-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DonInReno

-

Are all bobbin cases created equal?

DonInReno replied to MainiacMatt's topic in Leather Sewing Machines

Some cheap Chinese bobbin cases aren’t built correctly and may never work properly - it’s just a chance you take. If you were to buy one of each of $5, $10, $15, $20, and the $25 bobbin cases, I’d bet you’d find at least two of them were the same. The $5 case probably is the worst of the bunch, and the highest priced is probably an over priced $15 model, but the quality of the rest may or may not reflect the price. Personally I’d buy two $10 cases, from two different suppliers. One of the two always seems to be of much higher quality - toss the worse one. I’ve purchased over priced low quality parts from reputable sources, as well as top quality parts directly from an unknown source in China for Pennies on the dollar. I also get a good laugh out of the “high quality” Japanese built replacement parts that ship from China! -

Lol

-

Part needed for a Singer 21w180

DonInReno replied to stitchbystitch's topic in Leather Sewing Machines

I don’t know anything about this model, but I did see a questionable cross reference on the hook with a number of Consew and singer machines. Do you have the broken pieces? -

As with anything used, if this machine isn’t just what you’re looking for, there will always be another better deal next week or next month. Be careful of buying a machine that doesn’t work for $350 that you can’t get parts for. My personal rule of thumb is it’s only worth half as much if the seller can’t demonstrate it sewing correctly, than if it sews perfectly - maybe it’s an easy fix, maybe it will never sew right. Having said that, it’s a cool machine and if it’s in the budget I’d grab it and keep looking for another.

-

That’s awesome!

-

Help finding a part!! Singer 111w155

DonInReno replied to chefben4's topic in Leather Sewing Machines

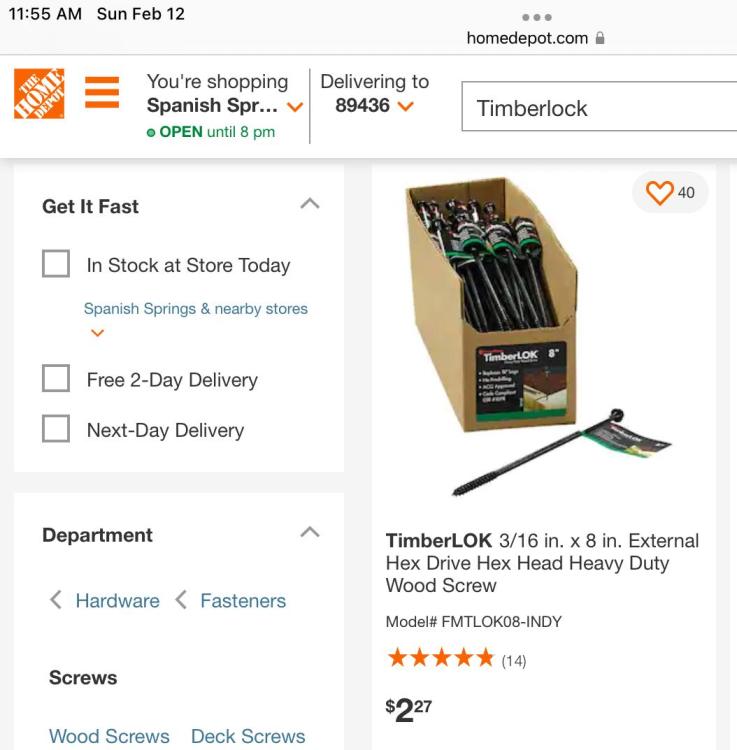

Glad to help! I just thought of another 3/16” piece that’s easy to get locally. These timberlock screws are sold everywhere and are a medium carbon steel. I measured one and it’s just barely over 3/16” - you might have to spin it with a drill and sand paper to reduce it a tiny bit. -

