-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DonInReno

-

I have a question - is the feed dog of your machine essentially a disk that rotates in step with the needle feed? Is the main shaft connected to the lower shaft with a rubber belt or a drive shaft? Ok, two questions.

-

Cheap Chinese sewing machine question

DonInReno replied to Wdiaz03's topic in Leather Sewing Machines

Lol -

Please / Quick Recommendations between 2 Leather Machines

DonInReno replied to Brad2017's topic in Leather Sewing Machines

Given that they have very similar capabilities and are set up with identical motors, if the prices are identical I’d recommend the Juki since resale would be a little higher. Just show a potential buyer the built in bobbin winder and thumb through the really nice manual with the soundtrack to Hamilton playing in the background and it’s sure to sell for as much as you’re paying for it now. Don’t let the details in the Juki manual get the best of you - it will be just as easy to use. Having said that, for personal use I’m a fan of more simple oiling systems, separate bobbin winders, and older more traditional designs and would get the Seiko. As for the reducer, the best advice is to sew on a machine with a reducer and you’ll be sold on it. The good news is you can’t go wrong either way. Any new machine is exciting - have fun with it! -

Favor to ask - tension assembly measurent on 206RB

DonInReno replied to rlevine's topic in Leather Sewing Machines

My Consew 206rb (part is stamped Seiko) measures 56.33mm at that point. I tend to keep the main tension plate and swap parts off of a new assembly - cheap replacements are notorious for being not quite right. Hope that helps. -

Lu-562 111w155 BIG bobbin conversion

DonInReno replied to DonInReno's topic in Leather Sewing Machines

Thanks Greg for adding the part numbers - and I think you are right about the benefit of using genuine parts if possible. It was definitely an omission on my part to not say there are different hooks for either light thread or heavy. I’ve been scanning eBay for genuine Juki hooks, but the only ones that seem to come up are for fine thread - I definitely want to use the xxxBOA hook for heavy thread. For fellow part scroungers, I’ve had much better luck searching for used or new old stock parts by the Juki part numbers. Many people don’t know what a part fits, only what the part number is. I’ve ordered four case openers from different suppliers and the gentle upward curve varies in height by .75mm (.030”) - This is another item that would be nice to use real Juki parts since the tab the case opener operates on is only 1.72mm (.068”) thick and alignment should be somewhat close. These cheap openers will have to be clamped in a vice and “adjusted” with a hammer. One of the case openers looks noticeably shorter in overall length with less of a “hook” than the others. There are also some differences in dimensions between genuine Juki bushings and hooks, and the cheap generic ones that I didn’t notice at first. The factory juki hook has a shaft .3747”, one generic hook is .3731” and another is .3744” - if you are a detail oriented person this much variation will drive you nuts. I also ordered five upper hook shaft bushings and their sizes vary as much. It is interesting that the factory hook is too large to fit any of the new bushings, while the undersized shafts of the generic hooks actually have a decent fit. My advice if ordering generic low quality parts directly from China is to order from various suppliers and count on some parts being unusable and all parts being slightly off in various ways. -

