-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DonInReno

-

Are expensive whet stones worth it?

DonInReno replied to Artificial Intelligence's topic in Sharpen it!

It’s been almost two years since I read that and after a reread it’s just as interesting - this is definitely a must read! -

Cobra 26 Walking Foot suggestions

DonInReno replied to Memphis514's topic in Leather Sewing Machines

I’ve bought a few dozen 111w155 feet off eBay and all I can say is buy two because one of them is likely not quite right. I’ve had short feet, overly long feet, twisted feet, feet without flat bottoms, feet that just don’t fit, feet with crappy finishes and feet with bad clearances. I simply assume half the sewing parts sold on the cheap aren’t right, so I’m not surprised when a new part gets chucked straight in the trash. Lol -

Can you post a clear picture showing the needle to hook gap and condition of hook?

-

Often that is a hook timing and/or hook-to-needle clearance issue. Hook point should just reach needle when the needle has risen the thickness of a nickel (3/32”) from bottom. Point of hook should be as close to needle as possible without actually deflecting the needle. If the point of the hook isn’t as sharp as it should be, or is bent from a needle crash, that can also contribute to a skipped stitch. edit: I now see this was already covered in your other post.

-

Looking at buying a machine but overwhelmed.

DonInReno replied to Brigeyboo's topic in Leather Sewing Machines

Wiz I have to compliment you not only on your professionalism and good judgement when it comes to sponsors, but also on the quality and quantity of great advice you’ve given out. You definitely enjoy helping people across the board from rank novice to the veterans, and we all appreciate all you do. -

Restoration for Juki LU-562 & upgrade to LU-563 Bobbin

DonInReno replied to Vinito's topic in Leather Sewing Machines

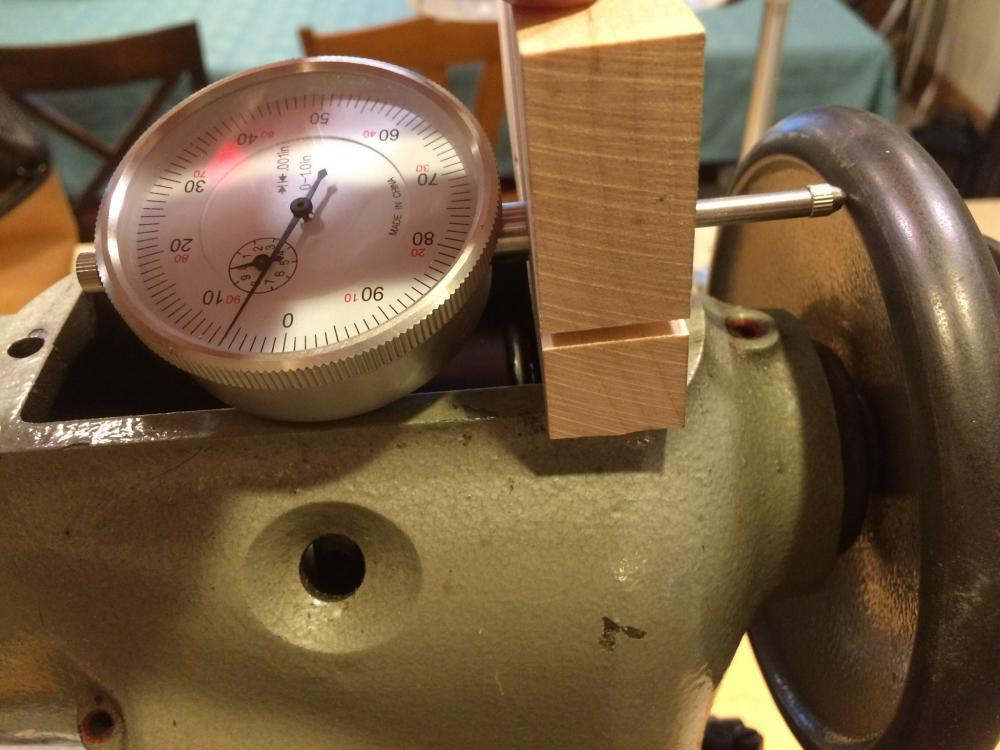

Yep, that’s about what mine looked like. The bend is right where the handwheel transitions from thin portion that cracked to the solid part of the wheel. I used the damaged handwheel, a few wood blocks and a hammer to tap it back to a normal range. An inexpensive dial indicator showed progress. -