Help finding a part!! Singer 111w155

DonInReno replied to chefben4's topic in Leather Sewing Machines

-

Help finding a part!! Singer 111w155

DonInReno replied to chefben4's topic in Leather Sewing Machines

-

Help finding a part!! Singer 111w155

DonInReno replied to chefben4's topic in Leather Sewing Machines

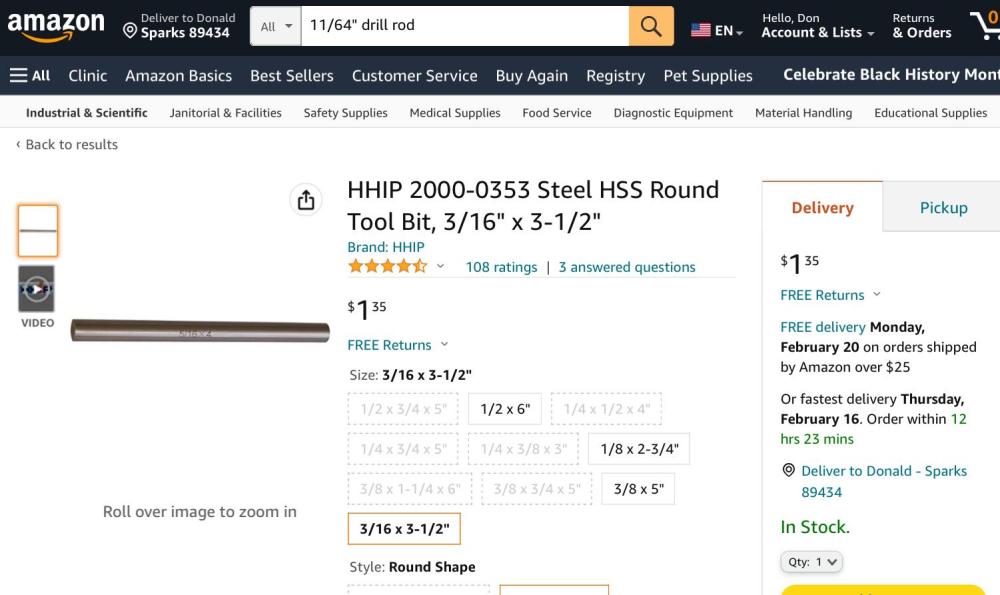

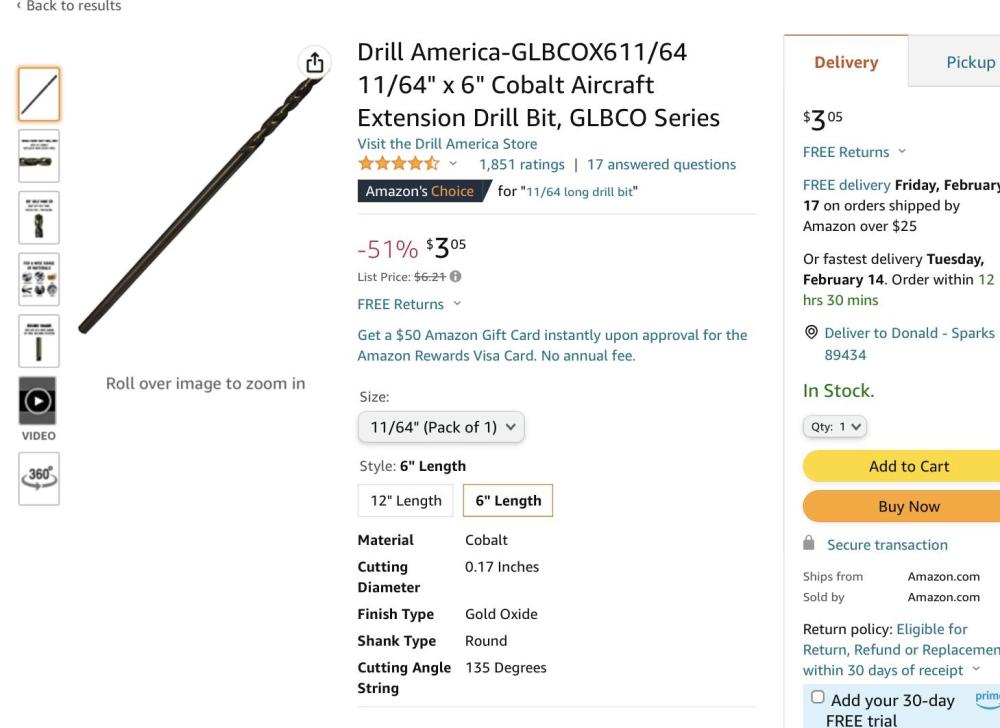

Give me a few minutes and I’ll pull and measure that pin. edit: This pin has a Simanco part number and is well worn from being a retired factory machine, so originally it was probably 2-1/4” long. I’m not sure how well it showed up in the picture, but in addition to the slight taper on the ends the very end is rounded over a bit and not flat. The diameter is essentially 11/64”, but at least on my machine a 3/16” drill bit fits the hole. Home Depot often stocks these longer Irwin drill bits - the shank of an ordinary drill bit is pretty short. The transfer punch is 4.25mm and would also work well. I ran a file across the original and it’s harder than a nail, but not by much. The shank of a box store drill bit or the shank of a Harbor Freight transfer punch are very close - I’d think they are all pretty ordinary medium carbon steel that’s not heat treated. The tip of the drill bit and transfer punch are hardened, but not the shank. -

Help finding a part!! Singer 111w155

DonInReno replied to chefben4's topic in Leather Sewing Machines

The pin (#20) goes in the hole - in there is a doohickey that’s moved in or out by the lift of the presser foot. I have two 11w155s and both of these pins are slightly different lengths - it doesn’t matter much as long as it fits the hole and moves the transfer lever. Pin #11 is normally the one that gets altered for proper tension release, but transfer lever #17 can be slightly bent, although changing pin length is pretty easy. The trick is to get the length of the pin so it opens the tension disks only when presser lift lever is fully open, but keeps thread tension when he presser foot is partially lifted to turn the leather. If the doohickey inside the head does not move with the presser foot lifter, there is often a broken tab on the doohickey and it has to be replaced. Unfortunately it’s pretty involved to get it replaced, but it’s not an uncommon failure. -

