-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DonInReno

-

Stitch length regulator singer 241-12

DonInReno replied to Threadbeat's topic in Leather Sewing Machines

If you’ve had it apart and oiled the moving parts that should take care of any stickiness from old oil. Once it moves a little it’s fast to loosen up. I really enjoy chechaflo’s upholstery videos. His slow sewing style matches how my brain works, and his use of glue on almost everything has been an eye opener.- 14 replies

-

- 241-12

- stitch length

-

(and 1 more)

Tagged with:

-

Stitch length regulator singer 241-12

DonInReno replied to Threadbeat's topic in Leather Sewing Machines

Old dried up oil can lock the stitch length mechanism - applying heat to the stitch length bits under the bed can go a long way toward freeing it up. Use a blow drier or other heat source until it’s too hot to hold with bare fingers - that point is about 140 degrees.- 14 replies

-

- 241-12

- stitch length

-

(and 1 more)

Tagged with:

-

What is the right bobbin thread tension?

DonInReno replied to Gymnast's topic in Leather Sewing Machines

A drop test/tension adjustment, with an industrial large bobbin case produces about 28g of tension - around the weight of five US quarters. Unlike fabric which allows little resistance to the take up of thread , leather requires a large enough needle to make a path for the thread to pull up into the leather. If the needle is on the small side and upper thread meets too much resistance, it can appear that the lower tension is too tight when it’s actually correct. Upper tensions can be quite high and it’s not uncommon to have an industrial originally set up for fabric sewing to require a heavier/thicker tension spring.- 28 replies

-

- thread tension

- lower thread tension

-

(and 1 more)

Tagged with:

-

Hopefully it’s an easy fix and you’re up and sewing soon!

-

How interesting this problem has become! We don’t know exactly what kind of machine this is. We don’t know what size thread it’s designed to sew. We don’t know what’s binding up the hook. We still don’t know what is causing the original tension issue, although it’s probably related to the hook binding up. I’d say you should find a repair shop to clear the hook, then get the machine to sew correctly with thinner thread, before trying to do anything more with thick thread. The hook has to be completely cleared of what’s jammed it up.

-

I’ll bet the low speed isn’t adjustable since the description from the Chinese manufacturer only mentions changing max speed. 2). Stepless speed can be controlled by pedal, maximal speed is adjustable; .....as does the description from the U.K. company reselling them as linzbek: “The maximum top running speed is 3800rpm, which can be adjusted simply by pushing the speed & mode buttons. “

-

Yes, I should have asked in a better way which side of the leather was up. Disregard everything I said.

-

The outer presser foot only goes up and down. You’ll need material under the presser foot or it can just hang there and not look like it’s doing anything. That’s the top of the leather? To me it looks like upper thread is binding or getting twists in it which creates too much tension and pulls the knot to the top. Make sure it’s threaded correctly.

