-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by DonInReno

-

Yes 20 is too small a needle.

-

Even if the timing is correct, the gap between needle and point of hook needs to be as close as possible without actually touching. The needle guard shouldn’t be keeping the hook away from the proper needle gap - it’s literally designed to be bent in or out as need be.

-

When the stitch length gets shorter and bottom thread looks like that I tend to think the bobbin tension (or binding somewhere in the bobbin thread path) is so tight it’s preventing the material from feeding correctly.

-

Please / Quick Recommendations between 2 Leather Machines

DonInReno replied to Brad2017's topic in Leather Sewing Machines

That’s awesome! Good choice! -

There’s no arguing that a big 3hp, or 4hp, or even 5hp cabinet saw (heavy stationary table saw) is the Cadillac of saws and every cabinet shop and furniture maker should have one. However, for professional finish carpenters who build onsite there is nothing more ideal than one of the 15 amp portable saws with universal brushed motors. A universal motor will draw more amps the harder it’s pushed and the little 15 amp Mikita 2703 saw that I prefer is direct gear drive between motor and blade and will easily trip a 20 amp breaker when ripping thick material. When scratch building something like a big oak staircase, or custom cabinets for an entire house it may run 6-7 hrs a day for a week ripping material to size. Other than changing cords and a set of brushes I tend to get 4 or 5 years out of them before the bearings for the blade get a little loose - I’m on the 5th one. Once there were 6 of us cabinet makers building custom cabinets and bars for an entire year as part of a casino renovation - we all have our own style and equipment, but we all used similar portable saws. I do admit it would be nice to have a big heavy cross cut sled, but the new track saws have been almost as accurate and fast if the user has a clear head and good technique. Ave has a great video showing a 12 amp Dewalt grinder and how many amps it draws under load...at one point in testing it even trips a 20amp breaker. After this tool review I picked up one of these grinders and it’s been a great purchase.

-

Here’s a list of Chinese companies - I’m not sure how complete it is, but there are a lot of ‘em. https://www.made-in-china.com/manufacturers/industrial-sewing-machine.html In the USA a Thomasnet search showed something like 107 manufactures. Most of which are industrial products not suitable for our kind of sewing, but it’s impressive.

-

Seiko stw 8 / consew 225 what to adjust?

DonInReno replied to bigsig11010's topic in Leather Sewing Machines

Ooops - that’s my mistake - there is no removable bobbin case on this model. -

Seiko stw 8 / consew 225 what to adjust?

DonInReno replied to bigsig11010's topic in Leather Sewing Machines

It looks as if something is keeping the bobbin from releasing thread properly - that’s keeping the material from feeding (short stitches) and not allowing the knot to be pulled up correctly. How have you adjusted the bobbin tension? Holding the bobbin case by the thread tail tension shouldn’t be so loose that it falls to the floor, but jiggling the bobbin case should let out more thread. -

Seiko stw 8 / consew 225 what to adjust?

DonInReno replied to bigsig11010's topic in Leather Sewing Machines

Upper tension. -

I’ve purchased a new Chinese industrial machine from a brand that doesn’t provide after sale support or even parts to the US. It was a great deal if you don’t mind troubleshooting and adjusting your shiny new toy. When people warn that you are on your own to sort out issues this is not a small task. Common adjustments can be figured out from the manuals of similar machines, but you should assume there are fit and finish issues, both functional and cosmetic, that nobody has written about. I had 3 or 4 linkages that had clearance issues that required some grinding. A few of these originally prevented proper adjustments at the factory, so fixing the binding was only fixing one symptom and half the problem. One linkage would bind no matter what - eventually it was tracked down to a tight bushing after 4 hours of disassembling testing and reassembling linkages. Working on a machine that’s new to you is three or four times as slow since no matter what you don’t want to miss adjust something and add a new problem. Finally there are some functions that just don’t work. The built in bobbin winder was such a poorly made mess that there was no way it could be modified to function properly. Knowing what I know now, I would still buy a no name Chinese machine, but only if it was 1/4 the price of a better quality clone. With careful bargain shopping I can eventually find a name brand machine in great shape for half of new price, so buying an inferior quality new machine that requires many hours of troubleshooting and adjustment is not worth much. I know someone who purchased a 441 clone that needed significant work and they didn’t realize the complexity of what was required. They paid 1/2 new price and if they were lucky, eventually fixed it for $500, but if a shop had to go through it that would cost well over $1000. With these kinds of choices I assume there is a 25% chance you’ll get a great deal on a well running machine, a 50% chance of having to spend a great deal of time and still saving some money, and a 25% chance you’ll get a lemon and by the time it sews correctly you’ll have as much invested in it that you saved nothing and have an inferior machine that has less resale. Good luck - be sure to let us know how it turns out!

