-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DonInReno

-

Cobra Class 26 needle not grabbing the bobbin thread

DonInReno replied to ToddW's topic in Leather Sewing Machines

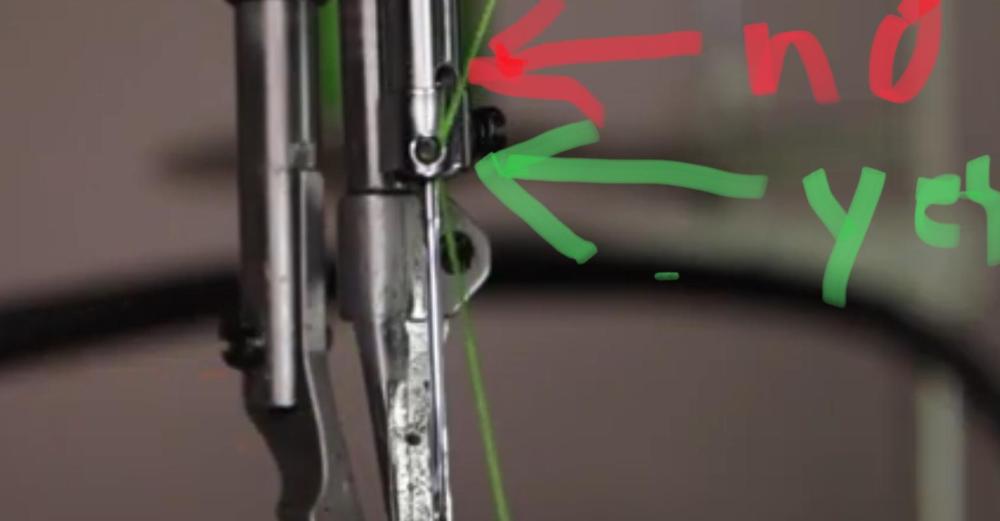

If you had to move the needle to pass thread through it, you threaded the wrong hole. The upper hole is a sight hole to see that the needle is seated all the way in - the lower hole gets the thread. As others have said, make sure the thread is passing through the eye of the needle in the correct direction - left to right. Since the needle was moved, make sure to put it back correctly - round needles rely on you to line them up correctly. -

78-1 Singer Model 78-1. Bought frozen to get sewing.

DonInReno replied to AlamoJoe2002's topic in Leather Sewing Machines

These always seemed like an interesting machine - being a needle feed design with no feed dogs. Yours seems to have a little surface rust, however, when the needle and presser bars are still rust free that’s a good sign it won’t be too hard to get it rotating again. There are some rules of thumb in sewing machine maintenance that are pretty universal: Do no harm - it’s important to not break, bend, spindle or mutilate parts. Many well intentioned people unfamiliar with sewing machines, damage something that is not easily replaced and turn an otherwise doable project into a door stop. Many adjustments aren’t intuitive and attempting to change something without knowing what affect it will have has caused many working machines to be so out of whack they can’t form a stitch. Old original singer parts in good shape are almost always better quality than aftermarket replacement parts. In general, if it’s not broke there’s no need to fix it. Well fitting screwdrivers are essential to prevent stripped screw heads. Some corroded or otherwise frozen screws can not be removed with a screwdriver alone and will need to be heated or impacted. Four or five or six years ago I almost bought one of these, but an industrial sewing parts supplier said the timing belts were no longer available from any of their aftermarket sources - that may or may not have changed. Be careful with compressed air if the parts are not being taken completely apart - not only will it clean off dirt, but it can push dirt into oil holes and other clean areas as well. Acid baths do remove rust, but they also etch, sometimes deeply etch, otherwise smooth areas. It’s easy to spot parts that have been soaked in vinegar or rust remover. Same for electrolysis. Personally, I wouldn’t try to dip a portion of a fully intact machine in an ultrasonic cleaner - dropping an industrial is the quickest way to damage it and the odds of a drop go way up with this. Degreasers that work their way into bushings and cracks will corrode anything that can’t be flushed out completely. Degreasers won’t remove rust. Acids will remove rust, but corrode even worse than degreasers if not fully removed. The only shortcut to cleaning up an industrial in rough shape is good old elbow grease. Old military manuals often suggest kerosene to deep clean sewing machines, but WD-40 is mostly kerosene and works well - just be sure and follow up with sewing machine oil since WD isn’t a suitable lubricant. Best of luck and we all enjoy seeing progress as you work through getting it sewing! -

Wow - that’s a lot of cool history! Those are the best kind of stories. The 31-15 is timeless - quite a feat to have lasted so long with very few changes.