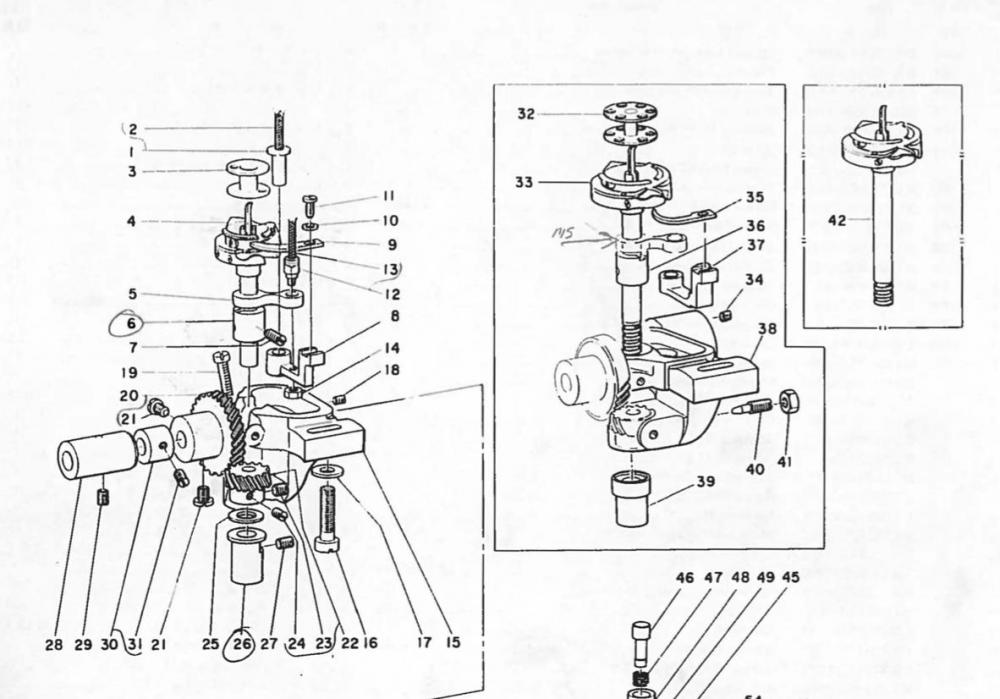

Honestly I never thought a big bobbin conversion would be worth the hassle - definitely not something that would increase a machine’s value enough to justify the cost of parts and labor. However....once you have one big bobbin machine all normal bobbins look tiny! Lol A Consew 206rb came along and spoiled me - it’s time to upgrade two Singers and a Juki lu-562. The plan is to make the conversion with the existing saddles, but if I run into problems I have 563 parts on hand to simply swap out the parts. The way I understand it there are two ways to go about it - use a lu-563 hook saddle assembly, or modify the existing hook saddle (#38) and case opener crank (#37). Either way a new lu-563 case opener (#35) and thread take up lever is used. I seem to recall someone saying if the saddle of a Singer 111w is modified it will expose a bushing set screw. I don’t know if a new hole can simply be drilled and tapped in a different location for that set screw, but that seems easy enough to overcome. You can get a bare lu-563 hook saddle or one complete with all its bushings and screws for not much more. The one I purchased was sold as an authentic Juki part, but I doubt it is. Still, it appears to be well made. What you’ll immediately notice is how much bigger the saddle is - much taller around the lower bushing and the hook shaft is longer. I ordered two generic Chinese take up arms and one generic arm from Japan. The Japanese arm is 4mm longer than one and 5mm longer than the second Chinese arm. The Japanese arm also has a smaller cylindrical shaft, but the slider thingy that rides on the shaft is also included so it should work fine - weird, but fine. I have a sinking feeling the Chinese arms are an inbetween size that works on either 562 or 563, but not ideal for either. I have yet to take out the original arms, so we’ll see soon enough. The three hooks are from two different generic suppliers - all have good machining and appear to be well made - only time will tell the quality of metal. Placing the 563 hook in the 562 saddle, it is 2.75mm taller (.109”) at the case alignment tab that fits into the needle plate, so that’s the amount that needs to be machined off both the upper bushing and surrounding area of the saddle. Relative to the top of the hook, the 563 case opener appears to be mounted (at the attachment screw) only .75mm lower than the 562. If that amount is taken off the saddle in the area of the case opener crank, the figure-8 connector will have to be ground down a few mm to clear the underside of the hook. A 563 case opener crank could be used if that area of the saddle is taken down the full 2.75mm. Also, if the 562 crank is used, a small portion will have to be ground away to avoid rubbing the hook. I seem to recall previous conversations mentioning the need to grind clearance on the underside of the bed for the 563 saddle to clear - I’ll let you know what I find when I get to that point. edit: The parts diagram shows a juki lu-563 on the right and 562 on left.

-

New Tech Motor and Needle Positioner Config

DonInReno replied to jackalopes's topic in Leather Sewing Machines

I have no experience with that motor, but synchronizers often don’t work well with speed reducers. ... are there any that do work with a speed reducer? I don’t know. -

Great video - thanks for showing us what it turned out to be. So often we never get to hear what actually resolved the problem.

-

I now have a third machine for the conversion....for that one a factory lu-563 saddle has been ordered so that should at least give us a better idea of what the dimensions are.

-

Good job - that looks like quite the project!