The first step should be changing the needle with a new one. This eliminates the possibility of a bent needle causing problems. How close does the hook come to the needle? Ideally the hook should pass as close as possible without actually bumping the side of the needle. It’s had to tell from the video, but the hook doesn’t look to be very sharp - it’s normal for a hook to get more dull every time a needle breaks or gets deflected into the sharp point of the hook. A dull hook makes it harder for the hook to catch the thread from the needle and makes needle/hook clearance extra important.

-

Restoration for Juki LU-562 & upgrade to LU-563 Bobbin

DonInReno replied to Vinito's topic in Leather Sewing Machines

You might consider straightening the shaft in place - these shafts are not especially difficult to bend in the first place, and bending them back is fairly easy if you have a way to measure progress. My lu-562 was damaged in shipment and after bending the shaft straight I couldn’t feel any roughness in the rear bearing - figured it wasn’t any more damaged then when the shaft was originally bent. It wouldn’t surprise me if that bearing eventually needs to be replaced. -

Im quite sure at least a couple of other people have had a go at it before you - that seems to be human nature with sewing machines - they just have to take things apart or at least turn screws not knowing exactly what they do. Lol

-

Feed dog screws keep loosening...solution suggestions?

DonInReno replied to Bj Dixon's topic in Leather Sewing Machines

Good quality, properly fitting screwdrivers make a huge difference working with slotted screws. Some of the best sets are sold as gunsmithing screwdrivers - Brownells probably has the best selection of thicknesses and widths if something special is needed. They also sell screw slotting files if you want to clean up a damaged slot or widen it a bit. Ive always been impressed with the quality of Singer screws - at least on par with most gun screws. -

Looking at buying a machine but overwhelmed.

DonInReno replied to Brigeyboo's topic in Leather Sewing Machines

Even though you don’t have a lot of need to fix it, getting your patcher up and running will certainly increase its value much more than the cost of the parts. -

205 Adler Clone Recommendation for Binding Work

DonInReno replied to anvlts's topic in Leather Sewing Machines

It’s my understanding most aviation carpet is wool or nylon with a fire resistant coating. Ive seen binding tapes that are just polyester or even vinyl and thread that seems to be primarily nylon - it seemed odd to use nylon thread rather than polyester, but there must be a reason. Regardless of its content it has to have passed FAA burn tests that are different for various categories of aircraft. It seems manufacturers typically supply FAR 25.853 burn certifications for any materials, but at least one aviation upholstery supplier was having the testing done on their end. My impression has always been that aviation carpet is on the light side and a walking foot upholstery machine would be more than enough. -

Looking at buying a machine but overwhelmed.

DonInReno replied to Brigeyboo's topic in Leather Sewing Machines

It sounds like you’ve almost answered the question - yes, the 3200 is larger than needed for most of what you’ve described. While it can do those things in a pinch, it’s a lot like driving a big flatbed truck to the grocery store - it’s more work, not as nimble to drive in tight spots or curves, and just isn’t as enjoyable for most. If you have a chance to sew with one for a few minutes it will make the difference quite clear. Having said that, the 3200 would make a great second machine if you ever run into projects that a smaller machine struggles with. -

I’ve found four that were quite nice, but the details in how to get them from the seller to me just didnt work out. On the west coast of the US nothing Below $800 has shown up in the last 12 months....soon....sometime soon....

-

Me to!

-

This post is a good example of how easy it is to get a commercial sewing machine up and running for very little money. These clutch motors can barely be given away - I’d bet lunch that in every town someone has one they don’t want in the landfill and would gladly donate if someone needed it. Same for K legs and generic old tops - you just about have to pay someone to take them. Lol At the most extreme I see about two free walking foot heads given away each year in between Reno and the Bay Area. The latest was a 111w155 complete with table and motor.

