent you an instruction manual by email as requested. Let me know if you need anything else. Ron

-

Hi Kenneth, we're promptly responding to everyone of your questions by email and offering a number of recommendations for adjustments. We would like you to try leather specific needles (LL or S or Diamond point) to decrease the puncture marks on the bottom. Please try our suggestions and let us know the results. Ron

-

Hi Kenneth, I noticed on another forum you changed to a different type of presser foot that you purchased and mentioned you were having issues with it not coming 100% back down. This might be affecting your bottom tension as the tension is released when you raise the presser foot. Please send us an email to support@techsew.com and we'll follow up with some adjustments. Ron

-

Source for servo motor with boxing day deals?

Techsew Ron replied to Sugarkryptonite's topic in Leather Sewing Machines

absolutely! Ron -

Source for servo motor with boxing day deals?

Techsew Ron replied to Sugarkryptonite's topic in Leather Sewing Machines

Shipping anywhere in Quebec including Montreal for a 1/2 lb of thread is $12. You're welcome to pay us a visit too! Ron -

Some machines require the motor to rotate in the reverse direction, but most machines do not.

-

not entirely sure the white one is one of our machines but I could run the serial number for you if you want to send it over.

-

Looks great! Give us a call if you have any more questions. Ron

-

We are.. Hi Kenneth, we have a technician looking into it, please check your email. thanks, Ron

-

Hi Kenneth, we're looking into the issue with the motor settings. It does sound like the RPM sticker may be slightly off as in our testing here this motor starts operating at around the 300RPM line. Now, depending on the thickness of the material you're sewing you may need to turn up the speed a bit since the material thickness will limit the motor's ability to operate at the minimum speed. If the speed is still too fast for you there are other options available ie installing a speed reducer. As for the presser foot alignment, can you please email us some photos of the new feet you installed so we can verify if everything was installed correctly? I have attached a copy of the instruction manual and parts manual for the 1460. Just wanted to make sure you received the right one. If there are any further questions you are free to give us a call or email at any time - we're always happy to assist. Best regards, Ron 1460manual.pdf

-

-

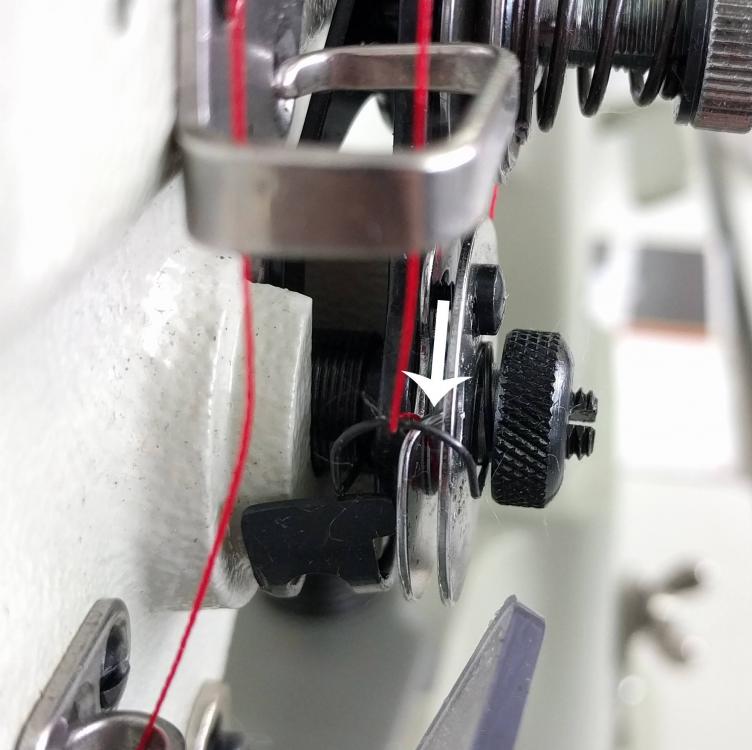

If the timing is in fact correct, and I'd be surprised if it was shipped with the timing off, you may want to check your threading and make sure you're inserting the bobbin correctly. This should be covered in your instruction manual and probably explains the half inch loops on the bottom of your material. What thread / needle sizes are you using? We have a threading video for our 1460 which is a similar machine: Ron

-

Both are our most popular machines for handbags - the 2750 uses a large bobbin and has a longer max. stitch length so if you're considering sewing with larger thread sizes you would be better off with the Techsew 2750. Both feature an upgraded Japanese hook as well. Feel free to reach out with any other questions. Ron

- 8 replies

-

- techsew 2700

- techsew 2750

-

(and 1 more)

Tagged with:

-

Hi there, I know you were in touch with us yesterday - feel free to give us a call for assistance! Ron

-

Patcher machine, straight line sewing

Techsew Ron replied to Silverd's topic in Leather Sewing Machines

I wouldn't recommend a patcher for production work on handbags. As mentioned above, you're limited in terms of thread thickness, presser feet options, bobbin size, sewing speed etc.. We love the machines for repairs on shoes/boots and sewing patches though - the ability to turn the presser foot and sew in any direction is nice to have. For handbags you'll want a light/medium cylinder walking foot machine which we and many other dealers sell. The prices on these are about the same as patchers but definitely more suitable for your needs. Ron -

For sewing backpacks you'll want a light/medium cylinder walking foot machine, you'll find many of them available from the advertisers on here (banners at the top of the page). Many of us sell flatbed attachments for these types of machines in order to convert it to a flatbed machine for wallets and belts. The big heavy duty 441-style machines would be overkill for thinner leather and not the most appropriate machine for your products. Ron