-

These are right out of the groovy disco days of the 1970s. I have one that was used by a tailor in a Nevada casino - when he retired the machine was gifted to him, but from the looks of it, he stopped sewing all together and it sat in a storage unit across the street from the casino. Back then he could smoke and drink while working - apparently a cosmopolitan was his drink of choice and there were hundreds of little dots of red on the frame and hidden sides of the machine. With a happy gleam in his eye - told me about living in the casino fast lane - the parties, the iconic shows of the time, all the excesses that surround VIP pampering. The sewing table would have certainly tested positive for cocaine residue. A tailor was always on standby in case a show girl’s outfit ripped a seam, the band ended up in a scuffle or Dean Martin or Sammy Davis Jr needed a last minute suit alteration. Maybe just a VIP with a dress that needed to flatter a little more. That old Juki had sequins of all colors in every conceivable nook and cranny - every time it gets deep cleaned a few hidden sequins appear…and it makes me smile. These are high speed machines and the automatic oiler doesn’t work unless it’s run fast, at least for a minute or so. They aren’t worth much and I rarely use it, but it’s a fun time machine so I’ll hang onto it until the estate sale. Lol

-

Your question catches many of us off guard, because we don’t normally change the presser foot height, but we do vary the pressure. I can’t think of anything it would hurt, but that is a lot of adjusting for those of us who sew a wide variety of items.

-

That awesome news - should be a solid machine!

-

I have a Juki ddl-555 and the parts look a lot like the one Uwe showed. I had no idea the thread tension release is cable actuated. When it worked, as you raised the presser foot it would release tension on the upper thread allowing you to pull the item out easier. An machine works without it, it’s just not as easy to use. Since your wire only has one end intact, I’ll bet you would have to replace the entire wire with a new one - there’s a little bracket in the shadows somewhere that we can’t see in the picture. There’s a small chance a Juki part would work, but it’s a wild guess and these old machines can be bought fully functional for well under $100 so it would be better to buy a different machine and sell this one.

-

You are very lucky to be in an area where parts stores can find something without it being attached to a specific car model! At our auto zone they literally are not able to understand the 3L belt sizes, not even the assistant manager - finally someone asked the store manager and he had to walk the person back and point to the number….the clerk was still very confused. Now I just look up the store inventory online and show them the picture. Lol Our Napa has three sets of counter guys - guys in the back only work with commercial accounts and probably know more than average. Then there’s the new guys that work weekends and evening shifts - they literally are no better than autozone. The best guys have the best shifts and the walk in counter is less busy than the commercial accounts so they are up there - old timers that actually know what all the big books are behind the counter! The guys at Napa in Lander, WY were great - finding odd bearings and seals was a fun challenge and they really taught me a lot every time one of the big binders came out :-)

-

You’re getting a lot of practice with these things! I thought those socket headed cap screws looked out of place - I wonder if the original screws were buggered up and someone retapped the holes? Normal bolts, even high strength bolts, aren’t nearly as hard on the tips as set screws, especially sewing machine set screws. Maybe you said this already and I’m missing it, but have you checked the set screw that holds the hook on its shaft to make sure it’s in its groove? Often, the various set screws all set in grooves or flats except in one spot that’s for the designated hook adjustment. I haven’t looked at a manual for this machine, but it is good to know that you aren’t trying to set hook timing in the wrong set of screws. It’s odd if there is a flat on the hook adjustment screws - defeats the purpose of adjustability. I only linked this video because it shows the lower guts.