-

There must be a nationwide shortage of 132k6s - for the last year they have been few and far between.

-

Need help on value of a Pearson No 6 bobbin winder

DonInReno replied to mogwild's topic in Leather Sewing Machines

Many antique sellers just rub down something like that with paste wax and don’t worry about cleaning it up at all. You could carefully scrub it for two hours with a toothbrush and not increase it’s value. -

111w155 walking foot machine 4 sale on fb

DonInReno replied to chuck123wapati's topic in Leather Sewing Machines

For whatever reason there just don’t seem to be many industrial machines in Wyoming, outside of the businesses that use them. This should sell fairly quickly, especially with all the stimulus checks about to come out. -

I don’t know why I find it so interesting to order parts from multiple suppliers just to see the variation in what is being sold, but I do! I usually encourage people to buy twice as many as they need since odds are something won’t be quite right. The two “40mm” servo drive pulleys showed up. Both are advertised as 40mm - a little smaller than I’ve seen advertised before. One measures 42.5mm - they wouldn’t be the first to round down or up to make the product sell better. The other is nothing more than a 45mm pulley being sold as a 40mm. It’s not even 44mm - measures a full 45mm. These are clearly not made in the same plant. The mold marks and design of the part are slightly different. The aluminum alloy is different and the darker of the two has a much better finish and fewer little voids from how the metal flowed into the mold. The one that appears nicer also has an entire extra operation performed to the bore - a reamer has taken down about 25% of the surface to exactly .591” (15mm). If someone was designing an injection molded part to not be reamed at all they’re cast it slightly larger - out of curiosity a quick check with gauge pins showed exactly that. The one that cut corners in not only material quality, but bore size was 001” oversized and was $3 more expensive. Once again I’d suggest that not all Chinese sewing machine pulleys (or machines, or anything else) are made in the same plant just because they look similar! Lol

-

I think these are great machines - it’s a niche between nothing and full 441 machine. The footprint of a big machine is not a trivial thing if space is limited, especially if it is only used once in a while. The lever on these machines also remind me of reloading ammunition. In use it can be relaxing, quiet, simple.

