-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DonInReno

-

Top thread breaks when removing work

DonInReno replied to MtlBiker's topic in Leather Sewing Machines

That’s great news! -

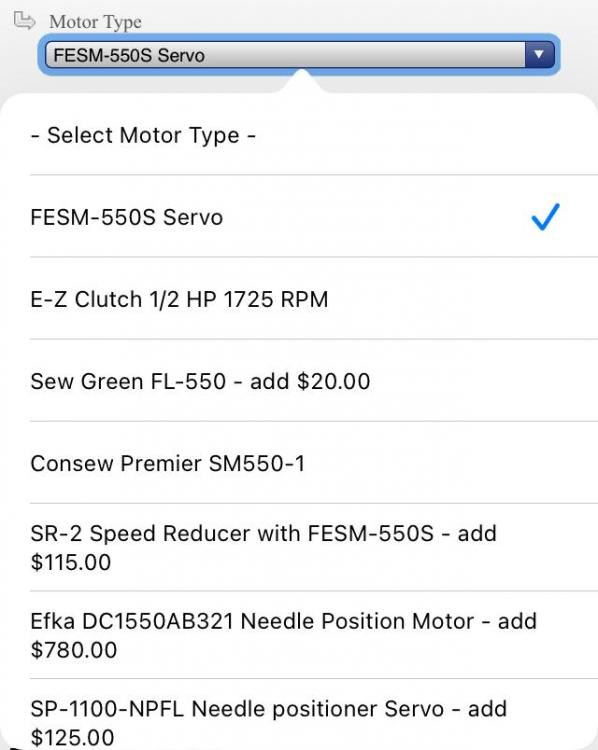

You’re in quite a good situation - either way will be a very nice setup. The drop down menu for motor options on that Keystone package shows a lower price on the reducer. The speed someone sews at varies not only on the type of product, but also personal preference - I sew at a relaxed pace in general, but many projects are new to me so I’m extra careful about material alignment and placing each stitch. For this style a 5:1 reducer is my favorite, but I also have a 7:1 reducer that was overkill, but still worked just fine. On the other hand a friend of mine sews a lot of belts and dog collars - she can whip em out quick and doesn’t want anything that slows down the machine too much. If you go with a big motor you may not need a reducer....

-

The trick to searching for posts here is to use google, but add site:leatherworker.net I found the post that convinced me to buy the motor:

-

I have purchased that sew pro 1100 motor from Keystone after the recommendations from a few members here that have tried a number of servos including the Reliable. The 1100 watts makes this a big powerful motor with great low speed torque. It appears all the 1100 watt motors on the market are nearly identical in appearance and price - probably the same manufacturer. Even though it comes with a needle positioner, when used with a speed reducer, it isn’t needed - there’s enough control to simply stop the needle wherever you want it to stop. The only catch with this motor is the $300ish price. At this price most low speed sewers would be better off with a $150 servo and speed reducer. Edit: I tried to find the discussion of the 1100 watt motor, but it’s buried in one of the “which servo to get” posts. The servo posts from the past few years are worth reading - a lot of wisdom.

-

There’s more than a little marketing with all the claims of slow speed performance in the servos. The sailrite motor is a rebranded Reliable sewquiet motor. https://reliablecorporation.com/products/sewquiet-6000sm-servomotor

-

I highly recommend a speed reducer of some kind if you can swing it. It’s especially useful for leather or other intricate sewing, but just as important it makes learning to sew with an industrial less stressful - you’ll have enough of a learning curve without being frustrated with a lack of low speed torque. No servo will have decent torque at the lowest speeds - that’s why there are 100 discussions here on how to improve low speed performance and zero on how to speed things up. Honestly it’s the single best investment to improve the entire experience, and if a new machine is set up for a speed reducer it saves the hassle of a retrofit.