-

Reducing the motor pulley helps a little, but a separate 3:1 reducer cuts the speed to a third and increases torque by three times - much more controllable for those of us who enjoy sewing slowly. It’s often worth it to add a smaller pulley in addition to the separate reducer.

-

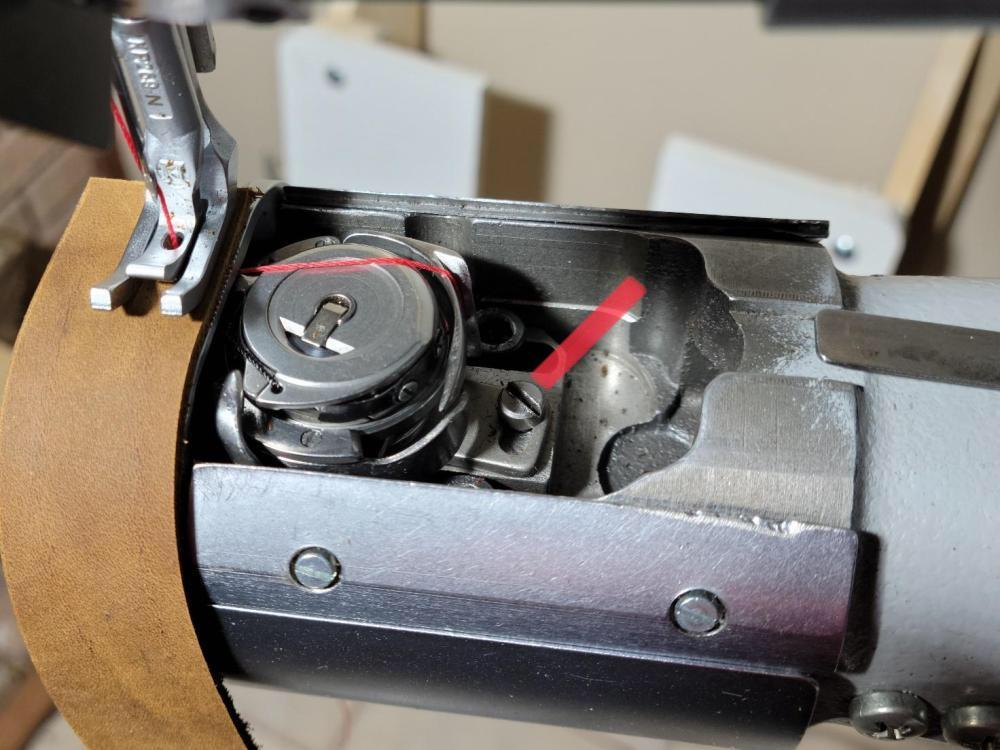

I strongly suggest getting down close with a flashlight and adjust the case opener so it opens the gap enough for thread to pass through without binding - having the bobbin case tab centered in the notch isn’t required (doesn’t hurt), but thread has to pass through that gap easily. The adjustment range is quite small and 138 thread is only .4mm so this adjustment can’t be guessed at. If this is out of adjustment it 100% will cause problems - maybe not your main problem, but it’s not an optional adjustment. As the hook is pulling thread around the bobbin I’d want to pull on that thread with an O-ring pick so you can feel the amount of tension at any given portion of its travel - compare that to the tension above the needle plate. Same for other places in the thread path - more than one machine has been sold because a single thread guide had a defect that restricted thread movement. You mentioned it’s a new hook - if anything screams out a warning it’s a new part installed right before the machine stopped working - cheap replacement hooks are normally poorly dimensioned even if the surface finish looks good. If possible compare its dimensions to a known good hook - some replacement hooks are so far off they never work correctly because the distance from tip of hook to the area that transports thread around is too long or wrong shape. Id look closely for other parts that might have been replaced. I don’t remember any talk about snags in the thread path that would prevent a little upper thread from being pulled through the tensioners. Sometimes these are small grooves in the feed dog, improper case opener, thread guides that aren’t quite right, groove in take up lever, etc. A groove or sharp corner that functioned perfectly with a small thread, even one size smaller, can bind a thicker thread. I also agree with the others that the odds of this being a take up lever timing issue are very small, (a tiny fraction of 1%) while the odds of it being an issue with thread path or bottom end are over 99%.