-

Trouble getting started with Seiko STW 8 help please

DonInReno replied to bigsig11010's topic in Leather Sewing Machines

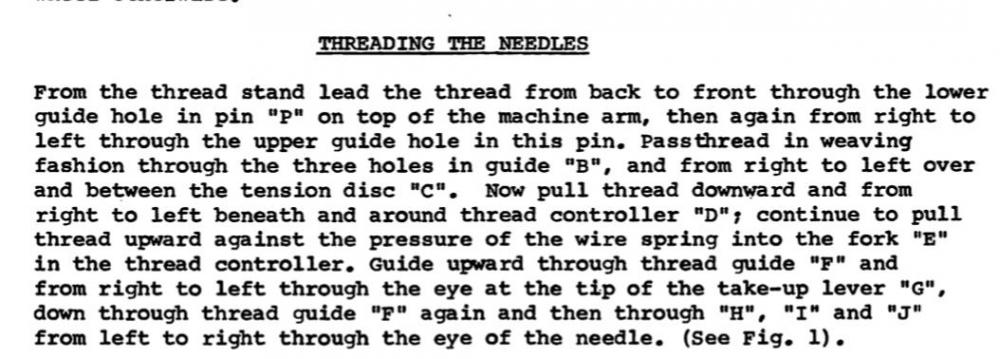

This is the threading description from the Consew manual for the 206rb (rebranded Seiko) It makes no mention of passing thread over the pin. Neither do a number of Singer manuals for machines that use the same tensioning setup. Technically Uwe is correct and this is somewhat of a myth passed on, often with no idea why. However, with many half truths there is probably a sliver of truth to it. A fellow working in a garment factory once said they treated the factory recommended thread path as a starting point, and deviated from it when needed to increase tension. Passing over the pin will definitely increase tension. Maybe this allows less pressure on the tension disks and slightly longer time between disk changes. I see nothing wrong with the practice, the extra step just isn’t necessary, and it won’t make the machine sew better. -

That’s a nice simple solution. Let us know how it works out. I have a portable Mikita table saw that doesn’t have soft start and it would be nice to calm it down.

-

I also have a similar needle feed singer 212g140 and the parts for different needle spacing are quite affordable. The biggest downside to these machines are the lack of specialized presser feet. I have 1/4” spacing and typically use a narrow zipper foot, or a standard foot that’s been sanded down in width. Ei

-

Honestly I don’t know much about motors and the only soft start motors I knew existed were three phase, but this manual popped up for a single phase motor soft start thing-a-majig. https://www.baldor.com/Shared/manuals/834-602.pdf

-

Trouble getting started with Seiko STW 8 help please

DonInReno replied to bigsig11010's topic in Leather Sewing Machines

Welcome to old machine land - where previous owners get tired trying to sew with poorly adjusted machines and sell them to the optimistic. Often when something simple makes the difference between a machine sewing or not, the machine is out of well out of adjustment and it’s just a matter of eliminating possible causes. Don’t worry, these machines will run great once you have the kinks worked out - and any old machine usually has a number of problems. I never seem to have any luck trying to adjust old check springs - there’s always a bend, twist, or break that makes it quite frustrating....the easy fix is just buy a five pack for $10. Even if you only need one, it’s nice to not have to worry about damaging the one you’re installing. Uwe has a great video on that. Next I’d watch Uwe’s video on setting timing...that might be the cause of your skipped stitches. It could also also be your timing is correct, but the point of the hook has too much of a gap between it and the needle. Before making any adjustments always start with a brand new needle - many machines have been adjusted to match a damaged/bent needle only to have new problems the first time the bent needle is changed to a good one. Keep in mind the point of the hook should be come as close to the needle as possible, without touching it. The larger the gap, the more likely it will skip a stitch, or break thread. Also, the sharpness of the hook point is important - sharper hooks are more likely to properly reach behind the upper thread and pull it off the needle. -

New Tech Motor and Needle Positioner Config

DonInReno replied to jackalopes's topic in Leather Sewing Machines

That’s great if most do work with reducers - I really don’t know - just repeating what a few people found and talked about in previous posts. I should stop throwing away synchronizers and actually try one, but I sew so slow that the needle just stops when the gas pedal is released. Lol -

-

The upper and lower thread is very close to setting the stitch when the noise happens so that narrows it down. The upper thread is jumping at the sound as the stitch is pulled tight, but bobbin thread doesn’t seem to jump at all....and only in reverse....hmmm You might look under the feed dog for a wear groove that might not normally pinch the thread except from the slightly different thread angle it gets in reverse. If there is a groove made by a smaller diameter thread it can grab the thicker thread and release it in a jerky fashion like that. Maybe the bobbin case is pinching the thread and it just doesn’t look tight and jumpy in the video. Turning the machine by hand as it makes a stitch you could feel what the tension on the bobbin thread is doing with the tip of a small screwdriver. If it’s real tight and jerks then the pinch is on the bobbin side - if bobbin thread stays rather loose then the pinch is more likely in the feed dog. If it were on the bobbin side it would do it forward or reverse, no? I look forward to hearing what it turns out to be!

-

I’ve also wondered why many people are hesitant to get rid of the factory hand wheel. Personally I like a big cast iron hand wheel, especially if it looks like a vintage factory part.