-

-

https://www.ebay.com/itm/20-80mm-52mm-65mm-Diameter-Spindle-Motor-Mount-Bracket-Clamp-with-Screws-For-CNC/363048049399?ssPageName=STRK%3AMEBIDX%3AIT&var=632174603941&_trksid=p2057872.m2749.l2648 I’d definitely buy from them again. When the order was placed the estimated shipping time from China was 5 weeks, but it arrived in 19 days. This is similar to other small parts I’ve ordered from a Chinese address, but some have arrived within a week and two items have taken two months.

-

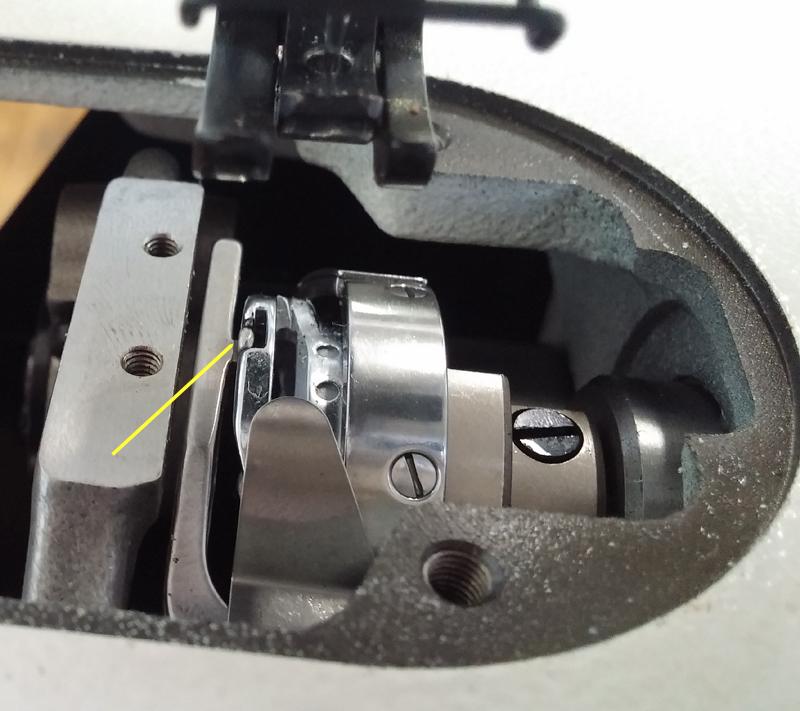

That tab has to be held in the notch so the inner portion of the hook doesn’t rotate. Don’t just move the lever that has the notch until you make sure it wasn’t the hook that move a lot rearward. Since your tab is so far away from the lever I can’t help but wonder what else has happened. I’d put in a new needle and check the gap between hook point and needle. The gap should be as small as possible without actually touching. If this gap is ok, then move the lever with he notch back to where it holds the tab, but has enough clearance for thread to pass between the tap and notch. edit: Definitely take the other advice as well - safety clutch, follow the video, etc.

-

Medium weight cylinder arm short list

DonInReno replied to wkleather's topic in Leather Sewing Machines

Just today I received a Japanese 206 hook from a US supplier.....then I notice an identical hook being sold by Evernice on eBay - but it ships from Wohan China. While it is possible Japanese hooks are being imported into China then exported to the US, it seems much more likely these are counterfeit, and the hook I was sold is probably also counterfeit. -

What is the tolerance for needle bar height?

DonInReno replied to williaty's topic in Leather Sewing Machines

What kind of problems are you having? For most sewing machines the rule of thumb (common to most service manuals) is to bring needle to bottom of its travel, then after the needle has risen 2mm (about 3/32” or thickness of a US nickel) the hook should be inline with the needle and 1/16” above the eye. This will show correct needle bar height, hook timing and hook clearance with the needle. As the hook passes the needle it should be as close as possible without actually touching. It’s ALWAYS a good idea to only perform this check after replacing a new needle. There’s nothing wrong with checking the 19mm dimension in your manual, but I’d suggest looking at the above as a double check. If your needlebar is only .015” low (so the hook is passing the needle closer to the eye) the only problem it might make worse would be increasing the chance of a skipped stitch. If the machine isn’t skipping stitches then the current needlebar height isn’t a problem. Even if it is skipping stitches, the culprit is most likely a function of hook gap and condition of the hook point. I hope that made sense. -