-

If someone is on a budget and looking for parts to cobble together a speed reducer there are most of the parts already assembled in the nose of a clutch motor. Parts 11-16 and 2 are the bearing housing/shaft assembly that spins when the clutch is engaged. The shaft already has the original small pulley on one end and the flange (11) can be replaced with larger pulley on the other or some pulleys can have the hub removed and simply bolted to that existing flange. Then the bearing housing (17) has to be held somehow - a couple of u bolts securing it to a wood board or whatnot.

-

Correct Bobbin Case Size for Thor GC-1541s

DonInReno replied to rchaven's topic in Leather Sewing Machines

Using small online sellers of clone parts is always hit or mis regardless of what machine the parts are for. China has a large number of small suppliers all with different standards - it’s quite a myth that all parts come out of only a few huge factories. Manufacturing centers in China are designed to encourage manufacturers of all sizes from mom and pop to the large ones, and the exporter may get the same part from any number of sources. The craziest example of this is buying tension assemblies directly from China - 10 tensioners will have parts from at least three obviously different suppliers. Roller presser feet are the same - I order more than needed and toss out the worst of the bunch. Lol -

Walking ft. comp. feed - when & why?

DonInReno replied to SouthernCross's topic in Leather Sewing Machines

Without a walking foot, stitch uniformity suffers even with canvas bags. Of course it’s possible to mostly compensate and spend enough effort focused on the stitching to end up with a good end result, but that takes away from what you should be focused on and greatly increases frustration. Just looking at an item at the seams and changes in thickness, it’s pretty easy to tell if someone is using a bottom feed. If three machines are set up identically side by side - a bottom feed, needle feed, and walking foot - the walking foot would get used first every time. If the walking foot was in use, the needle feed would get used next. I literally can’t imagine a circumstance where a bottom feed machine would ever be the first choice for canvas bags. -

There is a good FB group for the cornely.

-

Interesting - thanks for that picture - six class is much beefier in a photo than the few drawings I came across! This machine is listed on eBay and is in Salt Lake.

-

There are a couple of US government manuals online that take you through every part of the 111w155.... I seem to recall this one goes over adjustments ok, but there is another that’s more clear. https://archive.org/details/TM10-3530-202-24/page/n1/mode/2up

-

This isn’t a great picture, but what appears to be a gear-reduction, two foot, pedal powered treadle is directly connected to what I’m guessing is a 6-class Singer of some kind. Has anyone seen this setup before? ISMACS didn’t seem to mention any geared treadle in the 6 class info. It’s relatively compact and might make a fun curio for someone’s sewing room.

-

I agree with the others - you would be disappointed even if it was adjusted to sew ok with 138 or 90 weight thread. Mine big machine sews great with 138, but it’s a lot more of a workout than a 111w155 size machine. Everything is a longer reach, every movement requires more effort. Having said that, even if you rarely need it there’s something liberating about having a big machine that can handle really thick situations without flinching - so of course you have a good excuse for both sizes of machine! Lol

-

Recommendations for a beginners first leather machine

DonInReno replied to Cosplayholic's topic in Leather Sewing Machines

You’ll wonder how you lived without a walking foot machine! It can be overwhelming making sense of the capabilities of the multitude of models out there, but you’ll soon see that most flatbed machines with a walking foot have similar capabilities. My advice for anyone buying their first walking foot flatbed in the lower price range is to look for the one that is the best deal and is essentially ready to sew without a lot of additional work or money - that way it can be used for as long as you want and can be sold for essentially what you bought it for. That’s like leasing it for free or for very little money. Six months sewing with any of the machines on that list and you’ll know what special features you wish it had and if you really need that larger machine to sew holsters. I’m guessing the typical cosplay holsters are somewhat thinner and have softer leather than are typically used for high end models often talked about here. Keep in mind there is a significant learning curve to sew if the machine has a high speed motor. A good rule of thumb for Learning maintenance is to put a single drop of oil anyplace two pieces of metal move against each other, and maintain any oil reservoirs (if any). That’s about it - just wipe the machine off with a rag and a little sewing oil and you can probably sew for a number of years without any special detail cleaning. Don’t turn any screws to “adjust things” unless you are absolutely sure what the adjustment is. You’ll want screw drivers that fit screws so the heads don’t get buggered up.