-

Yes I think you’ve got it - about 3mm is removed from the well. Cowboy Bob had mentioned in the past they take .100” off that area (2.54mm). I may be wrong, but it was my understanding the case opener lever stays at the original level and gets slightly clearances to avoid rubbing on the hook. The figure-8 thingy is then given a step, or the entire height is reduced enough that it sits under the hook, but that is the part I’m not sure of. My large hooks won’t be here for another two weeks.

-

I just noticed a hook I purchased on eBay is $29 shipped, while same Kunpeng hook on Amazon is $44. That’s quite a difference!

-

You won’t regret spending extra money for a walking foot with triple feed, like the 111w155, or a newer big bobbin model from any of the major brands. Where you will notice the biggest difference is in the evenness of the stitches and how much easier the walking foot goes over thick seams. As for the 31-15, great basic machines, but at $200 that is what I’d call top dollar. After you get a walking foot and if the 31-15 still has your attention I’d suggest finding one without the table and swap both into the same table - the cutouts are the same. I don’t look very hard for them, but still see a handful well below $100 - often $50.

-

Years ago when I first heard of this conversion it sounded complicated, especially the alterations to the hook saddle that most people seem to do with a milling machine. It wasn’t until a few weeks ago that it dawned on me that the saddle alteration is just clearance for the hook and not a precision surface. Someone with a Dremel tool and a lot of patience could easily do a profession-looking job in an hour or two. Shortening the hook shaft bushing has to result in a precision flat surface, but even that could be done with careful filing followed by bluing the surface with a sharpie, rotating it against the hook to show high spots and carefully scraping until there is full contact. I have a lathe and can alter both parts, but I’m super slow so it won’t really save any time. :-) This information more or less applies to juki lu-562, the Consew like in this video, singer 111w155 and others that share nearly identical parts.

-

Juki LU-563 or Seiko STH 8bld-3

DonInReno replied to MCFromCanada's topic in Leather Sewing Machines

I have an older Consew 206rb (big bobbin) that’s made in Japan by Seiko and it’s every bit as smooth and well built as my lu-562, so I’d recommend one of these if they come up. The newer Consew 206rb are made in China, but how closely they compare to the new Seiko is something I don’t know anything about. Just keep looking and something will pop up eventually! -

Singer 108W20 - My New Binder Setup

DonInReno replied to Constabulary's topic in Leather Sewing Machines

That table setup is very interesting - do you know what it was designed to sew? -

I’ve ordered a few things from them without any issue. I’m currently waiting for hooks, take up levers and case openers for big bobbin conversions on a pair of 111w155s.

-

Since you don’t know the machine’s history, it might be worth while to confirm it has the correct take up lever - the lu-562 lever will physically fit a 563, but it’s a different juki part number. I notice many aftermarket take up arms are using one part number for both machines, which seems fishy.

-

Juki LU-563 or Seiko STH 8bld-3

DonInReno replied to MCFromCanada's topic in Leather Sewing Machines

In factory settings machines are run into the ground, rebuilt and run into the ground over and over. The quality and thoroughness of a rebuild can vary greatly, and you will need to inspect all of the wear surfaces carefully. Many machines claiming to be rebuilt are only adjusted, cleaned and have a $5 paint job. I keep buying used factory machines, but I’d still vote for the new Seiko if those were the only choices. -

Preparing to buy my first machine...