Claes 8345/34 Patcher Needle Size

DonInReno replied to Kristian99's topic in Leather Sewing Machines

There is not a requirement for manufacturers to label a needle size using a particular needle system, so there are often multiple needle systems that are mostly interchangeable. I say mostly, because the original specifications may be slightly different, but a more generic needle is the correct shank size and close enough in length, scarf shape and location, and eye location, to work ok. If you have needles that work well, you won’t gain anything with a different system. Before you had the machine there’s always the chance that the needle bar was replaced or the needle hole was enlarged - it’s pretty commonly done to cut down on the amount of different needles someone would have to keep in stock, or if someone gets “free” needles at work or from a friend - we discuss how to do that here pretty regularly. -

Help finding a part!! Singer 111w155

DonInReno replied to chefben4's topic in Leather Sewing Machines

Anything that fits in the hole will work - nail, coat hanger, prong off corn cob holder, thick paper clip, small drill bit, wire cut out of a fence, etc. edit: straight shank of a big fish hook, straight portion of a mouse trap spring, section out of a kitchen wire wisk -

He probably meant Consew 226 - it’s like a juki 562 - both of which are essentially a copy of the singer 111w156 and share the same hook dimensions. He is the first person I’ve ever heard that claims either of those first two can’t sew well with 138 because of a top loading bobbin or hook issue. There are some hooks designed specific to lightweight thread in some parts manuals, but it’s my understanding those aren’t common. I’d look elsewhere for advice. Even with a google search you can quickly find 100 users of those machines that sew quite happily with 138. Upholstery shops may very well use 90 weight thread for most things - but that’s a matter of cost saving over thicker thread and 90 weight is plenty strong, not that the machine can’t handle it. He wouldn’t be the first to spread urban legends in this industry.