-

-

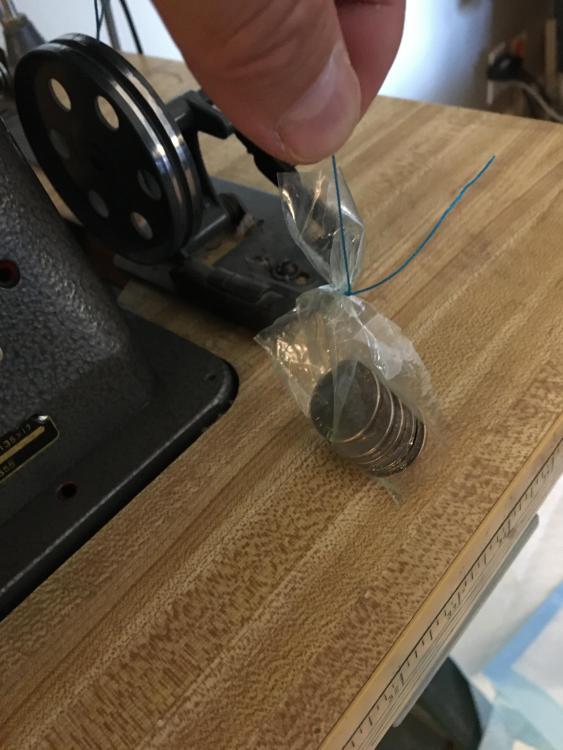

Patty, Maybe bobbin tension was talked about more and I missed it - at the risk of beating the dead horse here's a way to eliminate that as a cause. Because bobbin adjustments are so subjective, it's not uncommon for us to be helping someone who thinks they have adjusted the bobbin tension correctly only to find out it's way too tight. I'm assuming since the bobbin is loaded from the top that the bobbin case is built in and only the bobbin itself is removeable? Over a discussion forum its really hard to describe and judge the correct tension since the traditional way of judging a starting tension involves a removable bobbin case hanging from the thread tail. I measured that thread tension and it's about 30g. Putting 5 loonies or 5 US quarters in a baggie and hanging it by a thread gives you an idea about the amount of tension you should have coming out of your bobbin tensioning spring. 4 loonies is not enough - that's the equivalent of the bobbin case falling to the floor on it's own. 7 loonies is definitely too much. If nothing else this will help those of us who worry bobbin tension hasn't been ruled out. :-) You've been sewing heavy fabric with this machine - does the bobbin thread pull up ok in the fabric? A picture of the bottom thread in fabric would be nice. (this helps to rule out needle size as being the culprit since needle size isn't as big a deal with fabric - if the stitch looks great in fabric and crappy in thick leather that suggests needle size is still too small in leather.) Is this the same machine that says made in Japan, but the box said made in China? I have a few parts with similar pedigrees - I have no idea if they are Japanese, were assembled by Japanese, were inspired by Japan, or are just mislabled. :-) Hang in there - the more things you can rule out the closer you're getting to smooth sailing!

-

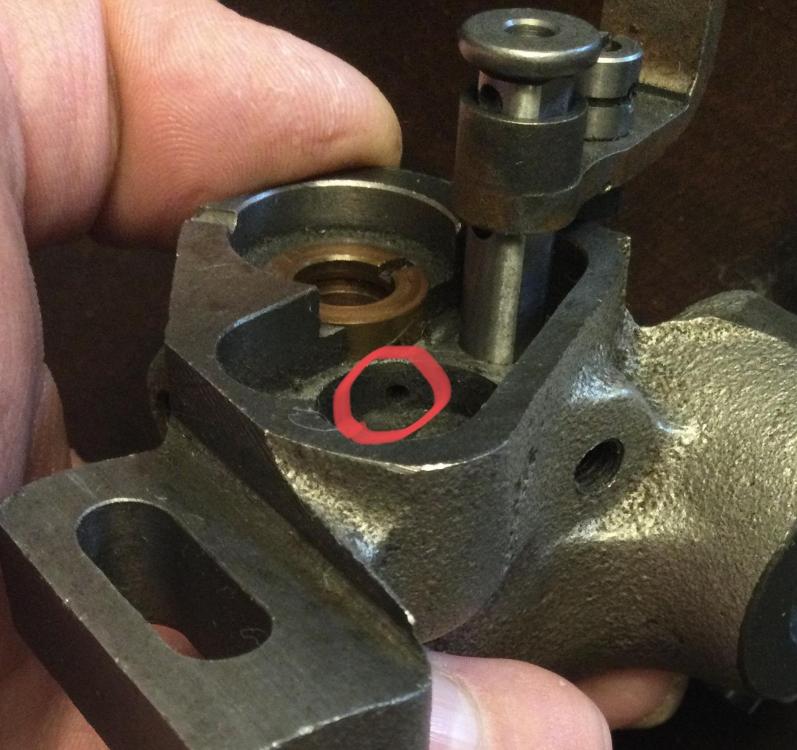

That sounds right on the money. The place that seems to get neglected is the upper bushing of the hook - many old machines have sloppy worn bushings. Oil has to make it down past the bobbin one of three ways. I’ve always just put a drop of oil dead center of the bobbin release lever - there is an oil passages down the center of the hook shaft that leads to both the upper bushing and the case opener eccentric on the hook shaft. Second, the depression the case opener lever sits in is also an oil catch - the additional oil passage circled goes directly to the upper hook bushing. It’s probably not necessary, but when changing bobbins I’ll also put a drop of oil under the bobbin so it runs down the exterior of the hook shaft for a third source of oil for that upper bushing.

-

...oh, and you’ll need a few sources for heavier weights of canvas and whatnot: https://www.bigduckcanvas.com/12oz-heavyweight-cotton-duck-brown-factory-seconds/