DonInReno replied to Dwolf01's topic in Leather Sewing Machines

Welcome! Don’t feel like you have to rush into anything - it sounds like your price range is high enough to get into a used but well functioning machine, and the area of the country you are in is full of used flat bed machines. I did a quick search on FB marketplace and Craigslist and you’re actually lucky to have such a large selection to choose from. Keep in mind the machines you are seeing for sale are most likely at market price or above - the below average price machines don’t stick around long, but they will pop up. Is that 562 the one for sale in Waterford? It seems like the same machine listed in Kent, but with different pictures. When I see a machine for the first time, paint is the first giveaway of what kind of life it led. Machines used in high volume production will have a lot of missing paint or have been repainted at least once and maybe multiple times. That Juki is missing some paint, but the small factory sticker on the back side is still in place so it’s most likely not repainted - usually only the main juki sticker is replaced on a repaint. The small wear pattern in the middle of the handwheel looks like the operator either palmed nippers while sewing, or had a ring on one of their fingers - not a lot of wear otherwise which is good. The leather belt is odd - but it’s pretty new so that was probably added to look good because it was on hand. For $700 you should be able to find a juki in this condition that already has a servo motor. $500 without a servo is about right. For $1000 it should have little missing paint, sew well, have a servo and a decent table - essentially newish. In general avoid repainted machines. Avoid a machine that can’t be tested under power. Take a strong flashlight and look it over closely for any cracks or damaged parts. Industrials are heavy - dropping one can crack the bed and bend all sorts of things. Avoid a machine with deep grooves worn into the thread path. As for bobbin size, that wouldn’t be worth worrying about if you’re doing small things. For a first industrial I also wouldn’t worry about top load vs side load bobbins. Oh...and watch out for industrials that lack a reverse. In the excitement of the moment more than one person has overlooked the difference between a lu-562 and lu-563 and come home only to be surprised there’s no reverse! Lol Buy one at or below market price and you can use it for years and still be able to sell it for the purchase price - a free machine. Now that’s a good deal! -

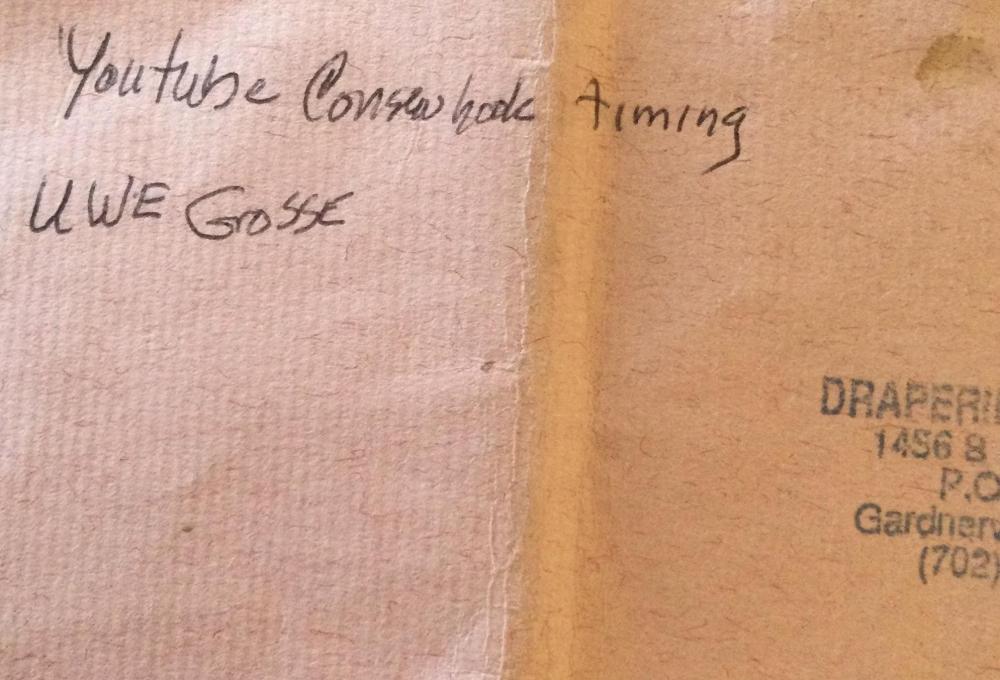

Uwe sorry this is so off topic, but when this was found it made me chuckle..... On a picking adventure to an obscure little town, at a little old ladies part time upholstery shop, wedged in the drawer of an unused sewing table was an operating instruction manual and on the back cover there you were! I think that makes you officially famous. Lol

-

Exactly right - Apparently I thought it, but it didn’t make it into the message. Lol

-

I want this machine - can it sew holsters?

DonInReno replied to Constabulary's topic in Leather Sewing Machines

Lol -

Did you end up getting it? This is way late, but I just ended up with a 206rb - here’s the Seiko cast under the bed just visible behind the shaft.

-

Best of luck on your PhD! Many people are under the impression the Artisan 3200 is similar to the Cowboy 3200, but the artisan actually has the same sewing capacity of the larger full size 441 clones.