-

This may not affect thread as it passes over the hook, and maybe it’s just the angle of the photo, but is the case opener adjustment fully to the end of its travel?

-

Thanks! It was fun. I came across a home made 3:1 reducer used to drive an electric hydrofoil board thing. It uses the nose of a small grinder - apparently the rotor shaft going into the nose is supported by a pretty good bearing so guys cut the shaft leaving an inch or so to attach a coupler to, and fabricate a spacer to fill the gap between motor and grinder casting. A 10mm to 15mm rigid shaft coupler is $20, so it seems all a guy would have to do is come up with a 2”ish spacer for sewing machine use. I may try this just for something different. Lol

-

I think it’s a good thing you’re not afraid of digging into it, and there’s a lot to be said for learning how things work. I don’t know if helped any, but it sounds like you’re no worse off. :-) Imagine how many different people have turned a screw in those 60 yrs - it’s a testament to how durable these machines are. The individual history of sewing machines has always fascinated me - the artifacts left behind by all the users not to mention the guys who built it are really quite varied. There’s a 99.9% chance your machine is exactly what the tag says and various parts, correct and not, have been added just to keep it going in a production shop. Then there’s an occasional machine that doesn’t have the correct tag. The quickest way to add $$ value to an old machine is to change the tag into something slightly more desirable or expensive. I have an old industrial “Singer” probably from the 50’s, that doesn’t have a single Singer part in it. In my twenties I worked briefly for a guy selling industrial parts who wouldn’t hesitate to embellish or bend the truth if it meant an extra $5. If he were selling sewing machines back 60 yrs ago and one of his clients dropped an H2, ruined it, and called up frantic that they needed a new machine that day to not disrupt productivity I know exactly what he would say. He’d look over at the three H2’s and one H4 on the rack, and say, “Sorry to hear that - I’m all out of H2’s, nobody can get them right now, however you’re in luck - there’s a H4 in stock, but because you’re such a good client I’ll drop everything and readjust the needle bar and replace as many parts as possible so you would never know it’s not an H2 if you didn’t see the tag. Unfortunately, that machine is $100 more than an H2, but if you need it you need it.” Then he’d swap tags and tell someone else the H4 came with the wrong tag, but it’s full price. That guy still makes me laugh all these years later! Here’s a needle chart off of ISMACS that has some good information and a few typos so don’t take all of it as gospel, but it helped shed light on how a lot of different needles are related: https://ismacs.net/needle_and_shank/needle-cross-reference-chart-round-shank.html

-

There is a Cobra 4 in Ohio in the for-sale section.

-

Thread may be getting caught there even though there’s room on the two sides. There is a little lever that should just nudge the bobbin case about the time thread is passing that gap so it isn’t pinched on the one side with no clearance - just adjust the lever so it creates equal gap on the two sides.

-

The output shaft of these reducers vary in size a lot - some are metric and some are inch size - you just have to order a pulley to match the shaft. There is some drilling and head scratching with these - definitely not a simple bolt on, but not overly so. You have to keep looking at eBay every week or so until one comes up for a decent price. I’ve had the best luck searching “Wittenstein reducer”, looking at a few of the lowest priced used models, and then scrolling to the bottom of each page where similar items are shown. Then I’ll repeat that and search just for “alpha reducer” Almost every one I’ve picked up didn’t show up in the main searches - eBay has turned into pay-for-play just like Amazon. There are more details in this old post:

-

Wow - this is an old post - sorry Jeff I somehow missed your question! :-) For months the client and I were on the lookout for an old looking faucet for the bar sink, then one day he showed up grinning from ear to ear saying he found a good one! This is a $4k faucet, but it’s not available in brass, so he sent it to a plater and had it brass plated and with a clear coating of some kind - probably another $1k? It was nice to have such a good budget on that project! The caboose is a “yard bar” and when large parties are thrown a bartender is hired to pour drinks and the bathroom is fully functional.