-

Many machines have a separate bobbin case - in the 111w155 the case is built in and the part being opened is the gap between the needle plate and tab (which is part of the built in bobbin case). The wet/dry paper and Dremel are perfect for a number of sewing machine projects! I almost suggested them, but didn’t have to after all. Lol You know how there are small areas with light rust that are just a pain to clean up - just in the last year I’ve become a big fan of these abrasive polish pads for a Dremel. They are essentially soft scotchbrite-ish. The ones sold by Dremel are stupid expensive, but these multipacks aren’t bad and the finest grits are the most useful for light surface rust. Saves a lot of elbow grease for small areas. You’re in luck as far as adjustments go with the videos Uwe has on YouTube. You’ll find a lot of overlap in the design of the 111w155 and many other older triple feed industrials. The 111w155 was adopted by the military way back (40s?) as well as by all sorts of commercial users - it’s been very much the grand dad of many designs because it worked so well. So there are many videos that might show a Consew 225, or Juki 562, or Seiko something-or-other, or a less known copy, and most of the adjustments are the same. Uwe does a great job of describing what the physical movement should be at different stages of the cycle even though the exact way to adjust for it may be slightly different from the machine he’s using. If thread is hanging up on the bobbin case with a lot of tension it can be a situation where it helps if the hook is advanced just a small amount beyond normal hook timing - his gets the thread just a tad bit farther around the bobbin when the take up arm starts pulling the stitch tight. I suggest sticking with normal hook timing, but keep this in the back of your mind if nothing else helps. It’s not unheard of for inexpensive replacement hooks to be slightly off in shape and function. Some guys in here with way more experience than I have can tell stories of cheap hooks so far out of spec they never work quite right. Also, not all hooks are designed for thick thread - many companies have at least two part numbers - one for thinner thread and one for thicker. Now that you have a stronger sewing machine there are a whole new selection of materials to build stuff out of. In addition to leather projects, you’ll get a kick out of the whole range of upholstery vinyls, vinyl coated polyester (truck tarp), and dozens of different straps. Plastic 5 gal bucket material can easily be sewn into anything you need a stiffener for - and there are plastic suppliers with all shapes and thicknesses of other plastics, not to mention kydex can be heat molded and sewn in various outdoorsy projects. I bet you’ll get a kick out of the heavy duty hardware at Paragear - it’s nice to have a number of specialty suppliers for various things for unique projects. http://www.paragear.com/parachutes/10000171/PARACHUTE-HARDWARE

-

The Superior catalog is wholesale only, but it gives you an idea of what parts are available for various machines. https://supsew.cld.bz/Superior-Sewing-Digital-Master-Catalog

-

That’s a great bargain on a tough old bird! Just to see if it was me or autocorrect I typed in Rawlins and sure enough it changed it to Rawlings - that’s funny. The case opener and thread path between the tab and needle plate are pretty straight forward, but many people are hesitant to get in there with sandpaper to smooth out rough edges and make sure there’s enough thread clearance. The only thing the case opener does is nudge the tab over slightly as thread goes between tab and needle plate - so adjusting it is a simple matter of watching thread and moving the opener forward or back to where it helps the thread hang up as little as possible. It’s a normal part of maintenance to smooth out burrs in the tab recess in the needle plate if needed and actually increase thread clearance if thicker thread is snug passing through. I had a cheap replacement needle plate that needed a few edges taken down a little and an older needle plate that was well made, but appeared to be made for thinner thread, or was for a hook with a more slender tab.

-

Did you get the machine from the ad in the Rawlings Craigslist? Sounds like you are doing a good job sorting it out quickly. There just aren’t a lot of industrials in Wyoming it seems. Buggered up screws are pretty common - you’ll find they are all slightly different thread pitches and odd sizes - searching or ordering by Singer part number is usually the way to go and prevents a lot of confusion. The good news is one of the sewing shops that works with industrials like Keystone Sewing or Toledo Industrial Sewing can get any of the screws if you need to replace one. There is also good information on restoring screws to near new condition in gunsmithing videos and discussion groups. Essentially you peen the displaced metal back as much as possible, spin the screw in a drill and carefully file or sand the rough surface off. Then the slot can be cleaned up with a screw slot file available from Brownells or other gunsmithing suppliers. You’ll find sometimes it takes a few days for responses here, but there’s always someone who knows something helpful that will come along.

-

Singer Electric Transmitter how old and how save to use ?

DonInReno replied to Oldiesfan's topic in Leather Sewing Machines

If it runs smooth there’s no reason to change bearings. However you should lubricate them. Use an oil intended for electrical motors - probably something like 20 drops of oil in each bearing each year. There will be a third oil cup at the very front of the motor and the pulley shaft will have two additional bearings. It’s not clear if the bearings that support the shaft the pulley is attached to are lubricated by the oil cup in that area or if that oil cup only lubricates the back and forth action of the clutch mechanism. On newer motors the two bearings that support the pulley shaft are sealed, but you might have to see if there’s a way to get some oil into yours. -