Medium weight cylinder arm short list

DonInReno replied to wkleather's topic in Leather Sewing Machines

As long as it sews this should be a safe investment - you’ll be able to get your money out of it if something comes along that is slightly better - that’s essentially free. -

It sounds like the machine is right on the edge of sewing or not - very slight changes like type of needle point shouldn’t be making the difference between sewing or not. That’s assuming the needles are of known good quality - not mystery needles. When thread wads up under the material that’s usually upper tension being too low, bobbin tension not correct, thread is binding up somewhere in the thread path under the bed, or timing is not correct. I hate to sound like a broken record, but with sewers of all skill levels, when a problem comes up the first thing I look at are the basics. Double check the thread sizes - more than one spool of thread has been mislabeled. I’m guilty of giving my sister a dozen spools of the wrong size thread for her machine - to this day she hasn’t mentioned it, but there’s no way any of it worked. How do you determine bobbin tension and upper tension? As a starting point when the bobbin and case are out of the machine, suspending it by the thread tail the tension shouldn’t allow it to fall under its own weight, but bouncing it up and down should allow some thread to come out. For any given material it should be possible to over tension the upper thread so the knot comes to the surface. Time and time again when a sewer says they have the top tension tightened all the way and they can’t tell a difference that’s a big red flag either the upper tension isn’t working correctly or lower tension is way too tight or a tight spot in the thread path pinches the thread. Do you ride the knee lifter? Upper thread release that’s tied to presser foot lift can decrease tension if the pin is too long or someone rides the knee lift. How do you check timing? Hook timing is covered often and there are great videos showing what to look for. Also look at the timing of the case opener - as thread goes around the hook and is pulled up tight in a stitch the case opener should be timed to help the thread pass through the tight spots. Are the needles in correctly? It’s easy to forget the groove in the needle always goes away from and the scarf always goes toward the hook. One machine that was having problems and a frustrated owner gave all common sense - tried turning the needle around backwards and just randomly made adjustments in case by some random chance they would magically stumble across the correct combination. There should be a logical reason to make any adjustment. Have you checked the problem needles for size with the 138 thread? Thread a loose needle and hold the thread at a diagonal - the needle shouldn’t slide down quickly nor get hung up. If the lower thread path is adjusted correctly there shouldn’t be any tight spots that grab and suddenly release the thread as it makes its way around the bobbin and finally gets pulled up in a completed stitch. Good luck with it - sounds like you’re really putting a lot of effort into figuring it out.

-

Consew 206RB-1 Adjust Reverse Stitch Length

DonInReno replied to jackalopes's topic in Leather Sewing Machines

In the past when reverse stitch length had to match exactly I’ve simply added a strip of white electrical tape next to the reverse lever and marked the position it needed to be in with a fine point sharpie. Not a very elegant solution, but it works. Lol -

Singer Balance wheel replacement help

DonInReno replied to Campleathergoods's topic in Leather Sewing Machines

The supply and price of used 29-4 wheels on eBay varies - if you wait a bit one will come along for a better price. You can also have someone cut off the remainder of the broken area and braze or weld on a $2 collar. Sometimes welding schools do repairs like this for free - the hard part is getting someone that can do the repair straight enough it won’t wobble.- 11 replies

-

- singer 29-4

- industrial sewing machine

- (and 2 more)

-

Cylinder bed sewing machine table top help please

DonInReno replied to richco's topic in Leather Sewing Machines

I agree with taking measurements from the machine. Thin Masonite, 1/4” MDF, or even thin hard cardboard make great patterns - just trim a little at a time until it’s the shape of your arm and transfer it to your material. Many low cost factory tables have such huge gaps with the arm I’m embarrassed for them. -