-

There’s still a fairly good market for used 45k’s if you upgrade. I’m not actively searching for one, but on the west coast when they do come up I’m always impressed with what they sell for. The east coast seems to have more of them and the prices are more reasonable. Having said that, I’d just fix it - there’s not a lot of parts in the feed setup and nothing that can’t be fixed.

-

That’s a nice solid machine. I think you did the right thing - many functioning machines are put out of commission by “cleaning and adjusting”, but in your case even if it seemed to be sewing perfectly it was probably just on the edge of skipping stitches. I must have assumed you’ve adjusted the guard already - it can be bent as needed for clearance - the hook is only a problem if the needle guard is adjusted in as far as it will go and the tip of the hook is still too far away from the needle (needle hits the non adjustable part of the rotating assembly). Even without a manual for the specific model, most of it is very close to a copy of the other major top bobbin models - Juki lu-562, Singer 111w155, Consew 224, etc. Having said that, there are some adjustments that will stop the machine dead in its tracks if not done correctly, so it’s always a good thing to know exactly what an adjustment is before turning that screw. Industrials don’t normally need fine tuning on a regular basis. One major difference is instead of a clogged belt going off the main shaft you have two sets of bevel gears and a drive shaft - on old crusty machines the grease gets hard and should be changed. It doesn’t have to be anything special - just take off the gear cover, scrape out the majority of the old grease and replace it with automotive grease.

-

That sounds like the tip of the hook has been bent inward. Cheap replacement hooks aren’t known for having the best steel or heat treatment. You’ll probably be breaking needles from the large amount of deflection. Replacement hooks from Amazon or eBay aren’t going to be great choices quality wise. Even the moderate quality Japanese replacements are being faked with inferior Chinese knockoffs. It would be worth it to get a new hook from Cowboy Bob. Once upon a time I had a bent hook - since it was already screwed up a little experimenting wasn’t going to screw it up more - it bent out even with the needle deflector pretty easily - it was definitely a low quality replacement part with soft steel.

-

Poly vs. Nylon ? Same size, different adjustments

DonInReno replied to Wyowally's topic in Leather Sewing Machines

I seem to sew mostly with 138, even when I shouldn’t, and the type of 138 doesn’t make as much difference with tensions as the material thickness. It’s rare that I’ll ever change bobbin tension - just a little more or little less tension depending on the project. I can’t ever remember changing a needle for a different spool of similar size thread, but I tend to sew with a needle a little on the large size so it might not effect me as much as someone using a smallish needle. -

Poly vs. Nylon ? Same size, different adjustments

DonInReno replied to Wyowally's topic in Leather Sewing Machines

If you measure various brands of thread, it’s quite amazing how much variation you’ll find in diameter and breaking strength. I have a few spools of 207 that are no thicker than most of the 138 I’ve measured. I’ve measured 90 weight that was probably produced as 100 or 110 for a large contract, but the leftovers can’t be sold as 138, so it’s sold as a fat 90. I don’t know anything for certain, but it wouldn’t surprise me if some thread contracts were based on breaking strength - some thread has measured breaking strength over 50% higher than it should be for its size. These are definitely made with stronger than average fibers. -

Personally, for $20 more the slightly larger csm3000 700watt would be a better motor. Both of these aren’t known for very good low speed operation, so a speed reducer is a must have to get good control. You’ll see these motors sold under half a dozen different names. Essentially the same motor design is used a lot for a number of different sizes sold by various people up to 1500watts. I have a 1200watt model that has very good torque down low and is my favorite, but it was twice the price for twice as many watts. The family fesm550 servo is generally accepted as a better low speed servo, and bang for the buck is quite good, but it’s not nearly as compact and to me looks funny when used above a table. It’s also sold under half a dozen different names and is a very good choice for most sewing machines and most people.