Welcome to the site! Hook timing needs four things - if any of these four things are not right you’ll skip stitches. From the lowest position, raise the needle the thickness of a US nickel. We are talking 3/32” - not 1/8”, not 1/4”, not 1/16” and not a US quarter. In metric or inches, this amount is almost universally recommended. If someone won’t or can’t get this right the rest won’t matter. Second, at that needle position the point of the hook should be inline with the needle and 1/16” above the eye. This is so important in the past many of us insisted on a photo before giving any additional advice because it must be human nature to screw this up and think it’s ok when it’s not. Third, the point of the hook should be as close to the needle as possible without actually touching it. Literally, at most a piece of paper should barely slide through the gap, and literally the hook should not be deflecting the needle! Again, many of us don’t believe someone has actually set this gap correctly unless they can prove it with a close up photo. Fourth, the hook as to be correct. The sharp point of the hook has to be a sharp point. A blunt damaged point will not cleanly reach behind the thread as it should. A hook that’s been bent inward and someone has chosen to adjust it closer to the needle rather than replacing the hook is asking for trouble. A cheap replacement hook may not ever work correctly - I saw one on eBay that didn’t even have a needle guard. I often don’t believe people when they say the hook is in good condition unless they have a good quality photo. Good luck with your machine!

- 17 replies

-

- presser foot

- reverse

-

(and 2 more)

Tagged with:

-

That’s awesome - glad someone we know was able to pick one up!

-

Singer 132k6 added to the workshop

DonInReno replied to LomaeArts's topic in Leather Sewing Machines

Very nice! I’m still looking for a deal on one to add to the collection. -

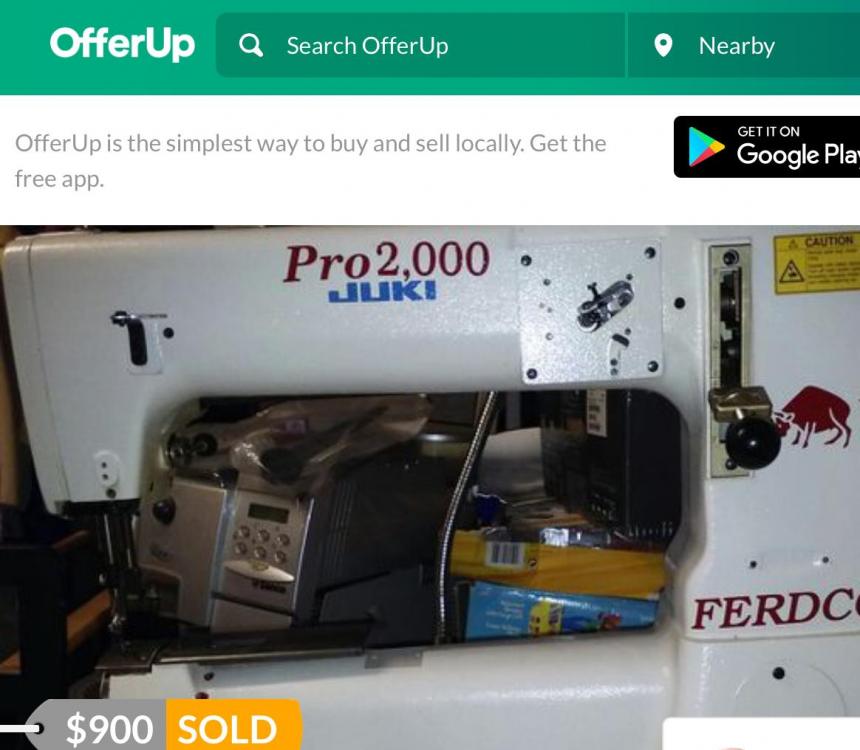

How interesting - I always enjoy the backstory of something like that and it’s great that you got it! It looks very clean I was surprised to hear the 20-something crowd talking so highly about offer up - our youngest absolutely loves it. It must be the newness of it...maybe only old people use Craigslist? Lol The usage statistics compared to Marketplace and Craigslist are quite low, but there have been a few very low prices. I haven’t enjoyed the clunky search feature and gave up rather quickly on it.

-

This is somewhat of a weird question, but has anyone had good results buying industrials off of the Offer Up app? I didn’t even know it was worth looking at, but while looking for Ferdco pro 2000 examples ran across a sold juki 441 that went for $900! I’ll take a dozen at that price and condition! Lol Right now there are three pro 2000 Ferdco 441 machines (not juki) on Craigslist in Washington. From the looks of them they were rode hard and probably not worth more than the asking price, but under those cute flat accessory plates are cylinder arm 441 clones for $1400.

-

There is no substitute for seeing and feeling leather. The selection of upholstery leather seems to vary tremendously from local supply shops, but it’s sure worth it to find one you like. ...or are you looking for online suppliers?