The thread take up spring only takes the slack out of the loose thread that might wrap around the tip of the needle right before the needle punches into the leather. I’d bet lunch it’s an issue with the hook. Maybe I missed it, but did you mention what kind of stitching inconsistencies? Does the bottom tension seem extra tight off and on with the knot not pulling up into the leather consistently? If the tip of any horizontal hook has been bent and damaged it causes two problems - skipped stitches because it’s not as sharp (even if the hook gap is tight) and once the hook clearance is readjusted now the hook crowds the thread path where upper thread makes its way around the bobbin case. These tight clearances can make lower tensions seem random. Some clearances may be listed in the service manual, but these may not be adjustable and the hook would have to be replaced. What’s the history of the machine? Did you recently buy it in this condition?

-

New holes are often required for many attachments - It wouldn’t be unheard of to drill and tap the needle plate (on the right side so a screw misses the hook), or to mount your binder to a flat plate that then reaches back to your existing holes. You might even mount it to a larger plate and tape it down. Old factory machines are sometimes peppered with holes, and binders are silver soldered to anything and everything, but with a little work it shouldn’t be too hard to reach existing holes. I seem to recall someone even used epoxy to glue a binder to a flat plate that was as wide as the table top and it was clamped down to the table. Lol

-

I finally found time to trim the hubs on those two pulleys. For $15 this spindle/motor mount is available in all sorts of metric sizes and it looks more professional, but a block of wood would hold the bearing housing just as well. At first I was going to simply add a hinge on one side and an adjustment bolt on the other to this block of wood and use that to adjust belt tension, but now I’m thinking a 2” wide hinged aluminum strap would look better. If it looks small, it’s because it is - visually it’s dwarfed by a traditional 3:1 reducer. All together I’ll have about $40 in it, but it looks great and the small size will make it much easier to fit under a table without moving the motor too far - I’m hoping to add a 4” wood spacer under the motor and move it about an inch to the right.

-

Isn’t the 18 a copy of the Singer 16-188? I’m not 100% sure - someone who actually knows will probably chime in. At least some parts appear to cross reference between the two machines.

-

Consew 255RB3 breaking top thread in reverse

DonInReno replied to sandmanred's topic in Leather Sewing Machines

Glad to hear it’s working out! -

Consew 255RB3 breaking top thread in reverse

DonInReno replied to sandmanred's topic in Leather Sewing Machines

Hopefully the gap between hook and needle as as close as possible without touching, the needle guard isn’t pressing on the needle and the condition of the hook point is good and sharp. Uwe’s videos are always very good about mentioning the hook/needle gap, but some people focus only on timing. Just this morning I’m looking at a machine that had 20 years of intermittent thread pickup and breakage issues and was “retimed” a dozen times - turns out the hook point was sharp, but it was never adjusted close enough to the needle. If there is any kind of loop, a sharp hook just barely/almost skimming the needle will pick it up. If timing is good, hook and gap are good, then maybe some other factor that interferes with loop formation? I like the idea of adjusting timing so needle has slightly more rise, and more time for a larger loop to form, before the hook intersects needle. 1/8” needle rise instead of 3/32”? Of course that means needle bar has to drop 1/32” so the hook is still contacting needle 1/16” up from eye. Let us know what ends up fixing the problem! -

Lost a valuable member of this Forum yesterday

DonInReno replied to shoepatcher's topic in Leather Sewing Machines

I really enjoyed his attention to detail and will always remember his japaning project. To this day it makes me smile picturing that 45k hanging halfway out of the oven. Well done ... rip -

Thanks for the pictures! That’s an interesting arrangement.

-

I just ran across a few photos of a disassembled machine like yours that showed the parts I was curious about - what an interesting design! I’ve ran across a few of these and always avoided them not knowing they were needle feed - now I’m excited to pick up the next one that comes along.