-

You will soon find out how inconsistent aftermarket feet are. They will vary in height and to a lesser degree, side to side alignment, and some will not be usable at all. On the positive side, they are a lot of bang for the buck, and I no longer hesitate ordering something on eBay shipped directly from China. When ordering aftermarket parts I usually order two - from two different suppliers. Typically one of the two is better and I’ll gift the other to someone who appreciates it - worst case, tossing one of the two in the trash is just part of the risk of inexpensive parts. When I’ve ordered $25 and $10 feet - price didn’t seem related to quality - kind of a crapshoot. Many types of feet can be altered for special purposes, which is another good use of duplicate feet - examples of modified feet are scattered around LW. As others have said, searching for the common walking foot models that share the same feet dimensions will turn up more choices. I typically search for Singer 111w155 or Juki Lu-562. Big feet with big teeth are ideal for canvas and heavy synthetic cloth, medium size teeth are ideal for vinyl, denim and light synthetics, and of course smooth feet for leather. There are also a variety of feed dogs and matching needle plates, although these are limited to other cylinder bed machines that share the dimensions of yours - I don’t know what that would be.

-

That sounds like he doesn’t know much about leather sewing or didn’t stock industrial needles and didn’t want to order any for your test drive. Lol Even my local supplier that stocks upholstery fabric, leather, thread, prewound bobbins, oil by the gallon, etc. doesn’t keep any industrial size needles in stock - they don’t like dealing with the hassle when residential users buy commercial machines that they don’t understand and want to blame other issues on the needles and return them. Or it could be he just doesn’t want to take the time to readjust the tensions, wind up a new bobbin, open a box of larger needles, and rethread for a test drive. I’ve met a few of those old school shop keepers.

-

The wife wife would have my clothes and belongings piled on the front lawn if she smelled transmission oil in the house coming from a sewing machine. Lol

-

This type of cast iron pulley isn’t a bad place to start - they aren’t as smoothly shaped as a custom part, but it just bolts on and is fairly cheap. This lightly used 6” made by Browning is on eBay in the US for less than $30US delivered - there must be similar pulleys made in the UK. At least in the US, many non-sewing pulleys sold for 3L (3/8”) belts are actually made for A belts (1/2”), but are close enough that they work for either size. The B size belts are 5/8” wide and don’t work at all. For some reason, no matter what size handwheel you think will work best, once it’s on you will wish it was a little larger or smaller - 5” to 6” is a good place to start. Lol

-

The old factory machines I have probably sewed balls-to-the-wall 8 hrs a day, 5 days a week for 50 years on nothing but common ordinary Lilly white sewing oil. Oil it often and the chances of ever wearing one out are slim at best.

-

Can anyone help me with a running a 3-phase Juki at home?

DonInReno replied to williaty's topic in Leather Sewing Machines

I’d also vote for not spending any money on trying to get the 3-phase motor controller to work, and just swap in a 110v motor. That’s not to say it’s not a good machine - I have a ddl-555 with a simple replacement servo motor that works great for light weight fabric sewing, but they are old enough to not be worth more than $250 with a working 110v servo. -

I’d suggest taking off the end cap so you can watch the thread as it goes through a stitch - modifying something that doesn’t need to be modified is just guessing.

-

Many machines have a 1/2” shaft so a pulley or larger factory handwheel from another machine with 1/2” bore can often be easily attached. The downside to an oversized factory part are the limited choice and cost - $150 and up for the few that I looked up. It’s a matter of searching through heavy duty machines that have about the size of handwheel you want and tracking down the part number and contacting replacement parts department. The “monster” pulley that Sailrite markets is available from numerous sources for $100 to $150, but it requires using an “xl” clogged timing belt. It’s a nice wheel, however it does make a noise that some find objectionable. 15mm clogged pulleys for the servo are available in steel from Sailrite or aluminum on Amazon. The belts are available in a wide variety of sizes and are sold in one cog increments - xl belts also come in multiple widths so you’ll want one that matches. You’d have to cobble together a few clogged pulleys for a reducer since I don’t think anyone makes a 3:1 reducer. Pulleys on the other hand are definitely the lowest cost option. Cheap aluminum pulleys like are used on swamp coolers can be had for $10. Just make sure it fits a 1/2” belt at most. 3/8” pulleys are less common and many are just a 1/2” pulley and also work with 3/8”. The main problem with a pulley is it looks like a pulley and feels like a pulley when hand turning it. In the first picture this hand crank wheel would look at home on an old Singer, and have a good feel once it’s smoothed out. I’ll machine a belt groove in the center, remove the handle, polish the outer rim and smooth out spokes. None of that is all that difficult, but if you don’t have a friend with a metal lathe it would be prohibitively expensive to have a machinist cut the groove. The second picture is a handwheel from a Singer 29-4. It has a nice size to have a belt groove cut in the rim, but it’s too dished to work well unless the hub with set screws is cut off and a new hub silver soldered to the other side. Some older machines like the Singer 144 use a stamped steel pulley as the handwheel, but the two new steel pulleys I’ve had aren’t all that straight and it would drive me nuts seeing them wobble.

-

A 3:1 reducer and servo motor is a good combination. I’ve had a small servo with 3:1 on a standard size hand wheel and wished it would sew a slightly slower on the low end so went to a 7:1 reducer and that was a little too much. I really like larger handwheels and think it’s just perfect combined with a 3:1 and small pulley on the servo.

-

Looking for Input on Machine Choices

DonInReno replied to Rubicon04's topic in Leather Sewing Machines

Those three machines will do just fine, but don’t overlook any of the other upholstery weight machines with triple feed. An older Consew 206rb in good condition will every bit as smooth and capable. Same with a Juki Lu-562 or Lu-563. As for the 1000d Cordura, 8 layers will sew easily even with 138. Needle deflection is more problematic with thinner threads and needles, so don’t be surprised if you sew most things on the heavy side. 138 seems thick now, but for many projects it’s rarely overkill. There are a lot of synthetics in your future that you haven’t thought of yet - a trip to a big fabric store that caters to upholsterers will really be fun. There are newer types of heavy nylon and polyester ripstop - some 1500d or even 2000d that are great choices over 1000d cordura. 1000d is the good reliable ordinary Toyota Camry, or F150, but the options are really fun to play with. I’m lucky to have a local place that buys a wide variety of mill end materials in small random sizes - it’s the material left over after a run of commercially sewn items. The vinyl coated polyester (vcp) is what the thickest commercial truck tarps are often made of and it makes a fantastic bottom for tool bags and other high wear and high strength areas. There are all sorts of vinyl coated and non coated netting, from thinnest mesh like on a tennis shoe, to thick mesh like would be used on a catamaran that would get walked on. Same for canvas - there are a huge variety from ordinary to ripstop to a dozen different weaves and treatments. Then you’ll someday want to sew outdoor cushions and shades and there’s another whole category of material to choose from there from breathable to waterproof. Then there are the automotive fabrics, vinyls, carpet, leathers and all the secondary fabrics and materials that go along those. You’ll probably want a smooth set of narrow feet and feed dog for leather sewing and a coarse aggressive set for canvas and cordura. Many of us just keep what is essentially a zipper foot that allows sewing to the far left side of the presser foot for general purpose. Big canvas and heavy fleece seams really benefit from a full size foot with long sloping nose to ride up and over thick seams. Id recommend a big pair of high quality upholstery scissors, like Ginger 10”, that are only used for sewing - $70 well spent. -

I’m out of ideas - it appears that there is roughly enough top tension to mostly pull the knot up, but that lower thread looks crazy and appears to have varying amounts of tension. I’d guess it’s partially whatever brand and type of thread and partially something underneath it’s hanging up on giving the inconsistent bottom tension. The finger that keeps the bobbin case in alignment has to have enough clearance for thicker thread to pass around easily. There is no bobbin case opener to adjust, but clearance is adjusted with careful metal removal and polishing. If this machine was made to only sew thinner thread, in addition to a tight area at the bobbin alignment notch, there may also be resistance from a tight spot somewhere else around the bobbin case that would have to be clearanced. Thats about all I’ve got.

-

Congratulations on the new sewing machine! Some people naturally sew nice straight evenly spaced lines, but I never have. One sewing shop had new sewers practice making square spirals until they were very square and uniform, and this has been a great form of practice for me over the years - much better than simple straight lines since it forces manipulating the stitch length going into corners. On a new project I’ll use the spiral on the exact material to fine tune the stitch and get back in the swing of things.